Method for testing processing residual stress of 'through-silicon via'-Cu structure

A technology of residual stress and testing method, applied in the direction of force/torque/work measuring instrument, measuring device, mechanical device, etc., can solve the problems that the accuracy of test results needs to be improved, and the residual stress results are quite different, and the method is simple and reliable , the effect of accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

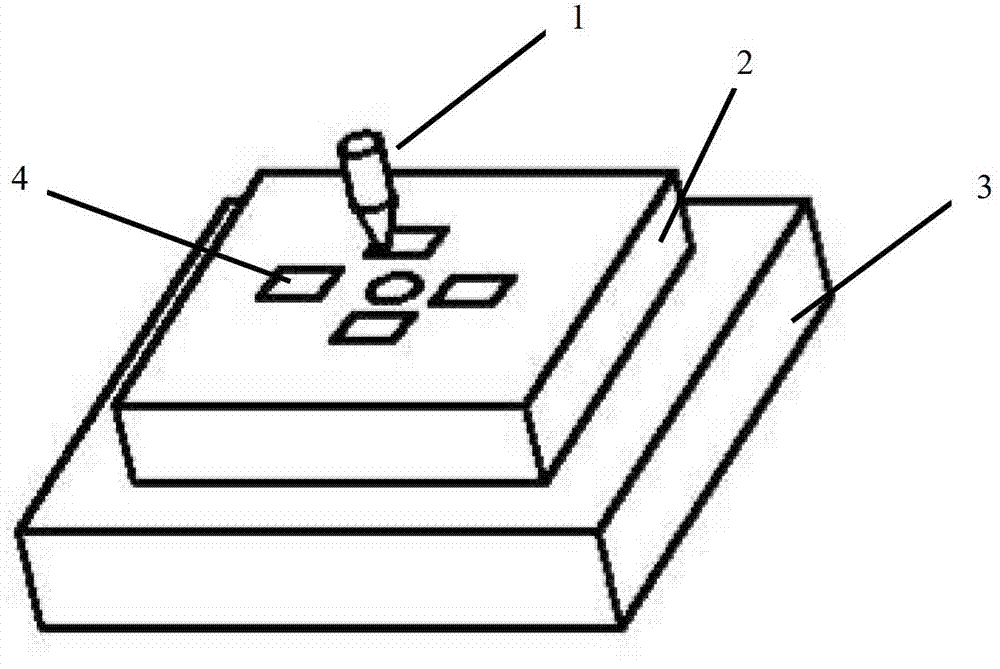

[0022] The experimental device is mainly composed of an indenter 1, an experimental sample 2, and a sample carrier 3. As shown in the attached picture. The experimental steps are as follows:

[0023] Firstly, the experimental sample 2 is placed on the sample carrier 3, the sample carrier 3 has a hole in the middle, and the diameter D of the hole is slightly larger than the diameter of TSV-Cu. Align the three parts of the indenter, TSV-Cu (copper-filled part) and the hole of the sample carrier 2.

[0024] Then, use the indenter 1 to slowly squeeze the copper downward, the loading speed is 0.1mm / min, and the diameter of the end of the indenter should be slightly smaller than the diameter of the TSV. During the loading process, the displacement and pressure values were recorded, and the platinum electric heating plate 4 was used to heat the sample at the same time, with a loading accuracy of 1K, which promoted diffusion slip at the interface between copper and silicon. By ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com