Compact device for testing interfacial shear strength of composite material and method for testing interfacial shear strength of composite material through device

A technology of interfacial shear strength and composite materials, which can be used in measuring devices, using stable tension/pressure to test the strength of materials, analyzing materials, etc. The device is large in size and difficult to integrate, so as to achieve the effect of convenient disassembly, small size and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

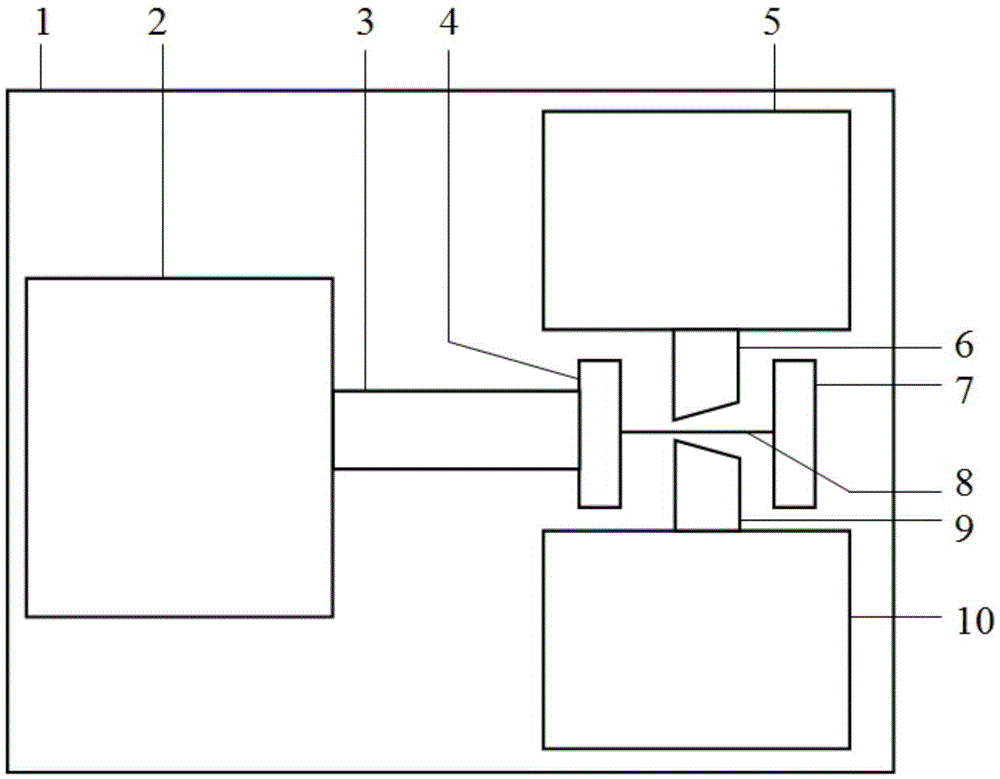

[0027] Embodiment 1: This embodiment is a compact composite material interface shear strength test device including a fixed base 1, a micro-tensile testing system and a droplet clamping system;

[0028] The micro-tensile testing system includes an x-direction piezoelectric ceramic displacement platform 2, a micro-stress sensor 3, a first fiber clamp 4 and a second fiber clamp 7;

[0029] The droplet clamping system includes a first y-direction piezoelectric ceramic displacement platform 5, a second y-direction piezoelectric ceramic displacement platform 10, a first micro-cutter 6 and a second micro-cutter 9;

[0030] The x-direction piezoelectric ceramic displacement platform 2, the first y-direction piezoelectric ceramic displacement platform 5, the second y-direction piezoelectric ceramic displacement platform 10, the first fiber clamp 4 and the second fiber clamp 7 are respectively installed on the fixed base seat 1;

[0031] One end of the micro-stress sensor 3 is connect...

specific Embodiment approach 2

[0038] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the x-direction piezoelectric ceramic displacement platform 2 can drive the first fiber clamp 4 to move along the x-axis direction, and the micro-stress sensor 3 is used to measure the x-axis stress value. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0039] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the first y-direction piezoelectric ceramic displacement platform 5 and the second y-direction piezoelectric ceramic displacement platform 10 can drive the first micro The blades of the cutter 6 and the second micro cutter 9 move along the y-axis direction. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Droplet diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com