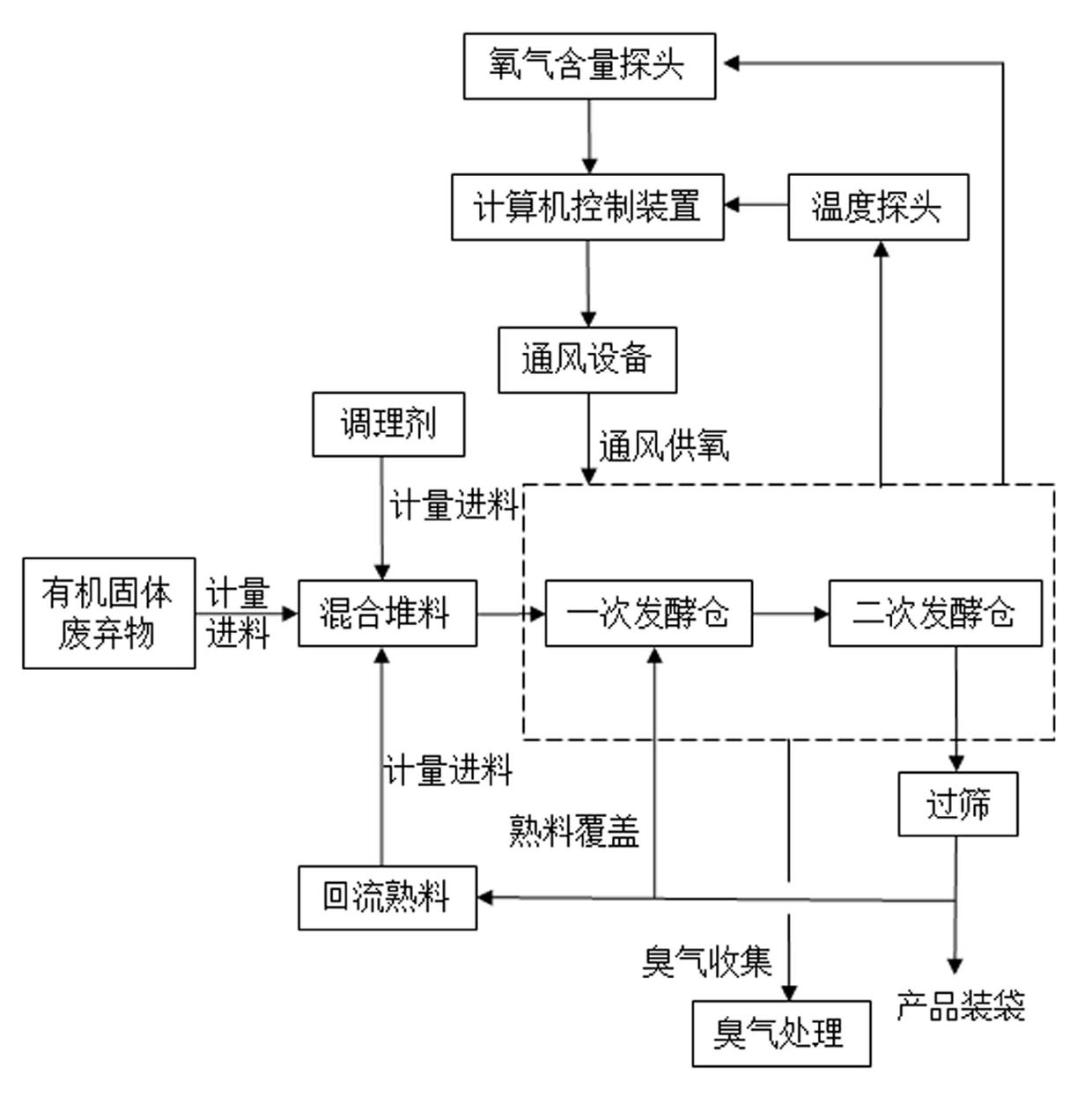

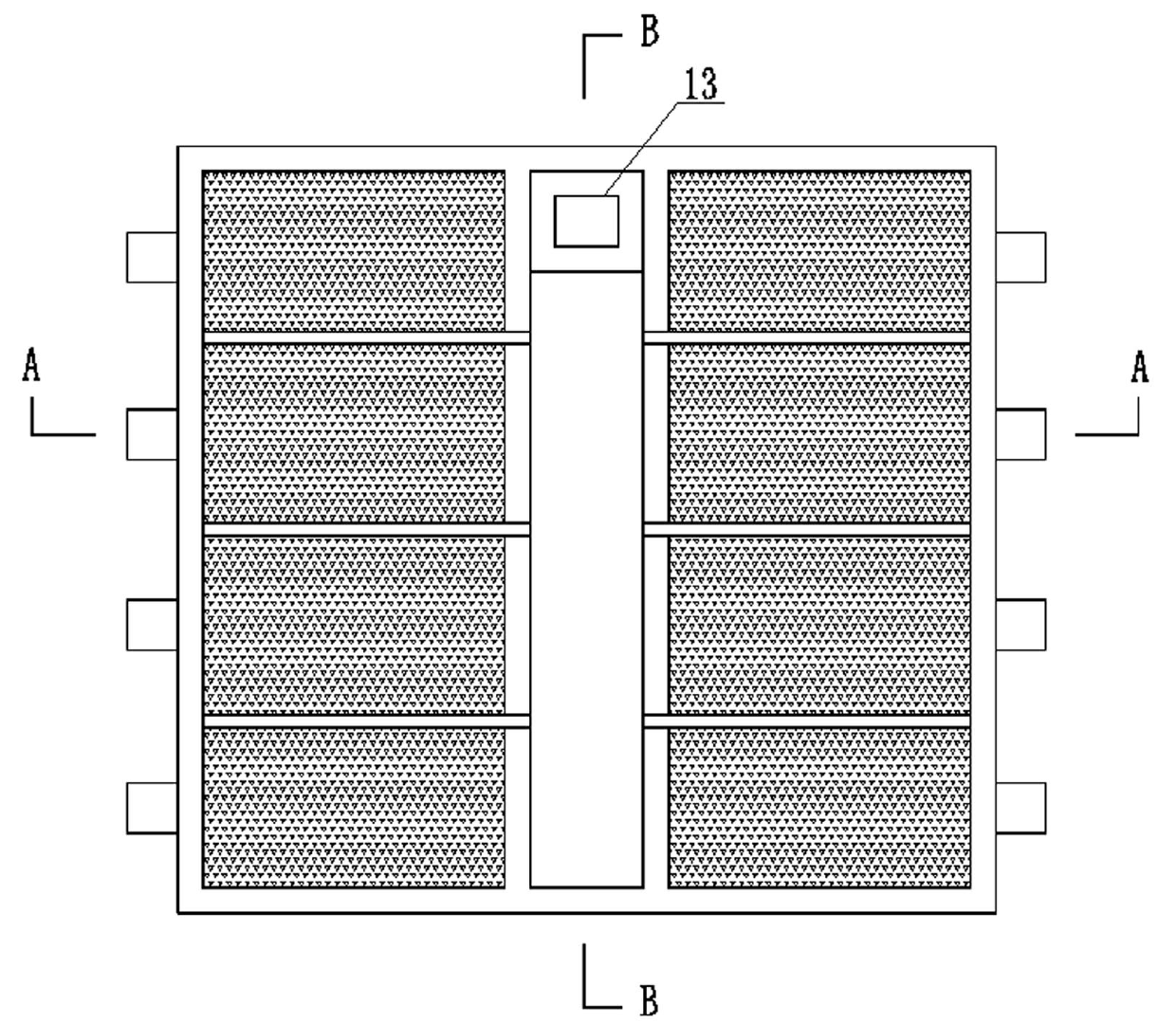

Aerobic fermentation fertilizer making device for organic solid waste and method thereof

A technology of organic solid, good oxygen fermentation, is used in the direction of organic fertilizer, fertilization device, organic fertilizer preparation, etc., to achieve the effect of good closedability, avoiding secondary pollution, and improvement of the height of fermentation warehouses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

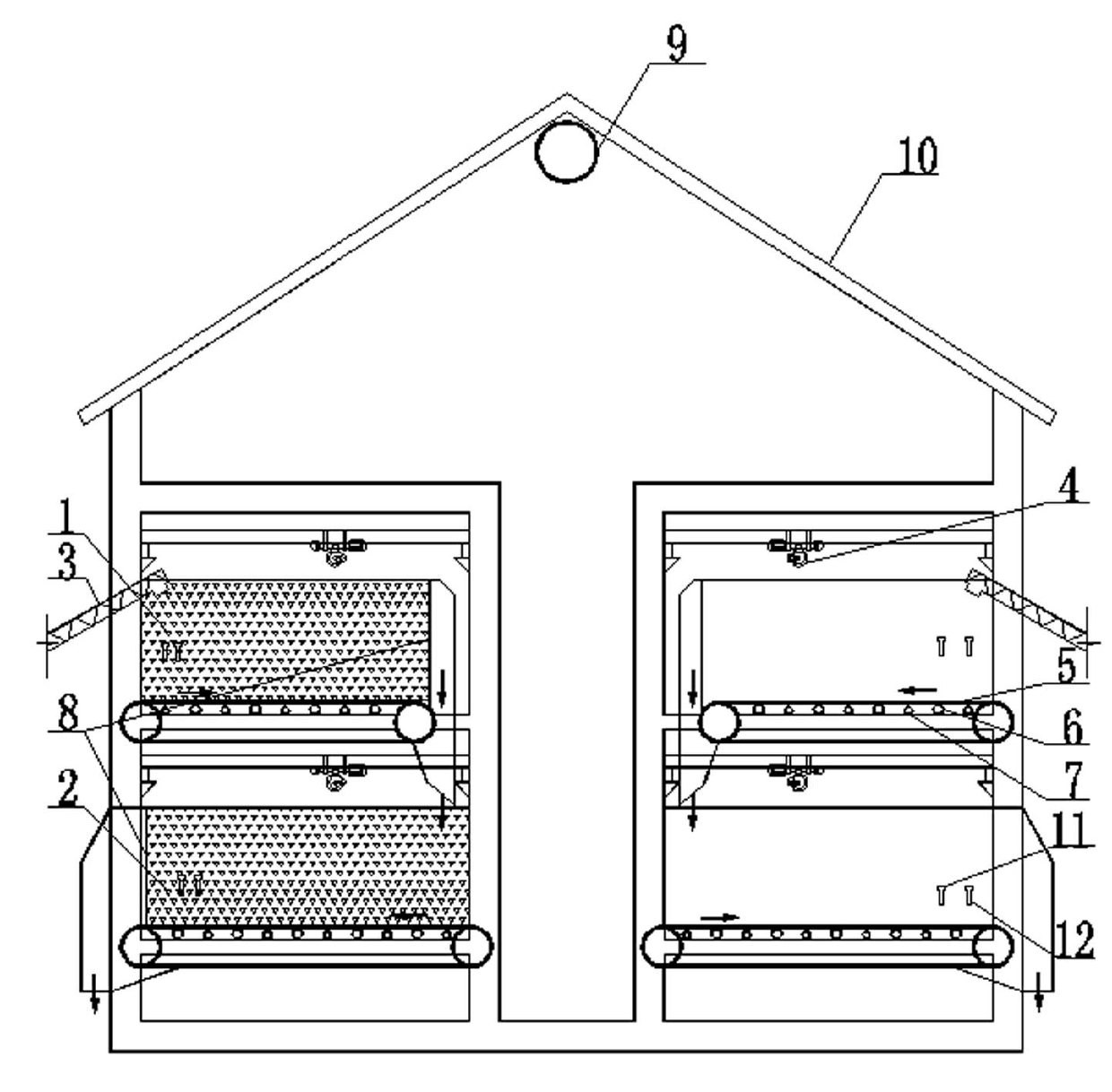

Examples

Embodiment 2

[0037] a. The organic solid waste with a moisture content of 60% and the conditioner and reflux clinker are mixed in a mixing mixer with a weight ratio of 1:0.5:0.02, and the pH of the material pile is 8; the mixed pile after mixing evenly contains water The rate is 50%, and then transported to the primary fermentation bin on the upper floor by a screw lift pump; the organic solid waste is urban sludge, poultry manure and urban waste, and the conditioner is wood chips: the weight ratio of rice husk is 1:2 Assembled materials, the large-grain sieve of step d of the reflux clinker usage method embodiment 1;

[0038] b. The height of the material stack is 1.8m; the surface layer of the material is covered with a 5cm thick conditioner for heat preservation and deodorization; the ventilation volume is 0.13-0.15m 3 Air / (m 3 stacking.min), the fermentation cycle is 8 days, and the rest are the same as in Example 1;

[0039] c. The material pile height is 3m; the ventilation volume...

Embodiment 3

[0042] a. The organic solid waste with a moisture content of 40% and the conditioning agent and the reflux clinker are mixed in a mixing mixer at a weight ratio of 1:0.5:0.02, and the pH of the material pile is 7.3; the mixed pile after mixing evenly contains water The rate is 50%, and then transported to the primary fermentation bin on the upper floor by a screw lift pump; the organic solid waste is municipal waste and food waste, and the conditioner is a wood chip: peanut shell weight ratio of 1:1 assembly material, The large particle sieve of step d of the described reflux clinker usage method embodiment 1;

[0043] b. The height of the material pile is 2m; the surface layer of the material is covered with a 3cm thick conditioner for heat preservation and deodorization; the ventilation volume is 0.1-0.12m 3 Air / (m 3 stacking.min), the fermentation cycle is 7 days, and the rest are the same as in Example 1;

[0044] c. The material pile height is 2.8m; the ventilation vol...

Embodiment 4

[0047] a. Put the organic solid waste with a moisture content of 30% and the conditioning agent and the reflux clinker at a weight ratio of 1:1:0.01, put them into the mixing mixer and mix them evenly, and adjust the pH of the material pile to 7; the mixed pile after mixing evenly The water content is 55%, and then transported to the primary fermentation bin on the upper layer by a screw lift pump; the organic solid waste is urban sludge, urban garbage and food waste, and the conditioner is wood chips: straw weight ratio of 1:1 Assembling materials, the large particle sieve of the step d of the reflux clinker usage method embodiment 2;

[0048] b. The height of the material stack is 1.7m; the surface layer of the material is covered with a 4cm thick conditioner for heat preservation and deodorization; the ventilation volume is 0.12~0.13m 3 Air / (m 3 stacking.min), the fermentation cycle is 9 days, and the rest are the same as in Example 1;

[0049] c. The material pile heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com