Cast-weld combined type cable saddle forming structure

A forming structure and combined technology, applied in bridge parts, bridges, buildings, etc., can solve the problems of large welding residual stress, reducing the compressive strength of the joint between the saddle and the saddle, and adverse effects on the structural performance of the cable saddle. , to achieve the effect of high molding quality, easy casting defects, and enhanced bonding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

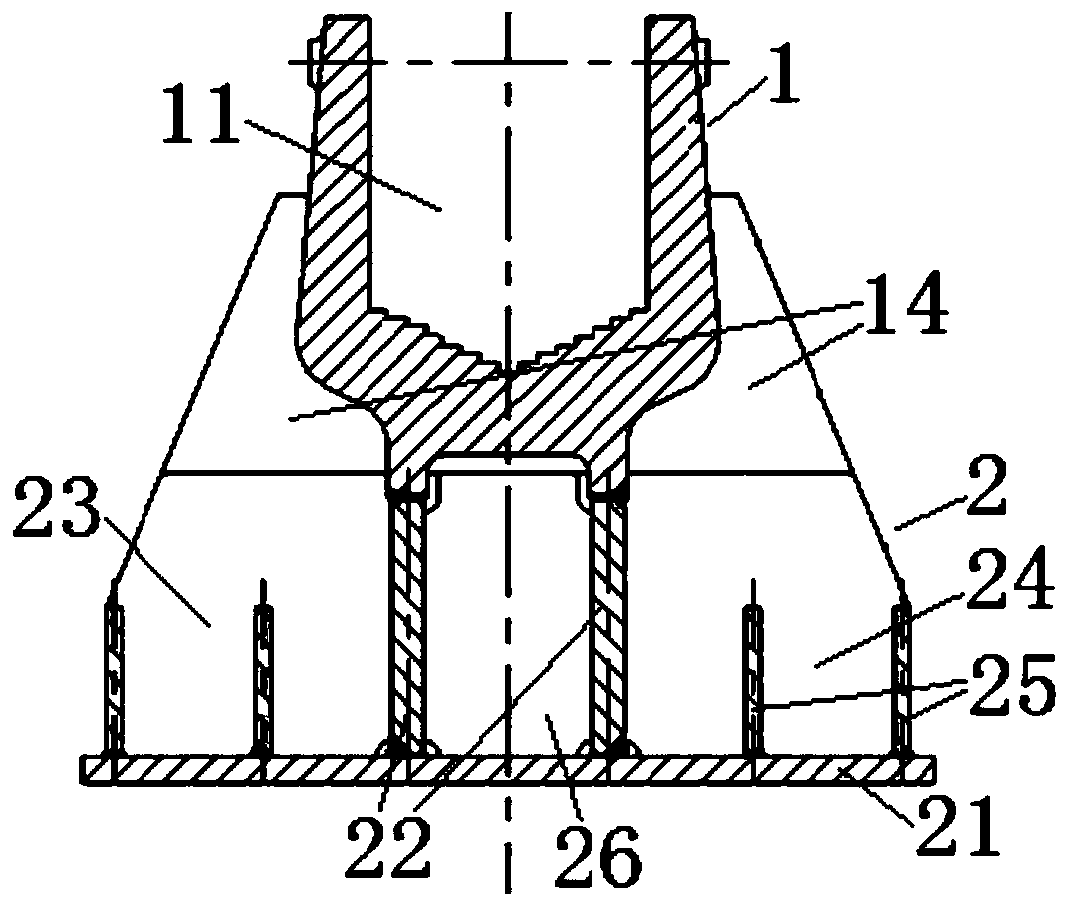

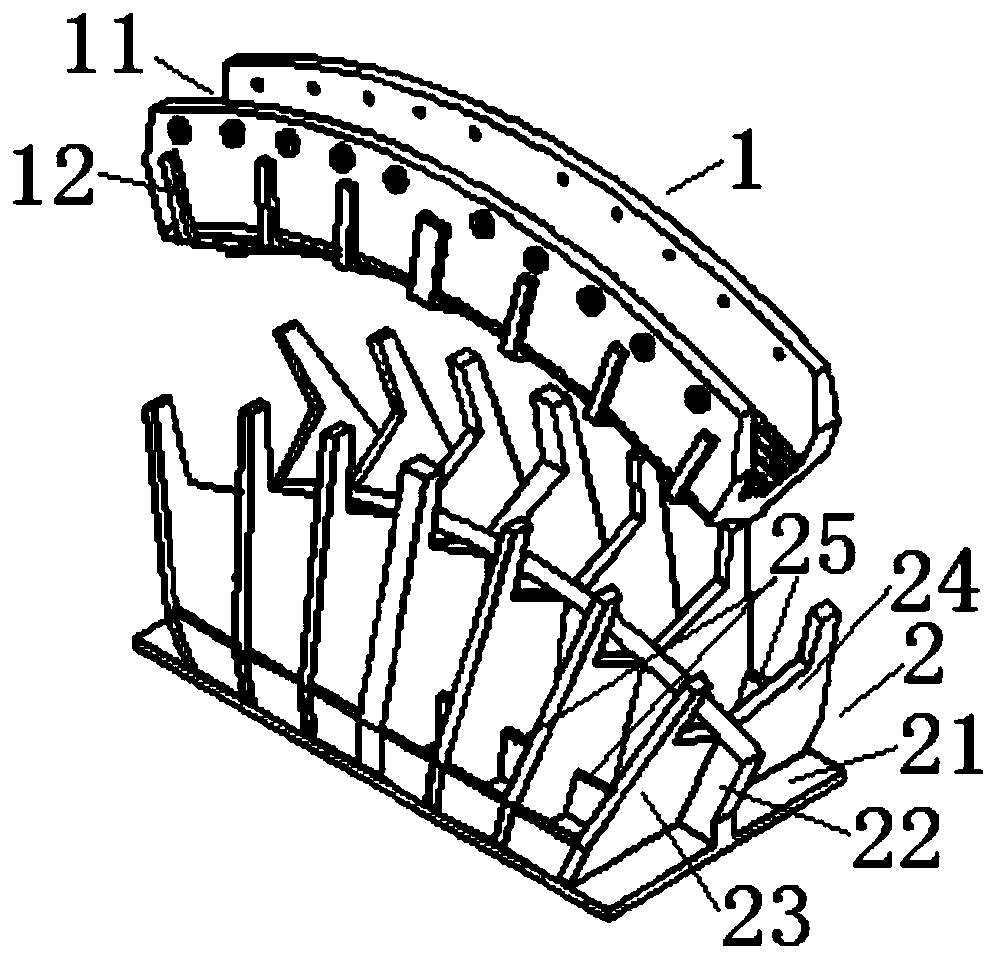

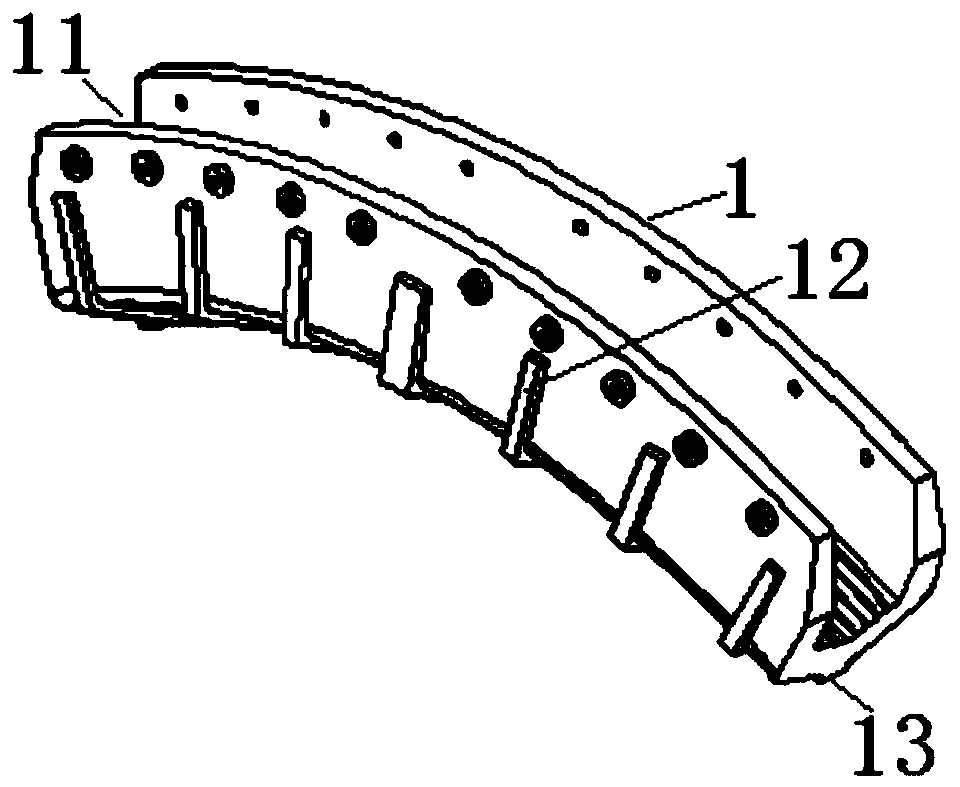

[0028] see figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the present invention is a main cable saddle for suspension bridge engineering, which includes a saddle head 1 of a casting structure and a saddle 2 of a weldment structure.

[0029] Among them, there is a saddle groove 11 along the longitudinal direction of the saddle head 1 with a concave structure and a curved bottom to support the main cable. The saddle groove 11 on the saddle head 1 is only corresponding to the height of the saddle head 1. direction of the two-dimensional saddle groove structure.

[0030] The bottom central area of the saddle head 1 has a longitudinal beam 13 protruding downward along the longitudinal direction of the saddle head 1 , and the thickness center of the longitudinal beam 13 basically corresponds to the width center of the saddle groove 11 on the saddle head 1 .

[0031] Both sides of the outer periphery of the saddle head 2 have a plurality of protruding rib...

Embodiment 2

[0046] The other content of this embodiment is the same as that of Embodiment 1, except that: the longitudinal beams protruding downwards from the bottom of the saddle head are arranged at two intervals; correspondingly, the longitudinal ribs on the saddle are arranged at intervals. Two sets of cloth, there are multiple sets of middle transverse ribs between these two sets of longitudinal ribs, and each set of middle transverse ribs is closely fitted with the pommel head by polishing, and supplemented by fillet welding, similar to figure 1 shown.

Embodiment 3

[0048] The other content of this embodiment is the same as that of Embodiment 1, the difference is that only the grinding and top tight fit between the saddle head and the saddle seat, without the assistance of fillet welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com