Steel coil feeding and centering method

A steel coil and coiling technology, applied in metal rolling, manufacturing tools, metal processing equipment, etc., can solve problems such as difficulty in realizing automatic coiling, increasing labor intensity and labor cost of workers, and operation accuracy being greatly affected by personnel quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the examples.

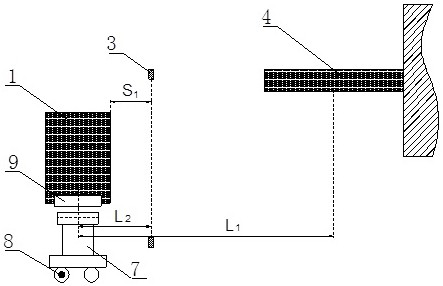

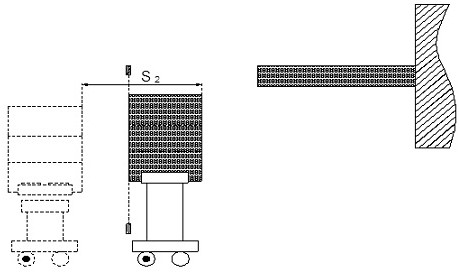

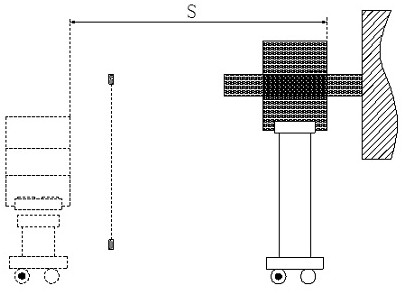

[0026] The invention discloses a coil centering method for steel coils, see Figure 1-Figure 3 , install the saddle 9 of the steel coil 1, the winding trolley 7 and the uncoiler mandrel 4, install the grating 3 between the saddle 9 and the uncoiler mandrel 4, and install the grating for distance measurement on the winding trolley 7 Encoder 8, when the winding trolley 7 is raised to the operating height, it moves towards the direction of the uncoiler mandrel 4, and records the value of the encoder 8 when the steel coil 1 blocks the grating 3, and then the winding trolley 7 continues to move, when the steel coil 1 When the grating 3 is out, record the value of the encoder 8 again, and calculate the deviation ε between the center line of the steel coil 1 width direction and the center line of the saddle 9 width direction when the steel coil 1 is on the saddle 9, by the saddl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com