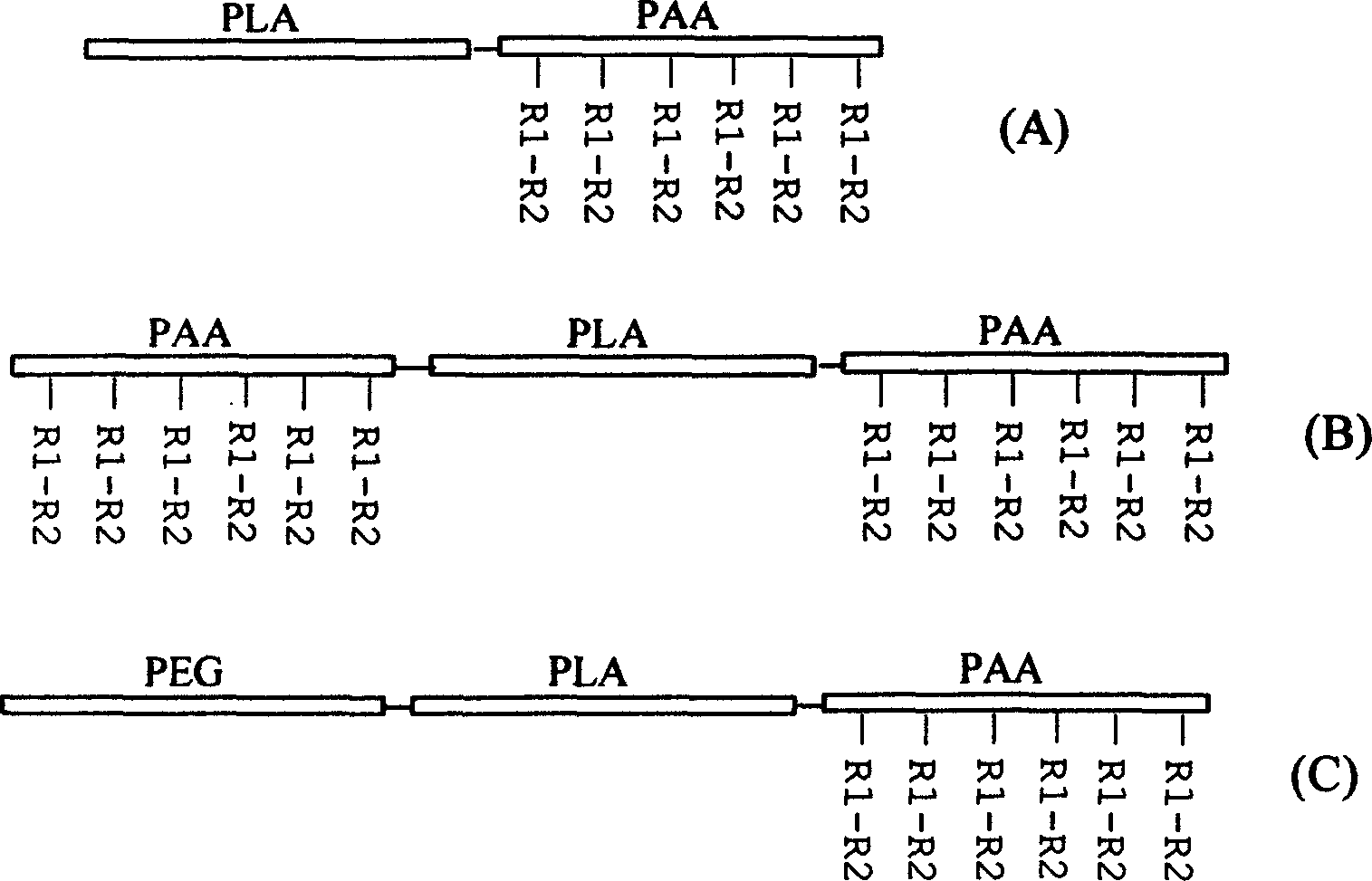

Aliphatic polyester-polyamino acids copolymer with biological function and its synthesis method

A technology of aliphatic polyester and polyamino acid, applied in the field of high molecular polymer biomedical materials, can solve problems such as difficult modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Preparation of polyethylene glycol-polylactide-polyglutamic acid block copolymer by hydrogenation reduction.

[0030] (1) 0.5g polyethylene glycol-aliphatic polyester-polybenzyl glutamate is dissolved in 15ml of tetrahydrofuran, add 5ml of methyl alcohol and a small amount of acetic acid, then add 0.1g of palladium / carbon (10%) as Catalyst, stirred and reacted for a certain period of time under hydrogen bubbling at room temperature, filtered to remove palladium / charcoal, settled with ether, filtered, and vacuum-dried to obtain the product. The results are shown in Table 1.

[0031] make up

[0032] (2) In the autoclave, add 1g of polyethylene glycol-polylactide-polybenzyl glutamate (DP PEG =16,DP PLA =44,DP PBLG =63), dissolve with 30ml dioxane and 10ml methanol, then add a small amount of acetic acid and 0.2g palladium / carbon (10%) as catalyst, react for a certain period of time at 50 ℃ 2 and 8atm, remove palladium / carbon by filtration, use Diet...

Embodiment 2

[0035] Example 2: Preparation of polyethylene glycol-polycaprolactone-polyglutamic acid block copolymer by hydrogenation reduction.

[0036] A certain amount of polyethylene glycol-polycaprolactone-polybenzyl glutamate was added to the reactor, and other reaction steps were the same as in Example 1 to obtain polyethylene glycol-polycaprolactone-polyglutamate segment copolymers. The yield is above 90%.

[0037] Numbering

Embodiment 3

[0038] Example 3: Preparation of polyethylene glycol-polyglycolide-polyglutamic acid block copolymer by hydrogenation reduction.

[0039] A certain amount of polyethylene glycol-polyglycolide-polyglutamic acid benzyl ester is added in the reactor, and other reaction steps are the same as in Example 1 to obtain polyethylene glycol-polyglycolide-polyglutamic acid (Molecular weight PEG=2000, PGA=1000, PLG=6200) block copolymer. The yield is about 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com