Steel coil diameter calculation method

A calculation method and steel coil technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of greatly affecting the quality of personnel, restricting the production rhythm, and low measurement accuracy, so as to improve the production rhythm and production efficiency and reduce labor costs. Intensity and labor cost, the effect of simple calculation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the examples.

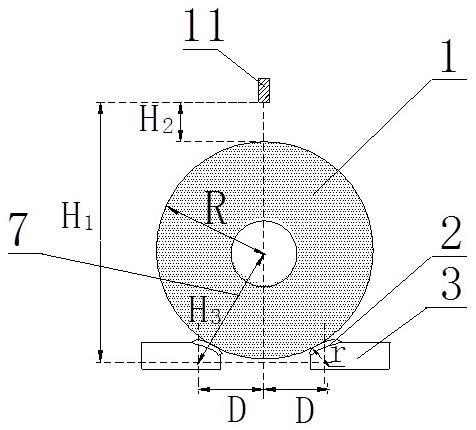

[0024] The invention discloses a method for calculating the diameter of a steel coil, which is used for calculating the diameter of the steel coil in a strip steel production line before it is rolled up and after it is rolled down. A saddle liner 2 with a circular arc structure, a distance measuring sensor 11 is installed directly above the center of the line connecting the centers of the two saddle liners 2, and the distance between the distance measuring sensor 11 and the bottom surface of the saddle 3 is greater than the diameter of the largest steel coil 1; The distance H measured by the distance measuring sensor 11 and the surface of the steel coil 1 2 , through the formula R=(H 1 2 +H 2 2 -2×H 1 ×H 2 -r 2 +D 2 ) / 2(H 1 -H 2 +r) Find the diameter of steel coil 1; where R is the radius of steel coil 1; H 1 is the vertical distance between the distance measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com