A composite anchorage of suspension bridge tunnel anchor and its construction method

A tunnel anchor and combined technology, applied in bridge construction, construction, bridges, etc., can solve the problems of the durability of the composite anchorage cable being difficult to ensure, the overall stability requirements are high, and the difficulty of forming a hole in a large chamber. , to achieve the effect of reducing the amount of excavation and the amount of concrete used, the construction progress is fast, and the construction process is less.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

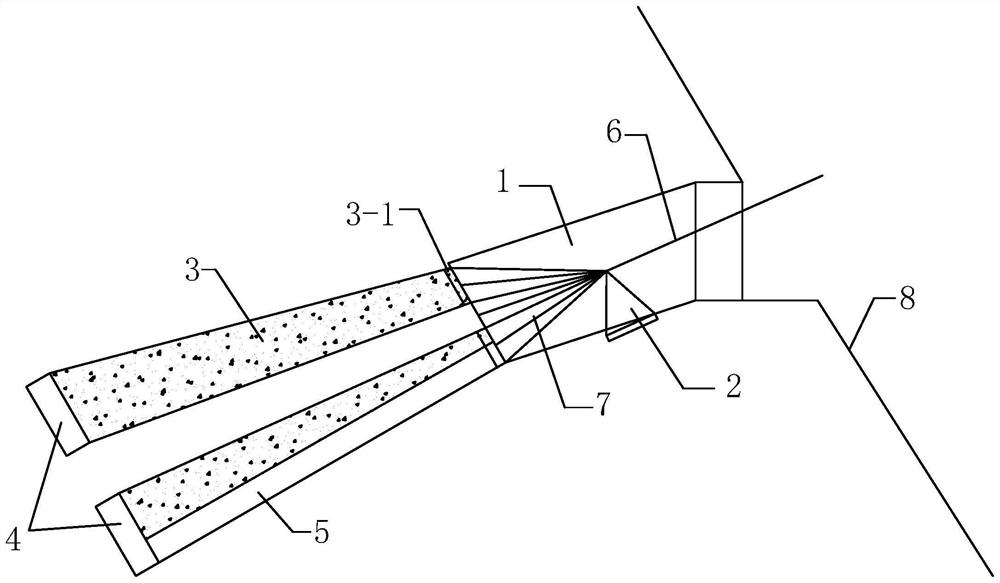

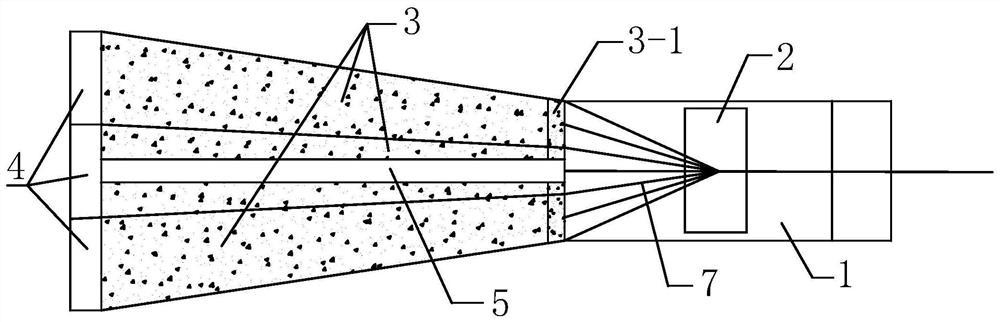

[0027] Embodiment: A construction method of a suspension bridge tunnel anchor combined anchorage, characterized in that the specific steps are as follows:

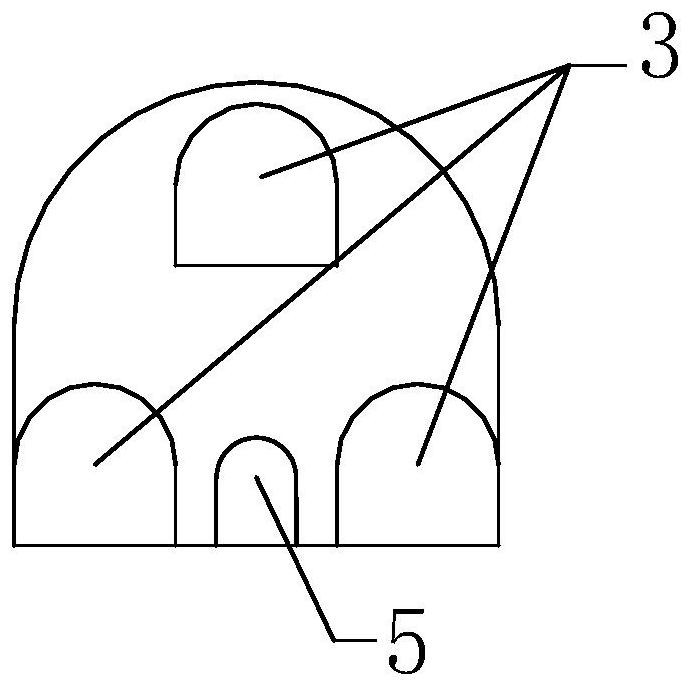

[0028] (1) Excavate the front anchor chamber 1 on the side of the mountain slope on one side or both sides of the suspension bridge, support or reinforce the cave wall and opening of the front anchor chamber, line the cave wall and bottom plate, and pour concrete on the front anchor surface; The front anchor chamber 1 is in the shape of a city gate with an inclination angle of 18°;

[0029] (2) According to the measurement, it is determined that the tension of the main cable of the suspension bridge to be constructed is 1.2×10 5 kN, anchorage and surrounding rock engineering quality grades are mostly grade III and some are grade IV. Three small-section tunnel anchorages are designed, and the front section height and bottom edge width of each small-section tunnel anchorage are respectively 3m. The height of the rear sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com