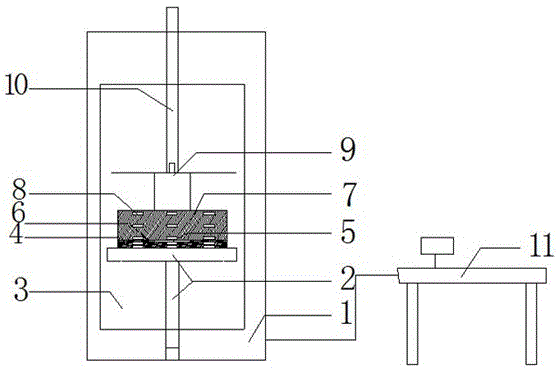

Method and device for shearing test on interface between steel bridge deck and pavement layer

A shear test and pavement technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of test influence, test deviation, and inconformity with the actual state of the pavement, etc., to achieve convenient operation and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

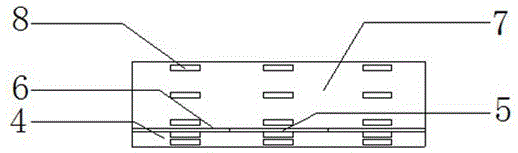

[0055] A kind of method for steel bridge deck and pavement interface shear test, comprises the following steps:

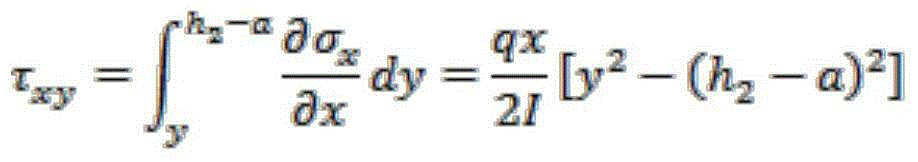

[0056] 1. Preparation of the test piece: Forming the steel plate, processing the 16mm thick steel plate into a 300mm×50mm rectangular steel plate on the machine tool. For the surface treatment of the steel plate, use a sandblasting machine to polish the steel plate to a roughness that meets the requirements, and manually polish the parts that cannot be treated by the sandblasting machine at the corners with a hand grinding wheel. Lay the adhesive layer, wipe the steel plate after polishing, and scrape the epoxy waterproof adhesive layer material. The bonding layer of the specimen was laid in two stages, and at the same time as the waterproof bonding material was scraped for the second time, single-grain gravel was spread. No bonding layer is laid in the middle third of the distance of the specimen, forming an empty layer, that is, a pure bend section. After the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com