Side span shape finding method adopting resultant force control in horizontal plane

A horizontal plane and side span technology, applied in data processing applications, instruments, electrical digital data processing, etc., can solve the problem of lateral inclination of bridge towers, tension of girder beams of portal towers, failure to obtain theoretical vertices of loose cable saddles or reasonable transverse direction of anchor points Position and other issues, to achieve the effect of simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

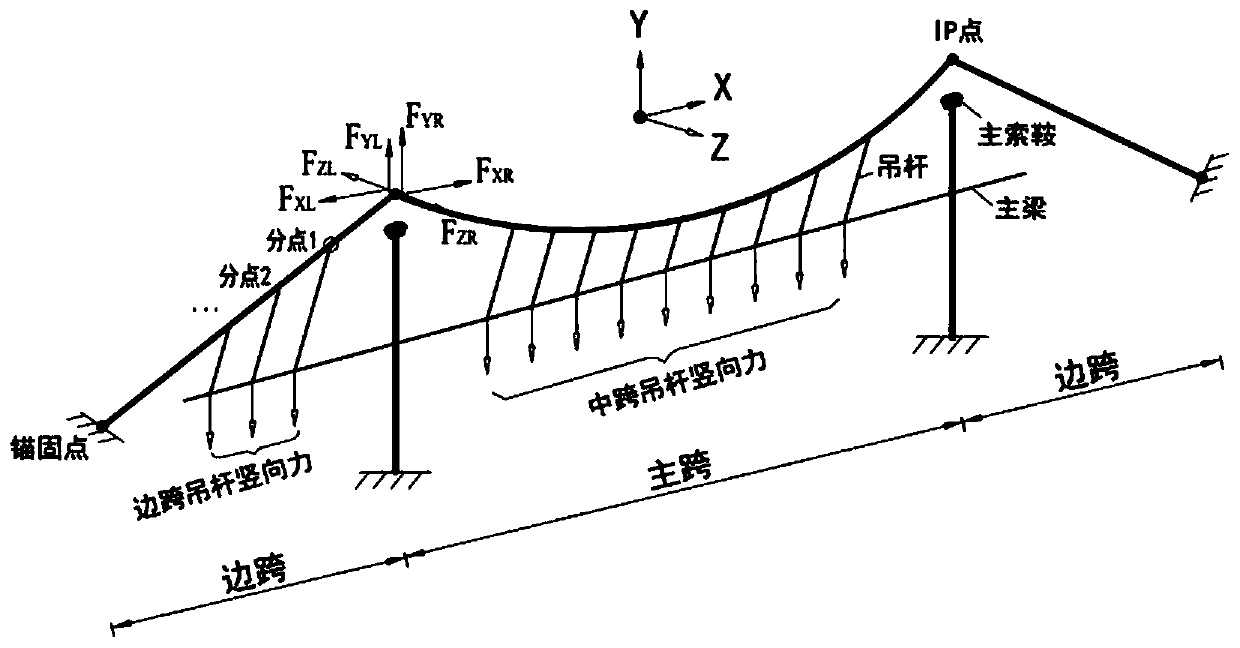

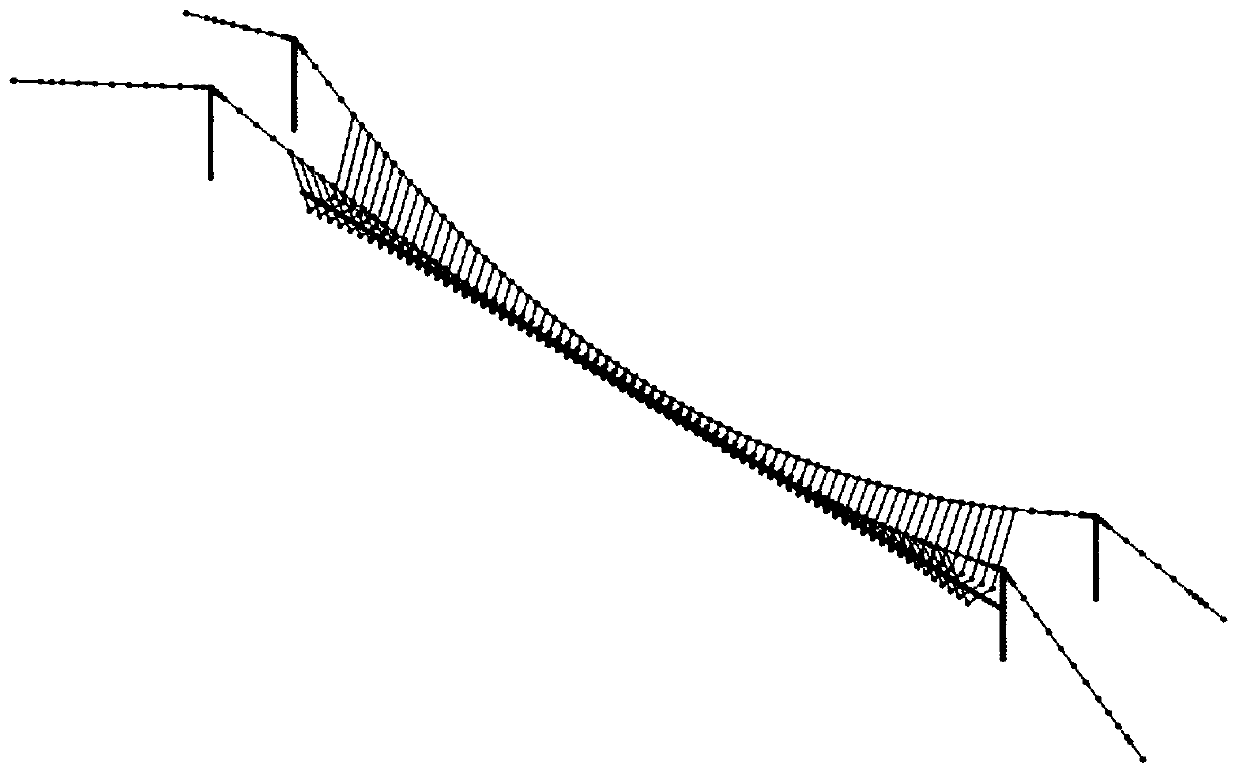

[0028] see figure 1 , figure 2 and image 3 As shown, the embodiment of the present invention provides a side-span form-finding method using resultant force control in the horizontal plane, including the following steps:

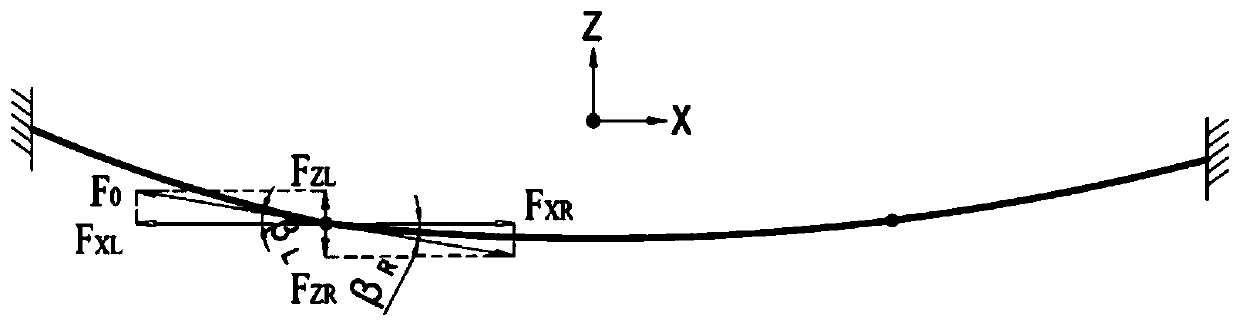

[0029] Step 1. According to the given mid-span rise-span ratio, use the spatial cable analytical form-finding method to iteratively obtain the mid-span line shape and mid-span theoretical apex ( figure 1 Longitudinal force F of mid-span main cable at mid-span point) XR , vertical force F YR , Lateral force F ZR , calculate the angle β between the resultant force in the horizontal plane at the end of the mid-span and the longitudinal axis R =atan(F ZR / F XR ).

[0030] Step 2. Let the longitudinal component F of the side-span main cable at the theoretical apex of the main saddle be XL =-F XR , the angle β between the resultant force in the horizontal plane at the end of the side span and the longitudinal axis L = β R . In step 2 of this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com