Microwave ignition system for improving combustion efficiency of internal combustion engine

A technology for internal combustion engines and microwave ignition, applied in engine ignition, engine components, machines/engines, etc., can solve problems such as low overall efficiency, low energy efficiency, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

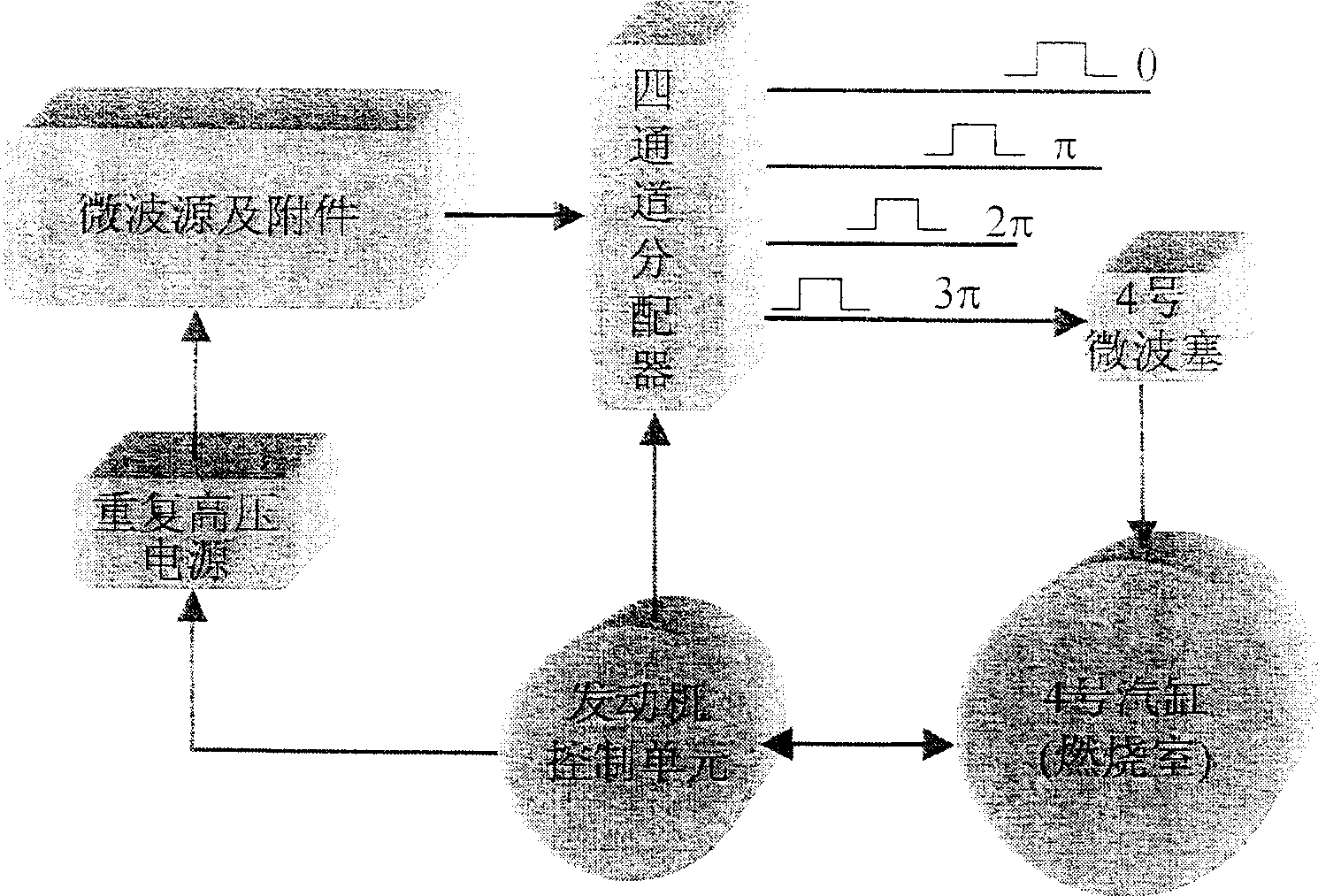

[0022] As stated in the claims of the invention, the invention is applicable to all internal combustion engines. For further description, the method, device and system of the present invention used in a four-cylinder automobile engine are only schematically illustrated below.

[0023] figure 1 A block diagram of the entire ignition system. First select a microwave source that can output the appropriate frequency, bandwidth, power, and pulse length. How to choose these parameters will be introduced later. The microwave source is driven by a repetitive pulse power supply. The pulse power supply outputs the pulse electric energy required by the microwave source at an appropriate time according to the instruction from the engine control unit. This pulsed electrical energy is converted into microwave energy by a microwave source.

[0024] Since the output pulse power of the microwave source is relatively large, an isolator is required for isolation. In this way, microwave ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com