Heat energy recapture and recycle and its new applications

a technology of heat energy and energy storage, applied in steam engine plants, air transport, engine fuction, etc., can solve the problems of no way to recapture hydrogen energy for work, no idea of using the super temperature of fusion energy for diamond making, waste of heat energy of hydrogen bombs to the atmosphere, etc., and achieve good sunshine and atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

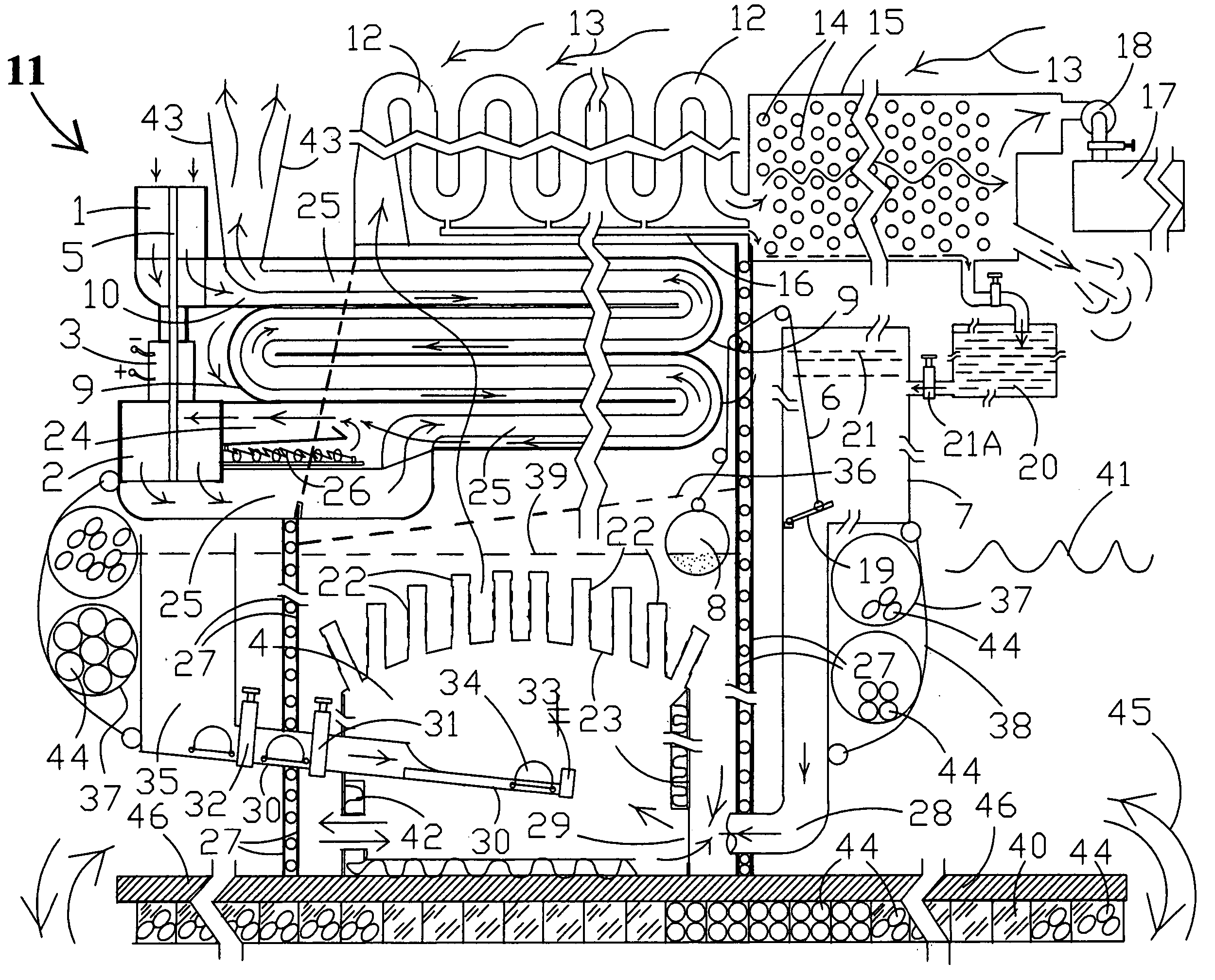

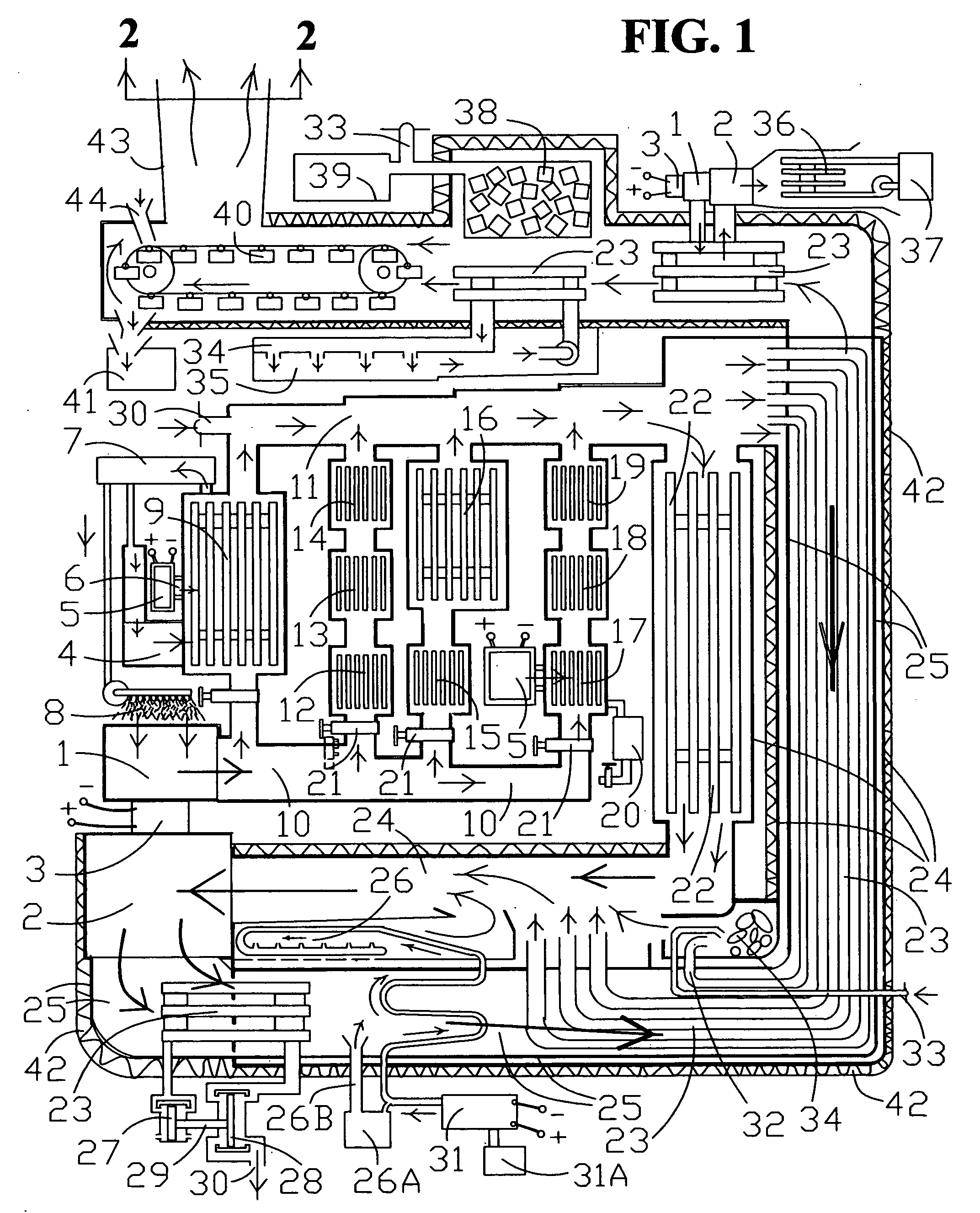

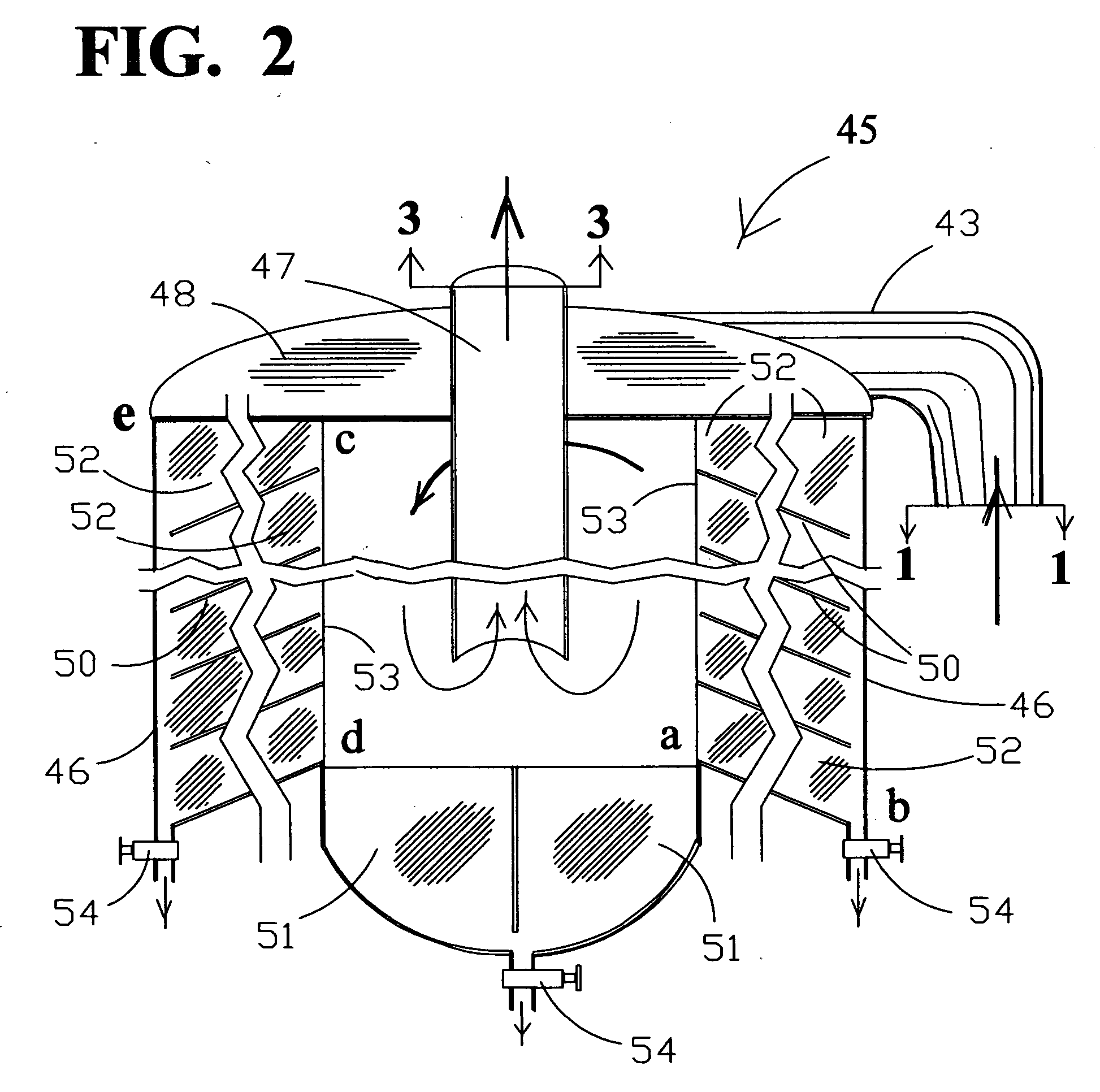

[0197] In support to the advocacy and to the missions of this invention, the following new configurations, new embodiments, and new structural and mechanical devices are created to provide the most appropriate technology to handle the processes involved, which can be more understood by further reading the following descriptions of the drawings, to wit:

[0198]FIG. 1—illustrates a new embodiment for a new innovative power plant displaying the most advance technology in maximizing benefits out of any kind heat source or any kind of fuel being spent, wherein, a cold compressed-air header duct 10 is communicated to a plurality of branches so that a multiple parallel and series of various kinds of heat-absorbing radiators of small tubes / pipes serving as energy collectors, parts 9, 12, 13, 14, 15, 16, 17, 18, 19, are communicated and able to conduct the cold compressed air supplied by the main compressor 1, which is either a wide-face bladed turbine model or a piston-chamber model, thru th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com