Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

193results about How to "Fold compact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

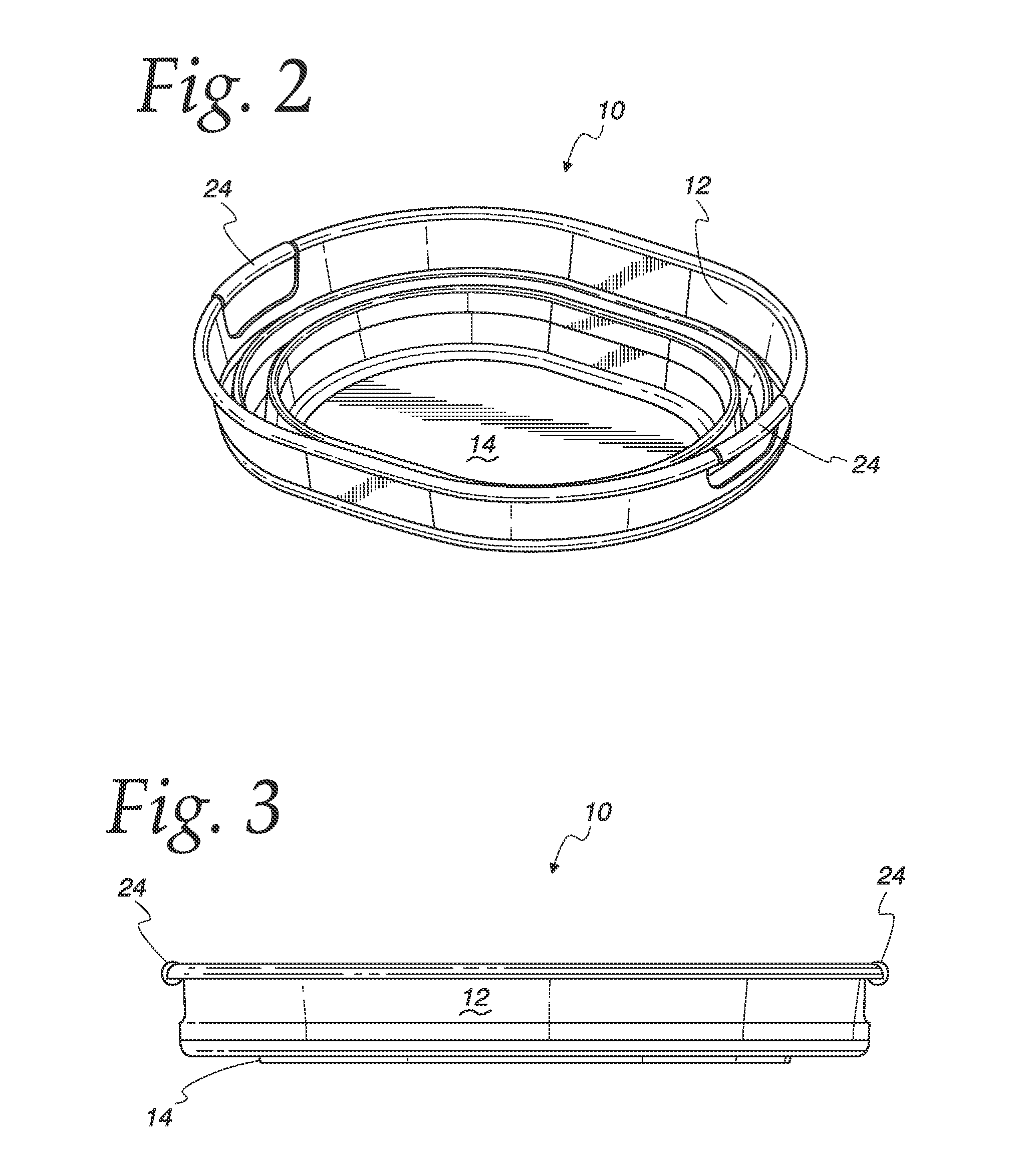

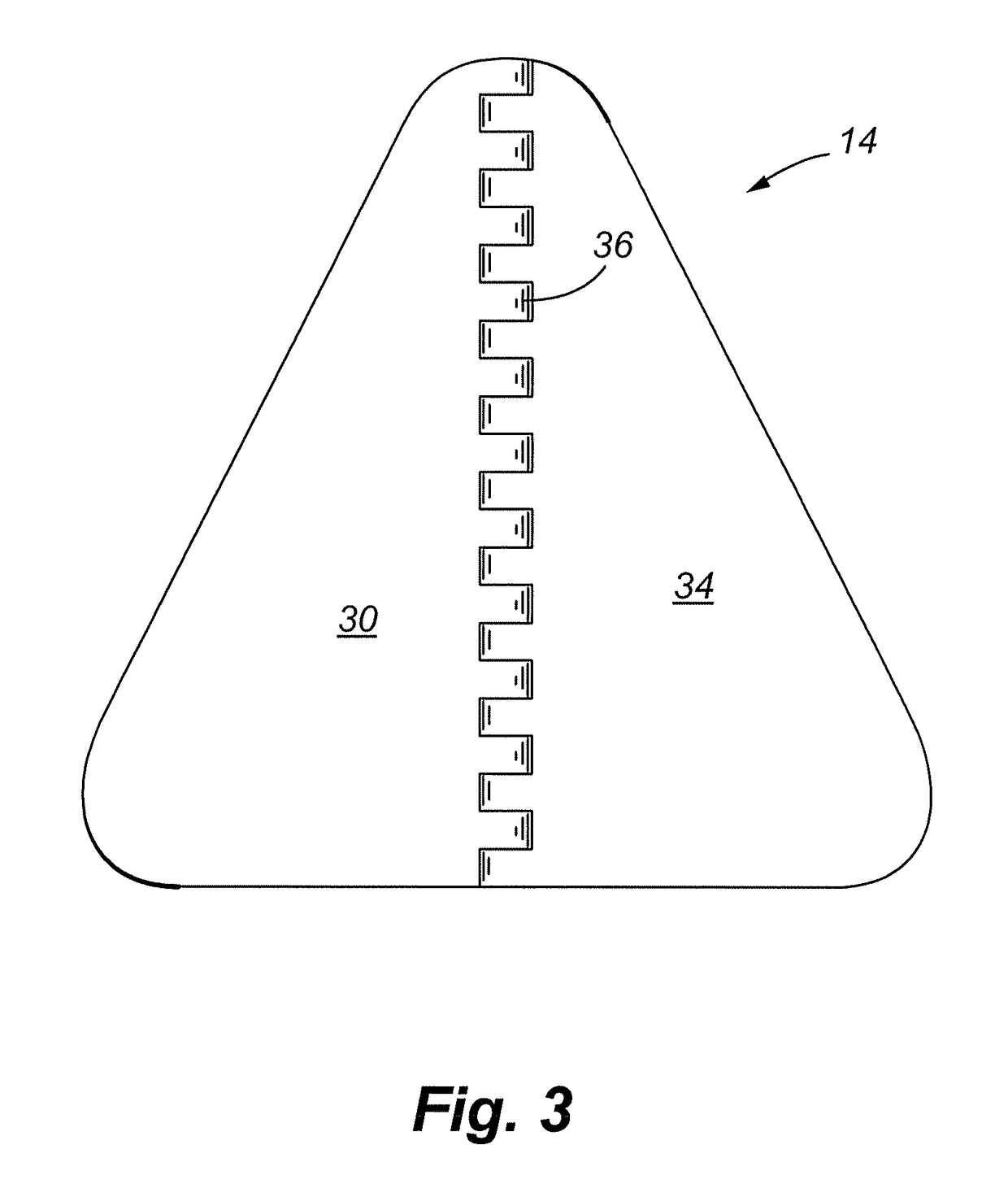

Edge and corner for a table top

Owner:LIFETIME PRODUCTS

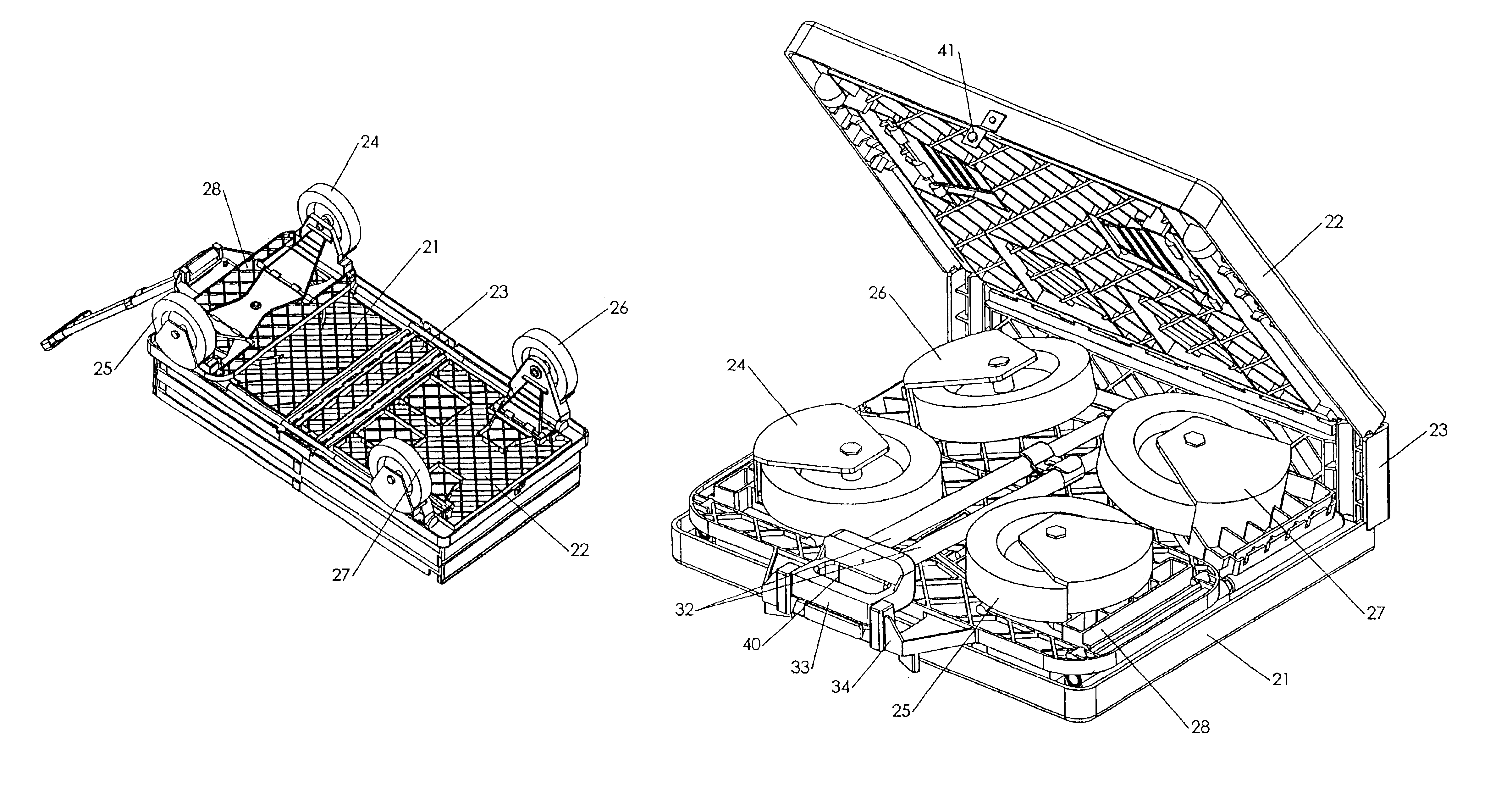

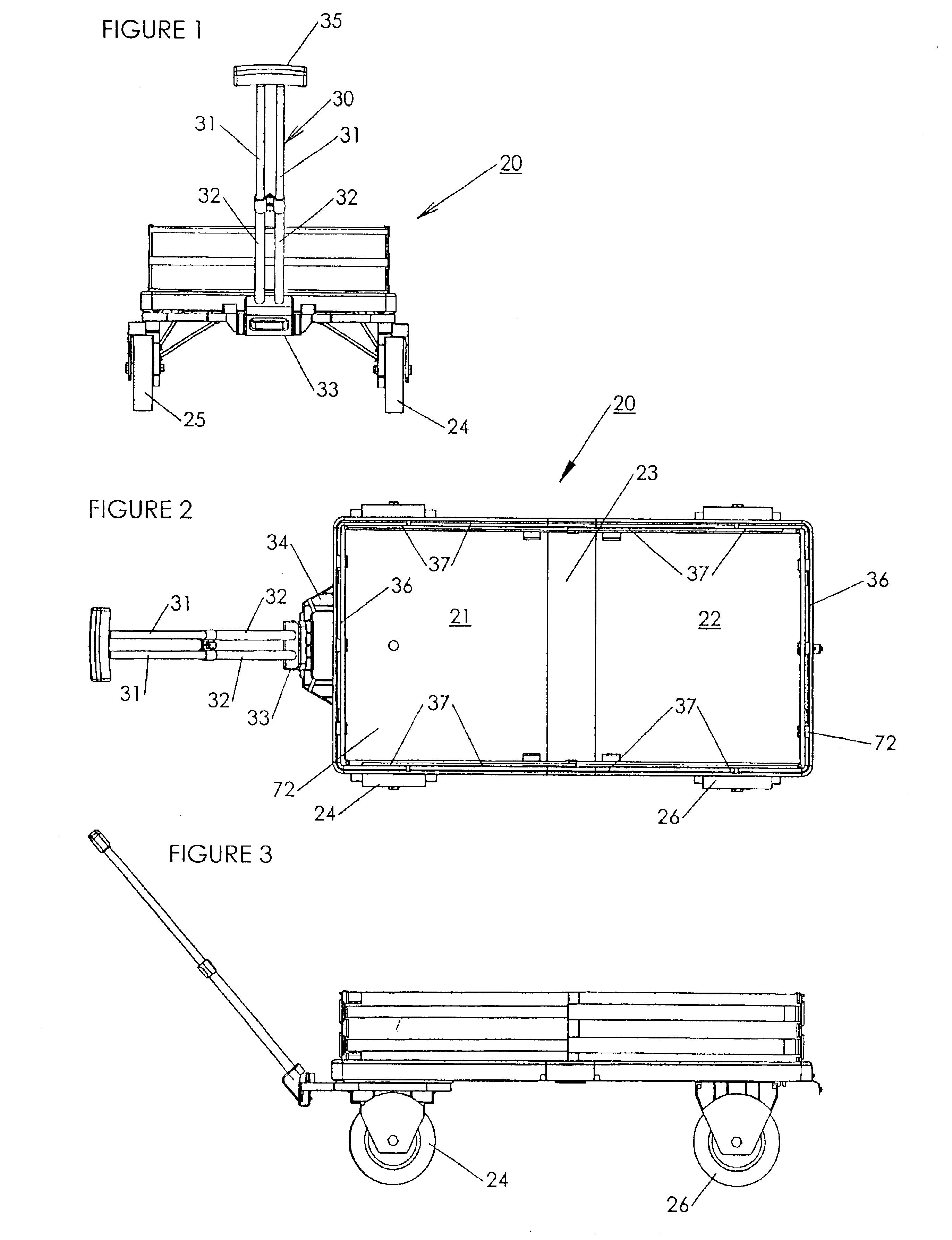

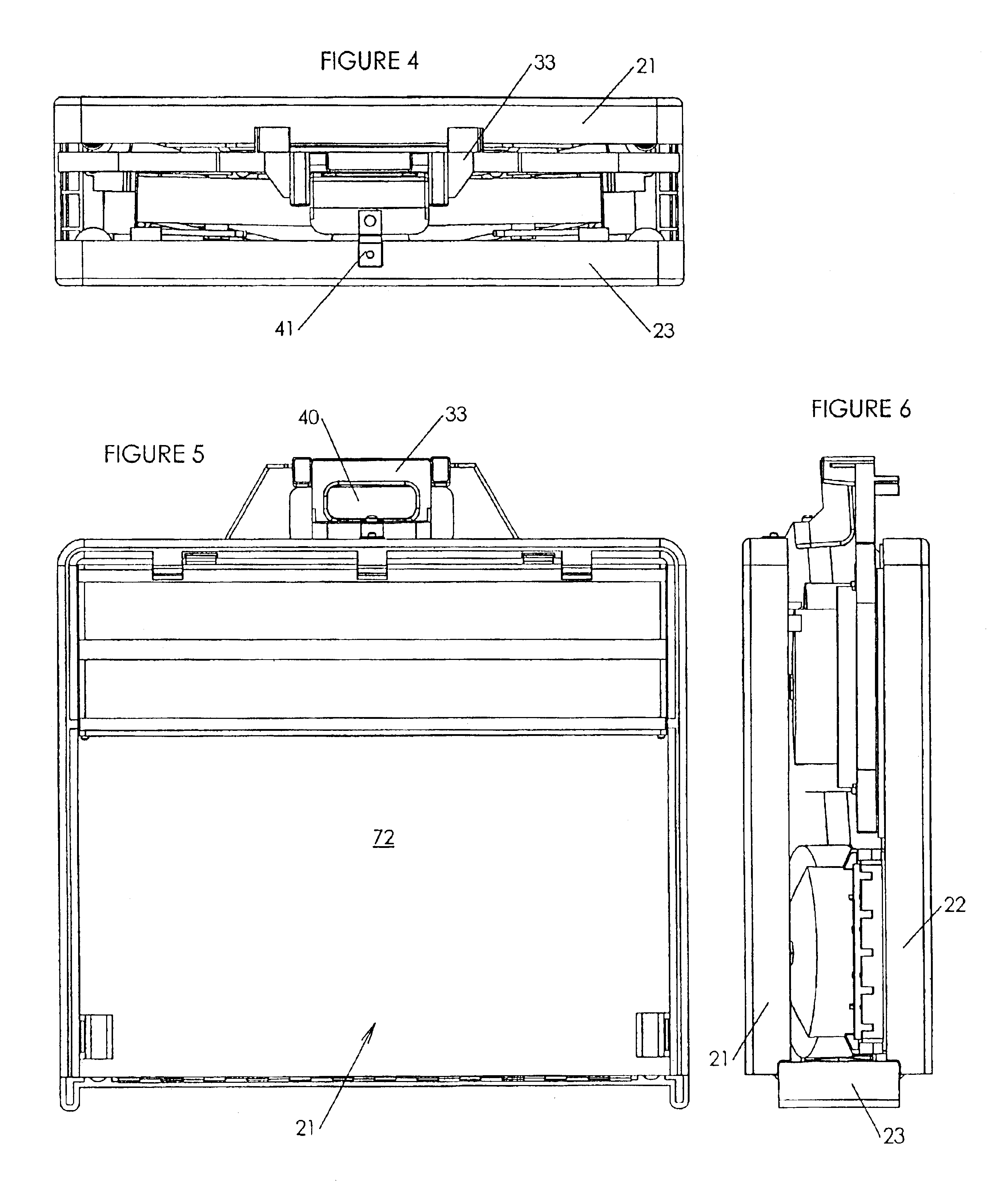

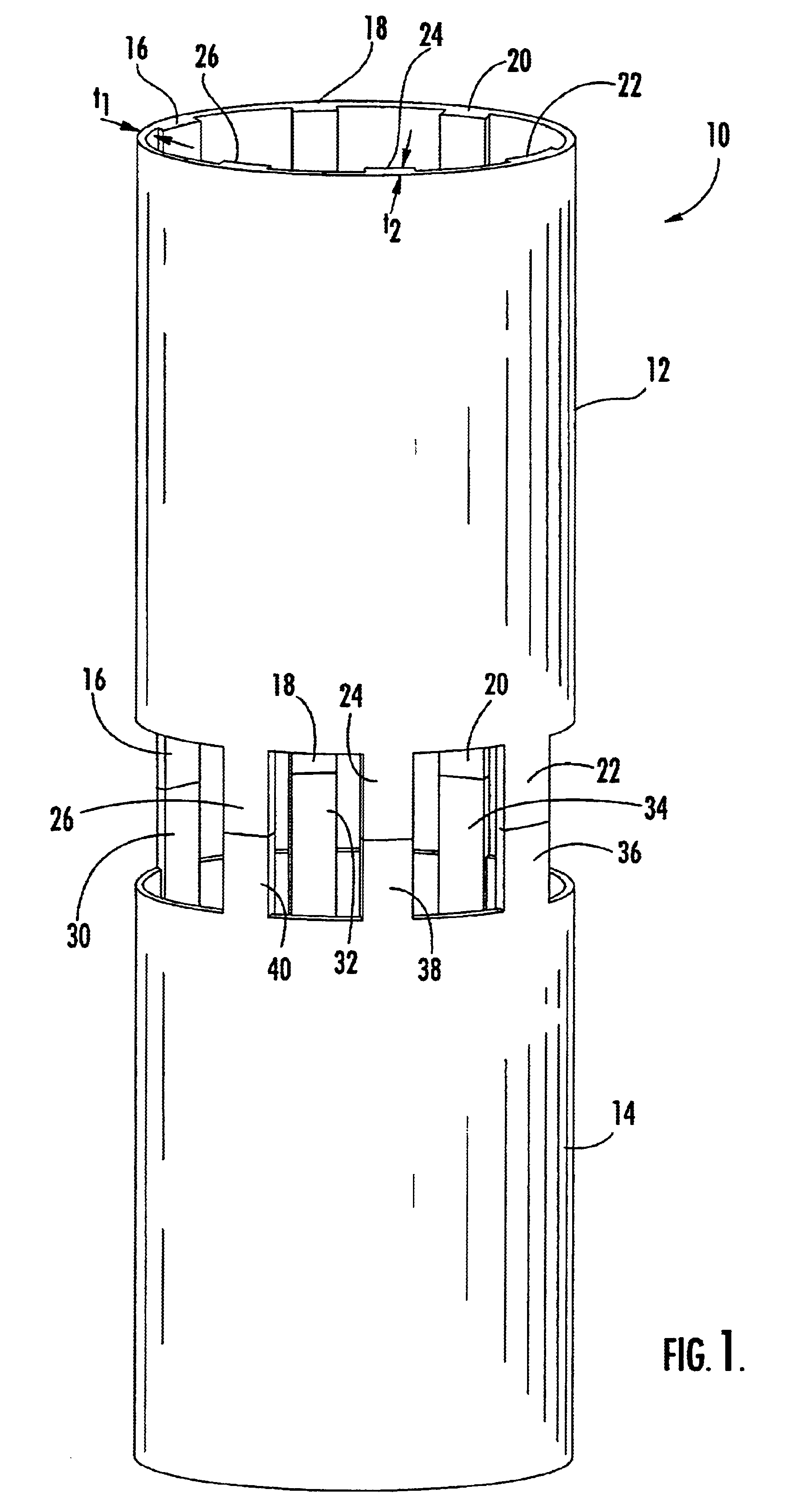

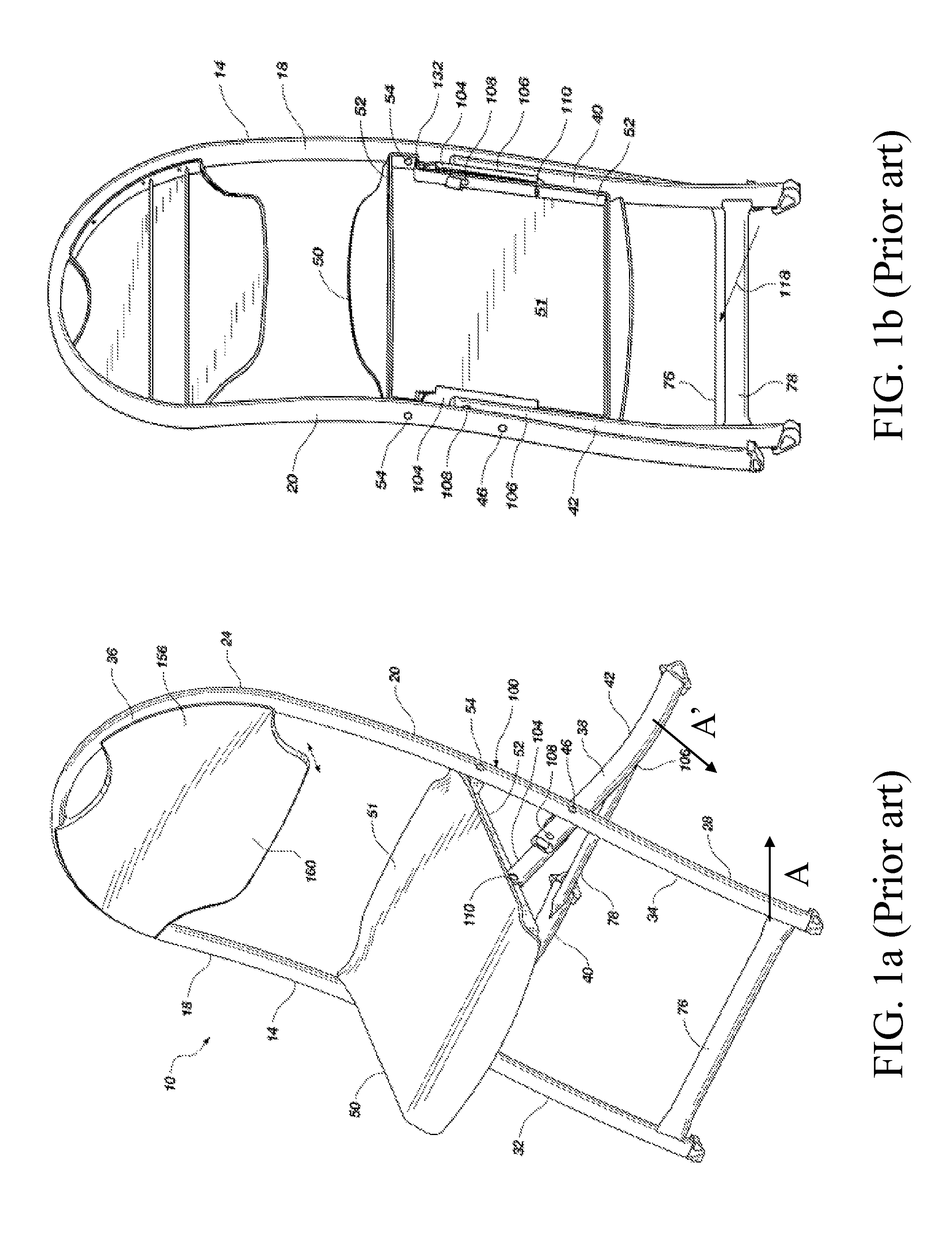

Folding wagon/cart

InactiveUS6845991B1Improve portabilityEasy to assembleCarriage/perambulator accessoriesCarriage/perambulator with multiple axesEngineeringTruck

By providing a plurality of cooperating, foldable panel members in combination with a plurality of foldable wheel assemblies, a unique wagon or cart construction is attained which is capable of being folded into a small, compact area, whenever desired, and then quickly and easily deployed into a fully erected and operational position, which enables virtually any desired object to be easily transported. In addition, in the preferred construction of this invention, an automatically deployed structural supporting member is incorporated into the wagon / cart for providing inherent strength and rigidity to the wagon / cart when fully erected. In this way, heavy objects previously incapable of being transported are capable of being accommodated with ease.

Owner:RITUCCI LOUIS N +2

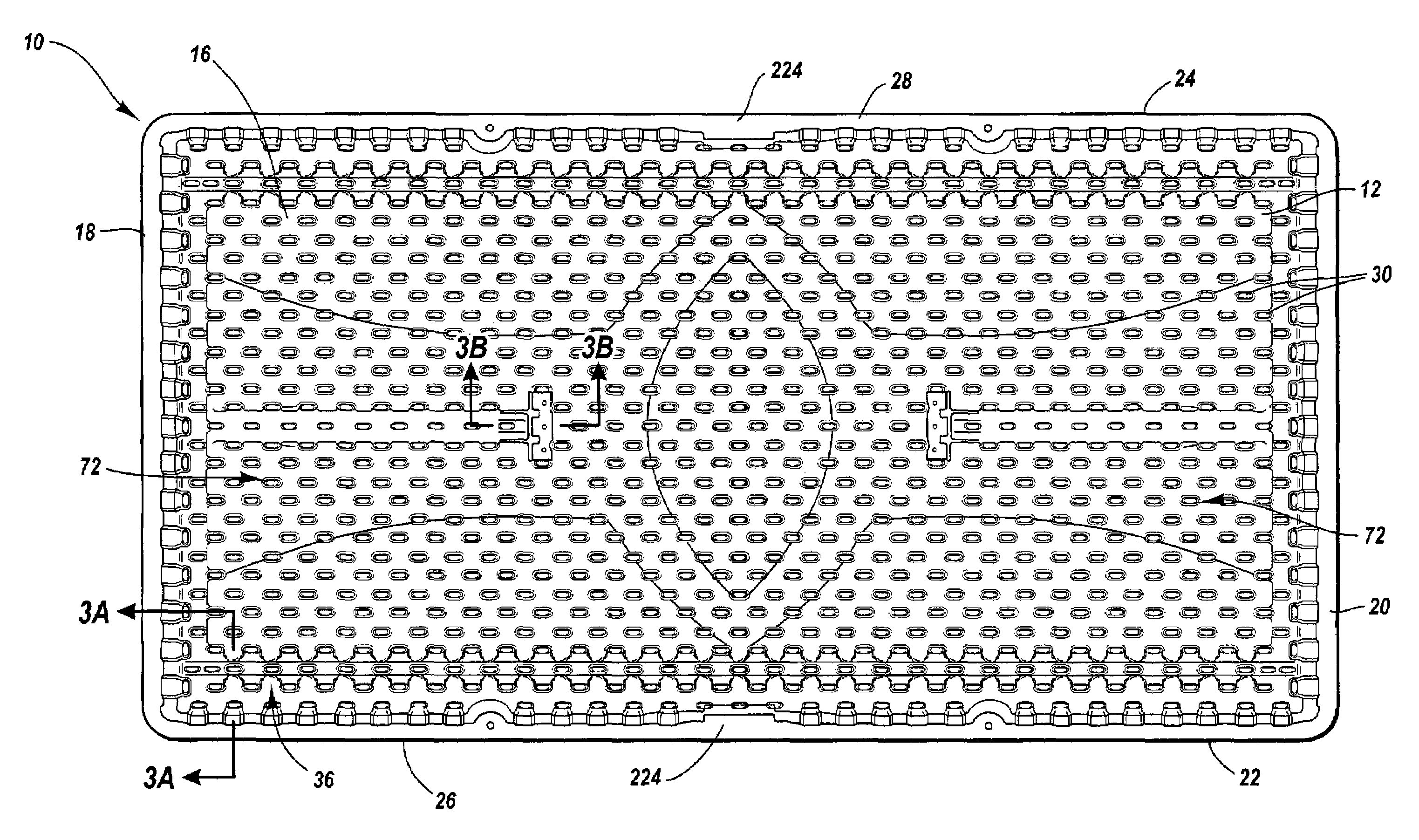

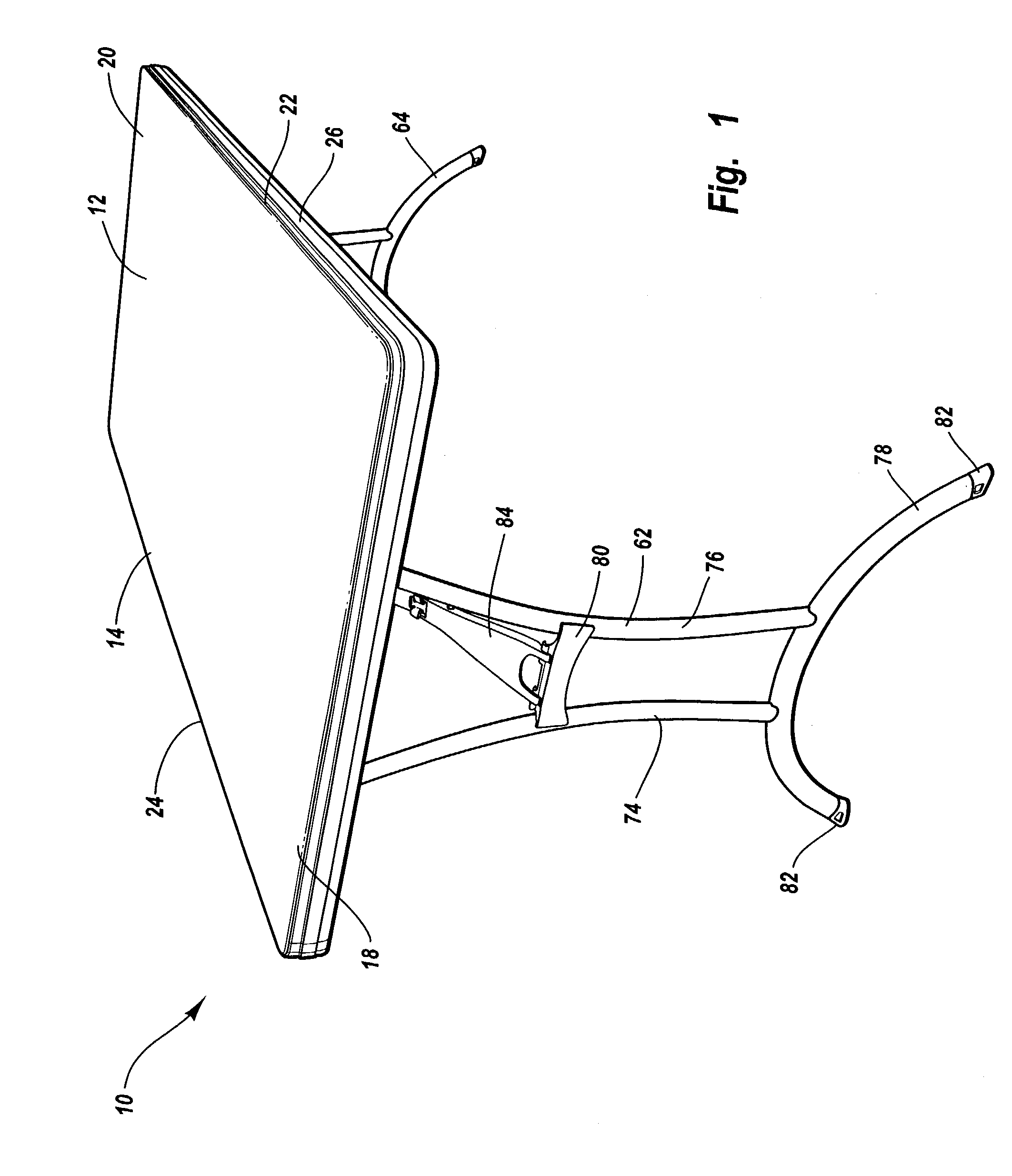

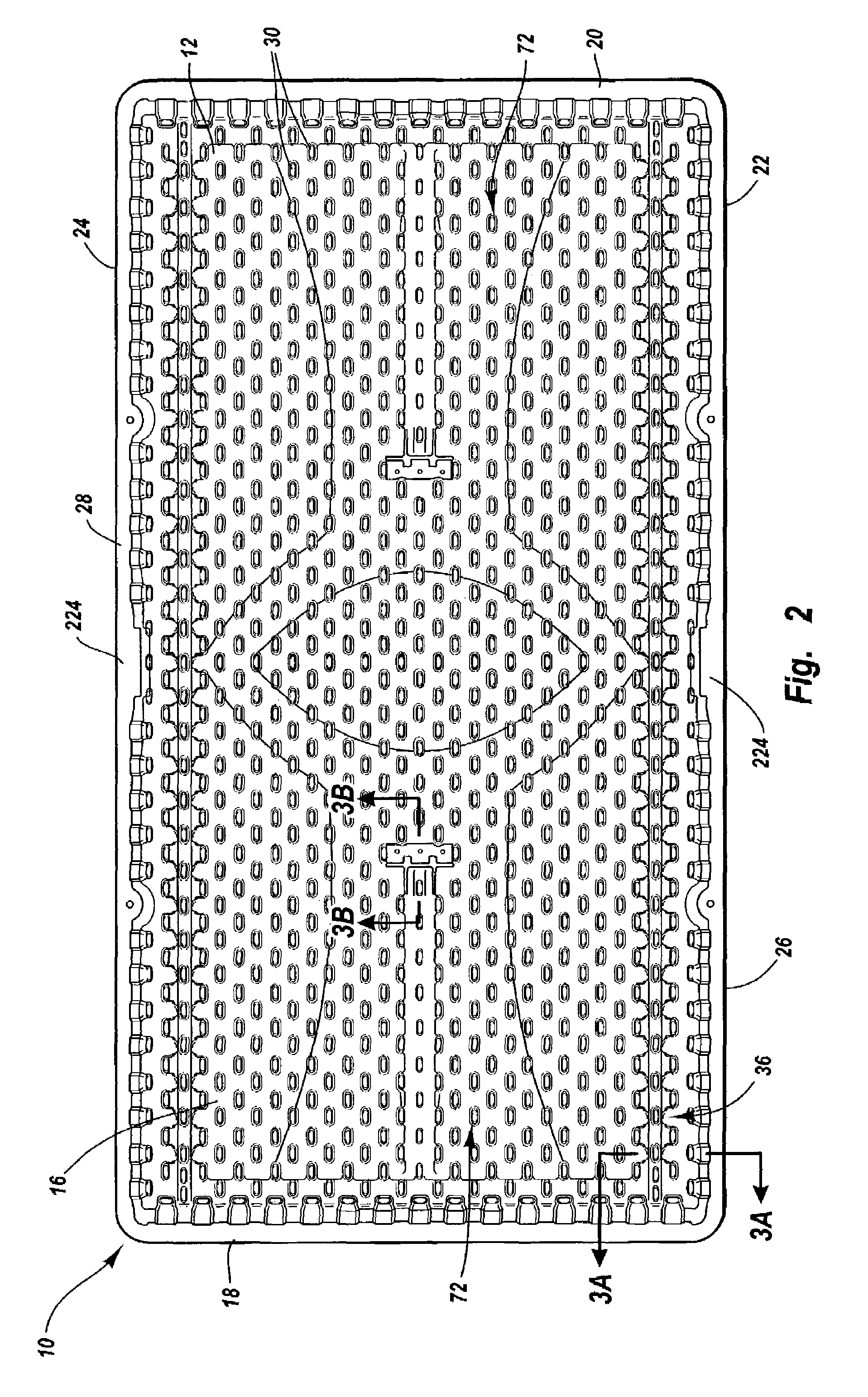

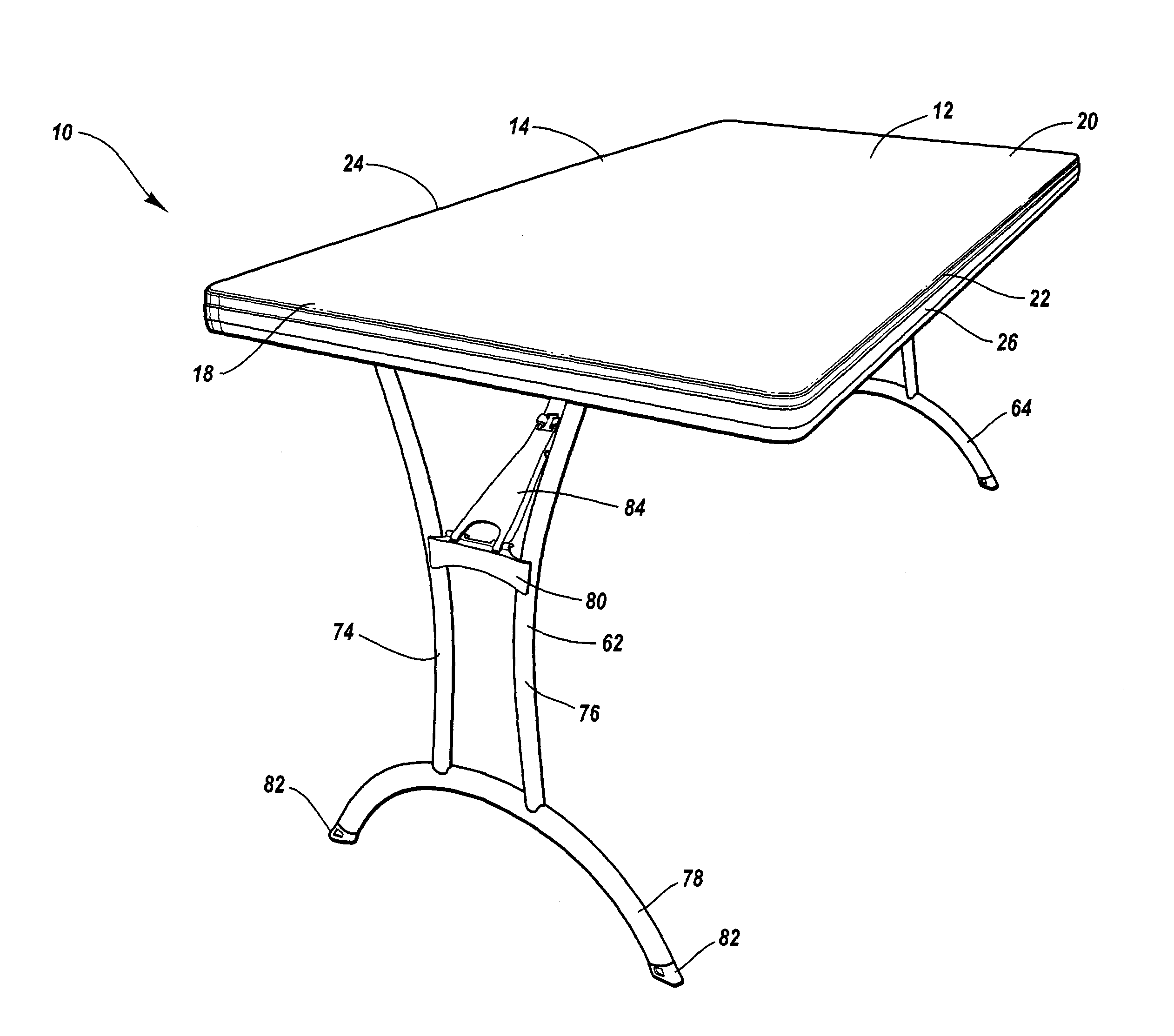

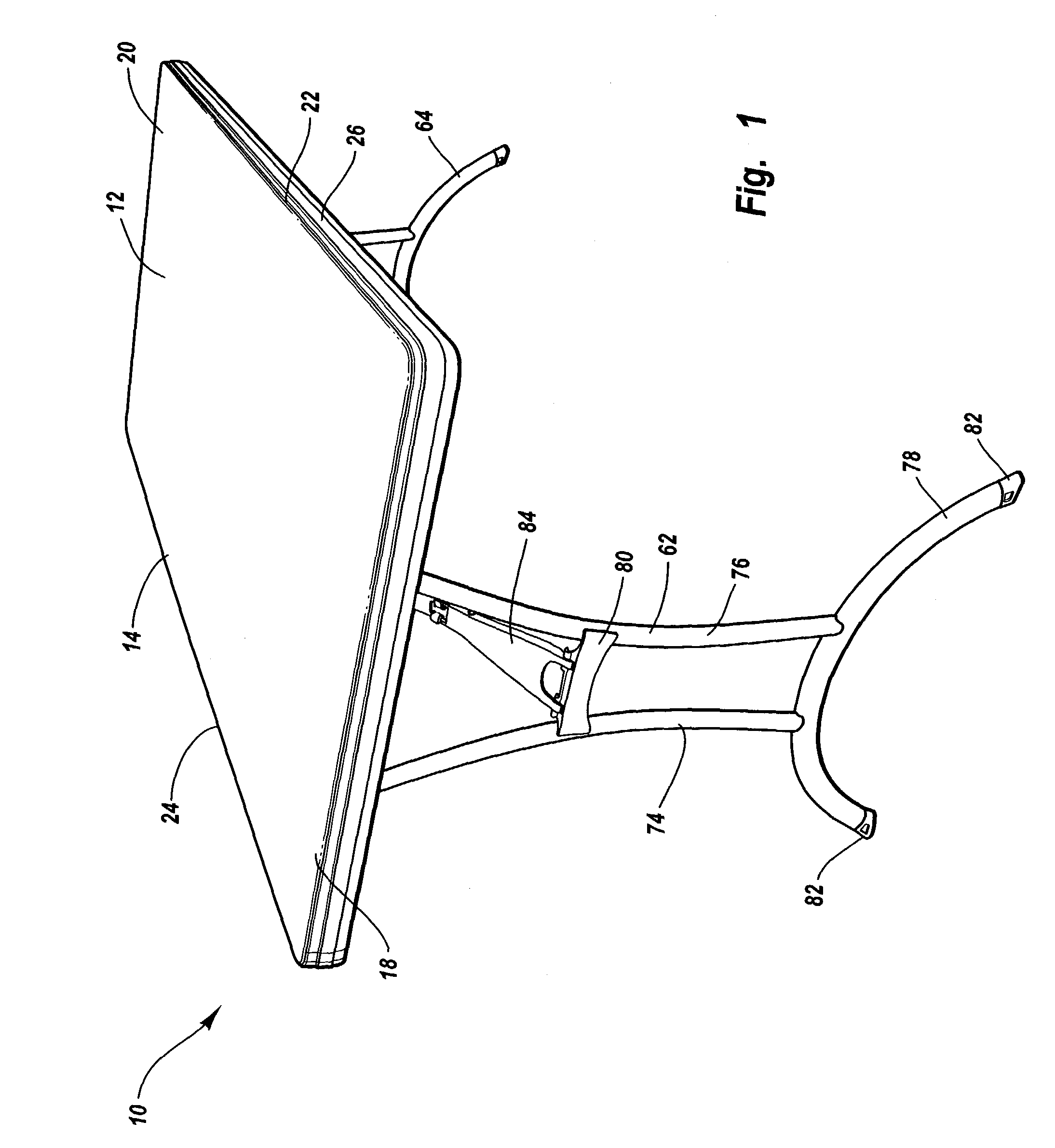

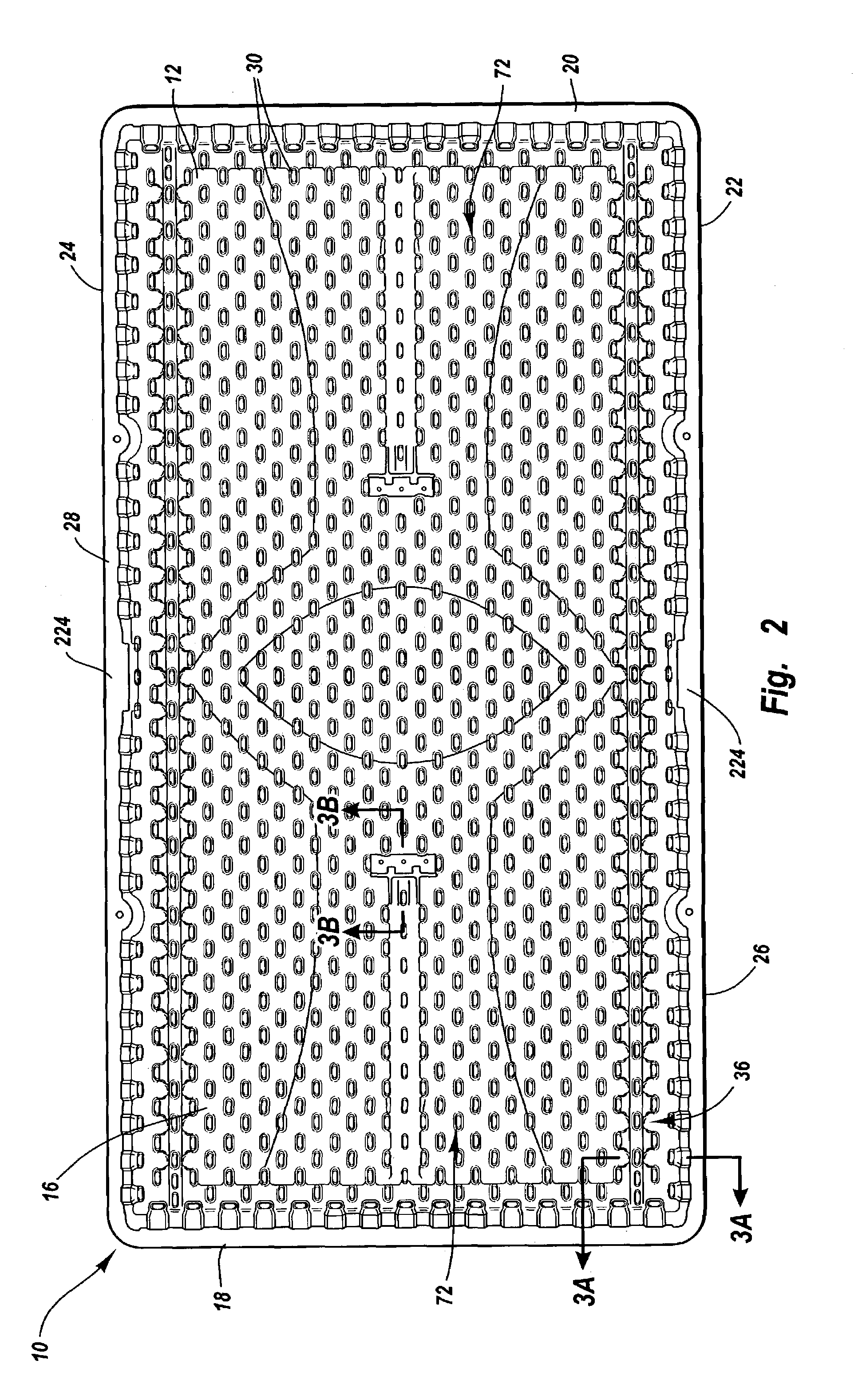

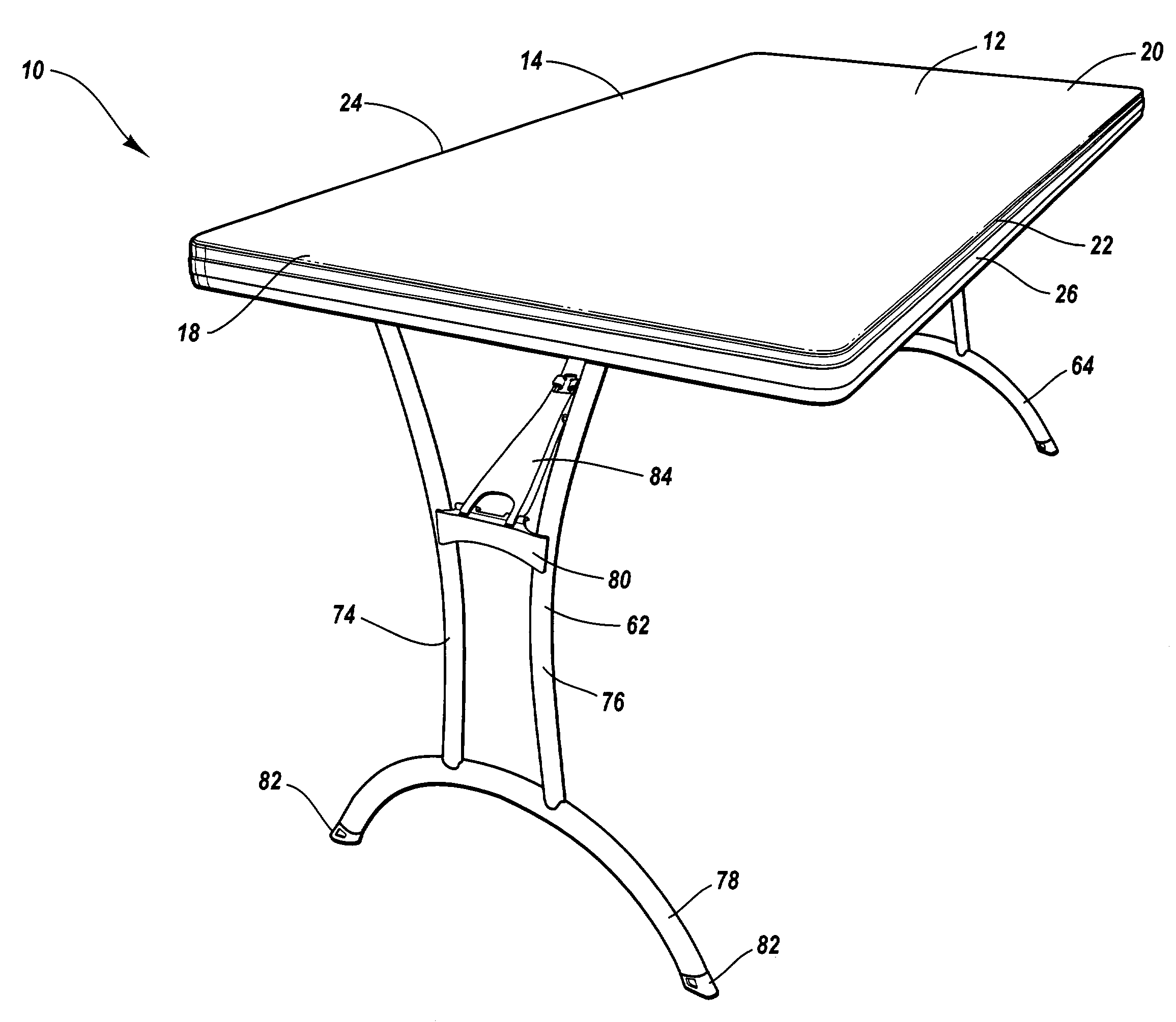

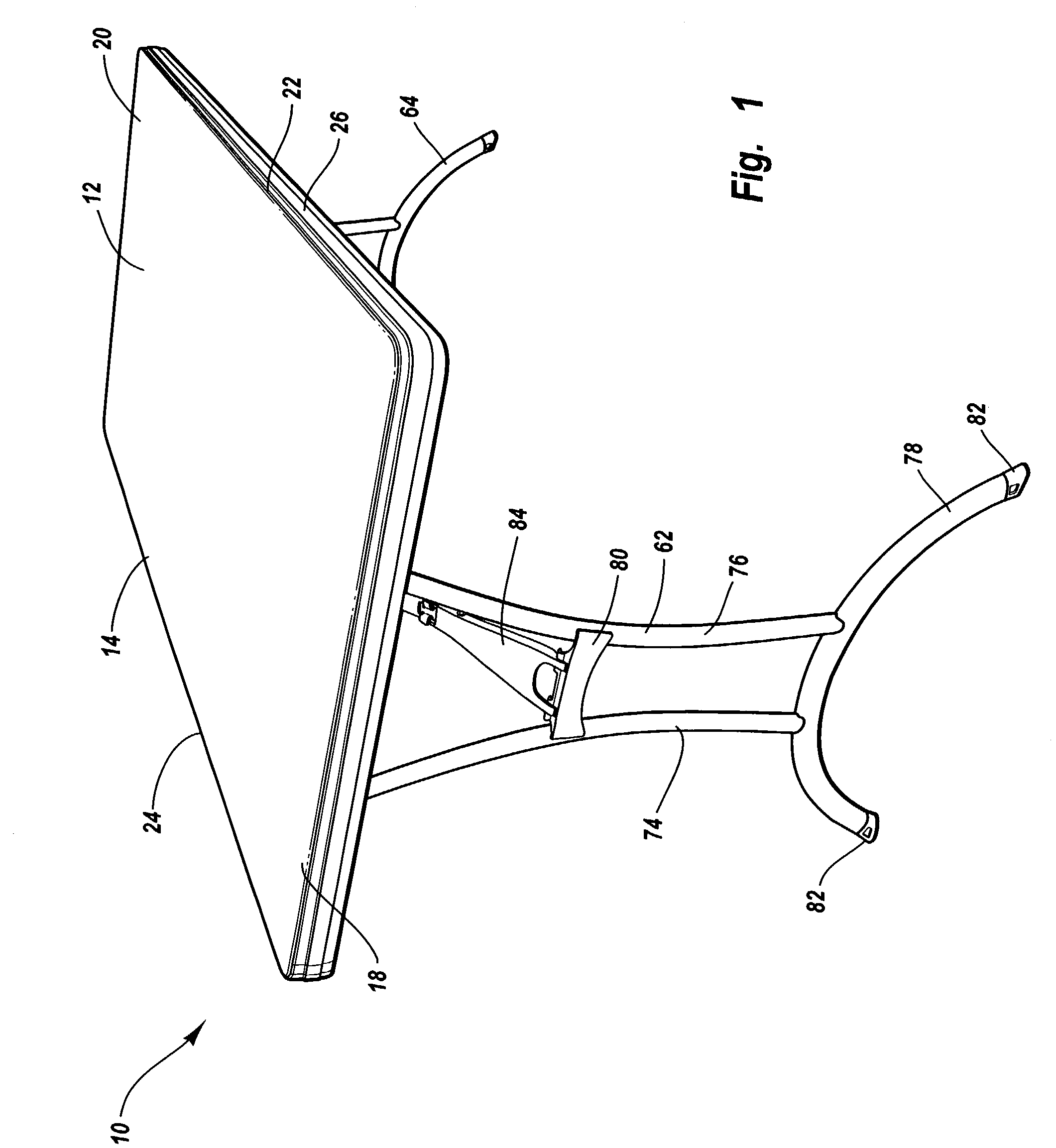

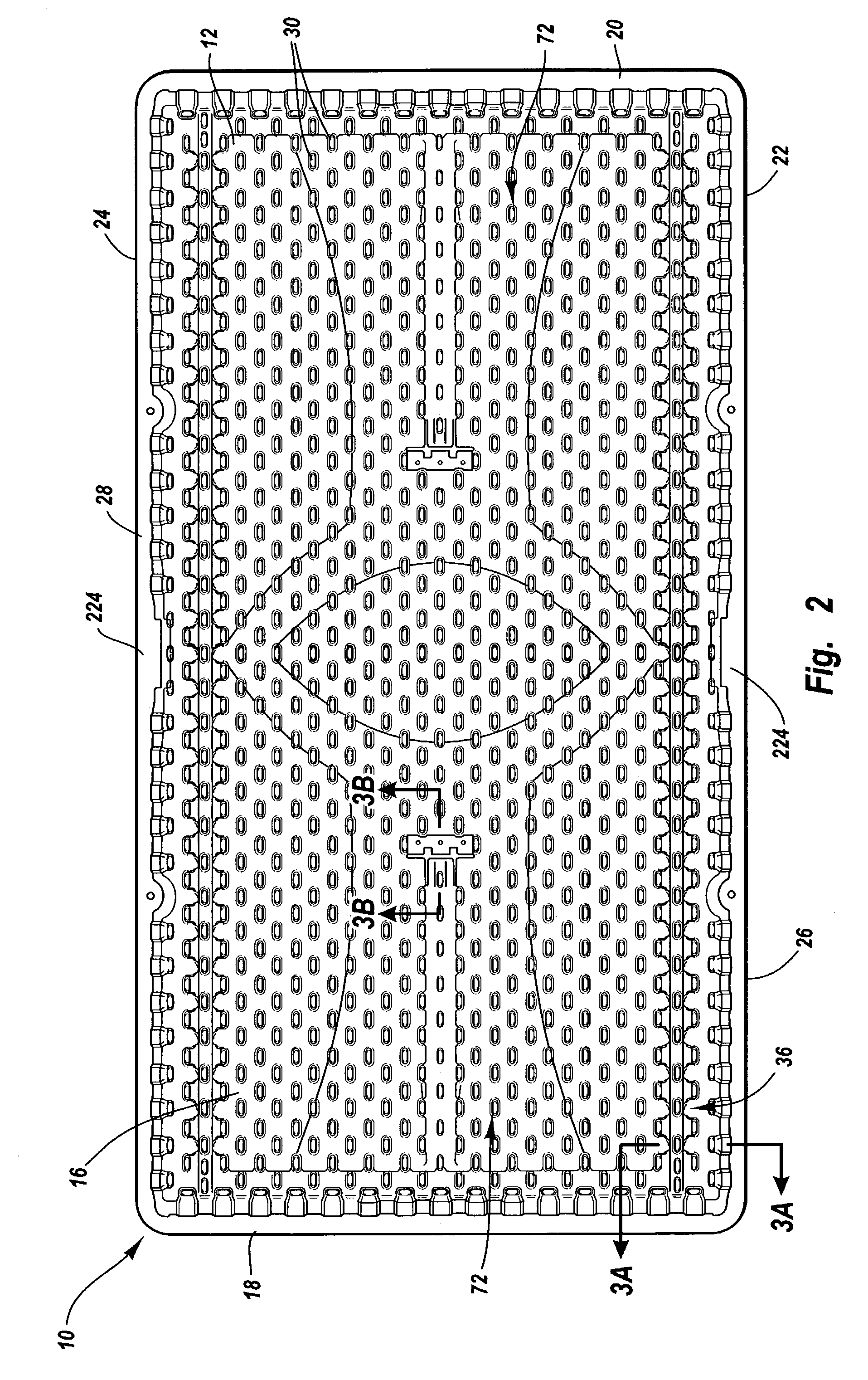

Portable folding table

A table that includes a table top with a first half which is pivotally connected to a second half. The first and second halves of the table top are movable between a first position in which the halves are generally aligned and a second position in which the halves are generally placed adjacent to each other. The first and second halves of the table top are preferably constructed from blow-molded plastic and each of the halves desirably have a generally hollow interior. The first and second halves of the table top may include interlocking portions that are interconnected when the halves are in the aligned position. Desirably, the interlocking portions have generally hollow interiors that are integrally formed with the generally hollow interiors of the halves of the table top during the blow-molding process. The table top may also include one or more overlapping portions that are interconnected when the halves of the table top are in the aligned position. The overlapping portions may also have generally hollow interiors that are integrally formed with the generally hollow interiors of the halves of the table top during the blow-molding process.

Owner:LIFETIME PRODUCTS

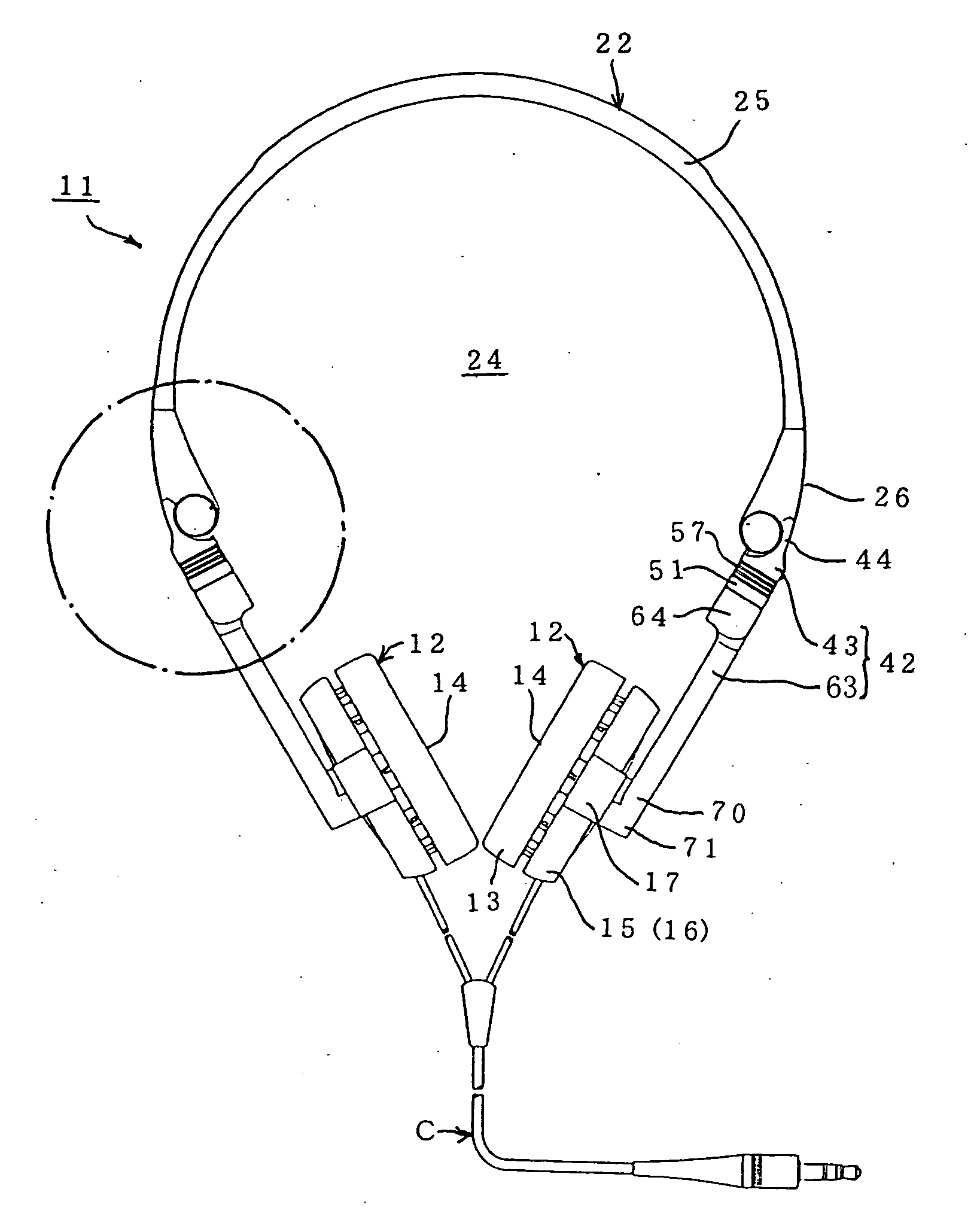

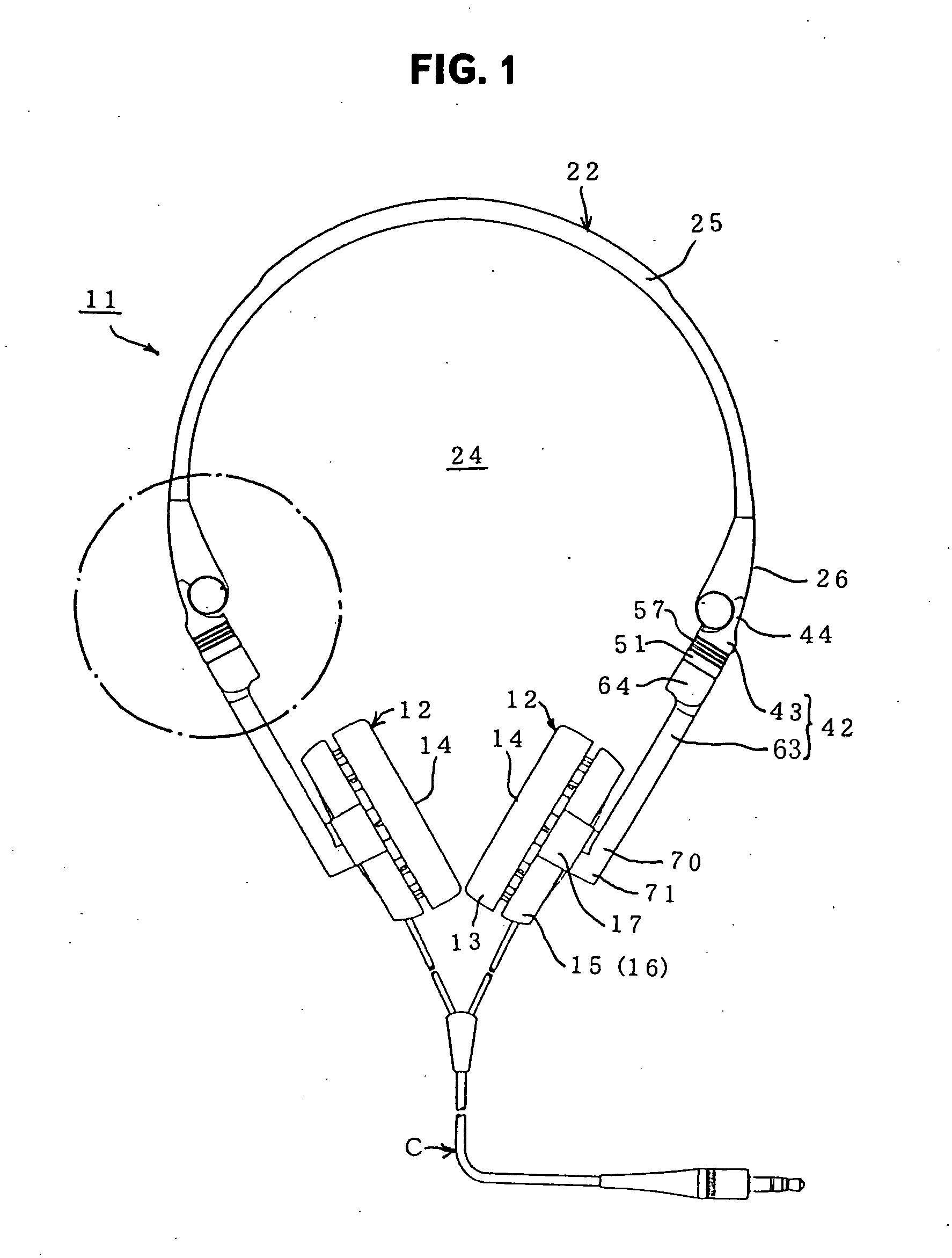

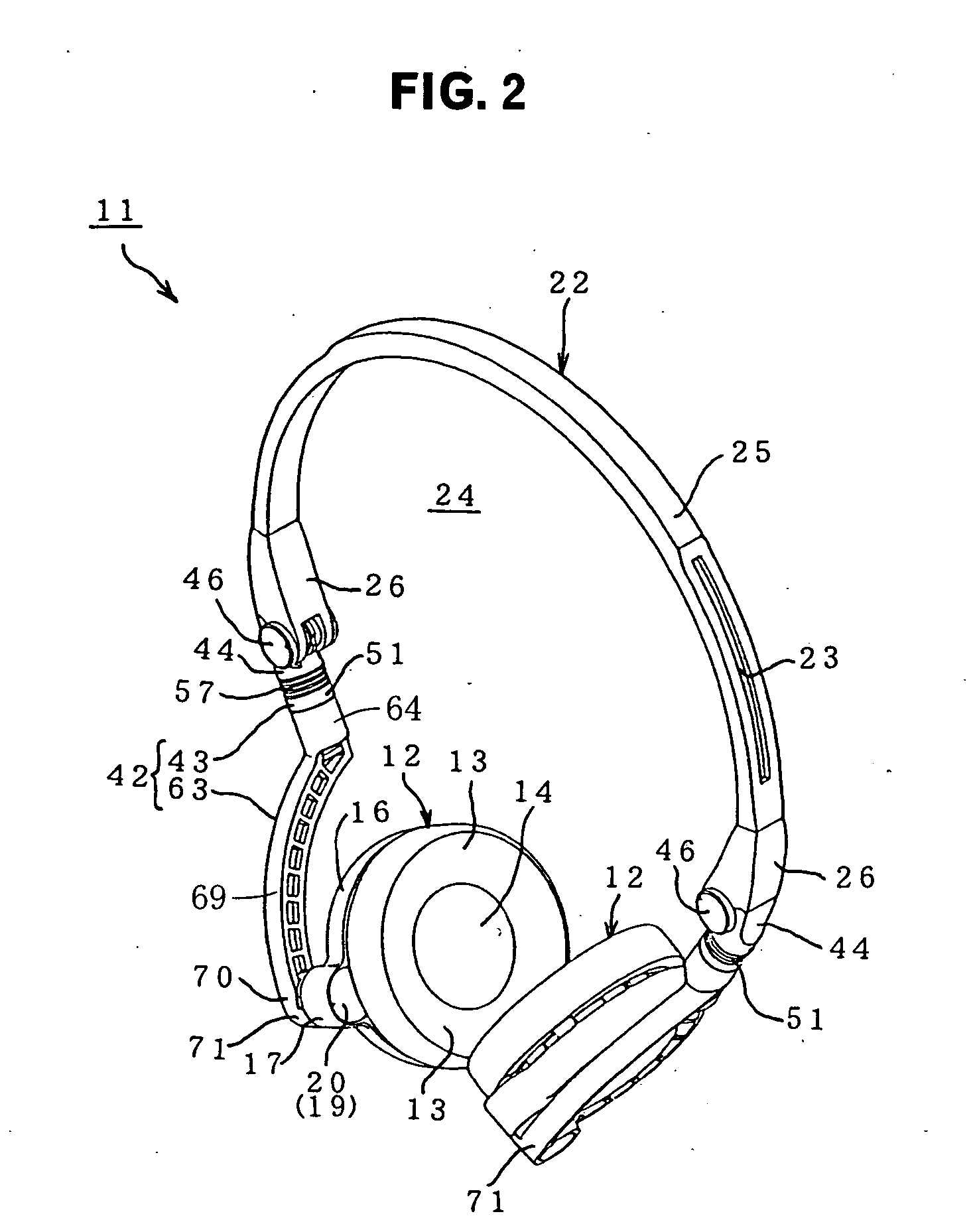

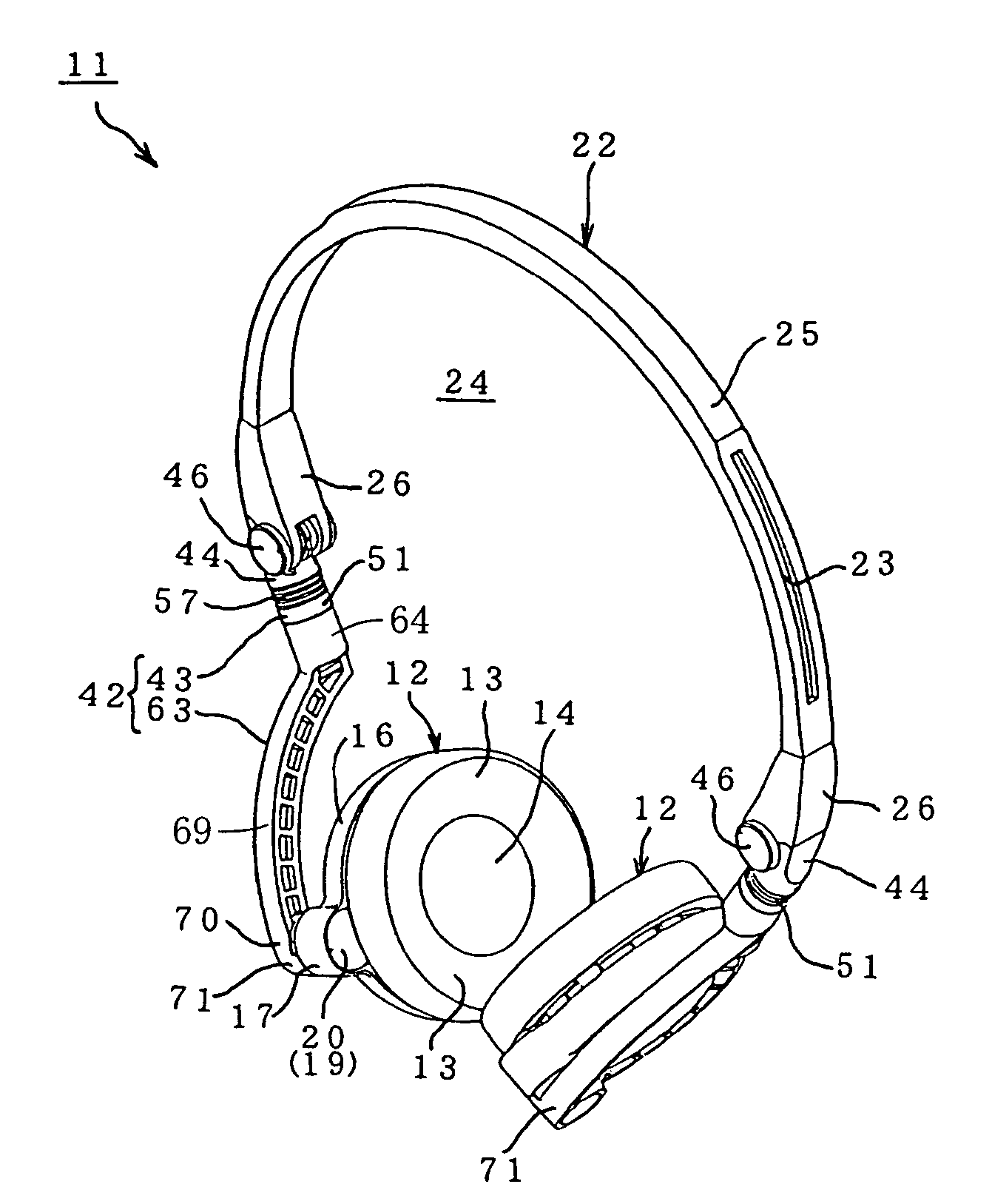

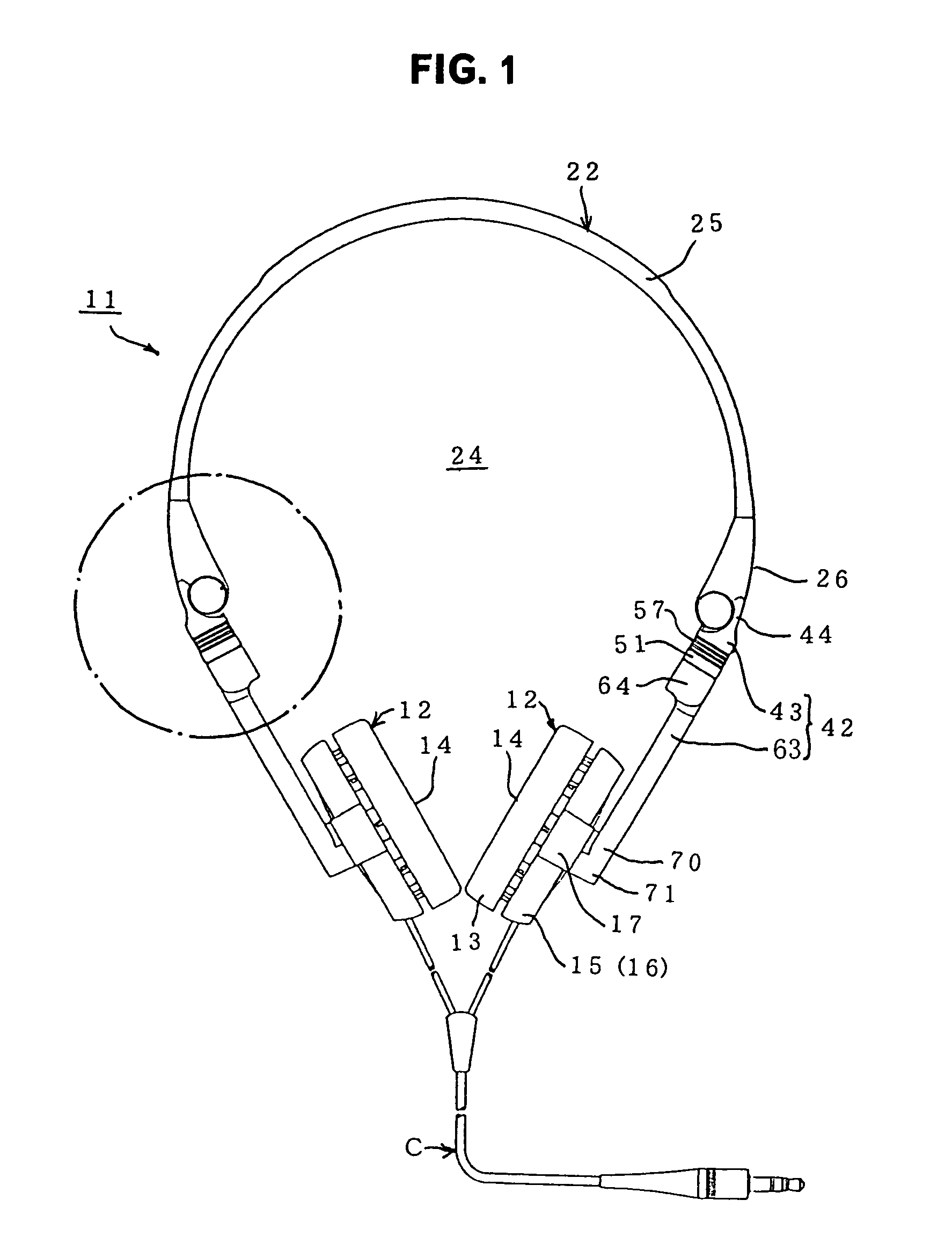

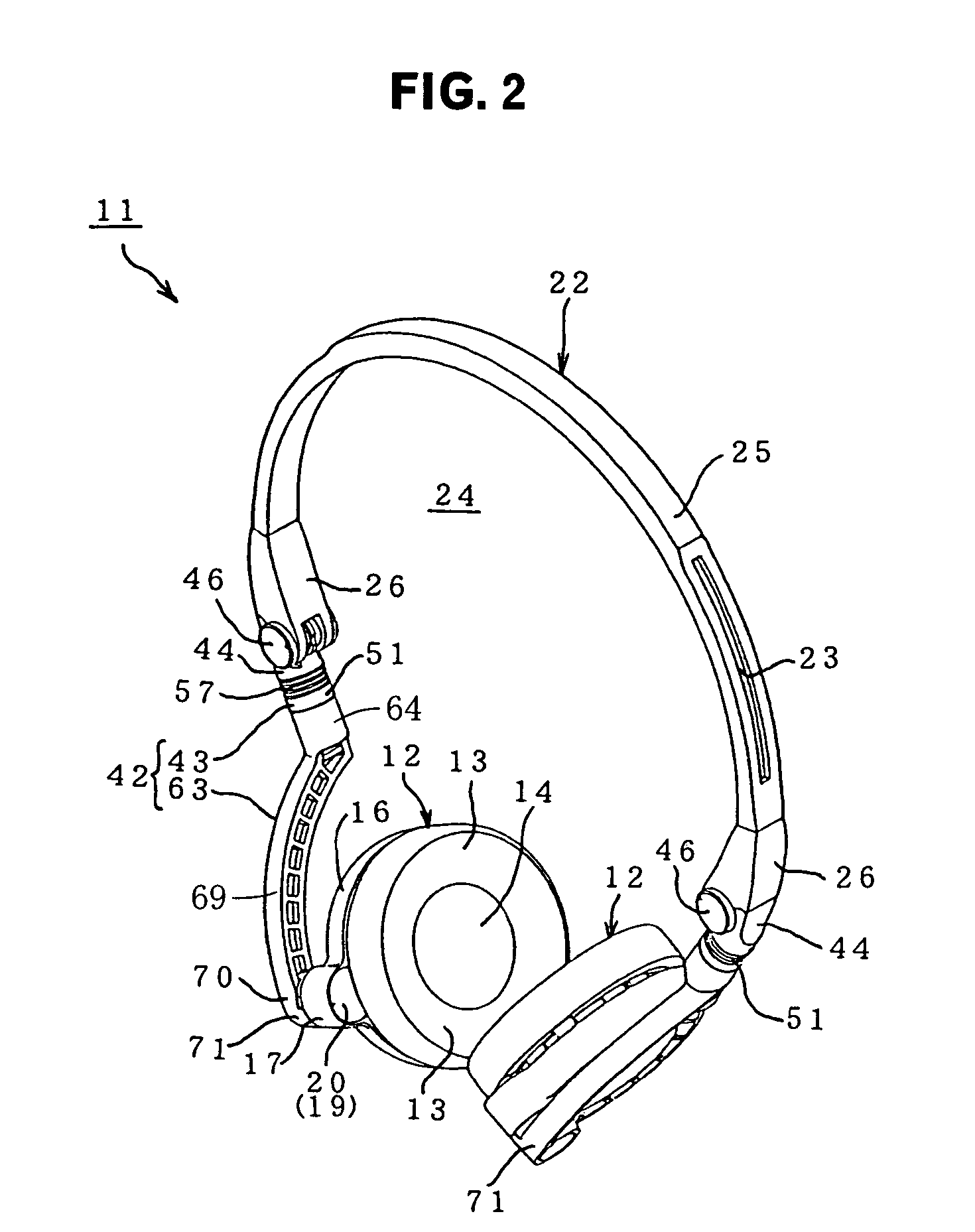

Headphone device

InactiveUS20060062417A1Easy to fixMounting property is not sacrificedDeaf-aid setsEarpiece/earphone manufacture/assemblyEngineeringHeadphones

There is provided a headphone which is handy for carrying or storing because of its compactness, and also provides a good sense of mounting. The headphone includes a pair of right and left headphone units 12 and an elastic band 22 formed substantially into a U shape, which is mounted ranging from the human head's crown to both sides of the head, and supports the headphone units 12 in end portions thereof. Between an end part of the elastic band 22 and the headphone unit 12, there is provided a multiaxial arm joint 42 including a first arm 43 one end of which is connected turnably to the end part of the elastic band 22 and a second arm 63 one end of which is connected turnably to the other end of the first arm 43 and the other end of which is connected turnably to the headphone unit 12. By tuning the connecting portions of the multiaxial arm joint 42 the headphone units 12 are housed within an internal space 24 encircled by the elastic band 22.

Owner:AUDIO-TECHNICA

Compact foldable headphone

InactiveUS7580539B2Mounting property is not sacrificedEasy constructionDeaf-aid setsEarpiece/earphone manufacture/assemblyEngineeringHeadphones

Owner:AUDIO-TECHNICA

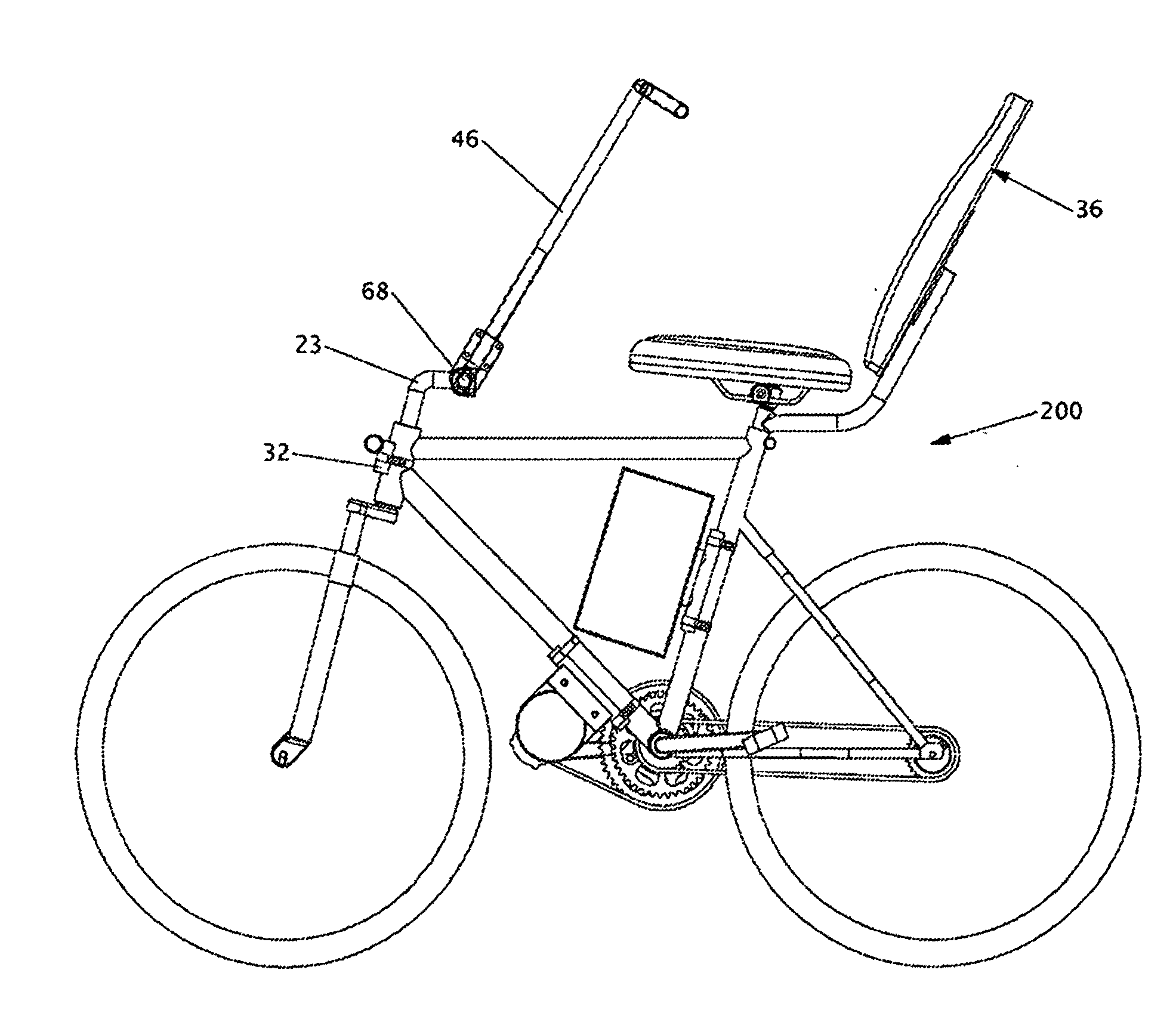

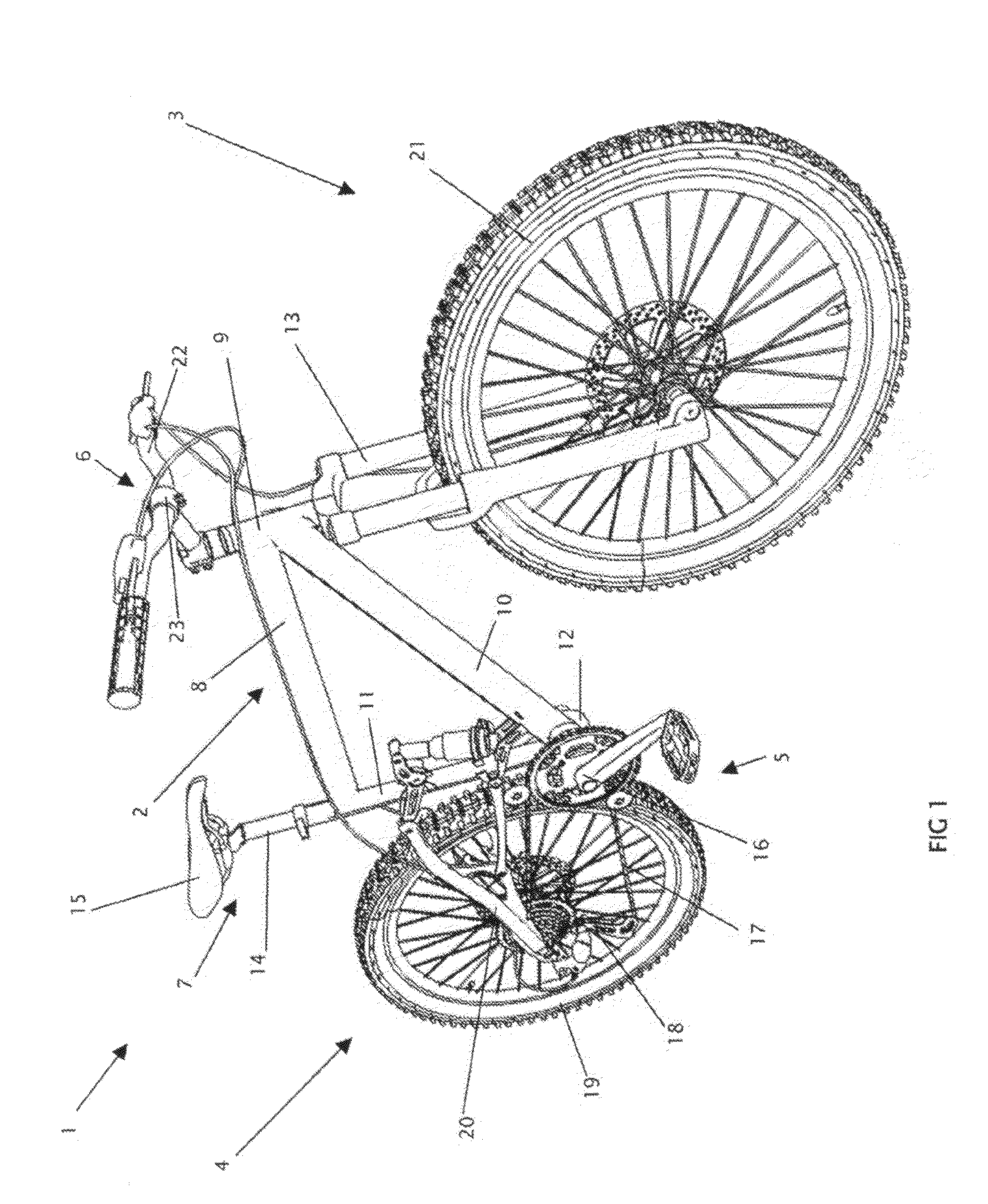

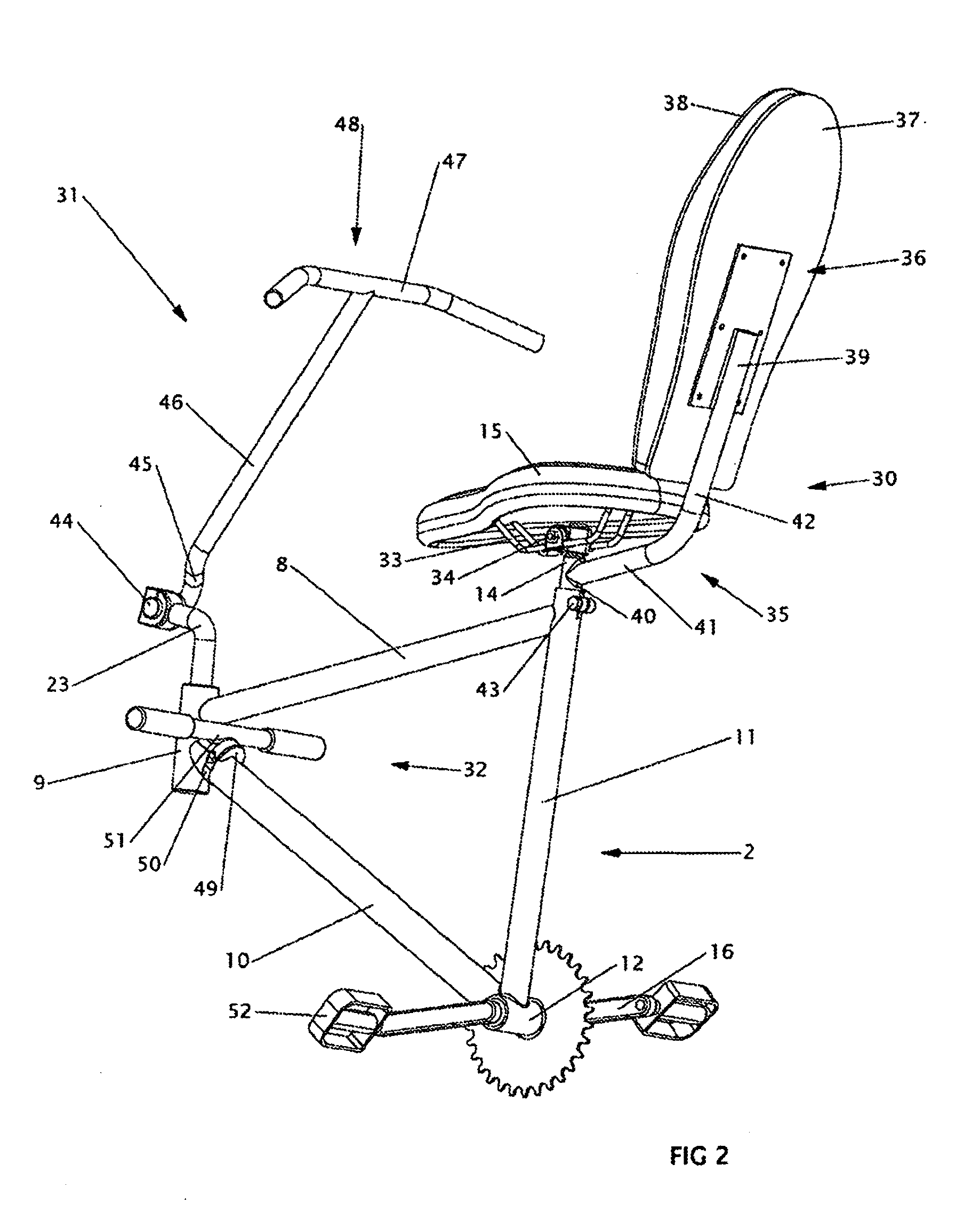

Dual-posture electric assist bicycle

InactiveUS20100206652A1Significant to useEfficient aerodynamicsWeather guardsFoot-restsRecumbent PositionVehicle frame

A dual-posture Electric Assist Bicycle (EAB) permits a rider to assume a rider-upright position while peddling or a rider-recumbent position while coasting with the electric assist propulsion system engaged. The rider can alternate between positions safely and while in motion. The dual-posture EAB comprises: a seat assembly, a footrest assembly and an extended handlebar assembly. The EAB's seat assembly includes an inclined backrest that is typically affixed to the EAB's seat post. Left and right footrests are affixed near the EAB's headtube. The extended handlebar typically includes means for quickly repositioning the controls while under way to optimize ergonomics for whichever seating posture is being used. In another example of the invention the frame of the bicycle is foldable into a dolly configuration for easy moving and storage. In yet another example of the invention the seat assembly, extended handlebar assembly, footrest assembly and an electric assist propulsion system are provided in kit form for converting a standard peddle bicycle into a dual-posture EAB. In still another example of the invention a trailer is provided with the EAB for towing additional batteries.

Owner:KIELLAND PETER

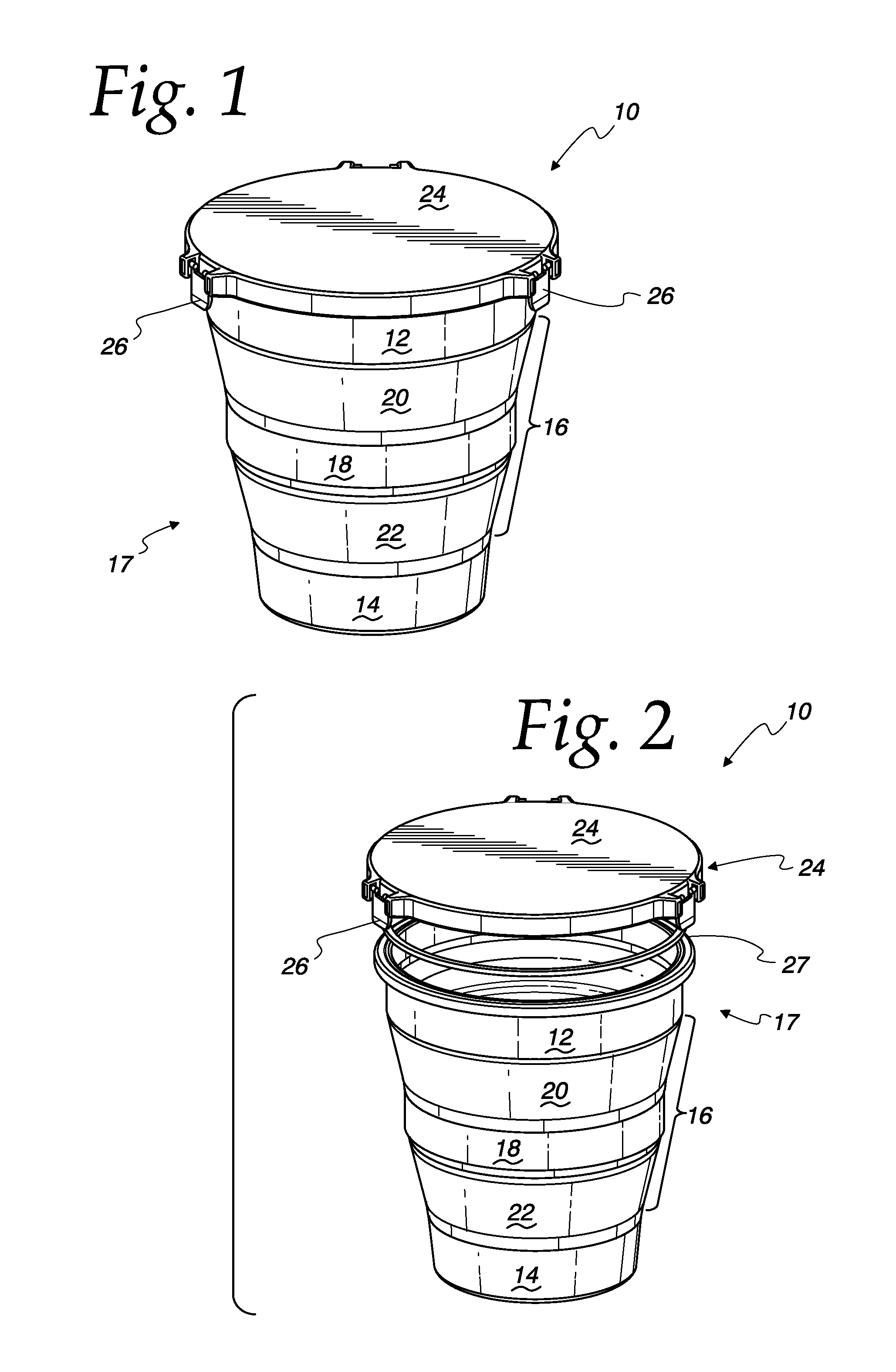

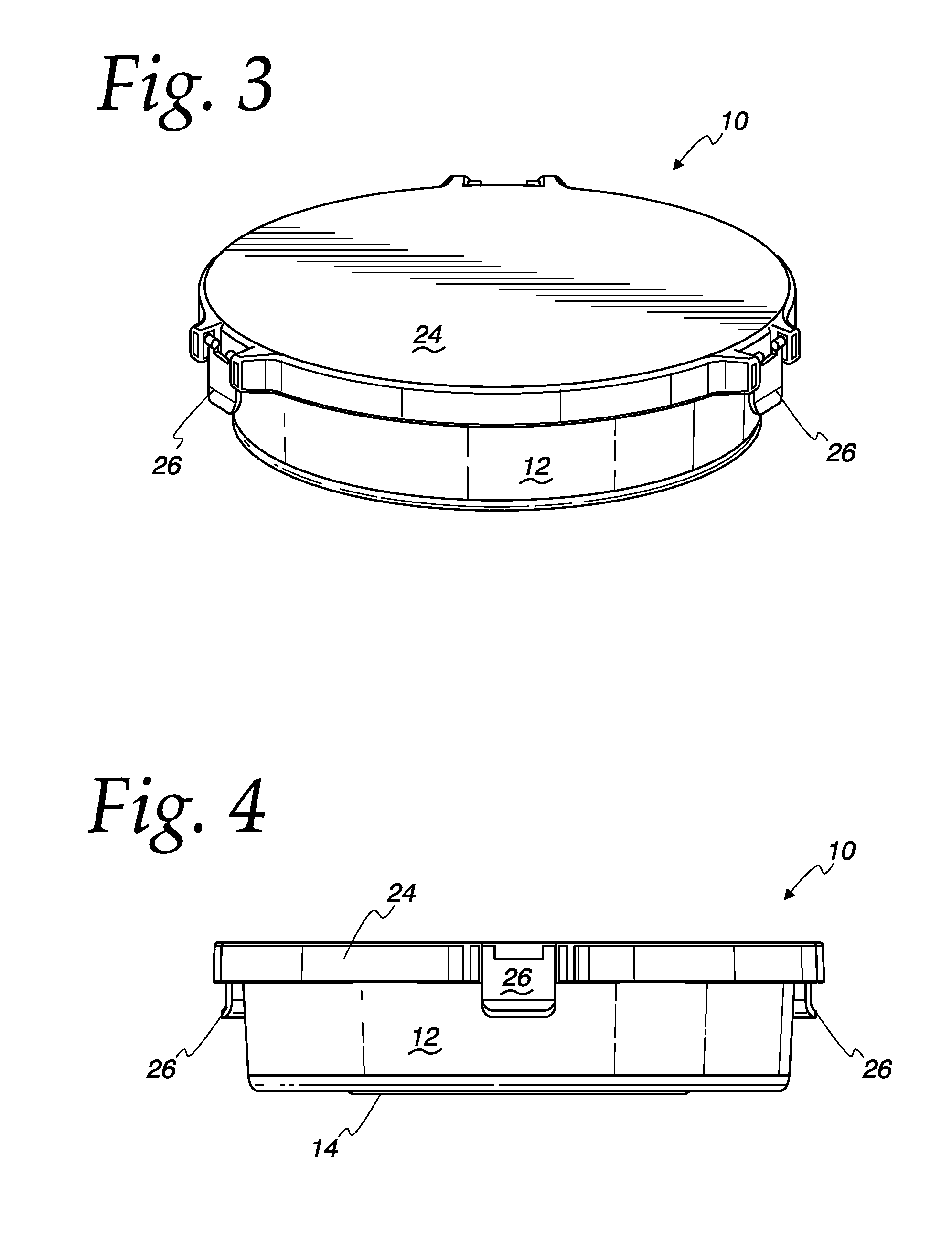

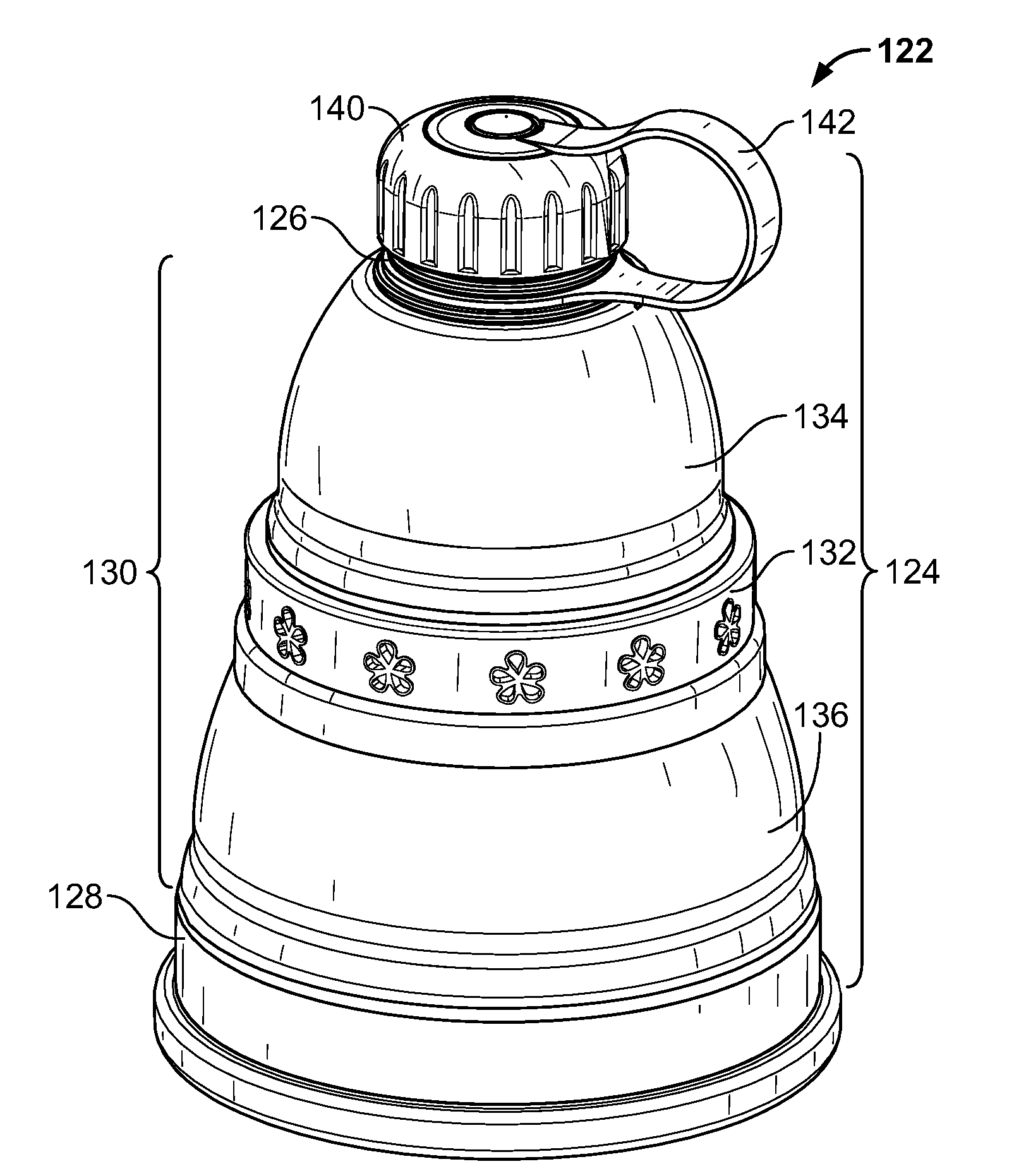

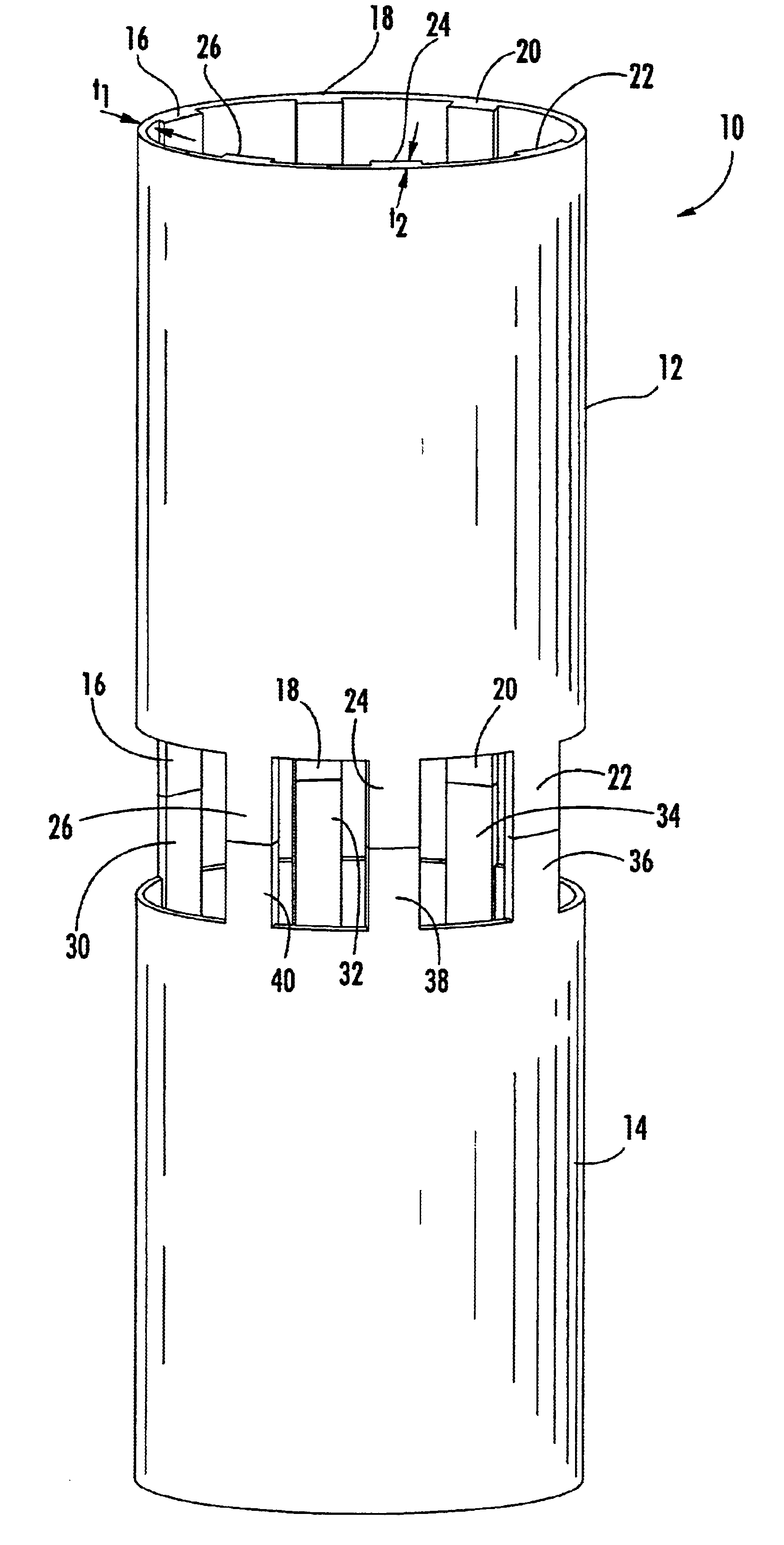

Collapsible Multi-Purpose Containers

ActiveUS20150253055A1Increase in sizeSmall sizeLighting and heating apparatusRemovable lids/coversEngineeringMechanical engineering

Owner:TSUI SAM TUNG

Pivotal connection of a table leg to a frame

Owner:LIFETIME PRODUCTS

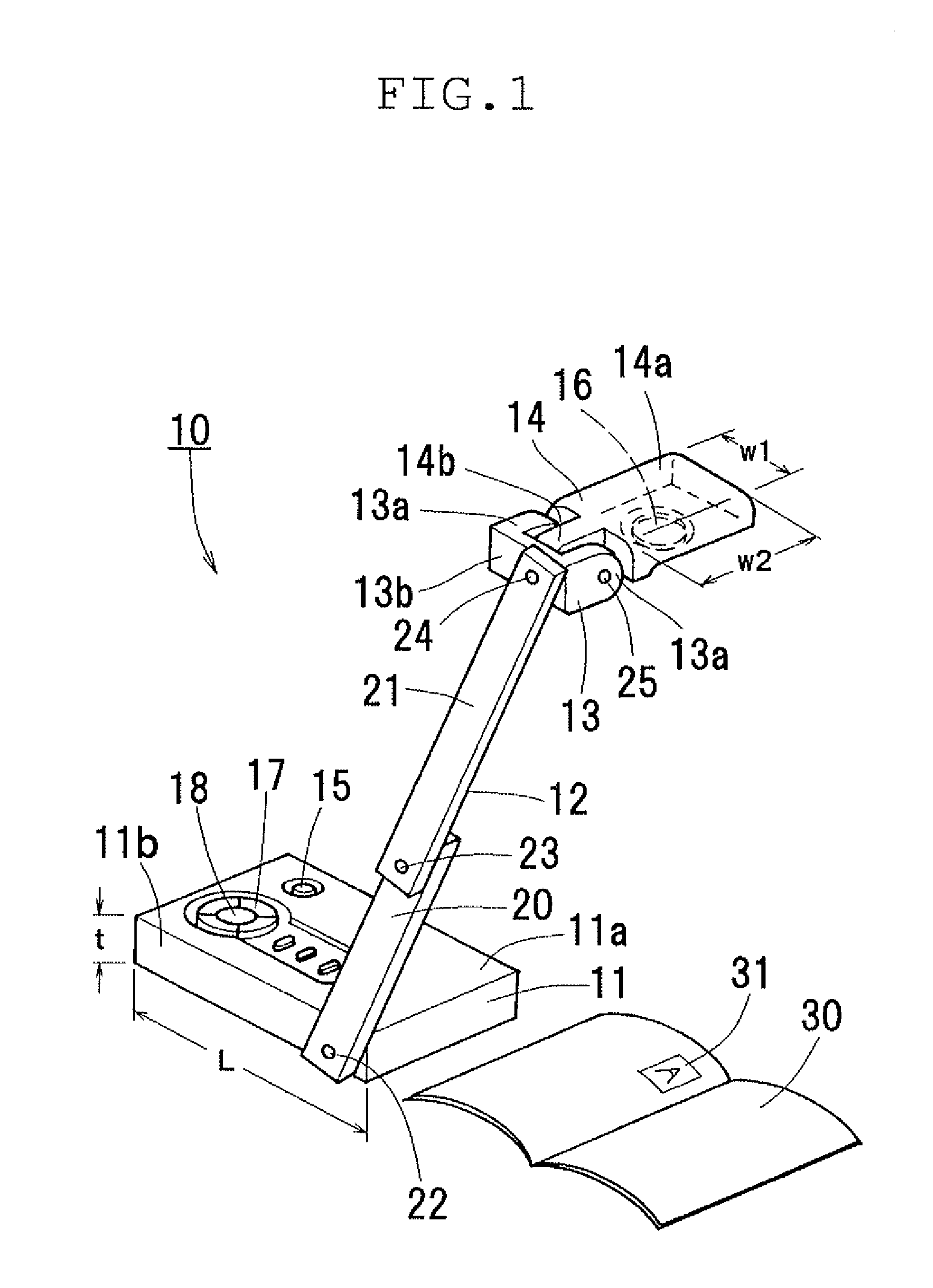

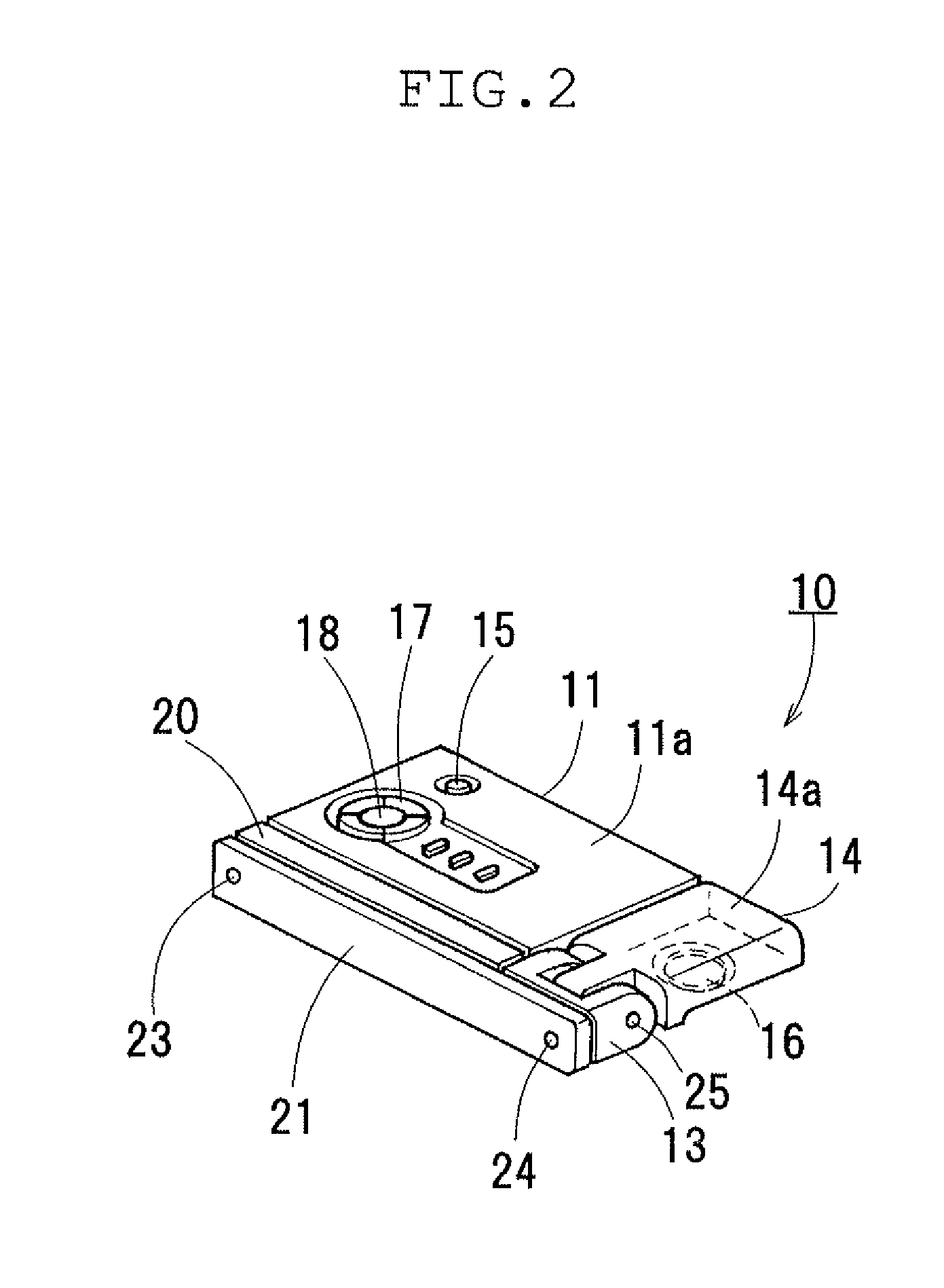

Visual presenter

A visual presenter includes a base, a support column mounted on the base and a video camera head mounted on a distal end of the support column. The support column includes a first support column and a second support column. The first support column is mounted on a right or left corner of a front of the base so as to be pivotable in a right-left direction relative to the base. The second support column is mounted on a distal end of the first support column so as to be pivotable in the right-left direction relative to the base. The video camera head is mounted on the distal end of the second support column so as to be pivotable in the right-left direction.

Owner:ELMO CO LTD

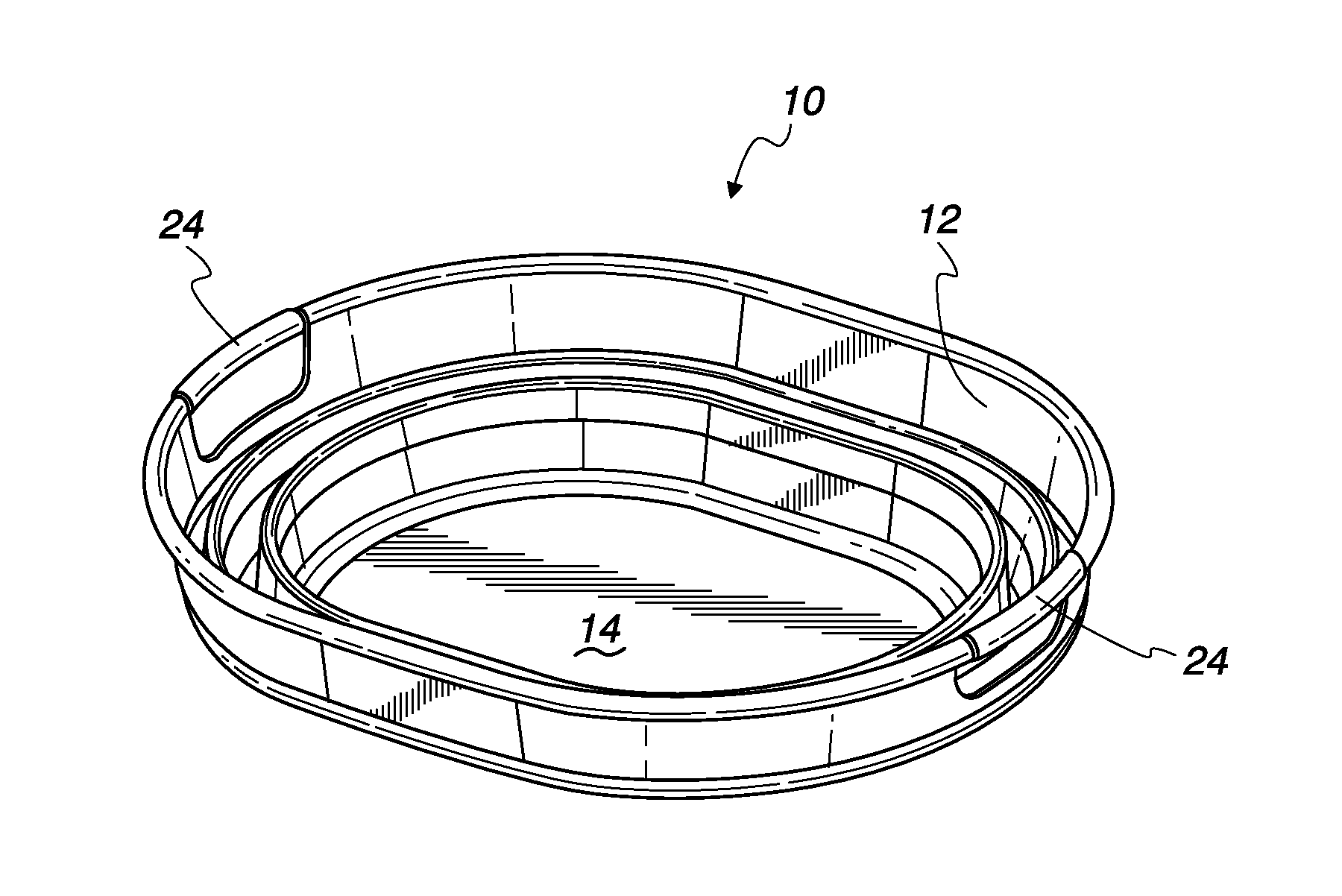

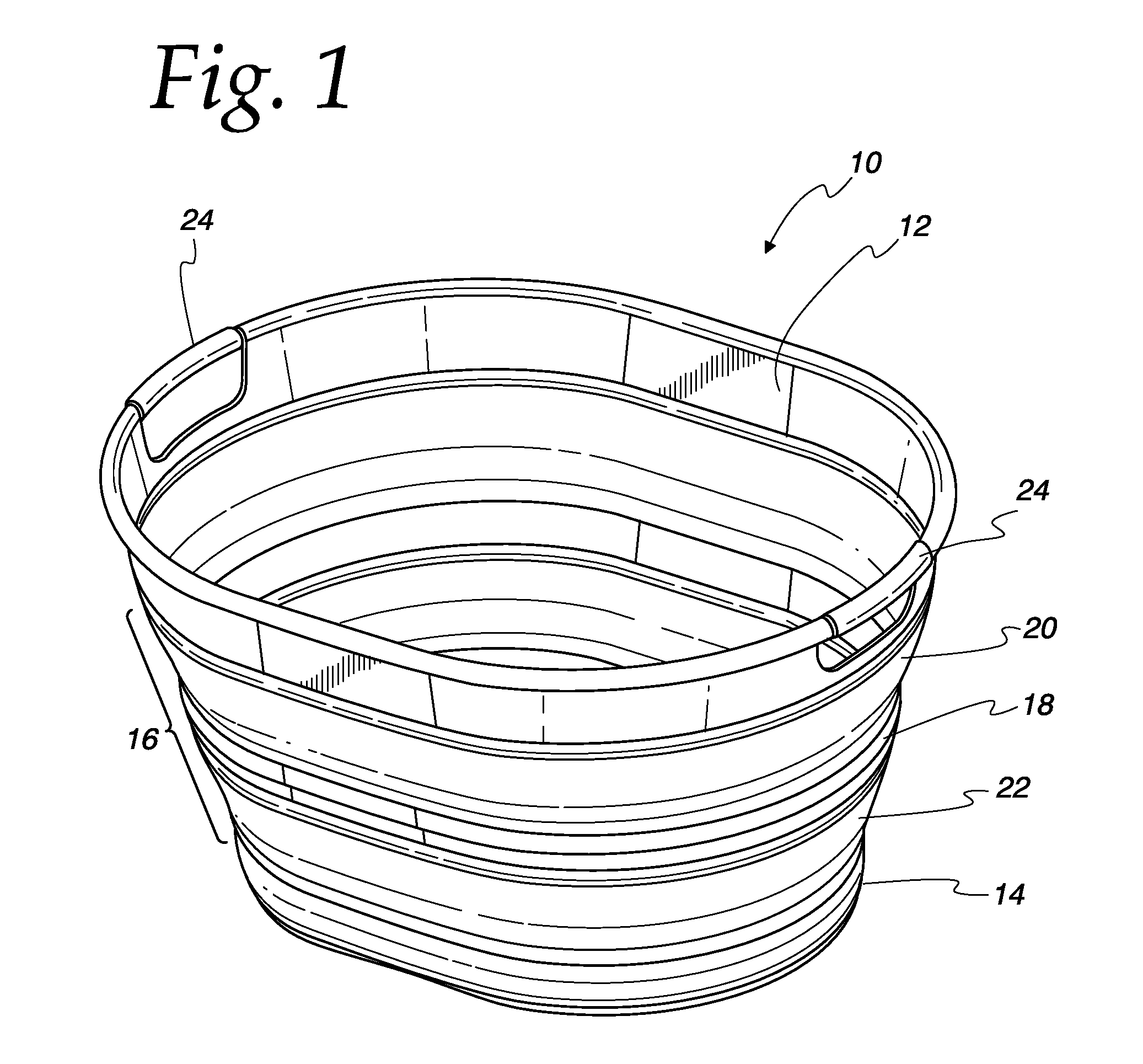

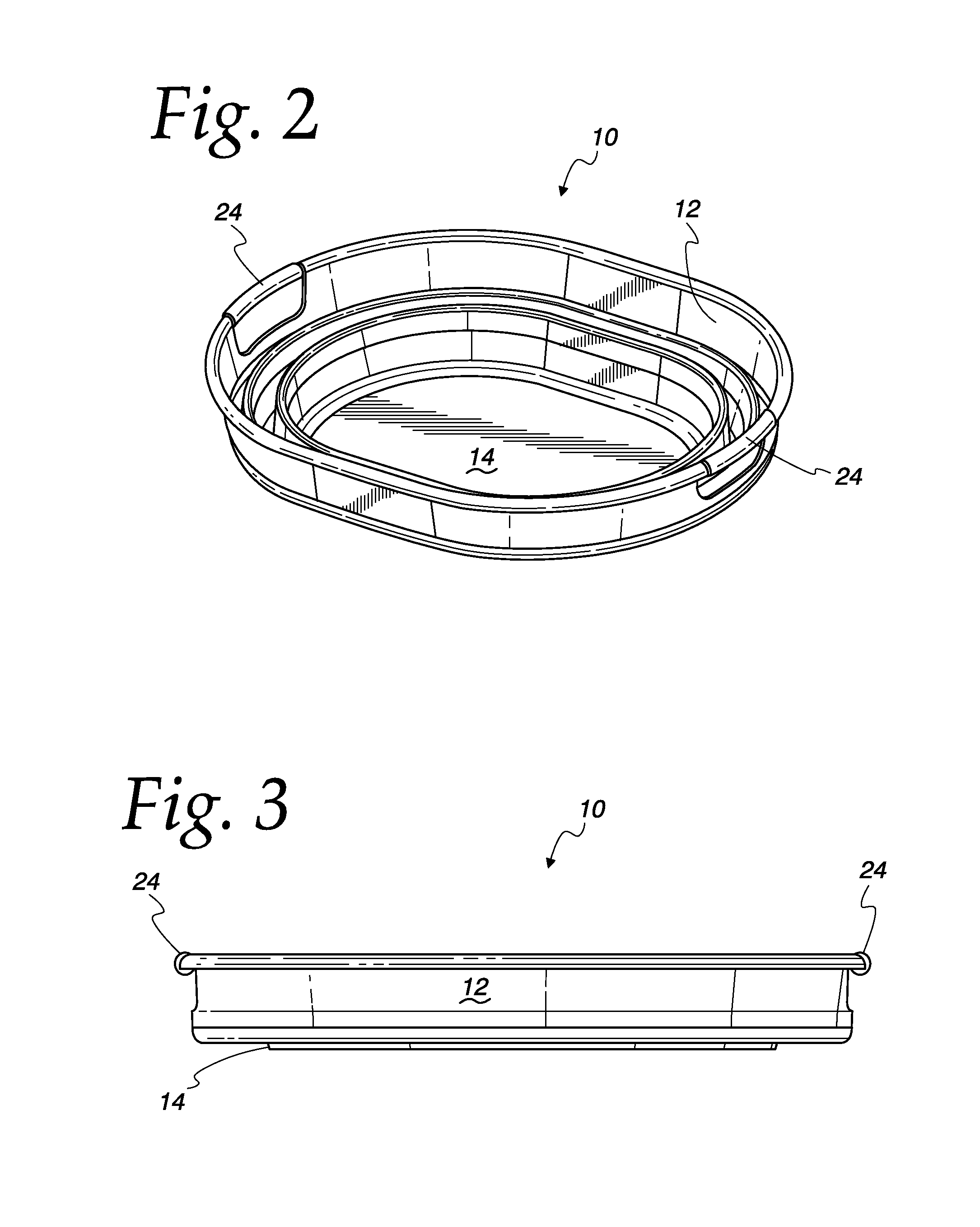

Collapsible Household Containers

Collapsible household containers having a foldable wall section with shape-retaining characteristics are disclosed. In particular, collapsible laundry baskets, buckets, colanders, dish drainers, cups, and bottles are provided. The folding region may include foldable tiers of a flexible material, each tier having at least one stable, relatively expanded position and at least one stable, relatively collapsed position; and an intervening, non-folding tier composed of a different, relatively rigid material.

Owner:TSUI SAM TUNG

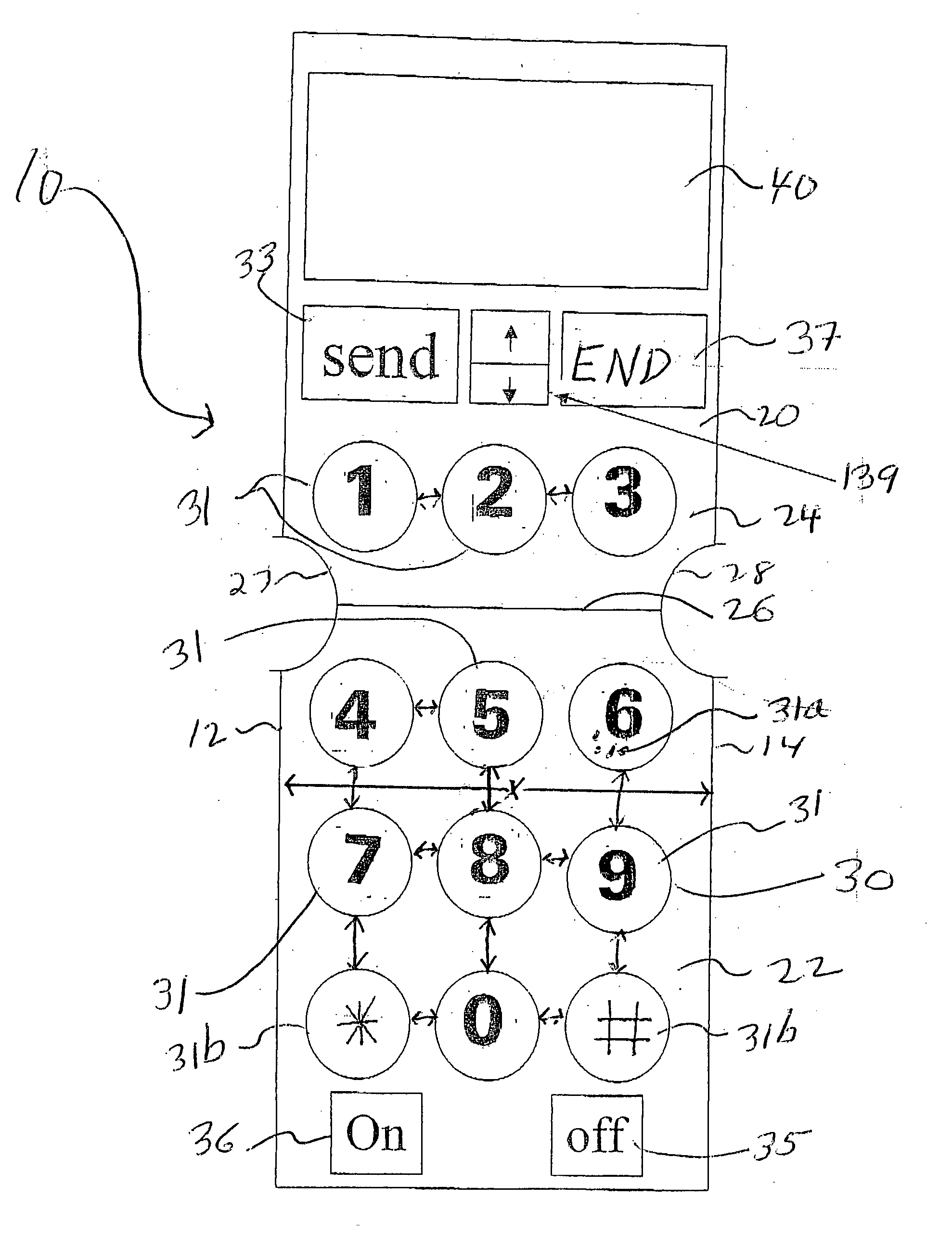

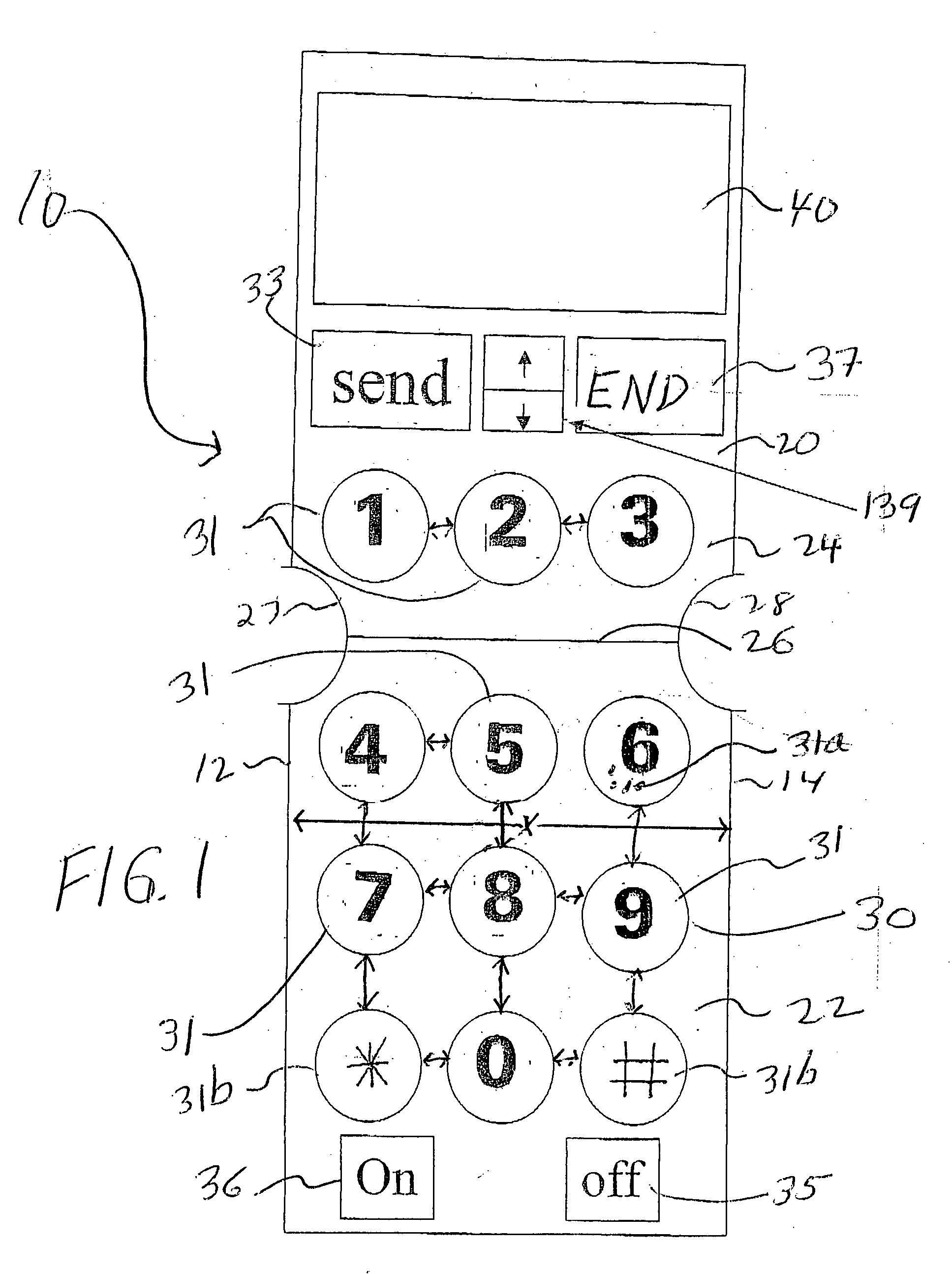

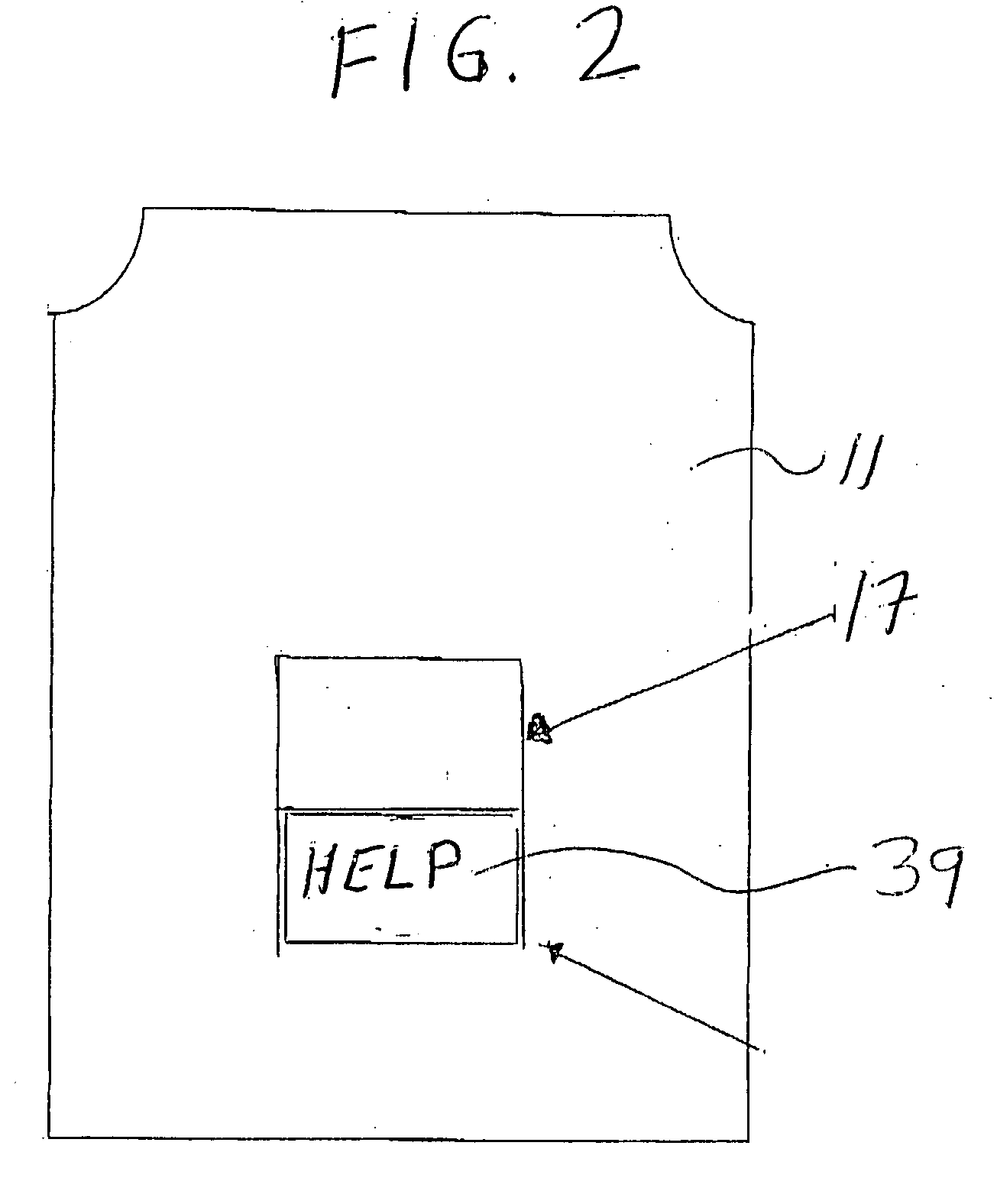

Cellular telephone design for the elderly

InactiveUS20060079269A1Minimize accidental pressingReduces instanceInterconnection arrangementsTransmissionMobile telephonyVisibility

A cellular telephone designed specifically to be visually appealing and practical for the elderly and those with reduced dexterity. Although the keypad buttons on the cellular telephone are approximately 260 square millimeters and have large spaces between adjacent keys to reduce instances of pressing the wrong button and to optimize visibility of the character digits on the key, the entire cellular telephone is approximately three inches wide, is lightweight and folds into a compact space, and can be held in one hand by an elderly individual. A large display is present. At least three jumbo integer keys are present on each portion of the foldable interactive surface. Unnecessary technological function keys are eliminated. Pressing the “HELP” key on the reverse side of the telephone body calls a medical or rescue service and displays medical information on the display.

Owner:SOROTZKIN MOSHE

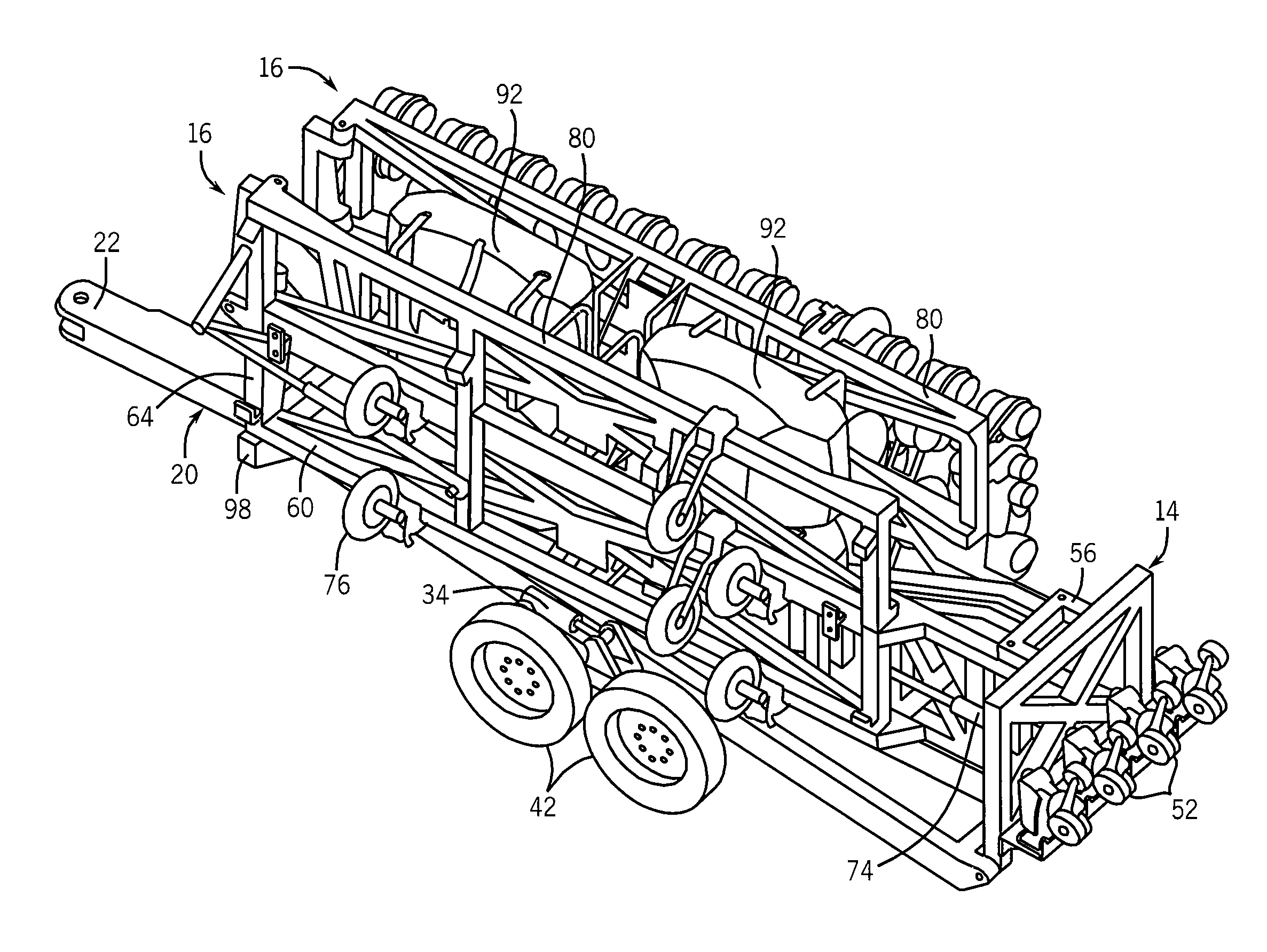

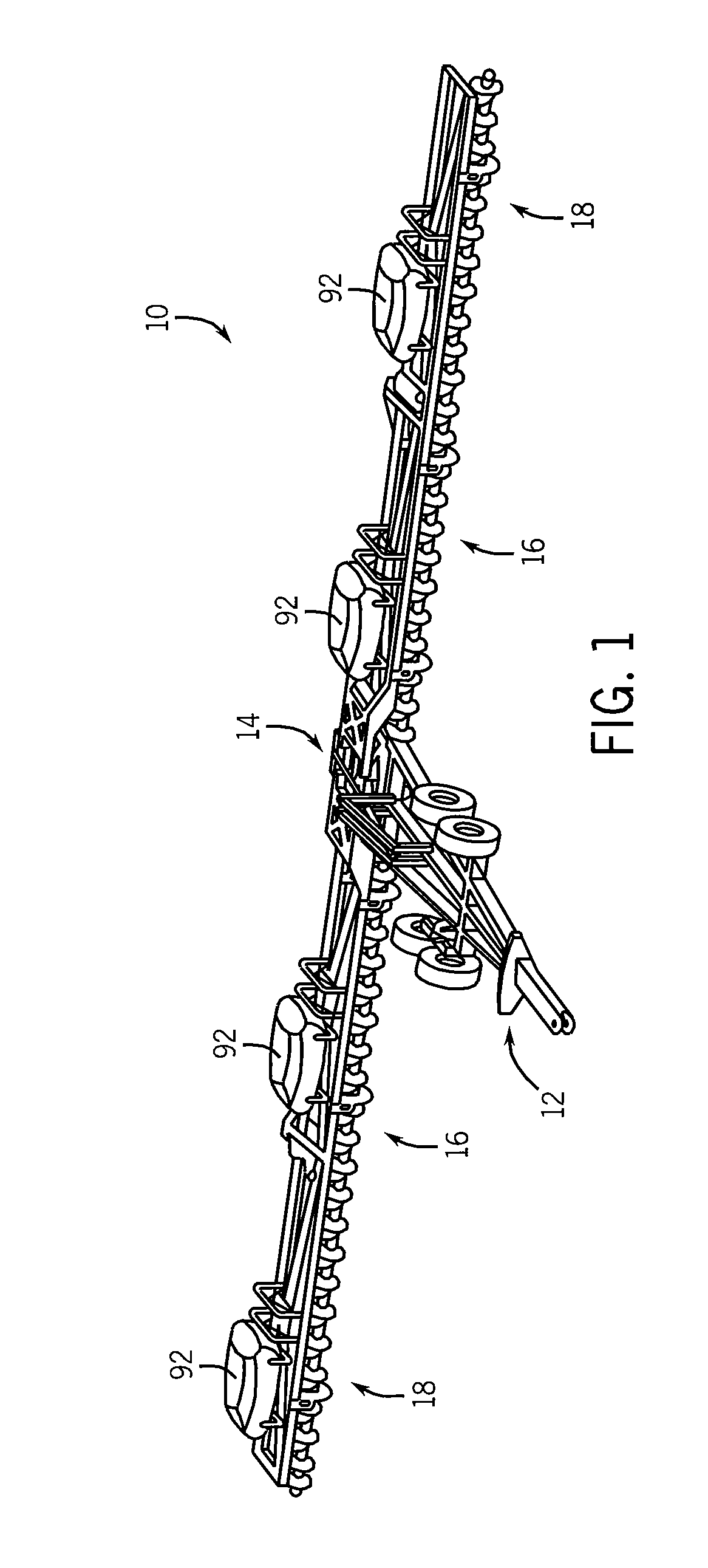

Foldable farm implement

A foldable implement frame is foldable about multiple axes to provide a compactly folded implement. The implement is foldable from a wide, field working position to a relatively narrow position for transport between fields, along roadways, and through field gates or storage doors. The frame is generally comprised of a center frame section that may be hitched to a prime mover, a pair of inner frame sections, and a pair of outer frame sections. The outer frame sections may be folded about their connections to the inner frame sections, and the inner frame sections are foldable about their connections to the central frame section. The central frame section may be rotated to rotate the inner and outer frame sections forward to an upright position, and the inner and outer frame sections may then be folded forward to fold the frame into a narrow position for transport and / or storage.

Owner:CNH IND AMERICA LLC

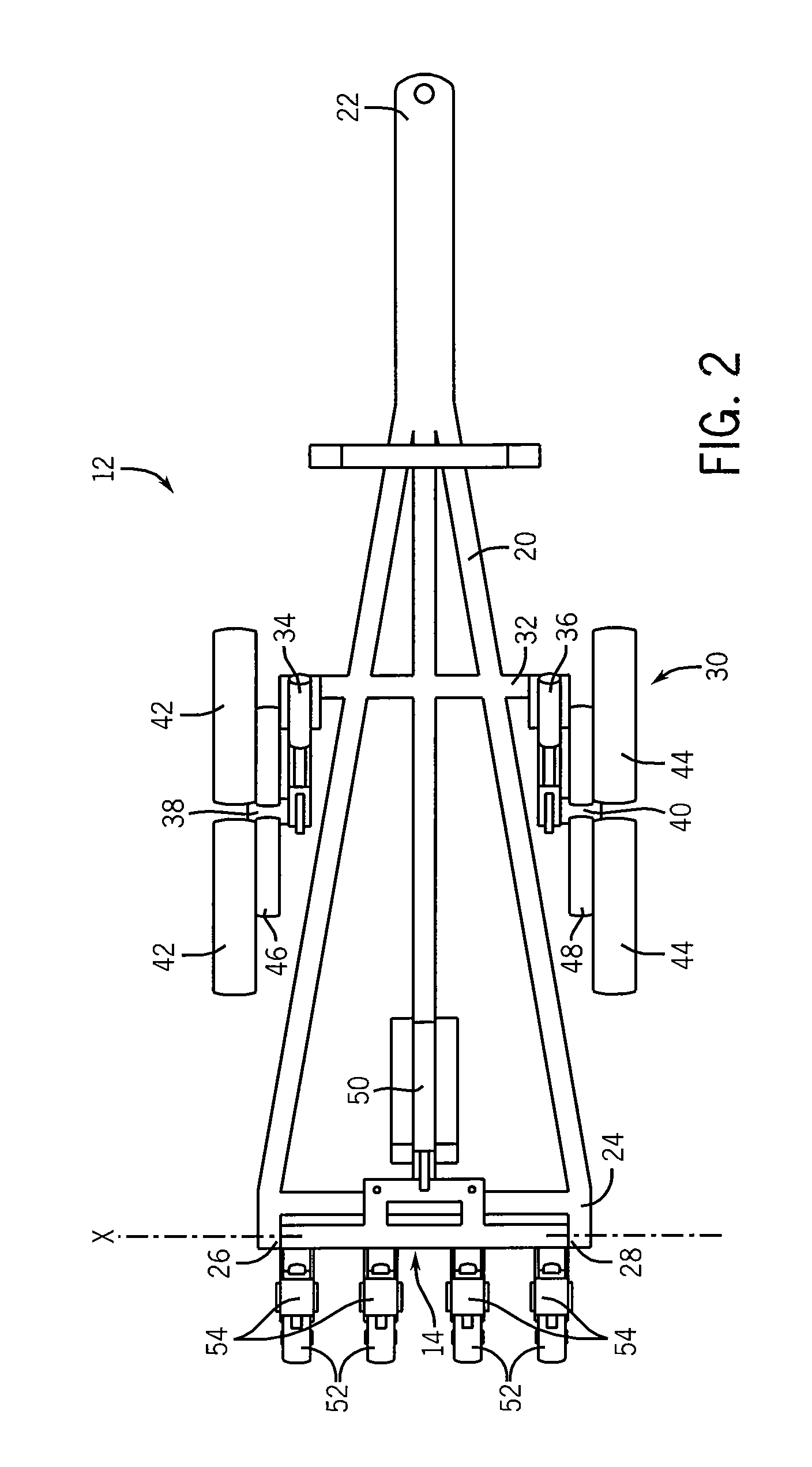

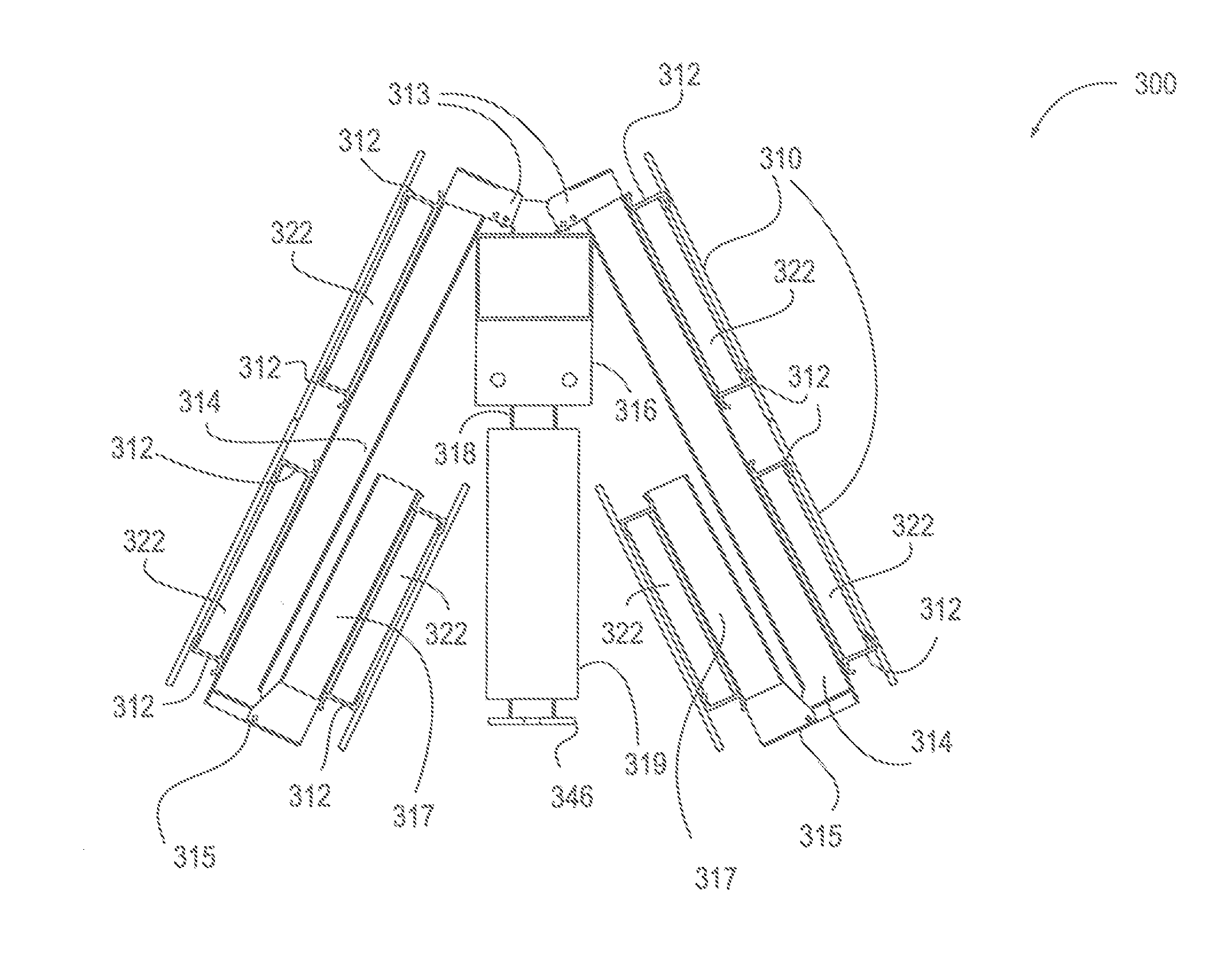

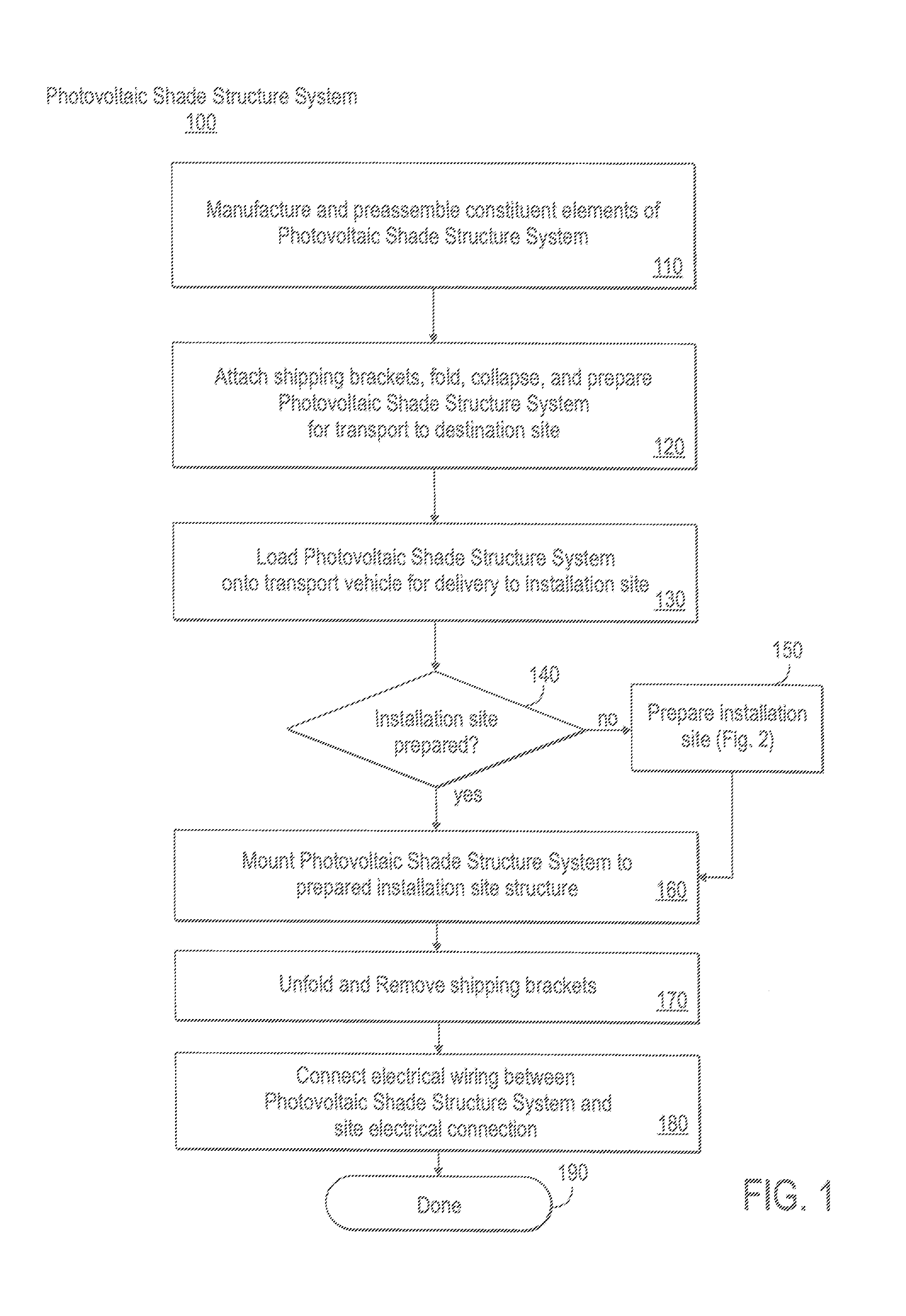

Folding solar canopy assembly

ActiveUS20140076378A1Easy to unfoldFold compactPhotovoltaic supportsSolar heating energyEngineeringHinge joint

A structure capable of folding into a compact form for transporting, and for simple unfolding for attachment to a base, the structure including: two or more hingably interconnected solar panel arrays each having a two or more of solar panels, a solar panel support channel, and a support beam; wherein the two or more solar panels are attached to top portions of the solar panel support channel, and a bottom portion of the solar panel support channel is attached to a top portion of the support beam, the support beam having a hinged joint for cooperating in folding into mutual, near coplanar juxtaposition; and where the structure, when unfolded includes a solar canopy and is L-shaped viewed on end.

Owner:ENGIE SERVICES U S INC

Collapsible Household Containers

ActiveUS20150251808A1Increase in sizeSmall sizeTravelling sacksKitchenware cleanersEngineeringMechanical engineering

Collapsible household containers having a foldable wall section with shape-retaining characteristics are disclosed. In particular, collapsible laundry baskets, buckets, colanders, dish drainers, and cups are provided. The folding region may include foldable tiers of a flexible material, each tier having at least one stable, relatively expanded position and at least one stable, relatively collapsed position; and an intervening, non-folding tier composed of a different, relatively rigid material.

Owner:TSUI SAM TUNG

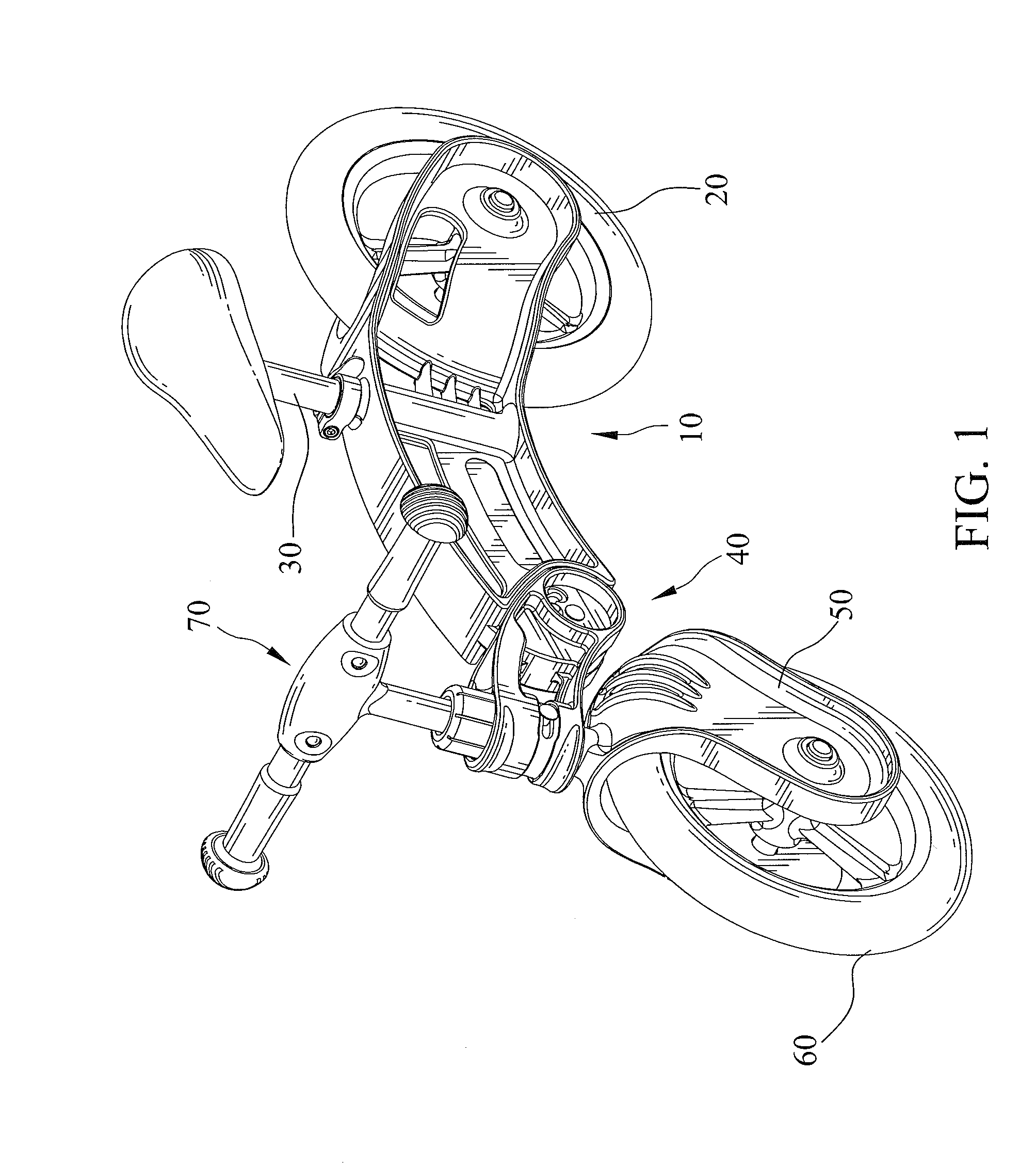

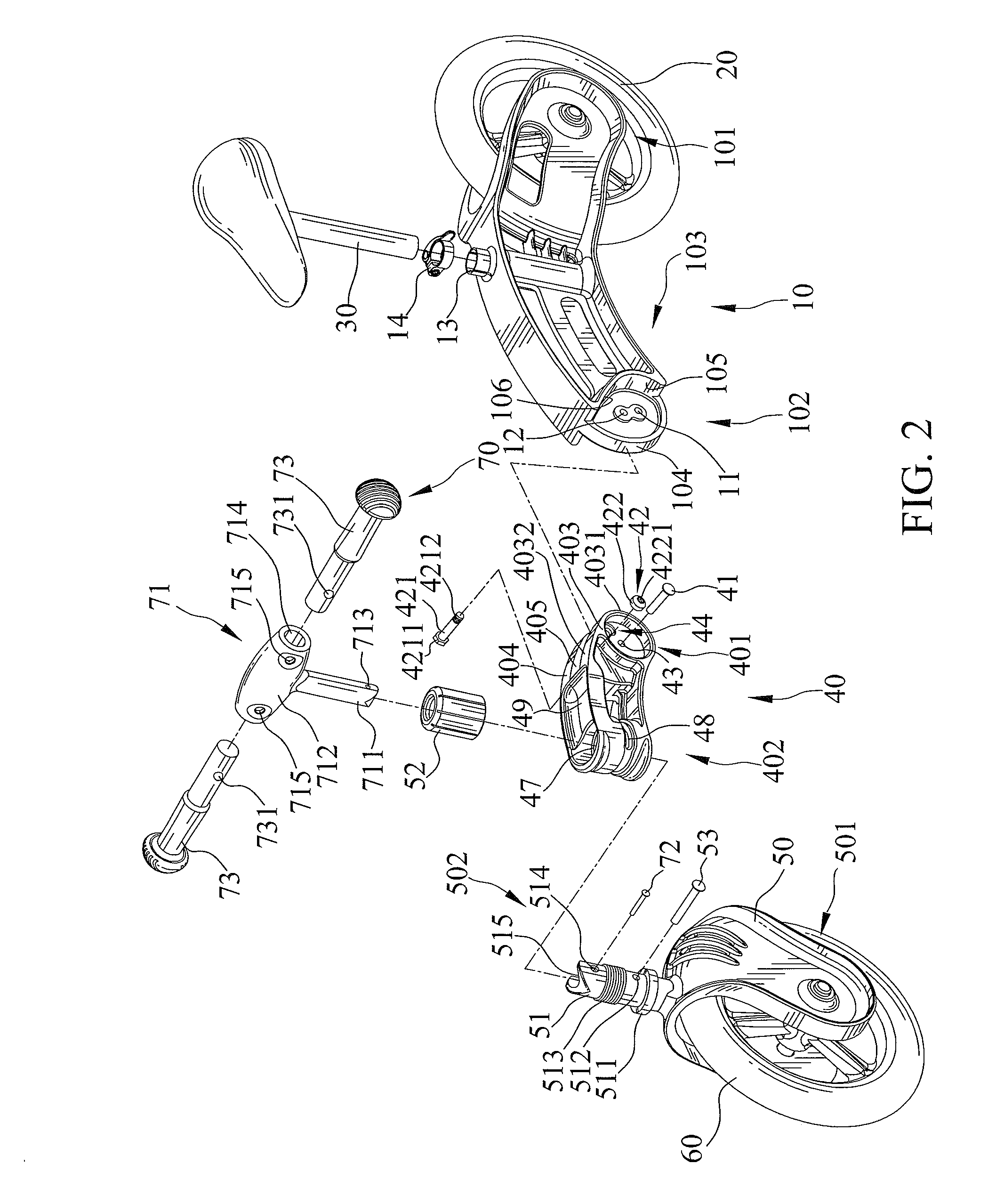

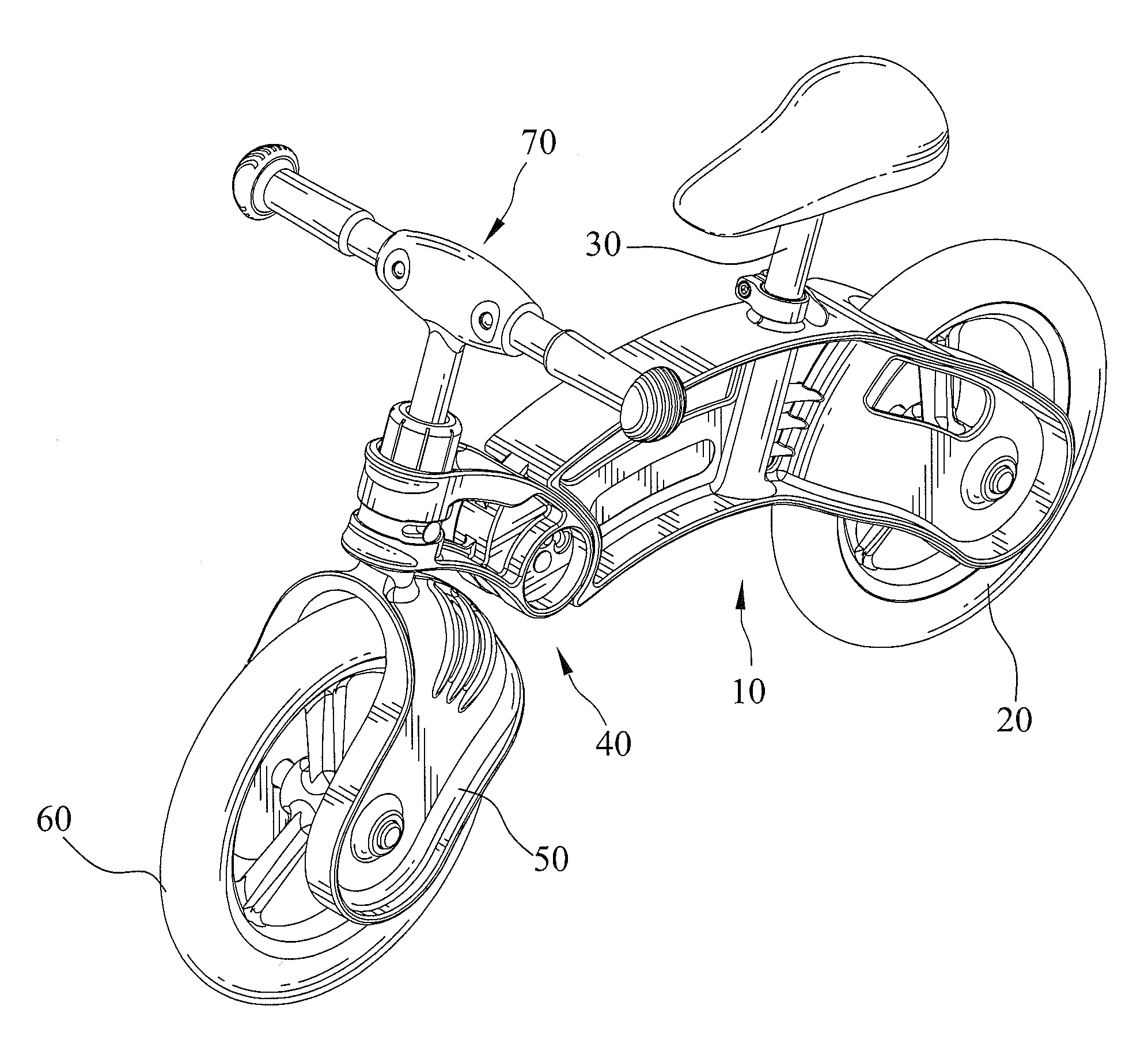

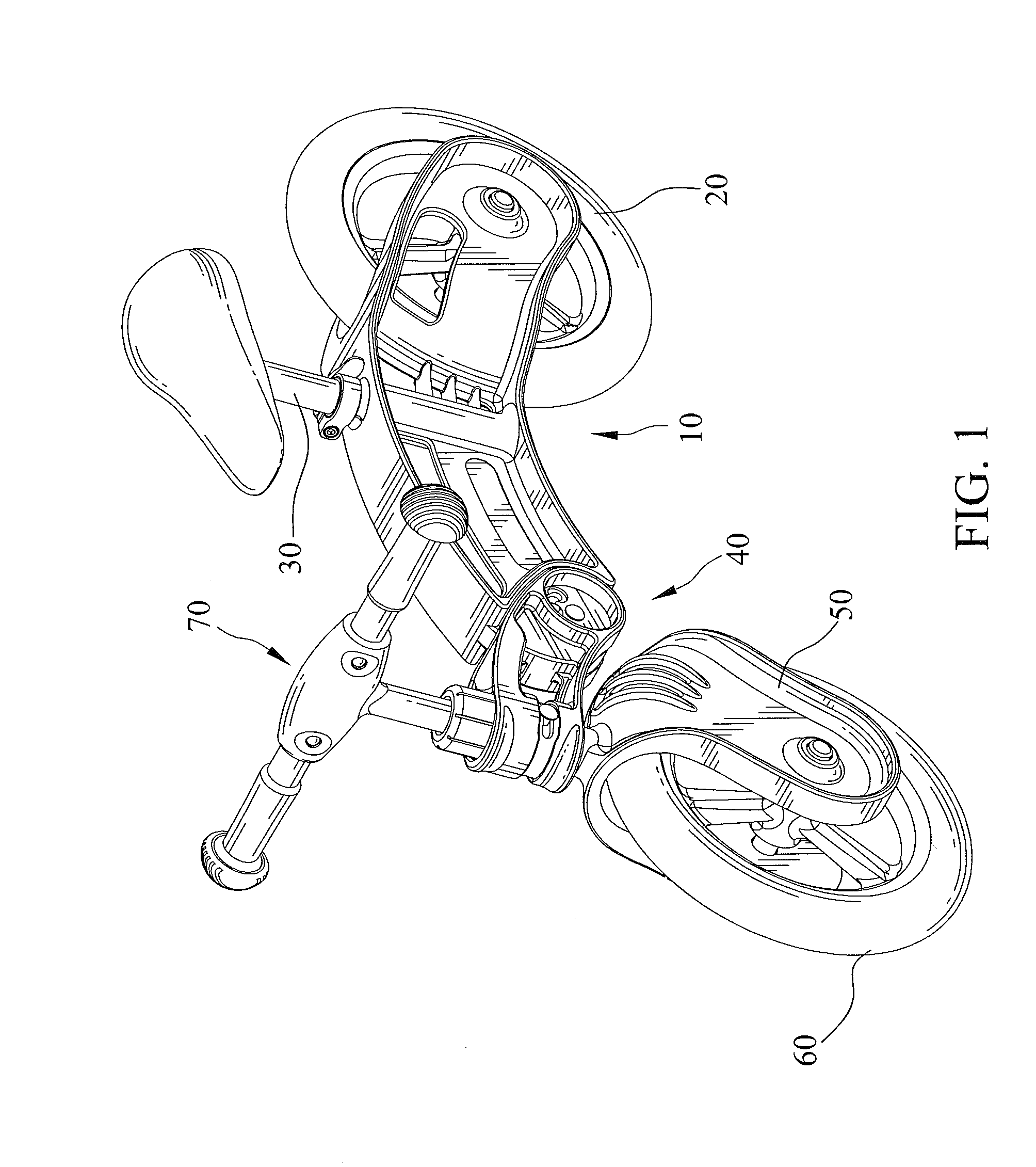

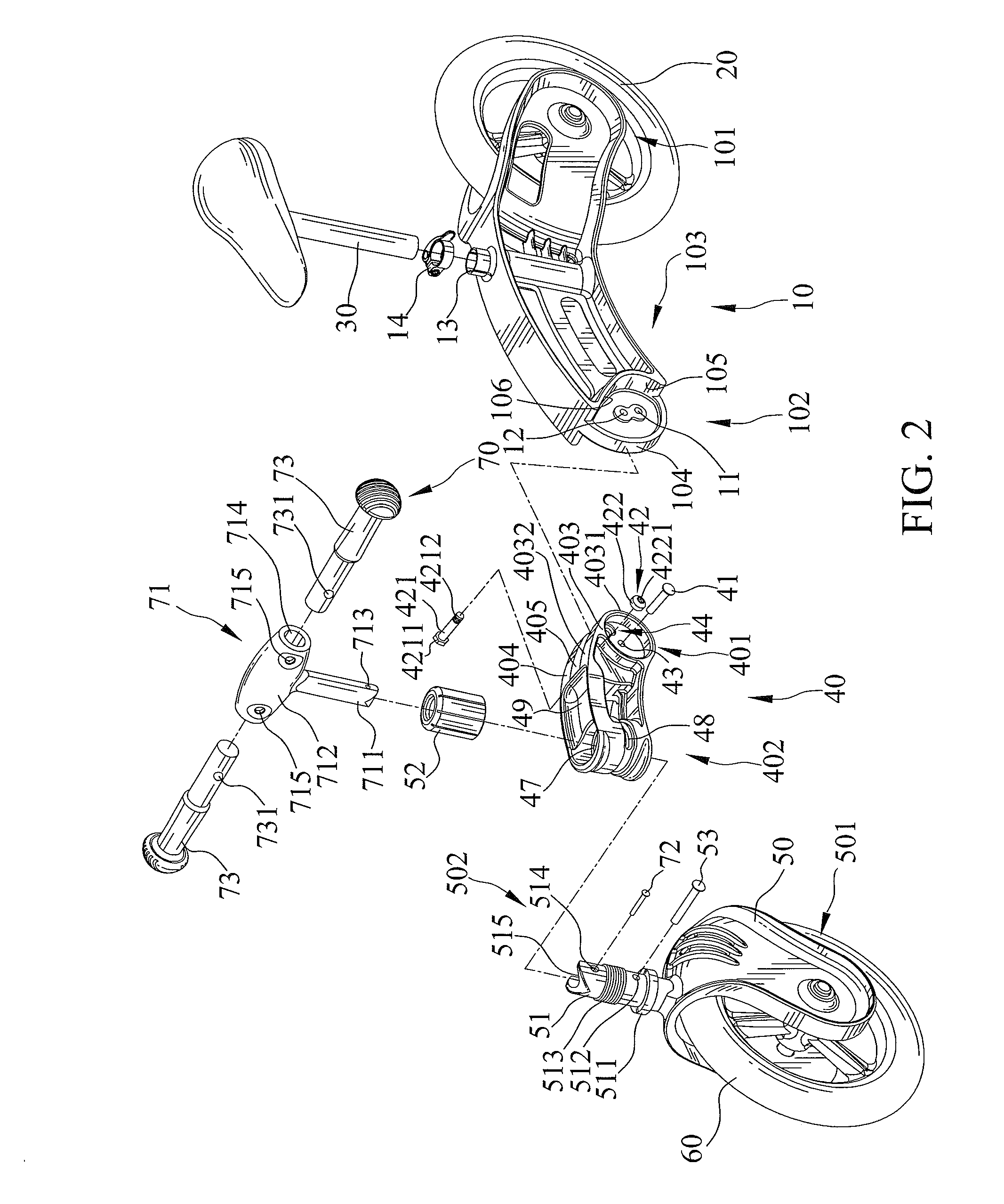

Balance bike

InactiveUS8414007B2Fold compactPassenger cyclesWheel based transmissionEngineeringMechanical engineering

A balance bike includes a frame, front and rear wheels, a seat, a joining structure, a front fork, and a steering handle. The joining structure is pivotally joined to the frame and pivotal between first and second positions. The joining structure includes a joining end and a receiving end. The front and rear wheels are disposed apart from each other, and the balance bike defines a first longitudinal dimension when the joining structure is in the first position. The front and rear wheels are disposed adjacent to each other, and the balance bike defines a second longitudinal dimension when the joining structure is in the second position. The first longitudinal dimension is larger than the second longitudinal dimension.

Owner:CHEN WANG CHUAN

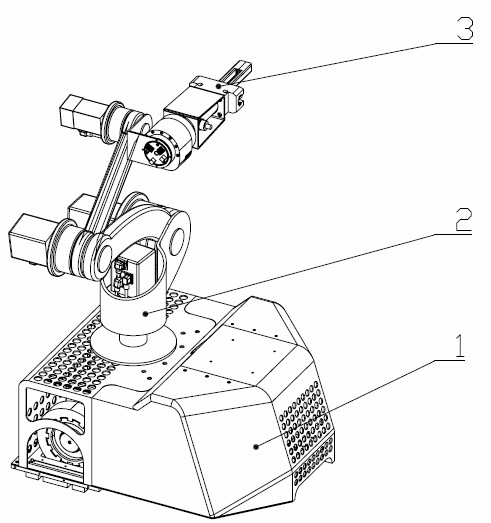

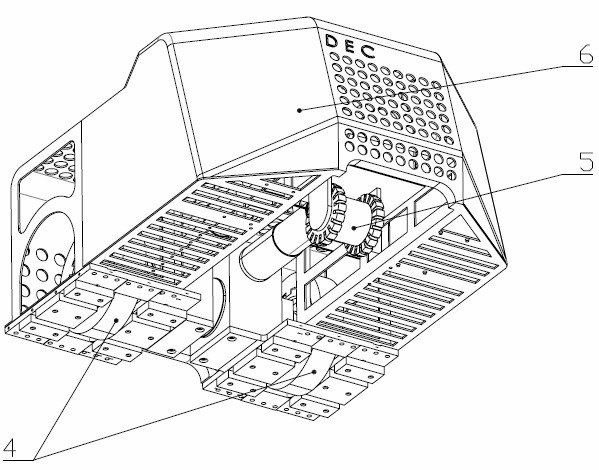

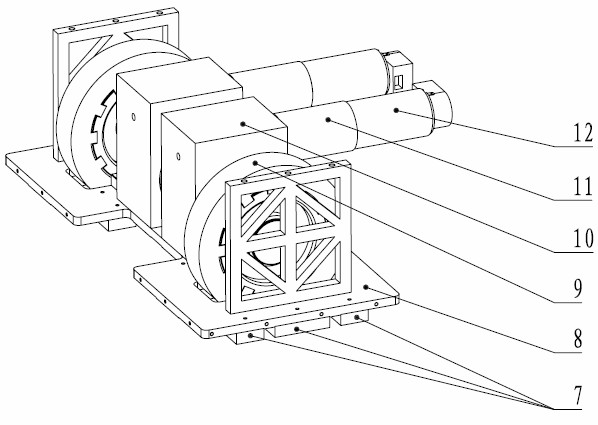

Differential motion driving magnetic adsorption type multifunctional wall climbing robot with small-folding-size mechanical arms

The invention belongs to the technical field of special robots and particularly relates to a differential motion driving magnetic adsorption type multifunctional wall climbing robot with small-folding-size mechanical arms, comprising a climbing mechanism and an operation mechanism, wherein the operation mechanism comprises multifunctional mechanical arms and tail end working modules; a base of each multifunctional mechanical arm is fixed on an adsorption type climbing mechanism; and each tail end working module is fixed at the tail end of each multifunctional mechanical arm. According to the invention, the small-folding-size mechanical arms are carried; with the adoption of a five-degree-of-freedom matching manner, the tail end of each arm can work in a working region at any position and any angle; and compared with the other mechanical arms with less degree-of-freedom, the movement of the multifunctional mechanical arms is more flexible. The small-folding-size mechanical arms refer to that the arm folding is more compact and the size of the folded arm is smaller according to explanation; and according to the shape represented on each arm, particularly a large arm adopts a curve design, so that other structures can be avoided when the arms are folded.

Owner:DONGFANG ELECTRIC CORP LTD

Stiffener reinforced foldable member

InactiveUS6910304B2Fold compactImprove packaging efficiencyCosmonautic vehiclesCosmonautic partsEngineeringElectrical and Electronics engineering

Owner:FOSTER-MILLER

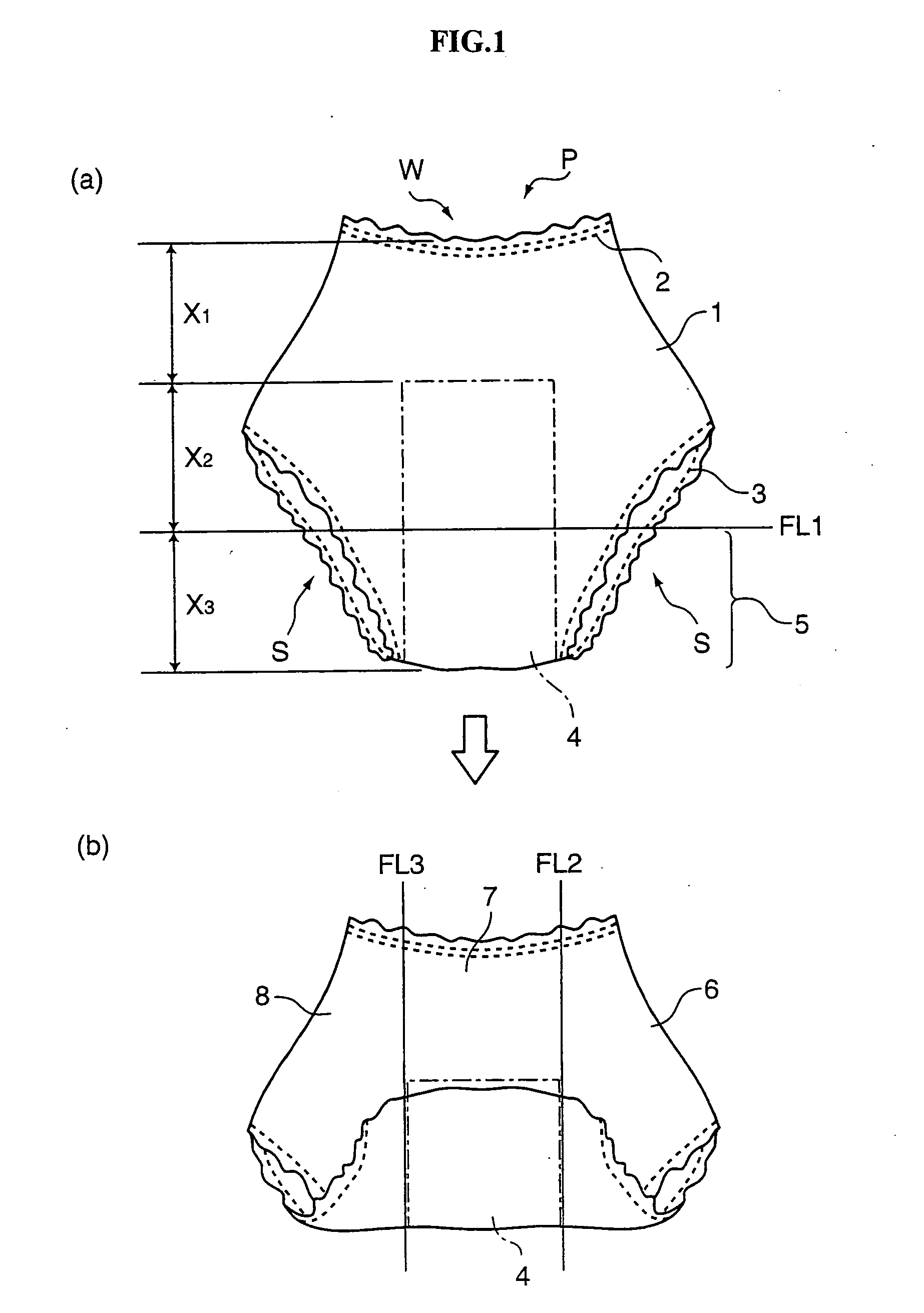

Folding structure of disposable underpants and disposable underpants

There is provided a folding structure of disposable pants which includes an outer wear sheet of pants shape and an absorbent main body adhered to a skin-contacting surface side in the outer wear sheet, wherein elastic members are added at least to circumferences of a waist opening and a leg opening. The structure is formed by folding back a crotch part 5 of the disposable pants over a center pants part 7 on the upside of the crotch part, folding back a left lateral part 8 and a right lateral part 6 of the pants over the center pants part 7, respectively, and then folding back an upper pants part 9 in which the left and the right lateral parts of the pants are overlapped with each other, over a downside part 10 thereof.

Owner:LIVEDO CORP

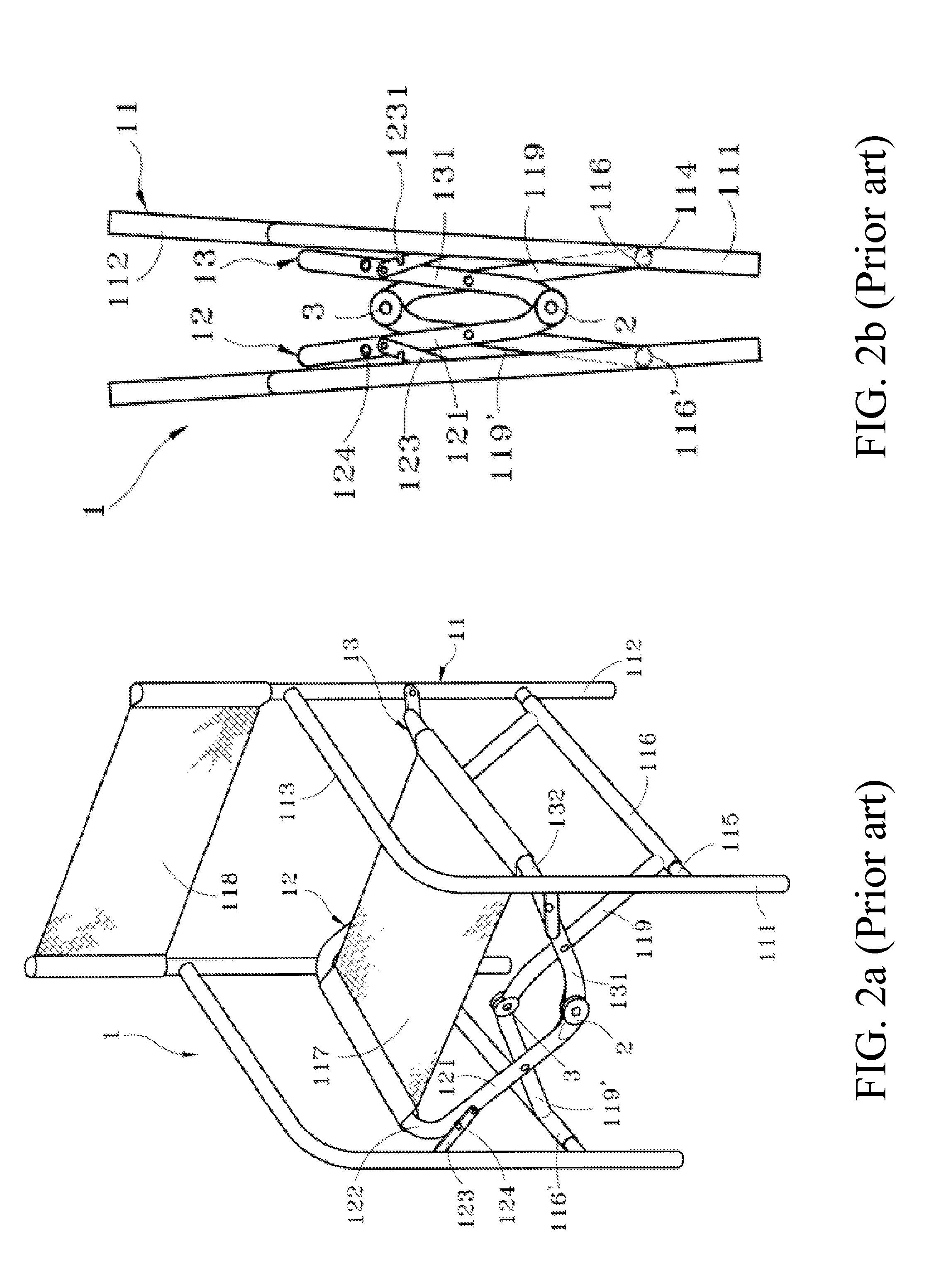

Folding chair

Owner:IP POWER HLDG

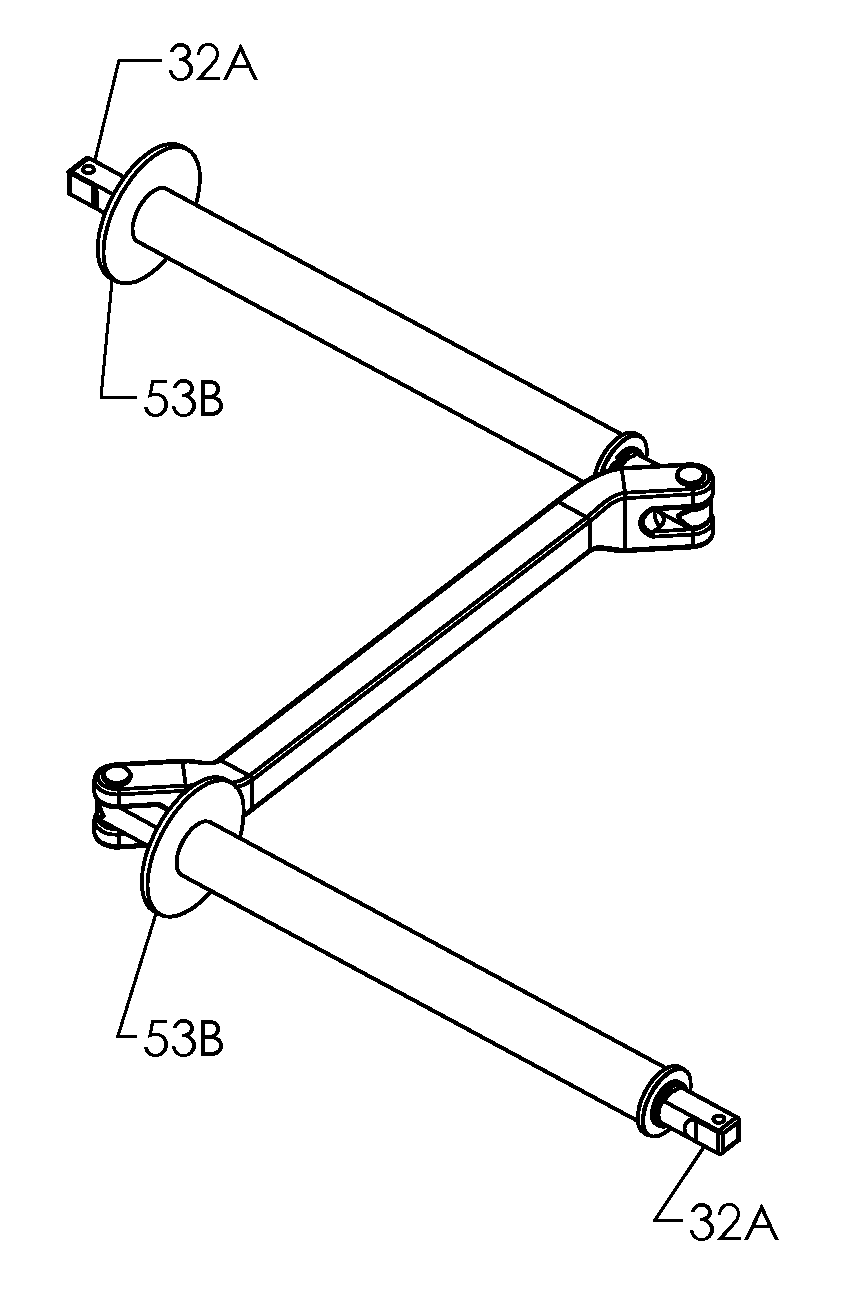

Manual dual end rotary driver of Z configuration

ActiveUS8474353B1Easy and smooth and controlled variationFold compactSpannersWrenchesHand heldEngineering

Multiple embodiments of a manual tool, for ergonomic, controlled and variable application of rotary motion, torque, and or axial force to an object. One embodiment is comprised of three elongated members connected at their ends in a chain by two pivoted joints. The two outboard members each have an outboard end shaped for connecting to an object to be rotated and a rotatable handle. One way to use the tool is to grasp each handle with a hand; one hand holds the tool in axial alignment and engaged with the object to be rotated and the other hand orbits about the other handle. The three members can be fluidly positioned in a nearly straight Z, crank, L or in-line shape, so as to vary and control the speed, torque, and force. Either end of the tool may be used to rotate an object by swapping the tool end for end.

Owner:MCELROY MFG

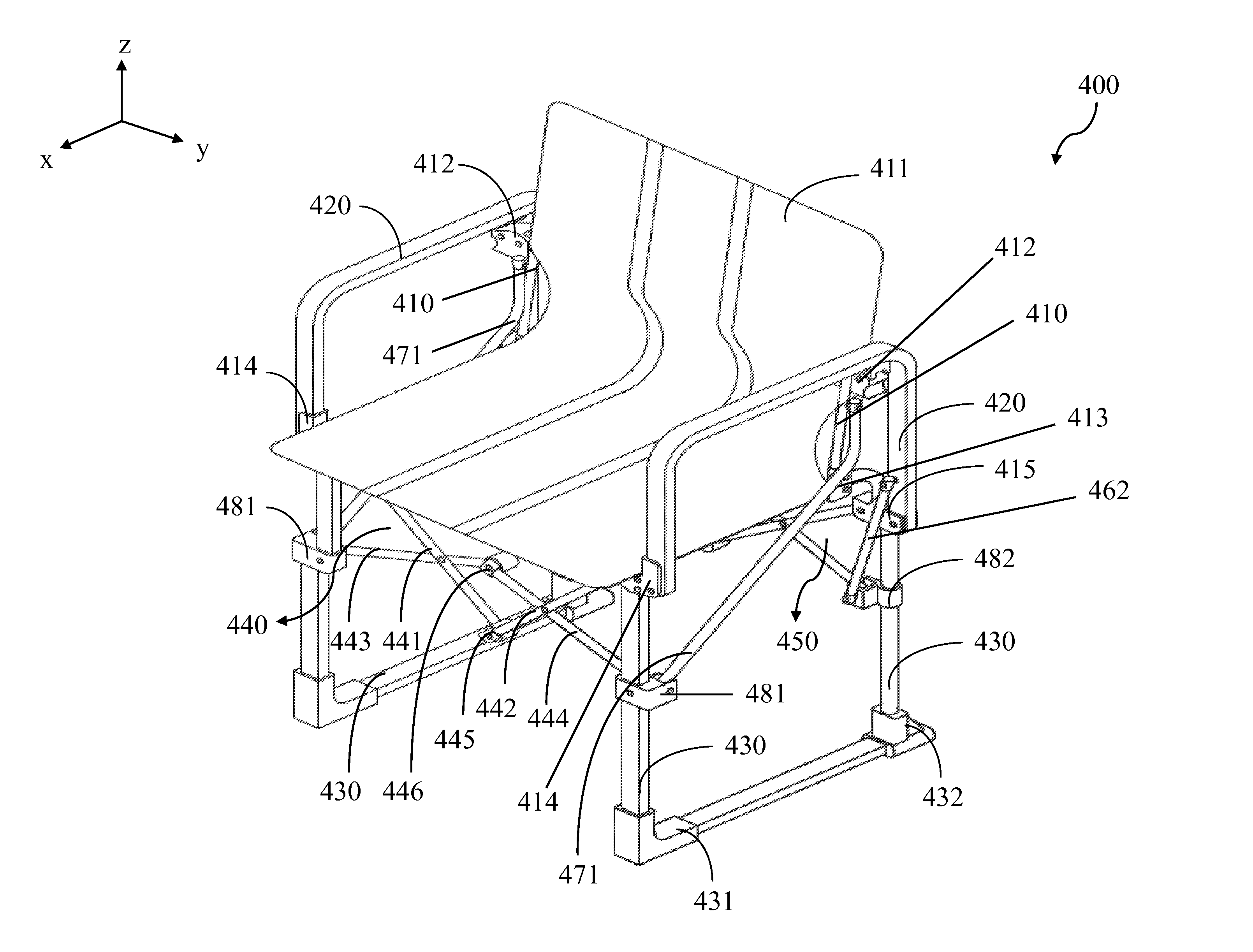

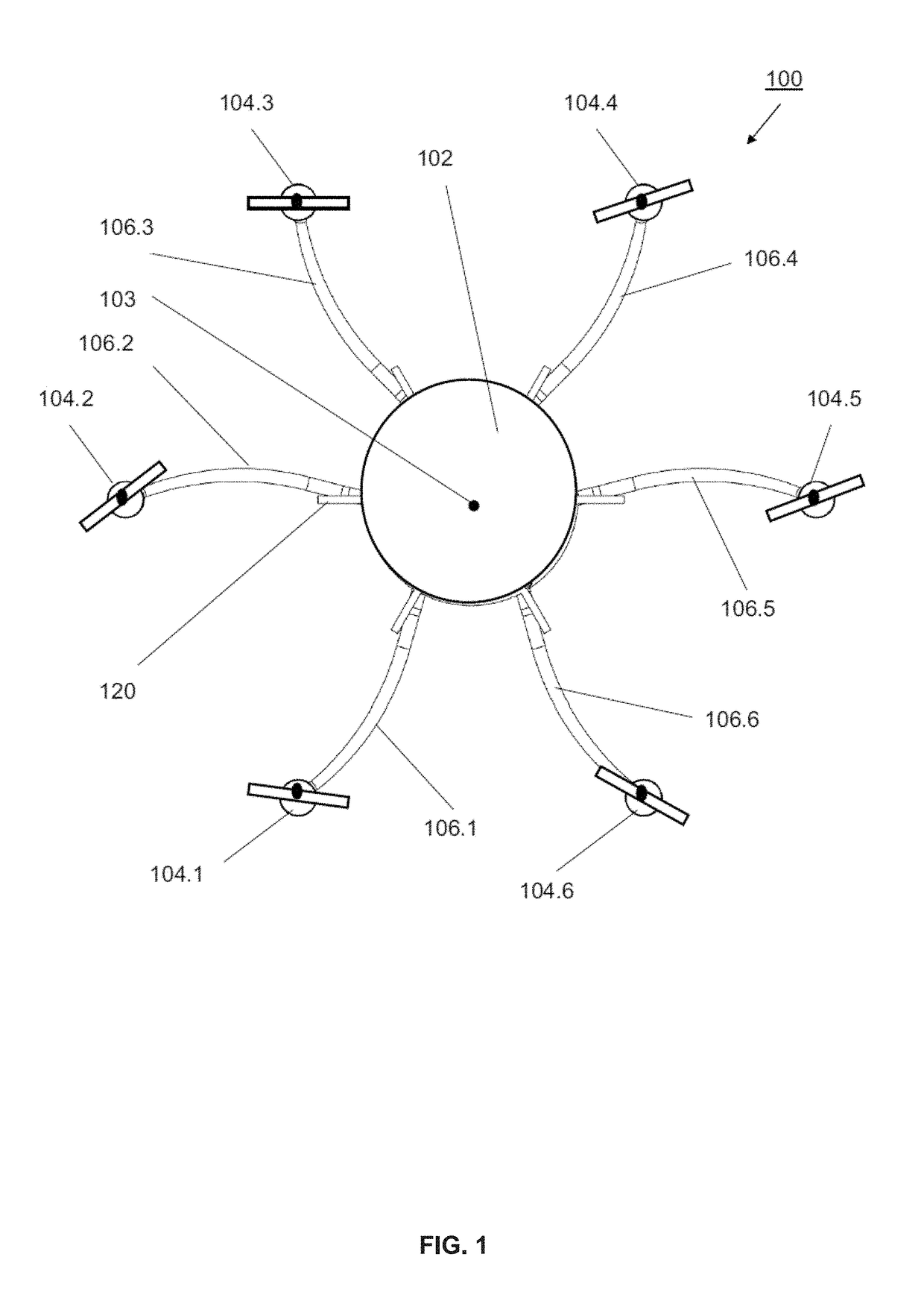

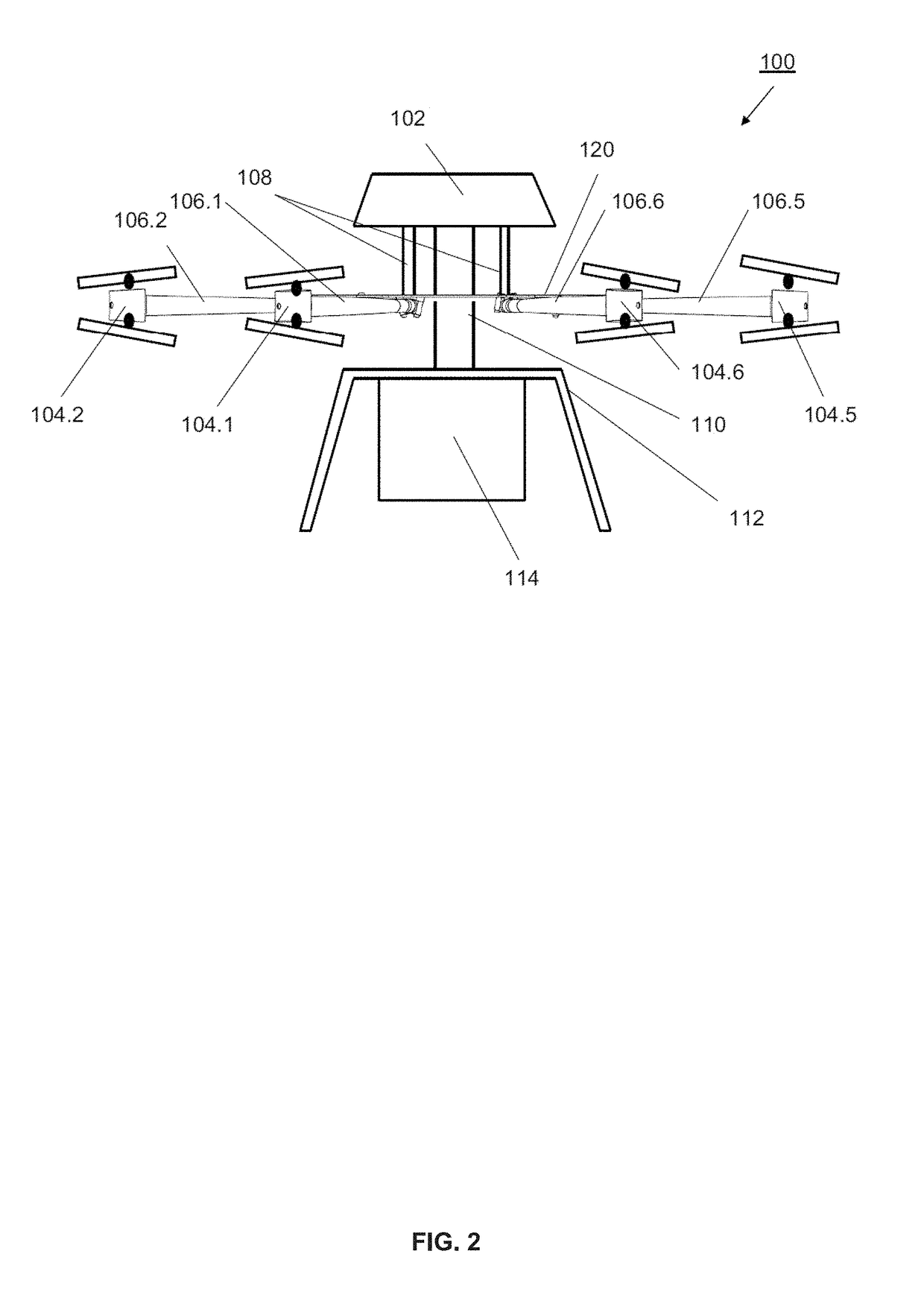

Multi-rotor UAV with compact folding rotor arms

ActiveUS20170197703A1Compact formMinimized in sizePropellersUnmanned aerial vehiclesEngineeringMechanical engineering

A multi-rotor UAV comprises a body and a plurality of rotor arms extending radially from the body. A rotor assembly is connected to an outside end of each rotor arm. An attachment interface is connected to the body and provides rotor arm attachment points for attaching the rotor arms to the body and pivoting the rotor arms from an unfolded operating position, to a folded position wherein the rotor arms are pivoted such that an outer arm portion of each rotor arm is enabled to cross the pivot end and an inner arm portion of an adjacent or arm.

Owner:DRAGANFLY INNOVATIONS

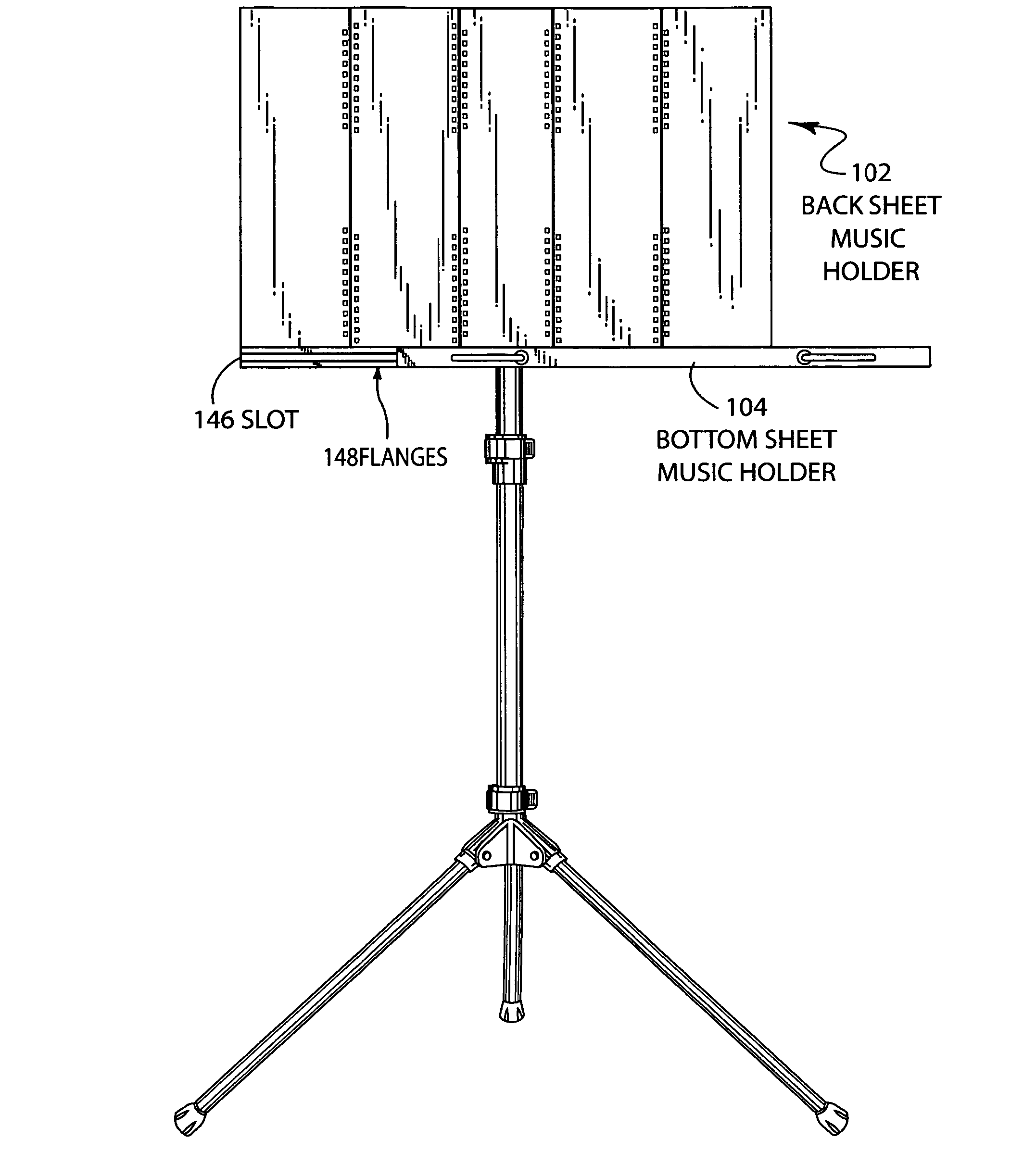

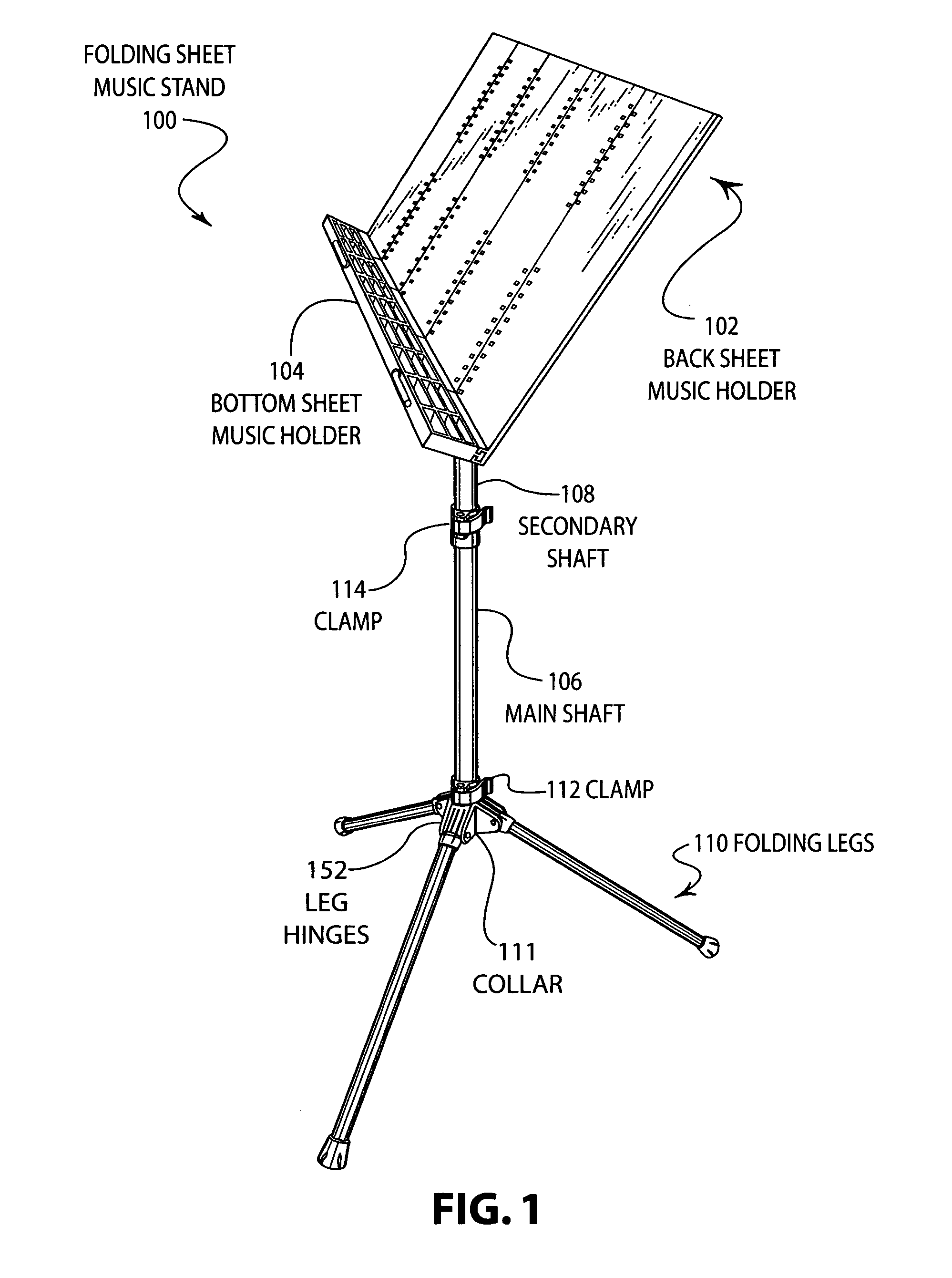

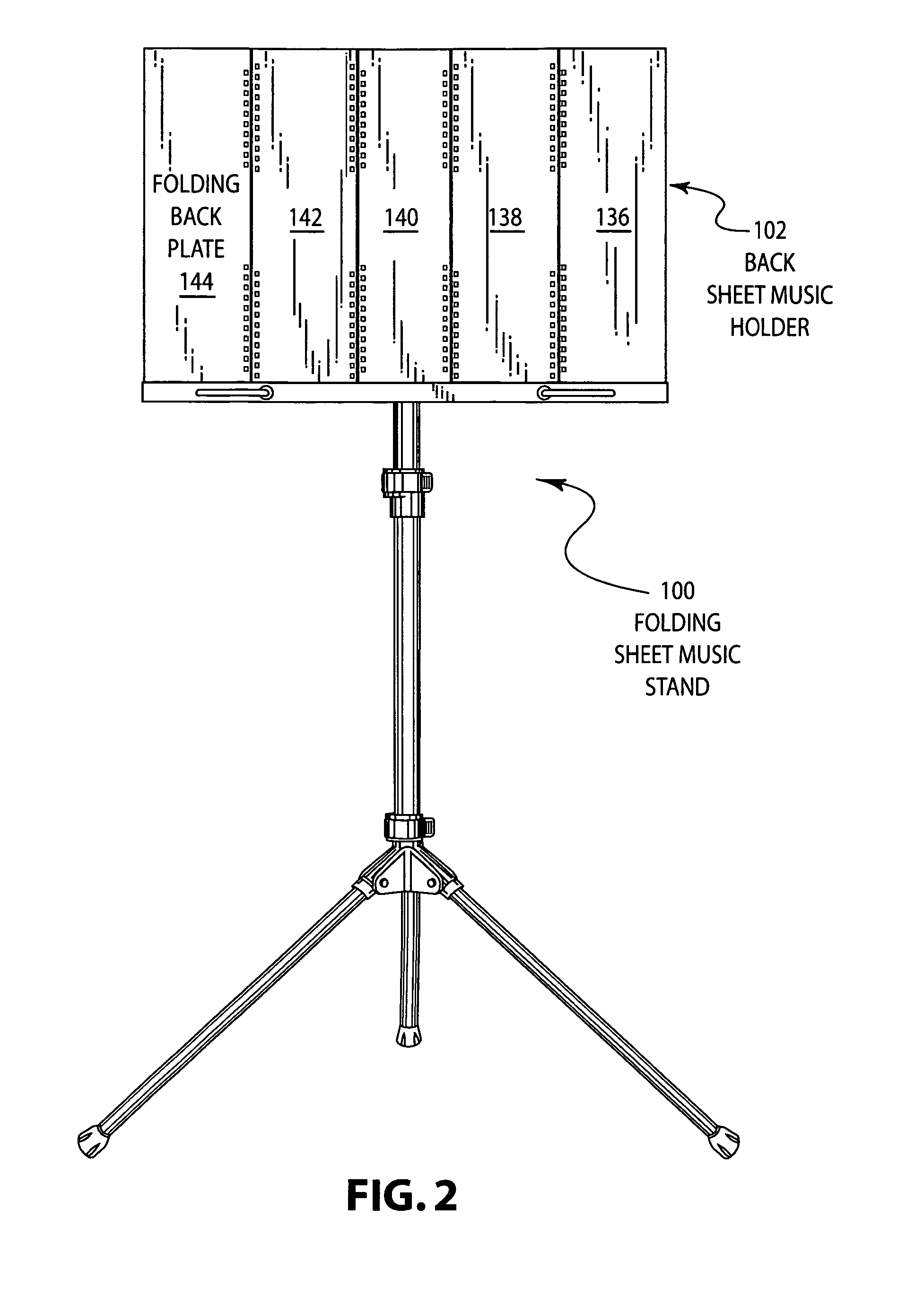

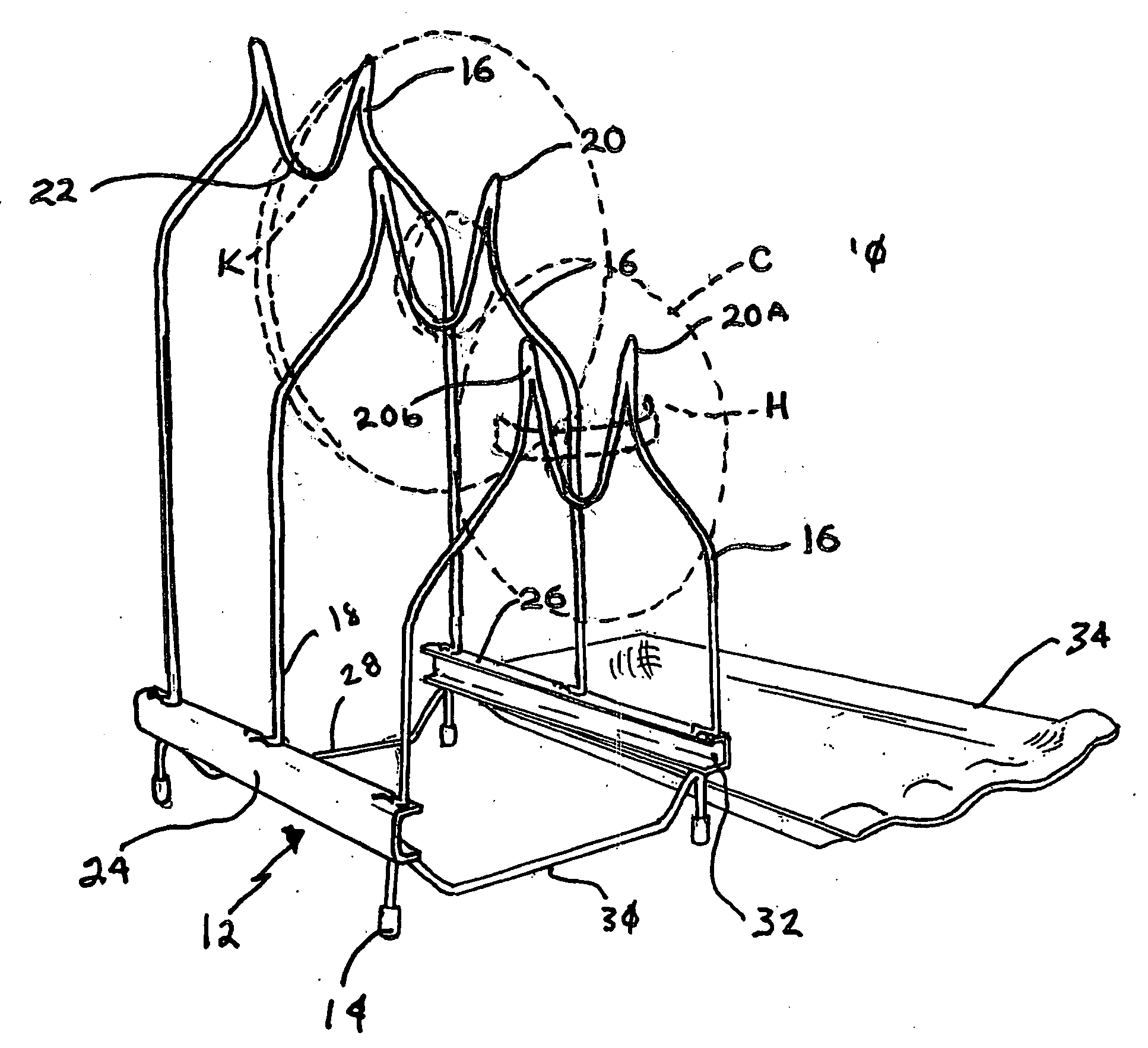

Folding sheet music stand

Disclosed is a folding sheet music stand that is capable of being folded into a very compact package. In the folded position, the folding sheet music stand is easily transportable and less susceptible to damage. A carrying bag can be used to transport the folded sheet music stand. The folding sheet music stand can be easily assembled and provides a sturdy platform for displaying folded sheet music to musicians. The folding sheet music stand is fully adjustable so that the folding sheet music stand can be used by musicians using various different types of instruments.

Owner:SHANGHAI MAX PRECISION INSTR

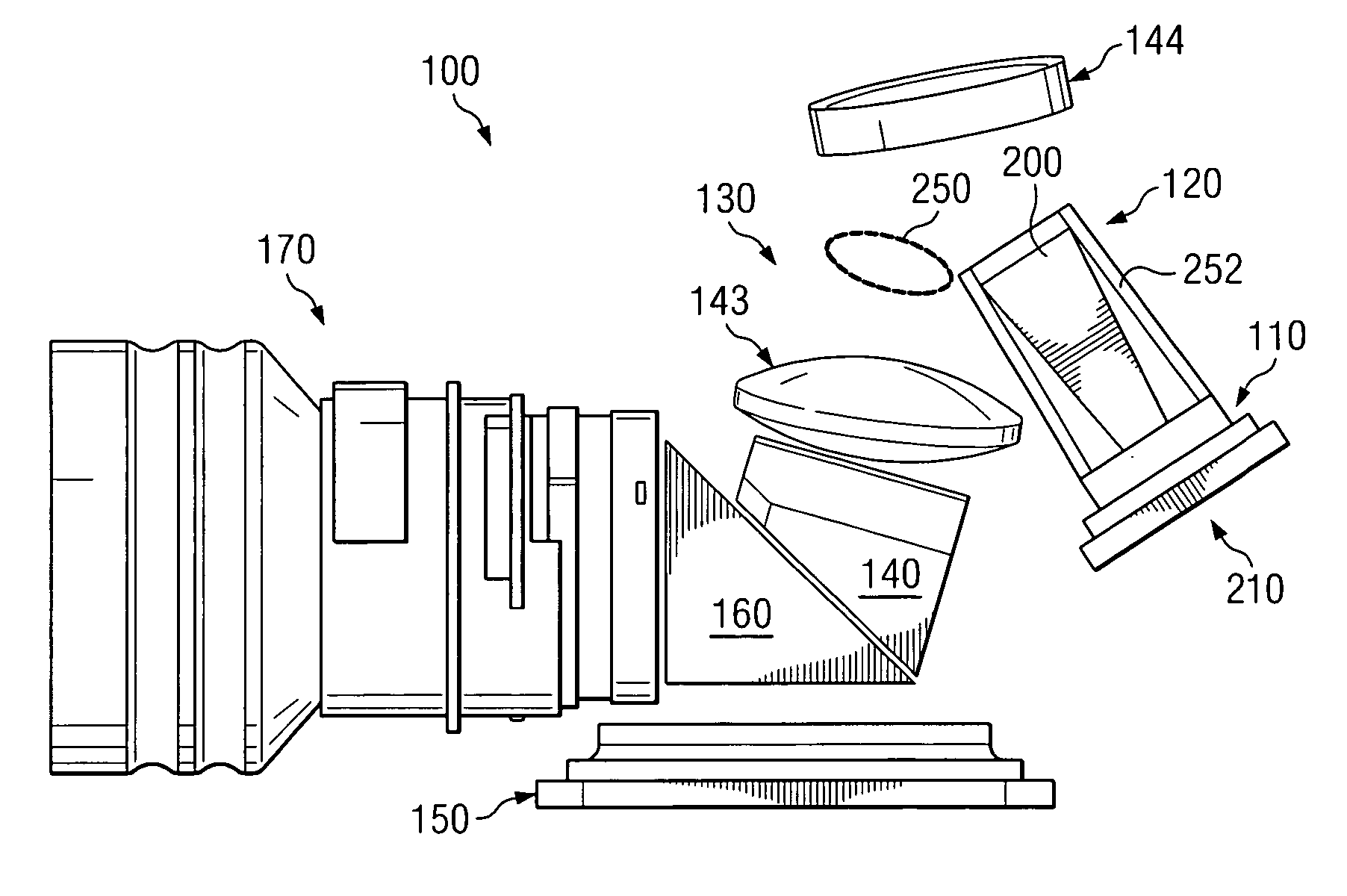

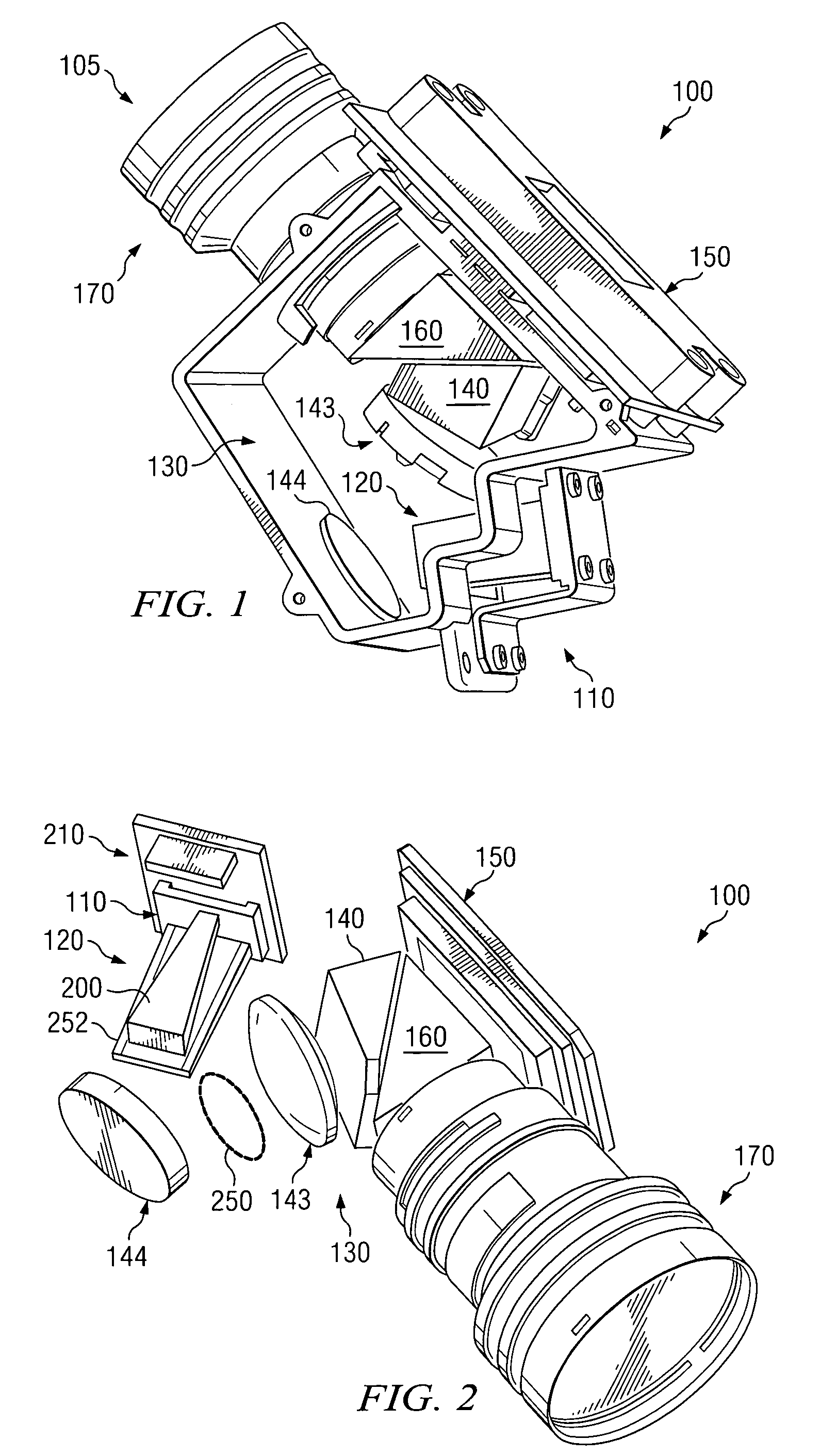

Compact optical engine for very small personal projectors using LED illumination

ActiveUS7360905B2Produce heatPower can be minimalTelevision system detailsProjectorsLight pipeLens plate

Owner:TEXAS INSTR INC

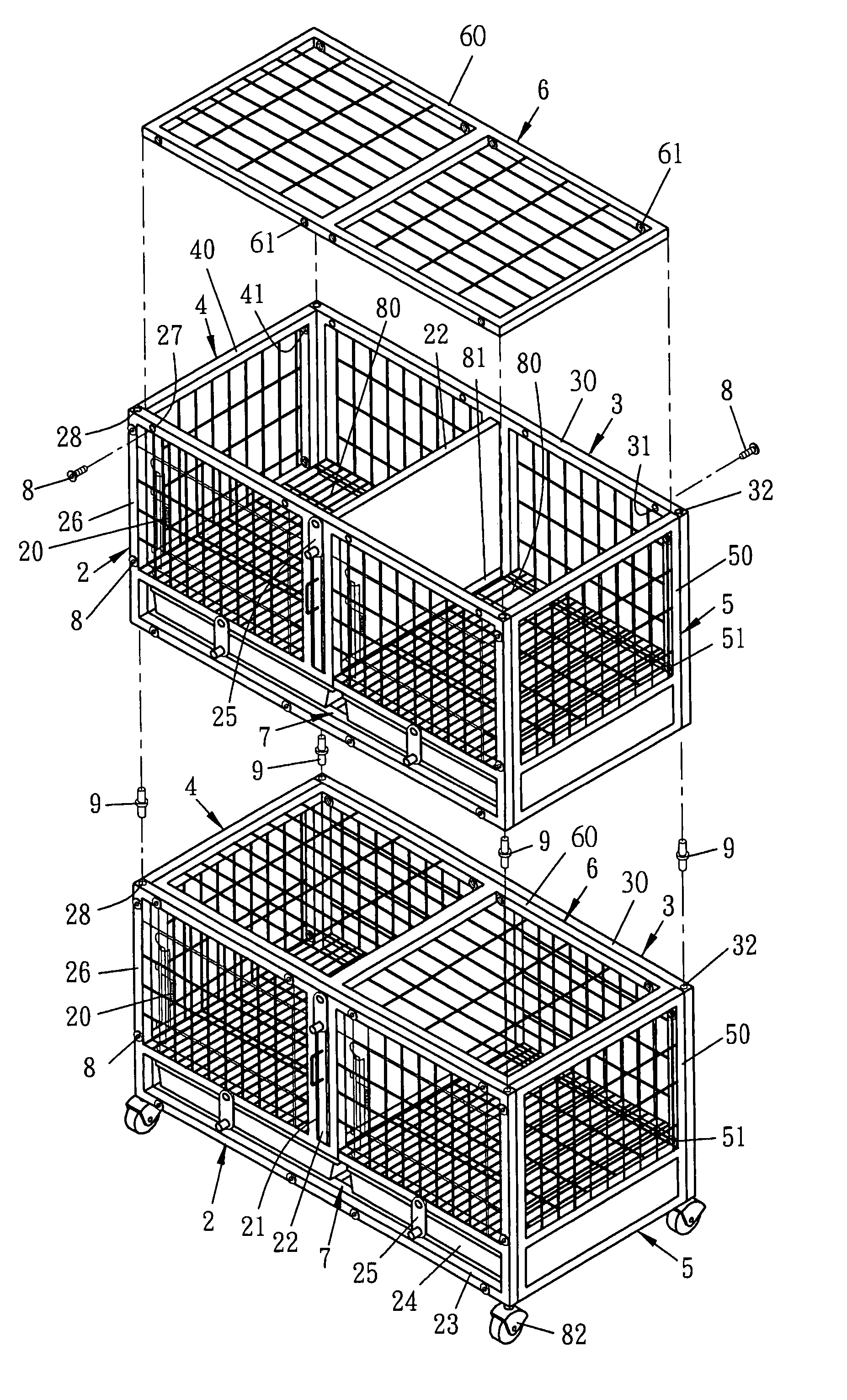

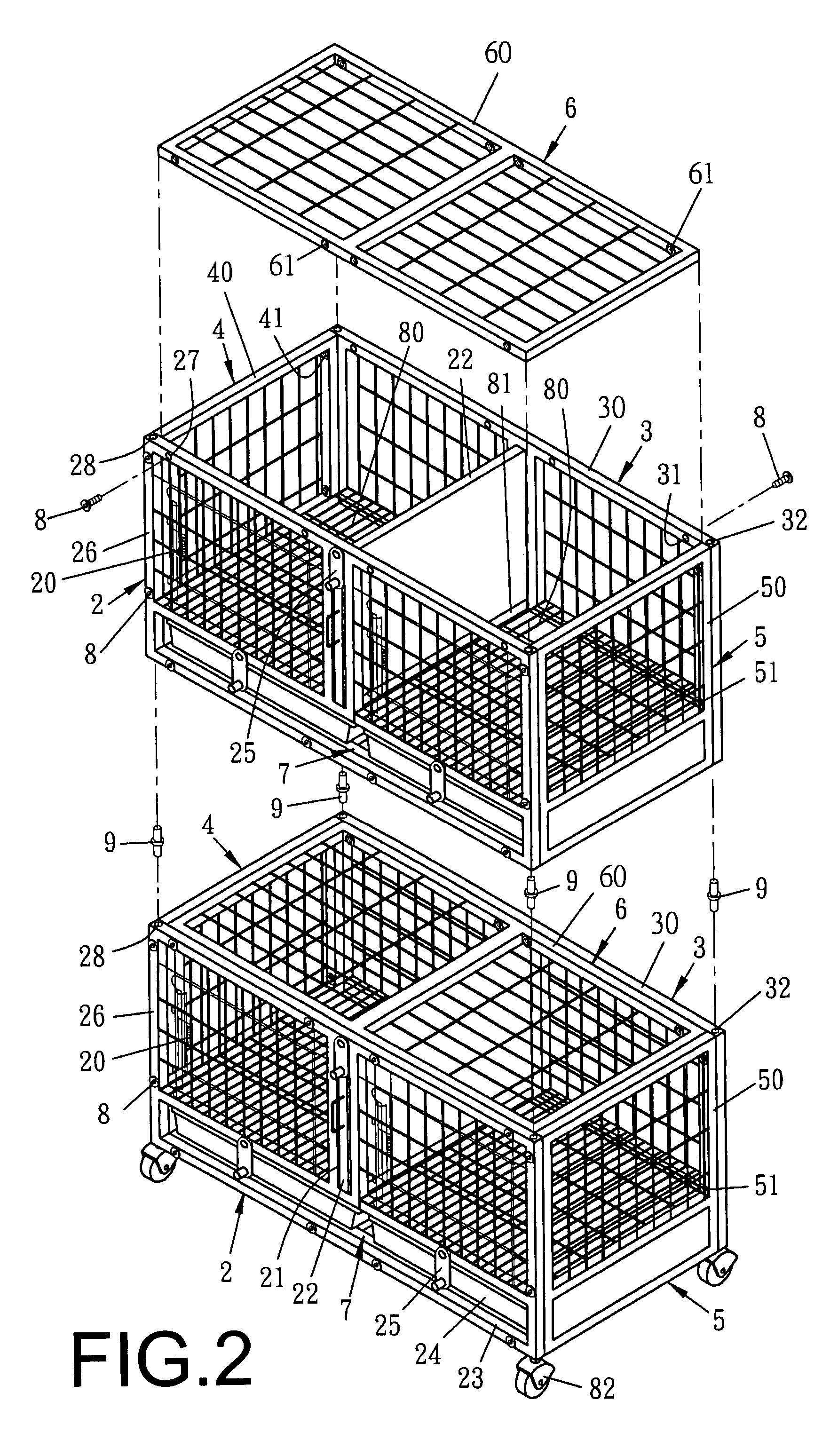

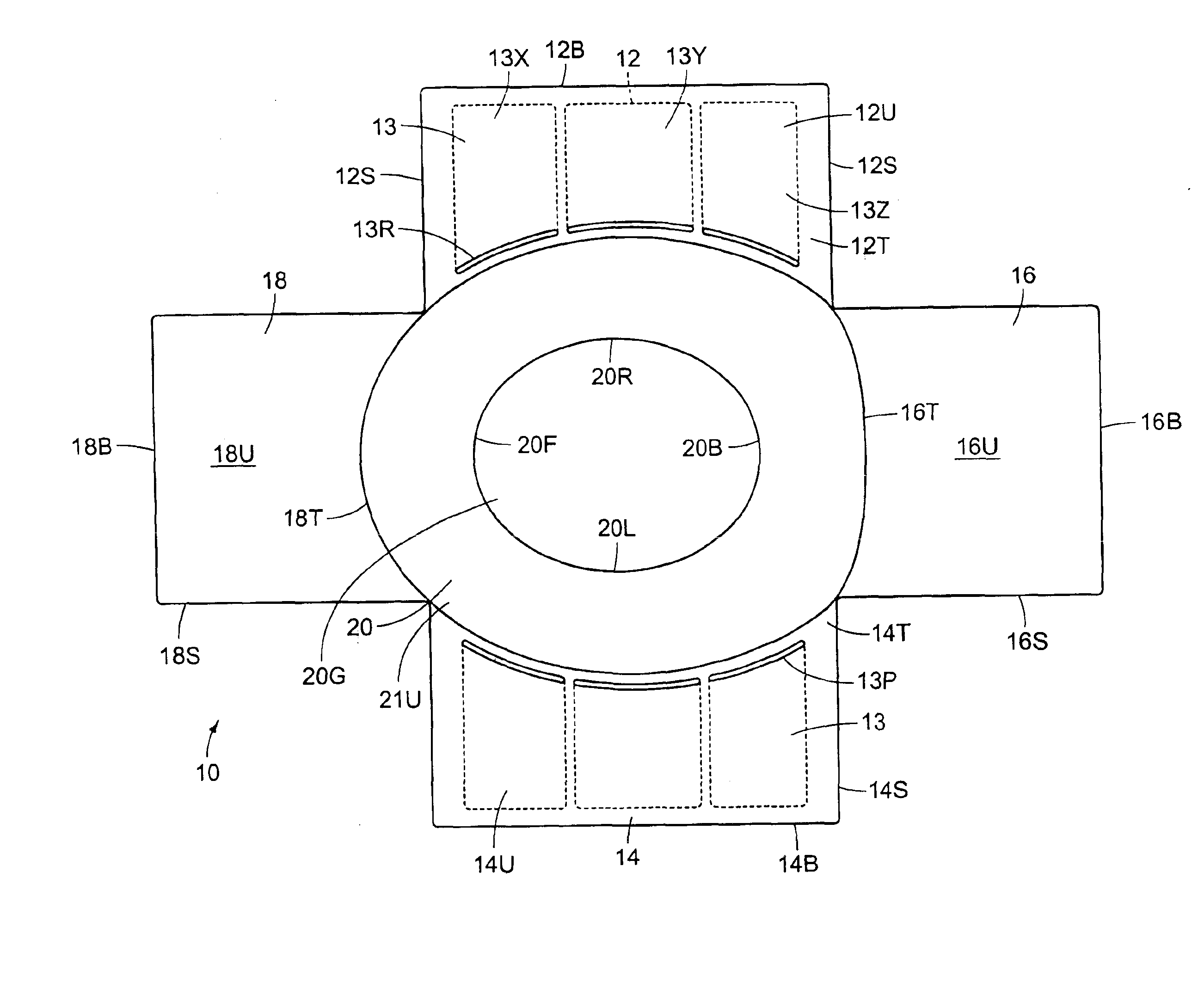

Combinative pet cage

InactiveUS7059274B2Easy to assembleEasily piled up and securedAnimal housingBird housingsMechanical engineeringEngineering

A combinative pet cage comprises a front meshed board, a rear meshed board, a left meshed board, a right meshed board, a top meshed board, a bottom meshed board, a plurality of screw parts, and a plurality of connecting parts. The frame of each of the meshed boards is provided with screw holes for the insertion of the screw parts, whereby the meshed boards will be assembles to form a cage body. The top and bottom faces of the frames of the front meshed board and the rear meshed board are further provided with a plurality of insertion holes, whereby two such combinative pet cages can be connected vertically by the connecting parts. A plurality of pet cages can be connected in the same way, and the combined structure thereby formed will be stable.

Owner:CHENG KUO HO

Portable toilet bowl cover

A portable toilet bowl cover, for selectively and substantially covering an existing toilet bowl, in order to prevent waste which may be present on portions of the toilet bowl from contacting the skin and clothing of an individual who sits upon the seat of the toilet bowl. The toilet bowl cover comprises a circular central seat pad having a left flap, a right flap, a front flap, and a back flap extending therefrom. The left flap and the right flap each have pockets for selectively storing various toiletries. In use, the central seat pad covers the seat of the toilet bowl, and the flaps substantially cover the bowl portion and the lid of the toilet bowl, thereby preventing waste material present upon the seat, the bowl portion, and the lid from coming into contact with the individual seated upon the toilet seat.

Owner:ADAMS TIFFANY

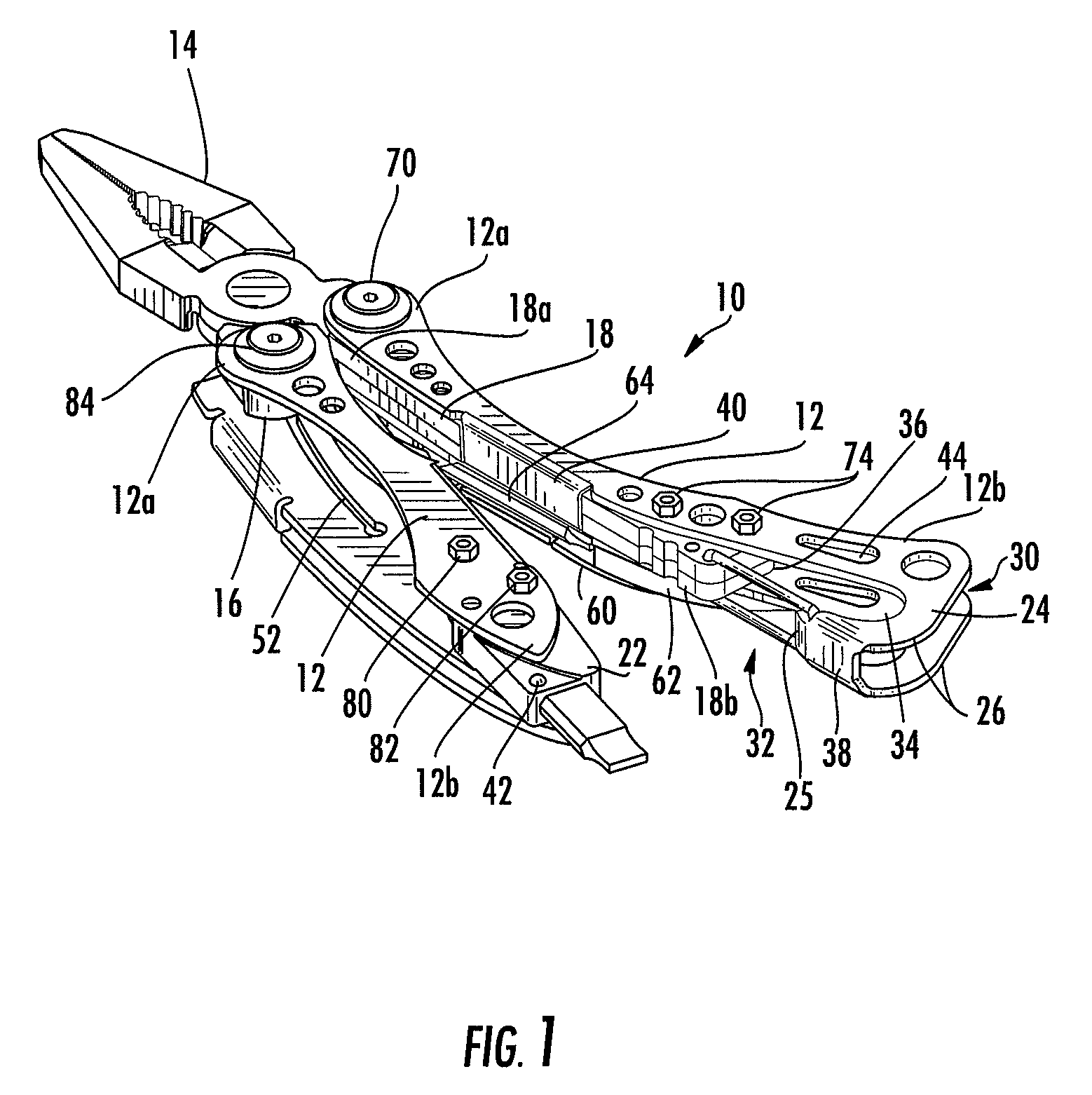

Multipurpose tool

ActiveUS7913591B2Reduce the possibilityFold compactPliersMetal working apparatusMechanical engineeringDrill bit

A multipurpose tool is provided that includes a carabiner and that is designed to fold into a closed position that is relatively compact. As such, the carabiner of the multipurpose tool can be utilized to secure the multipurpose tool to a user, such as to a belt loop or the like, while permitting the multipurpose tool to be folded into a compact form. A handle that includes a carabiner and that can be utilized by such a multipurpose tool as well as a method of forming the handle are also provided. Still further, a multipurpose tool is provided that includes a handle defining a pocket for storing at least one bit in instances in which the bit is not engaged by the bit driver, thereby reducing the likelihood that the bit will be lost or otherwise separated from the multipurpose tool.

Owner:LEATHERMAN TOOL GROUP

Balance Bike

InactiveUS20130020777A1Fold compactPassenger cyclesWheel based transmissionEngineeringMechanical engineering

A balance bike balance bike includes a frame, front and rear wheels, a seat, a joining structure, a front fork, and a steering handle. The joining structure is pivotally joined to the frame and pivotal between first and second positions. The joining structure includes a joining end and a receiving end. The front and rear wheels are disposed apart from each other and the balance bike defines a first longitudinal dimension when the joining structure is in the first position. The front and rear wheels are disposed adjacent to each other and the balance bike defines a second longitudinal dimension when the joining structure is in the second position. The first longitudinal dimension is larger than the second longitudinal dimension.

Owner:CHEN WANG CHUAN

Pot cover holder

InactiveUS20070199908A1Guarantee support safetyWithout fear of burningKitchen equipmentPlatesEngineeringFront cover

An apparatus for supporting pot covers includes a frame movable between a collapsed position and an expanded position; a support for resting the frame on a surface and at least one pot cover support pivotally connected to the frame. The pot cover support further has a leg pivotally engaging the frame, a pot cover knob support and a pot cover handle support.

Owner:KASDEN KEN +1

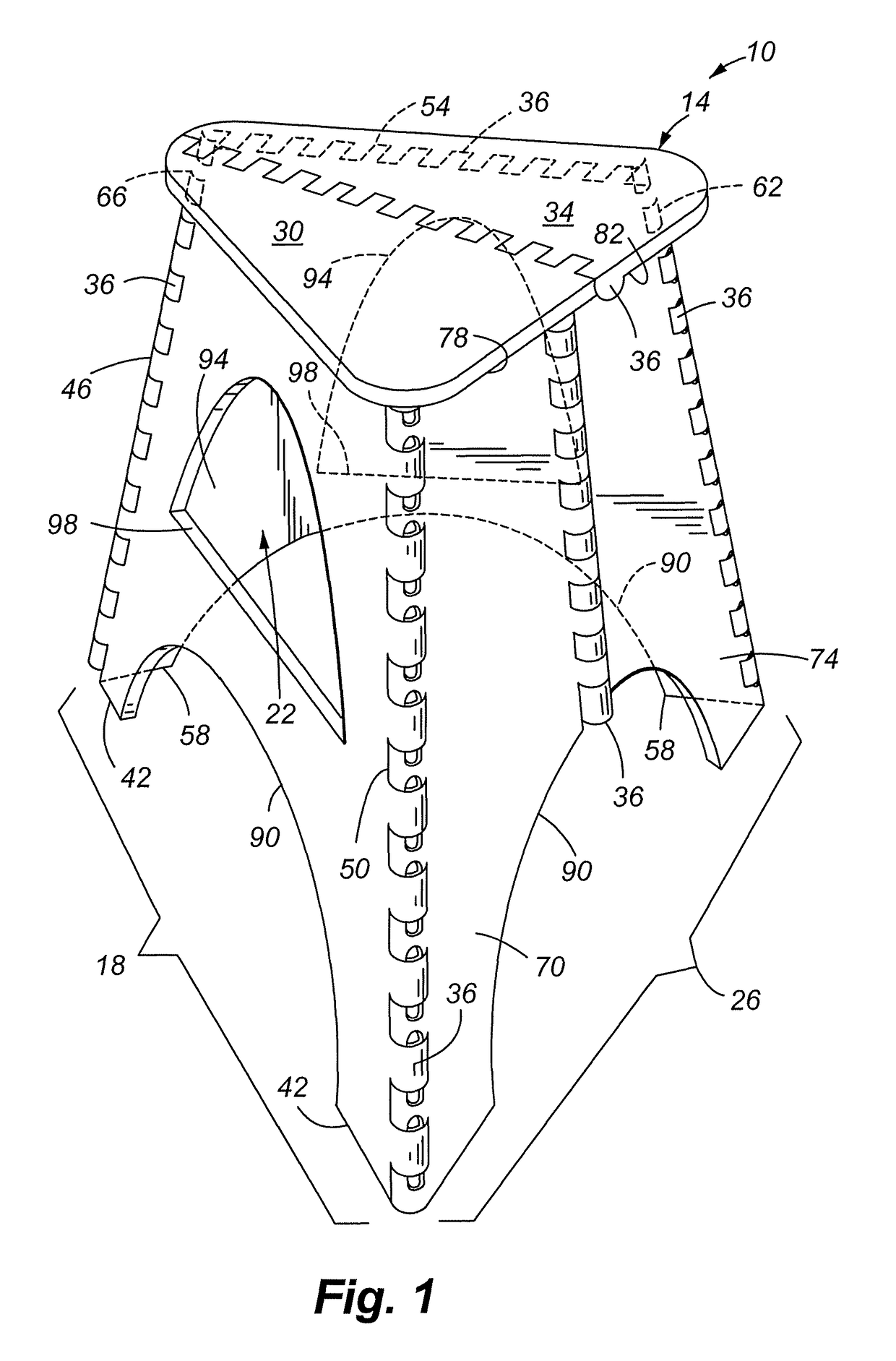

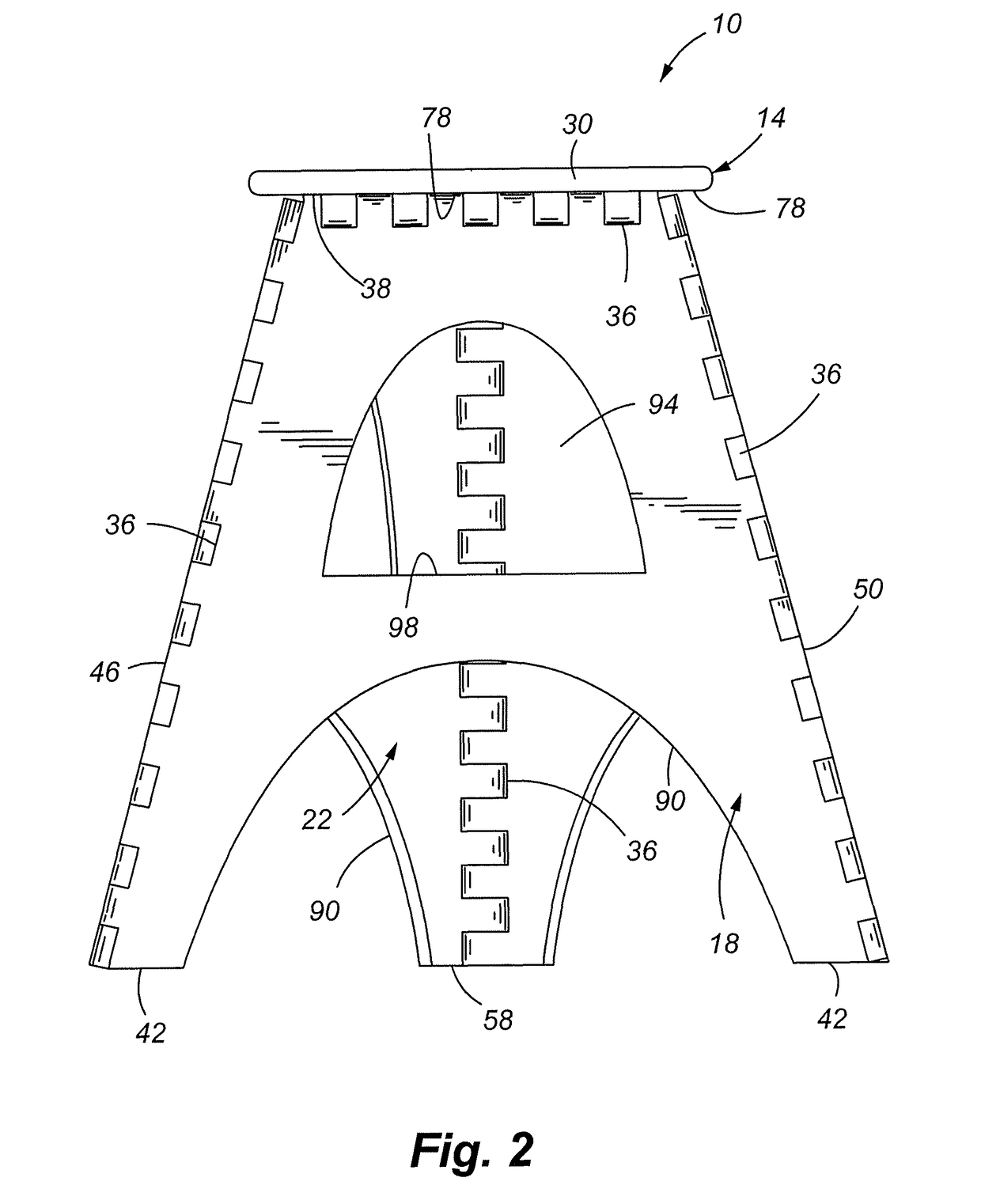

Foldable stool or table

InactiveUS7905184B2Cost-effectiveMaterial minimizationFoldable chairDismountable chairsEngineeringStool seat

Owner:FOLDZ

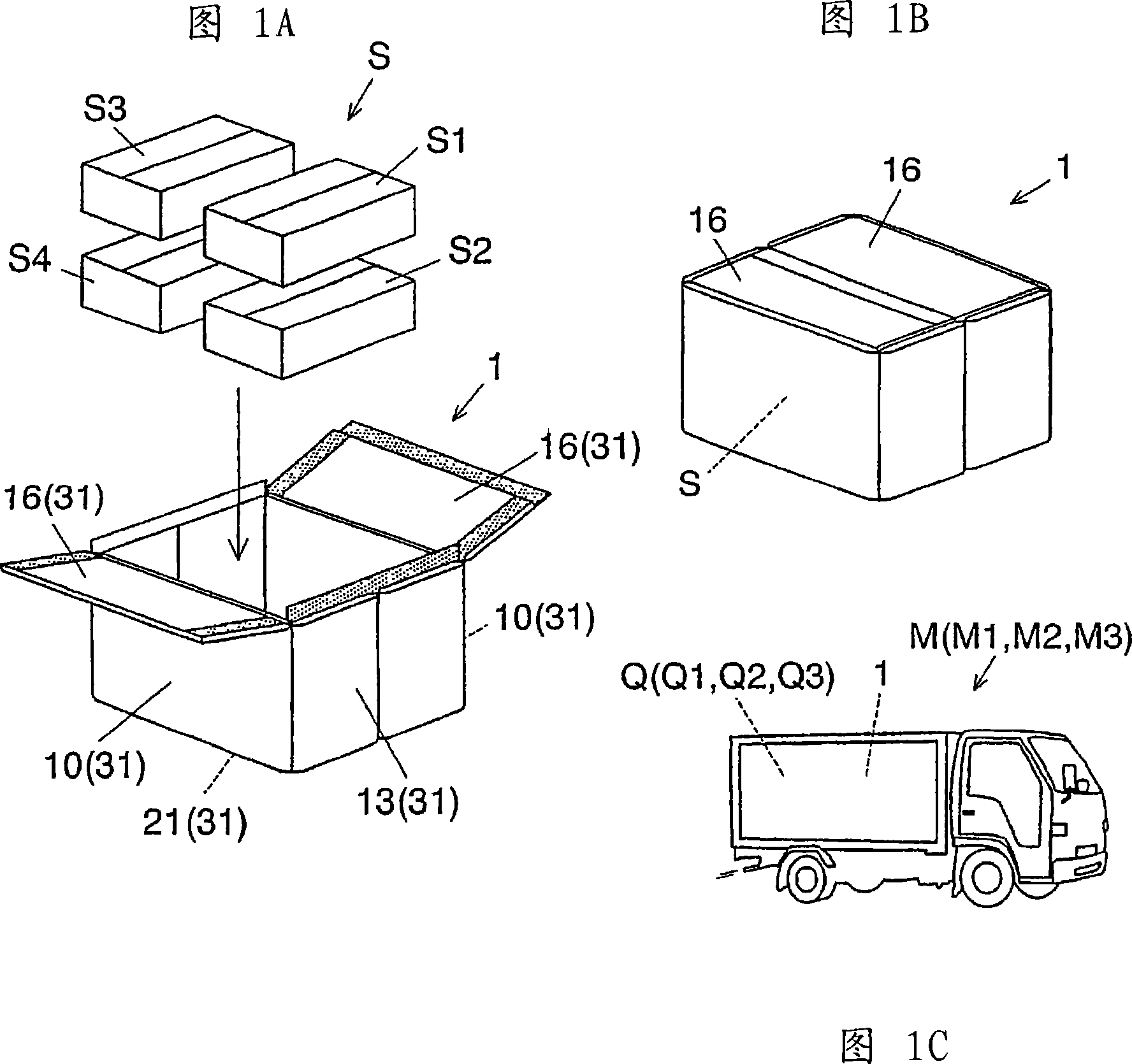

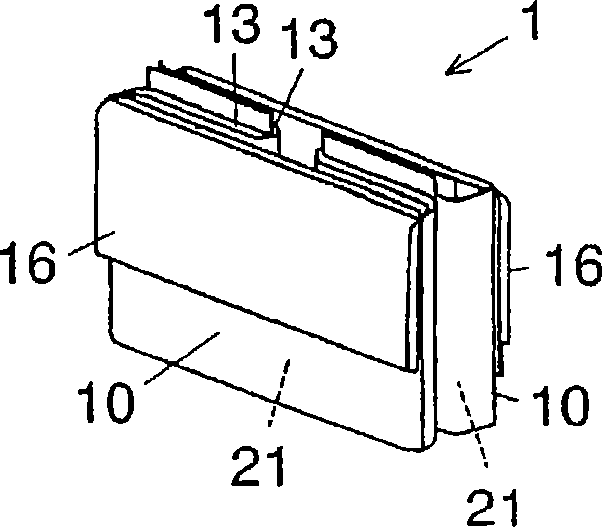

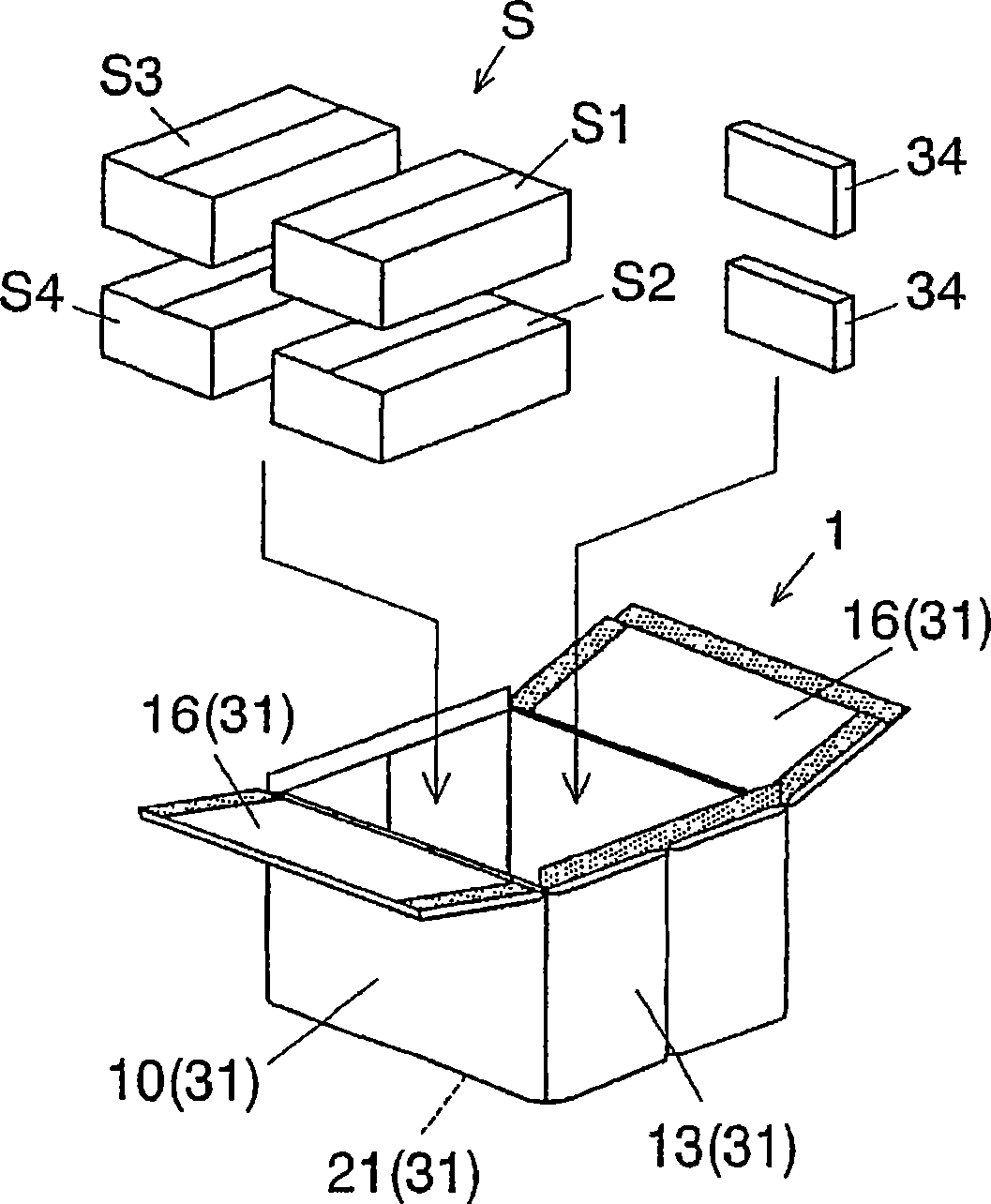

Foldable heat insulating container and distribution method

ActiveCN1914469AReduce delivery costsImprove distribution efficiencyDomestic cooling apparatusLighting and heating apparatusRefrigerator carThermal insulation

Provided is a frozen commodity distribution method reduced in labor and cost while holding the quality of frozen commodities and a cold insulation container unfoldable and foldable in a short time while providing high cold insulation performance. In the distribution method, the frozen commodities requiring cold insulation are stored in the cold insulation container formed of a vacuum thermal insulation material, and the cold insulation container is distributed by a refrigerator car, cold insulation car, or a room temperature car other than a chill car. In the foldable cold insulation container, each of peripheral wall parts, cover parts, and bottom face parts is formed by including the vacuum thermal insulation material in a sheet material, and the peripheral wall parts of the cover parts adjacent to the continuously arranged peripheral wall parts are foldable since the vacuum thermal insulation material is divided along pleat lines. When the container is used, the cover parts and the bottom face parts are rotated in closed attitudes to form into a box. When the container is not used, the bottom face parts are bent to the inside or outside of the peripheral wall parts, the cover parts are bent in the reverse direction of the bottom face parts, and the peripheral wall parts are allowed to approach each other while bending the peripheral wall parts inward along the pleat lines, stacked on each other, and folded.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com