Pipeline robot for internal diameter measurement

A technology for measuring pipes and robots, which is applied to measuring devices, instruments, special pipes, etc., can solve the problems of not being able to adapt to the inner diameter of pipes of different sizes, and the measurement accuracy is not high, and achieve the effect of high measurement accuracy and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

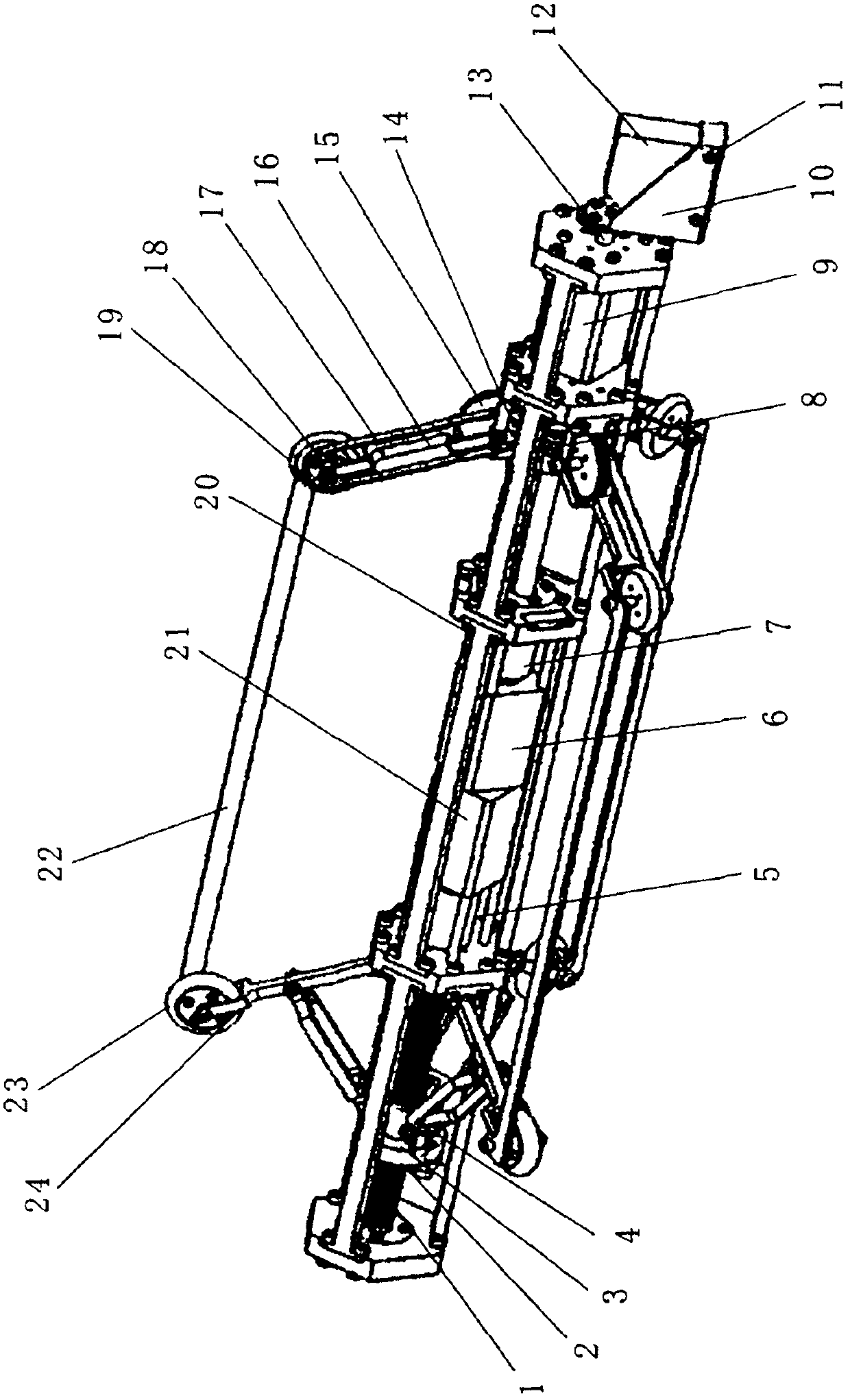

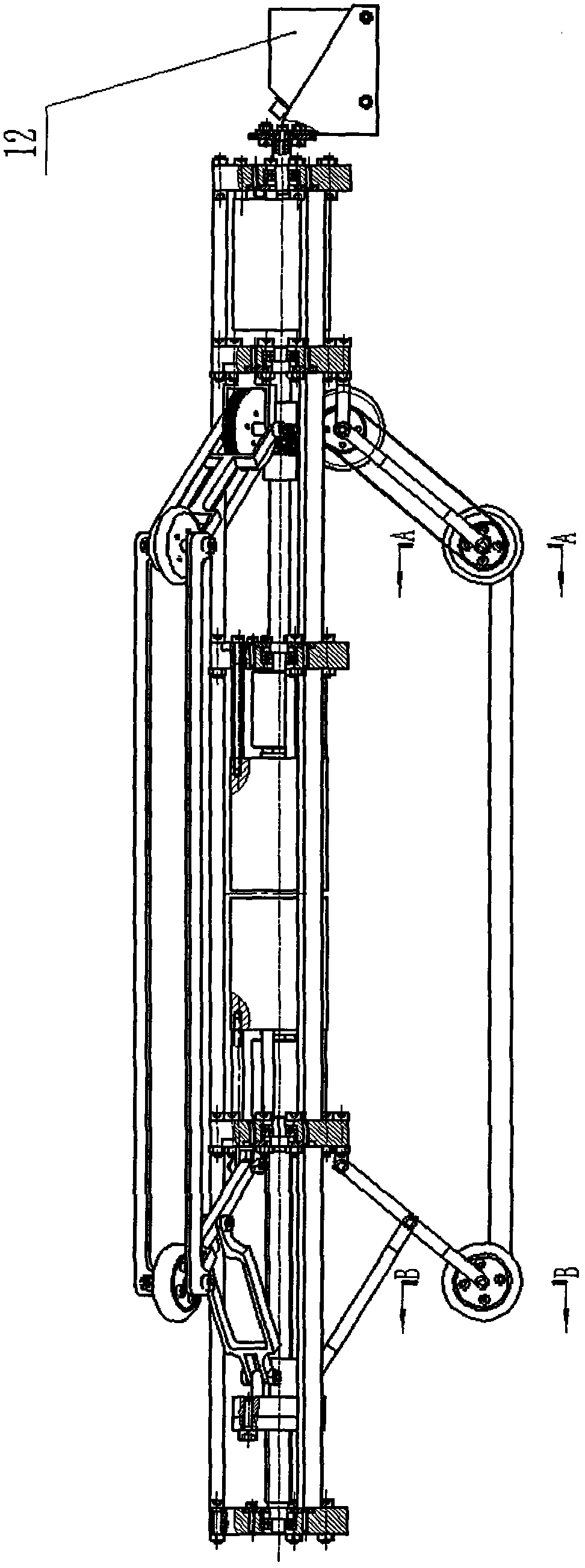

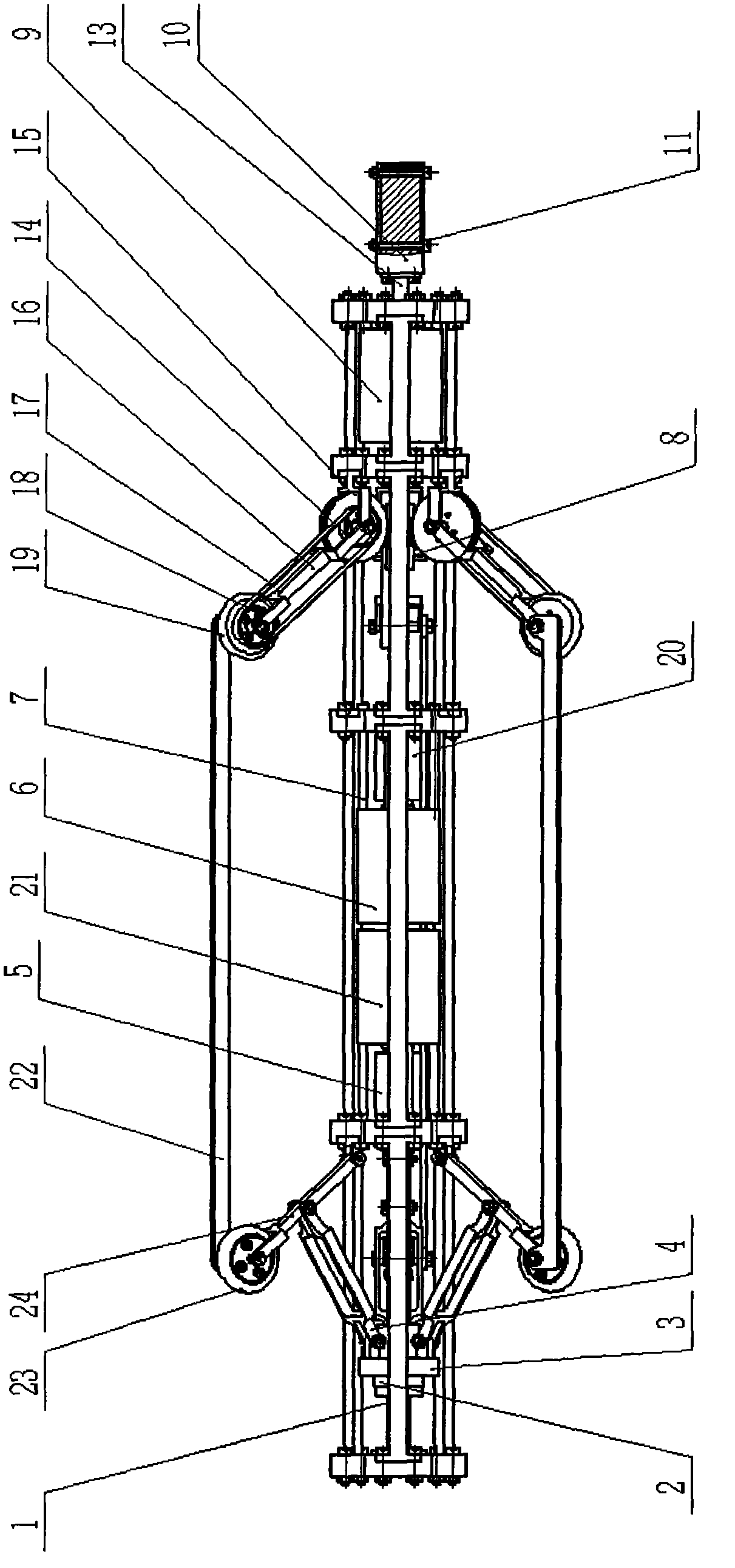

[0018] see Figure 1 to Figure 6 , There is a ball screw nut 2 on the ball screw 1. The rear wheel support seat 3 is fixed on the ball screw nut 2. One end of three push rods 4 is all fixed on the rear wheel support seat 3, and the other end is connected with the rear wheel support 24, and this end of push rod 4 can slide on the rear wheel support 24.

[0019] Worm wheel 15 is engaged with worm screw 8, and front wheel support 16 and belt pulley I14 are respectively housed on worm wheel 15; The other end of front wheel support 16 is equipped with belt wheel II18 and front wheel 19; Belt wheel I14 is fixedly connected with worm wheel 15, The pulley II18 is fixedly connected with the front wheel 19; such mechanisms share the same three groups.

[0020] The stepping motor I21 drives the ball screw 1 to rotate through the coupling I5. By controlling the number of pulses of the stepping motor I21, the linear movement distance of the ball screw nut 2 can be indirectly controlled,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com