Nanoindentation test desk and experimental method for interfacial shear force of carbon fiber composite

A nano-intrusion, composite material technology, used in the analysis of materials, the use of stable tension/pressure to test the strength of materials, measurement devices, etc., can solve problems such as influence and violation of original intentions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

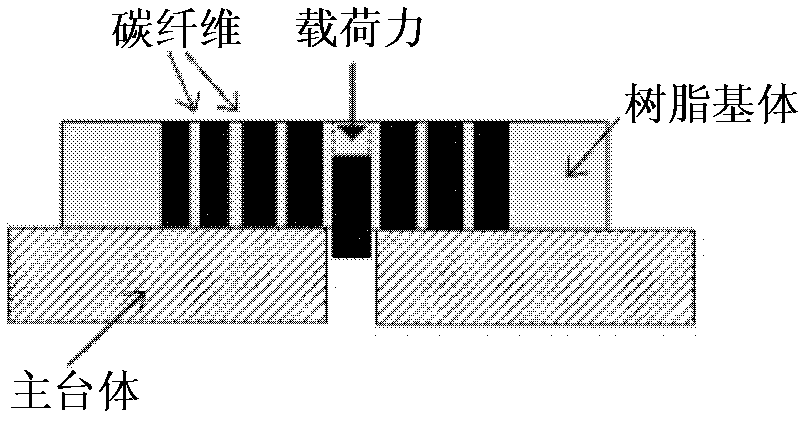

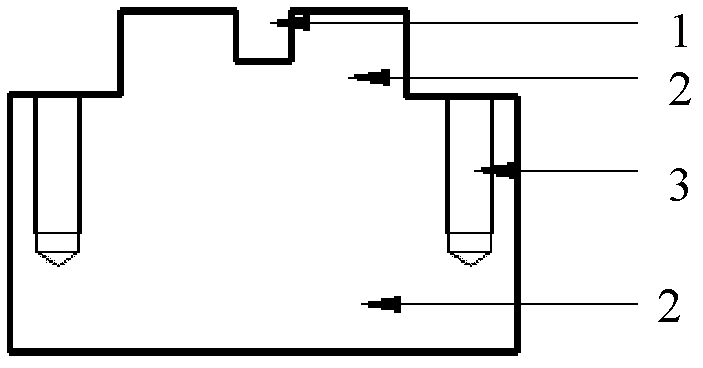

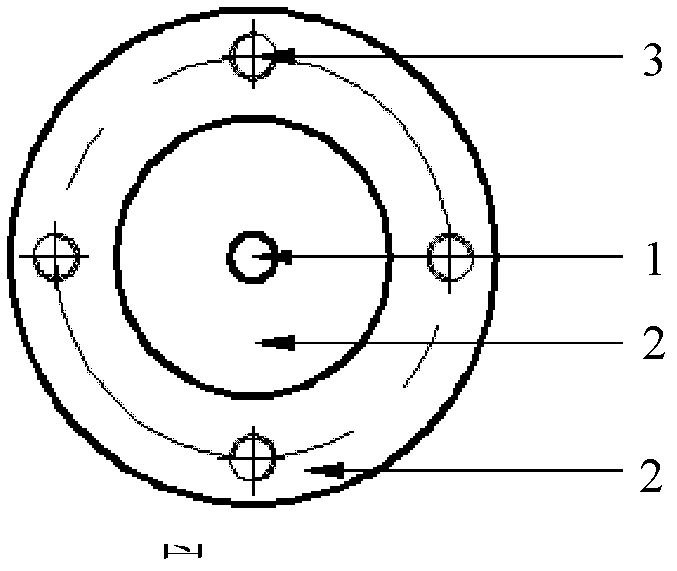

[0038] Attached below Figure 1 to Figure 8 The nano-indentation test bench for the interfacial shear force of the carbon fiber composite material and the method for performing the nano-indentation experiment using the test bench are further described in detail.

[0039] The nano-indentation test bench of the carbon fiber composite material interfacial shear force of the present invention is based on figure 1 Single fiber extruded schematic design, the test bench is mainly composed of figure 2 and image 3 main body, Figure 4 and Figure 5 Platen and Figure 6 and Figure 7 The rubber layer gasket consists of three parts. figure 2 and image 3 main body and Figure 4 and Figure 5 The pressure plate is connected by four screws and threaded holes 3 to form a normal loading fixture, and a layer of rubber layer 6 is bonded to the lower end of the pressure plate 5 to ensure that the composite material sheet sample can be effectively fixed. Align the fabricated sheet o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com