Control method for accelerating on-line coke burning for industrial pyrolysis furnace

A cracking furnace and industrial technology, which is applied in the field of regulation and control of the online burning process of the cracking furnace in the ethylene plant, and can solve problems such as inability to control the burning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

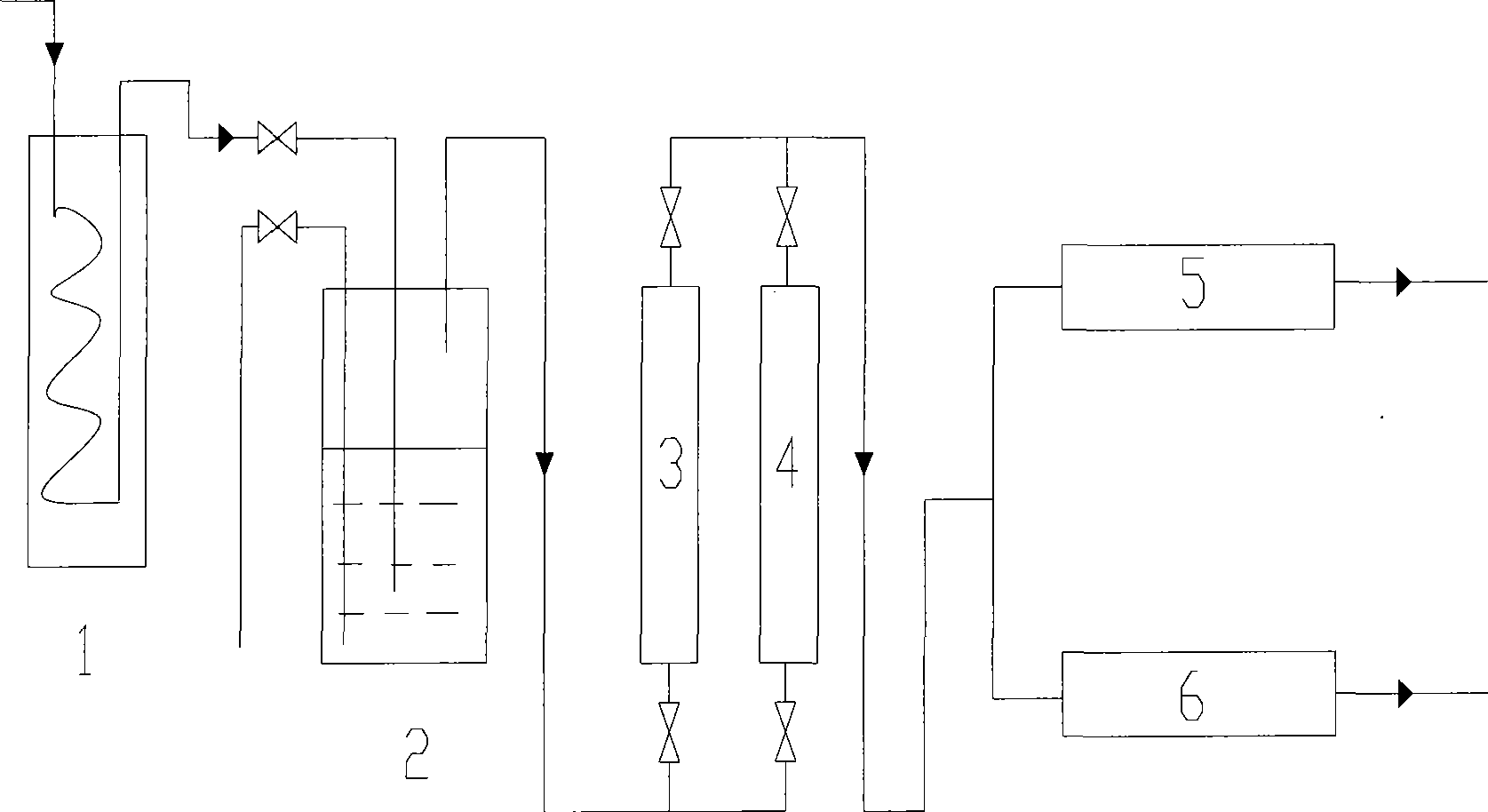

Method used

Image

Examples

Embodiment 1

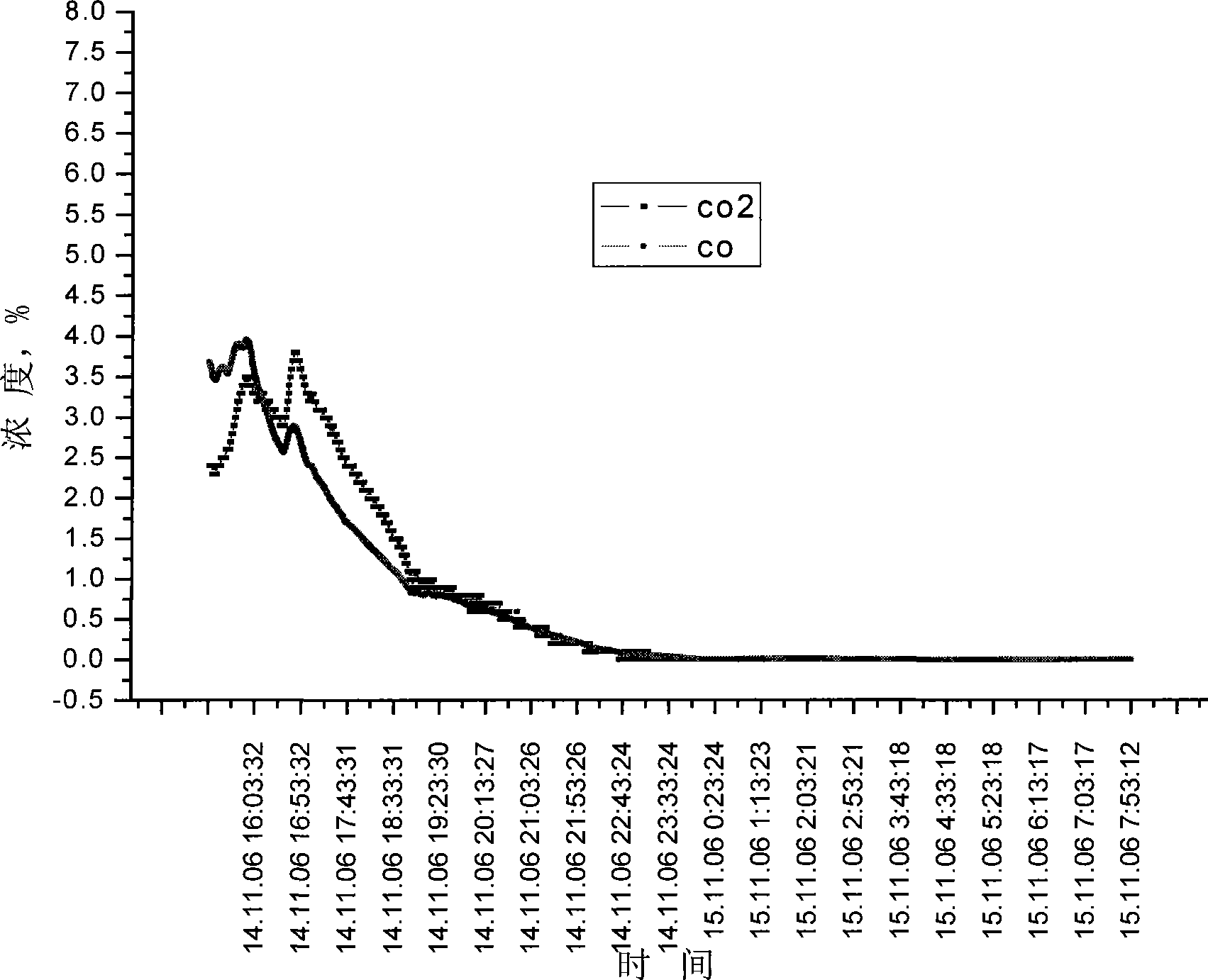

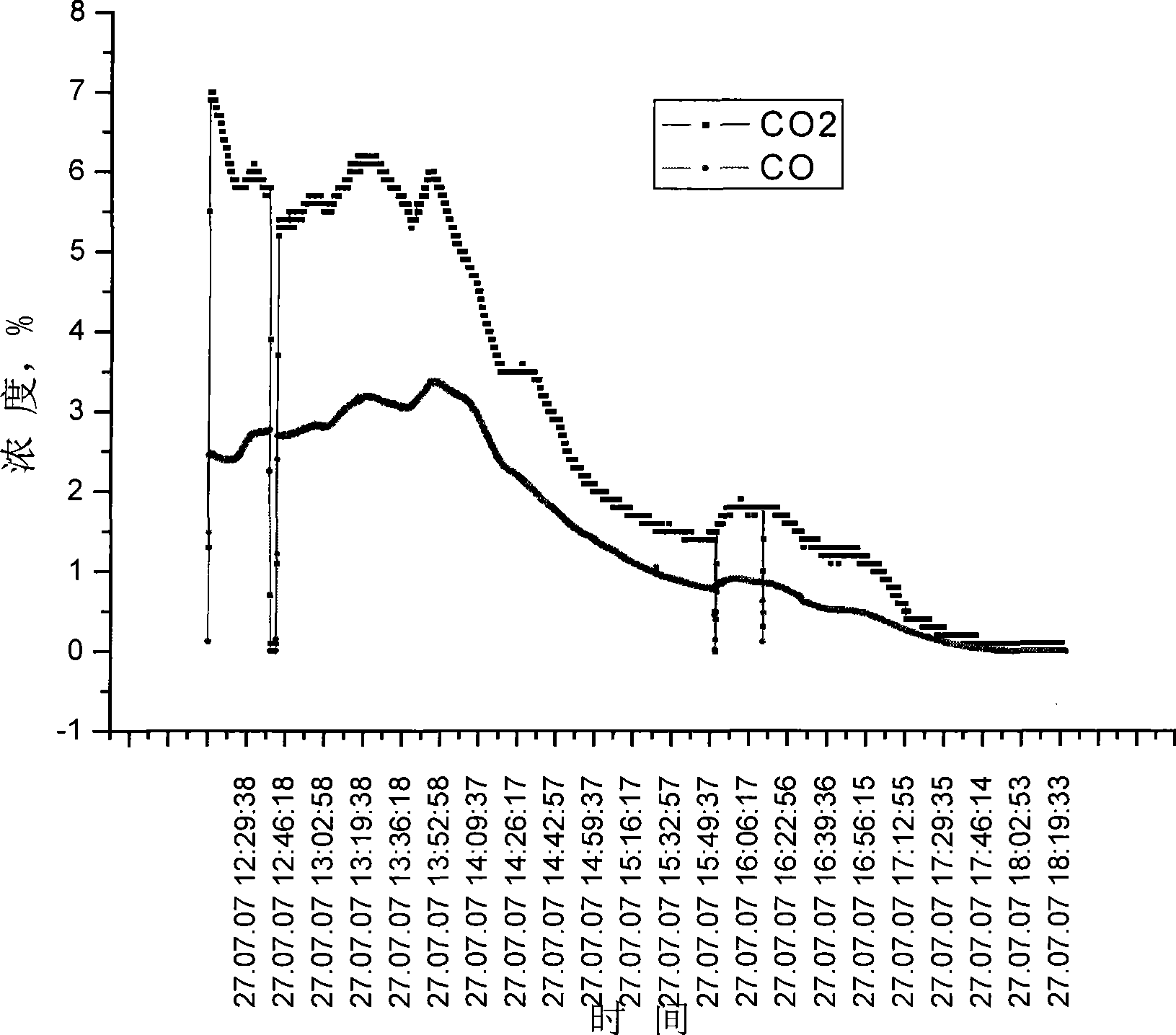

[0045] The method and on-line analysis device of the present invention are used to improve the coking process of cracking furnaces. The industrial cracking furnace is a GK-V cracking furnace. The raw materials for cracking can be naphtha, heavy diesel oil and hydrogenated tail oil, with an annual output of 60,000 tons of ethylene. The original on-line coking procedure of the pyrolysis furnace is 37 steps, and the design time is 22 hours before the 3rd step to the 37th step of the furnace tube scorching in the radiant section. figure 2 As shown, the original burning program is shown in Table 1.

[0046] By using this method of controlling scorching, according to the results of on-site analysis of the online analysis instrument, through manual scorching, and on the premise of ensuring that the analysis parameters are within the safe range, the amount of water vapor and air during scorching are correspondingly increased. The outlet temperature of the furnace tube was increased ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com