Double-layer assembly line with interval adjustable

An assembly line and spacing adjustment technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of reducing production costs, wasting resources, occupying space, etc., to reduce production costs, reduce labor intensity, and high positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

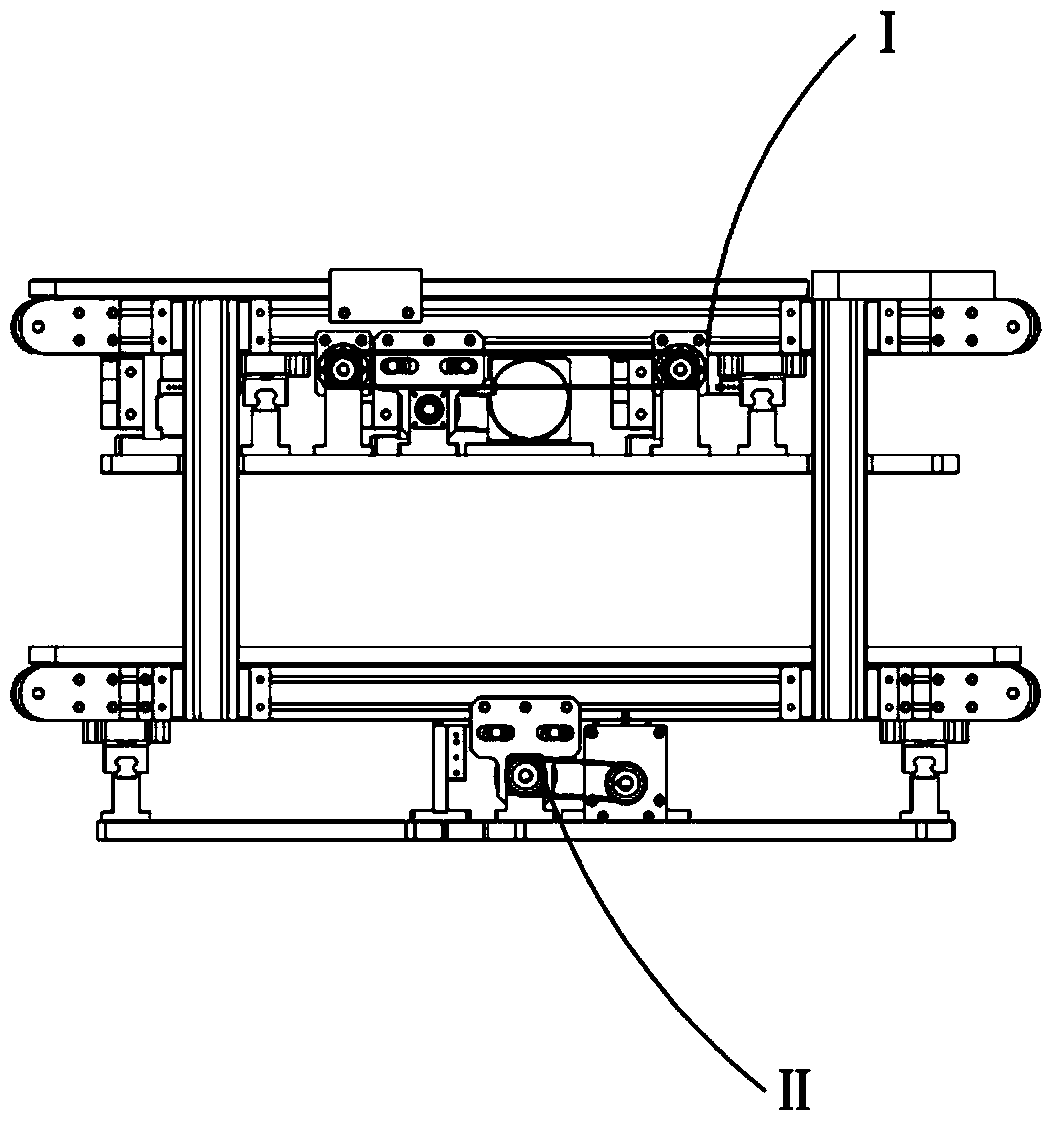

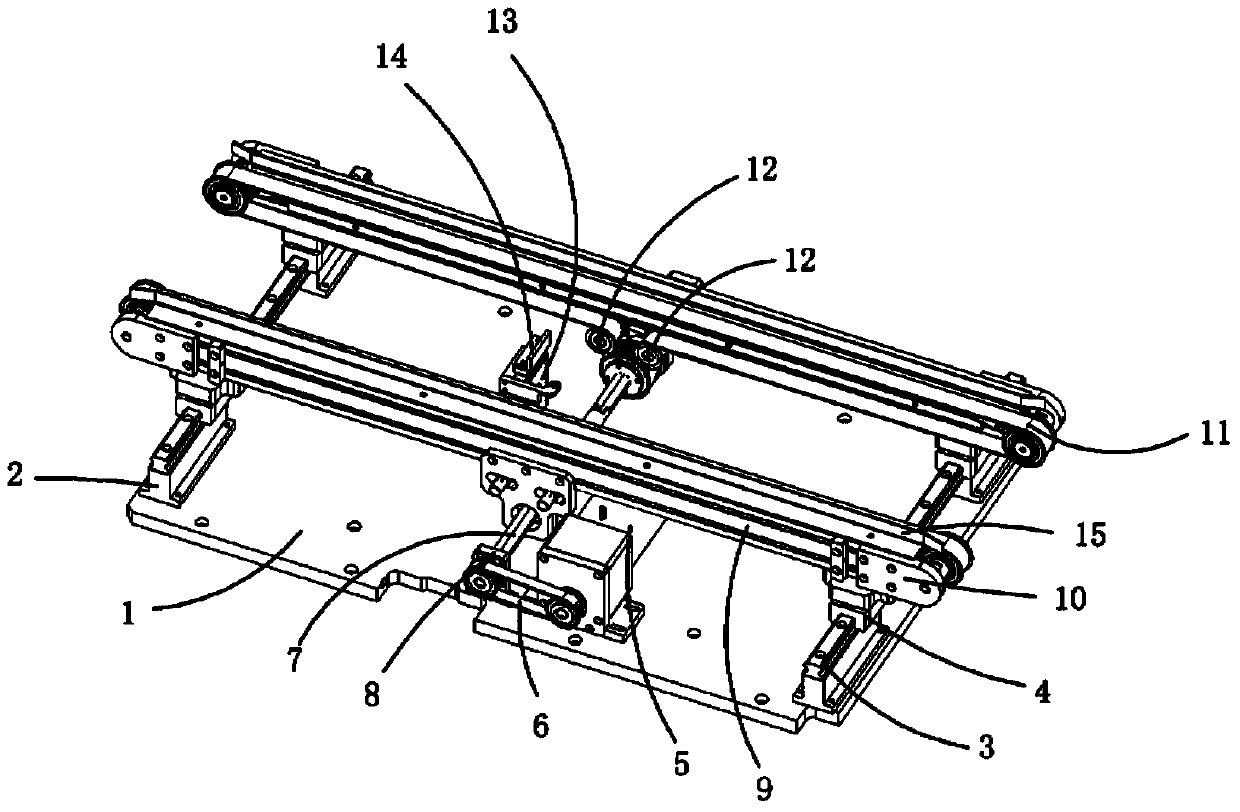

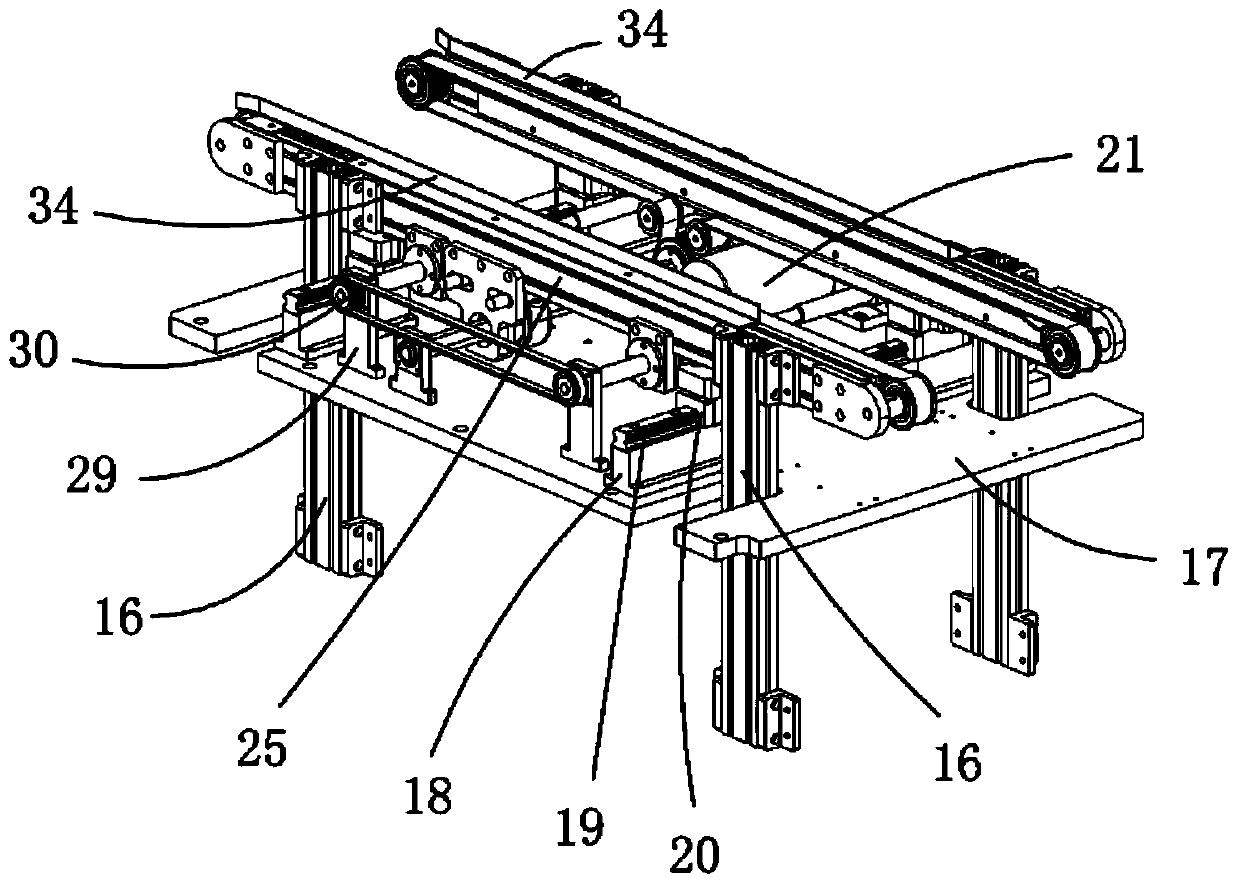

[0026] Examples, see attached Figure 1~6 , a double-layer adjustable-spacing assembly line, which includes an upper-layer adjustable assembly line I and a lower-layer adjustable assembly line II, the upper-layer adjustable assembly line is installed on the lower-layer adjustable assembly line; the lower-layer adjustable assembly line includes a lower plate 1, a lower rail Pad block 2, lower rail 3, lower block 4, lower motor 5, lower belt 6, lower driving shaft 7, lower driving shaft fixing block 8, lower belt mounting plate 9, lower pulley fixing block 10, lower transmission pulley 11, Lower tensioning wheel 12, lifting cylinder 13, block 14 and lower side rib 15, the left and right sides of the lower plate are respectively connected with lower rails through lower rail pads, each group of lower rails is equipped with front and rear two The lower sliders of the first group, the lower belt installation plates are respectively installed on the lower sliders of the front two gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com