Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Prevent pre-setting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

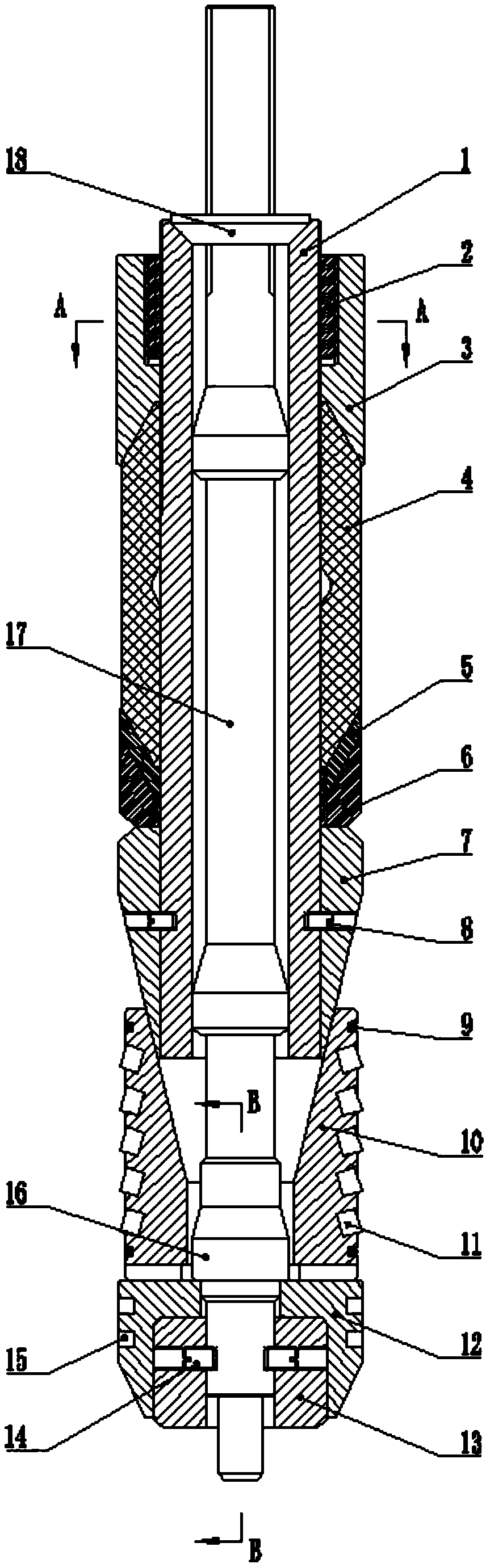

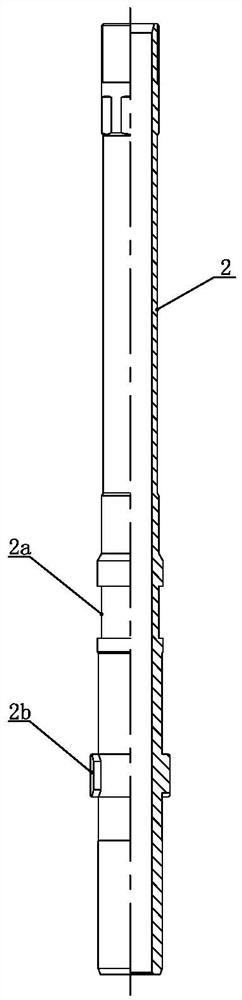

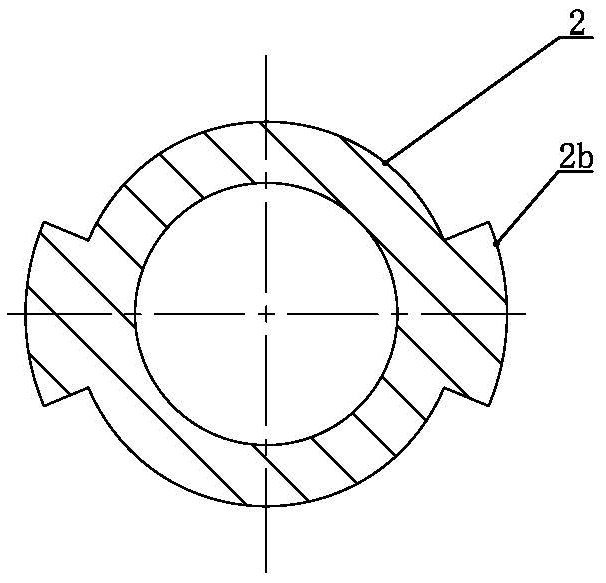

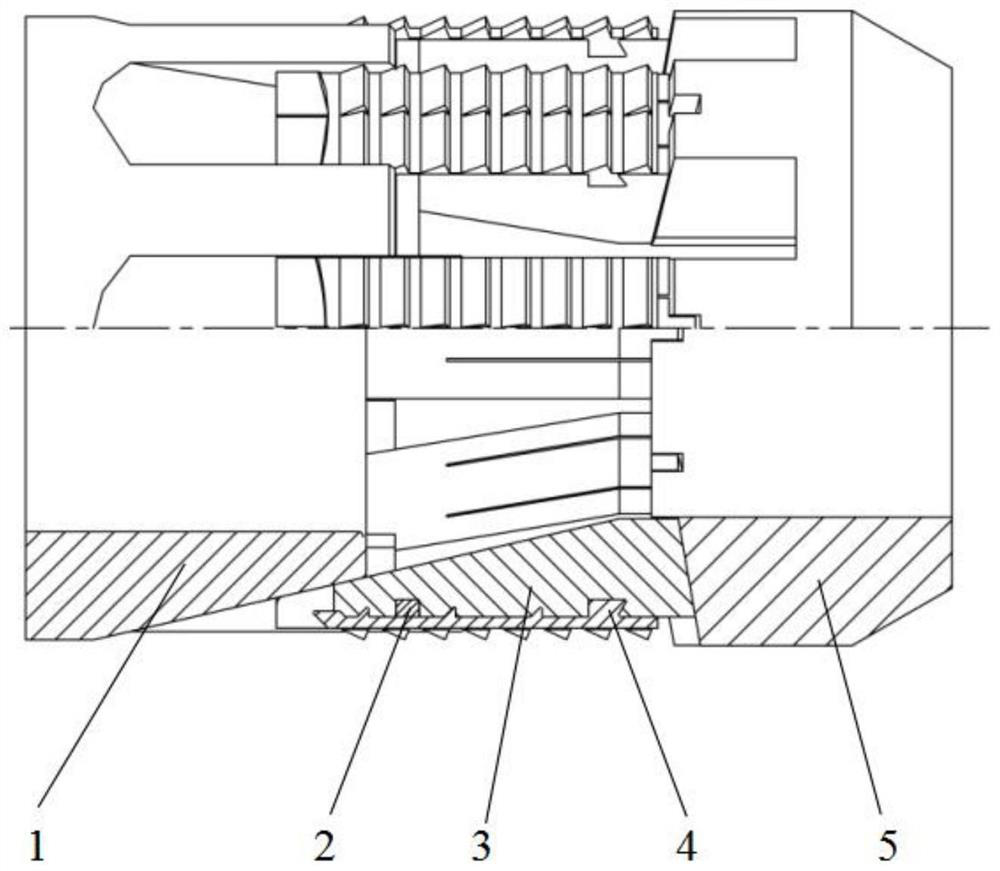

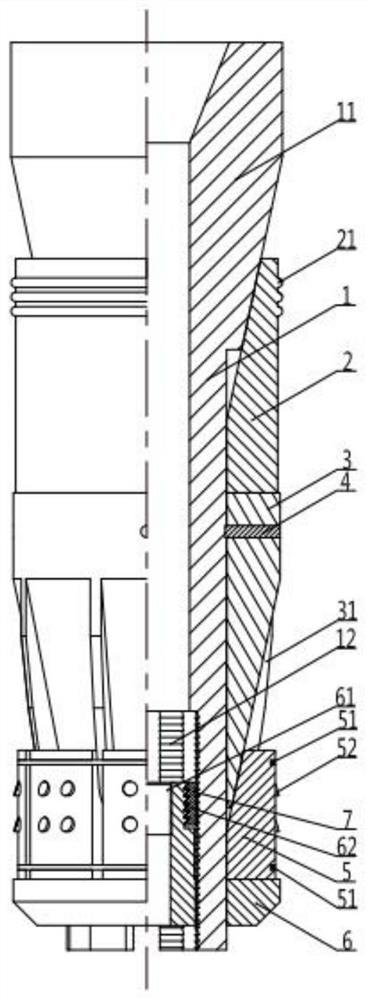

Small-sized soluble bridge plug

The invention relates to a small-sized soluble bridge plug. The small-sized soluble bridge plug comprises a central pipe and a compression sleeve sleeving the upper end of the central pipe and used for compressing a rubber cylinder; a limited C-shaped ring is sandwiched between the compression sleeve and the central pipe; the compression sleeve and the limited C-shaped ring are clamped and fixed by threads; the outer side wall of the central pipe is provided with a thread-like continuous protrusion along the compressed traveling direction of a compression assembly; the inner wall of the limited C-shaped ring is provided with a thread-like continuous groove engaged with the thread-like continuous protrusion. Compared with a traditional double-slip bridge plug, the matched structure of the compression sleeve and the limited C-shaped ring is fixed without expansion produced by relative movements of two components of an existing slip assembly, a setting stroke is greatly decreased, and setting by cable pumping is allowed; in addition, due to the omittion of one slip assembly, the use area on the central pipe is saved, rubber cylinder lengthening design is allowed, and accordingly the expansion degree of the rubber cylinder and improvement of setting capability with expansion increase are ensured.

Owner:四川长宁天然气开发有限责任公司 +1

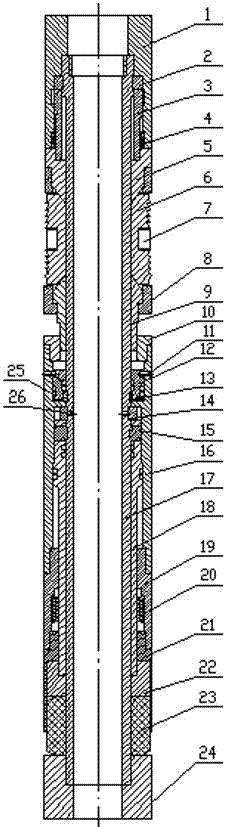

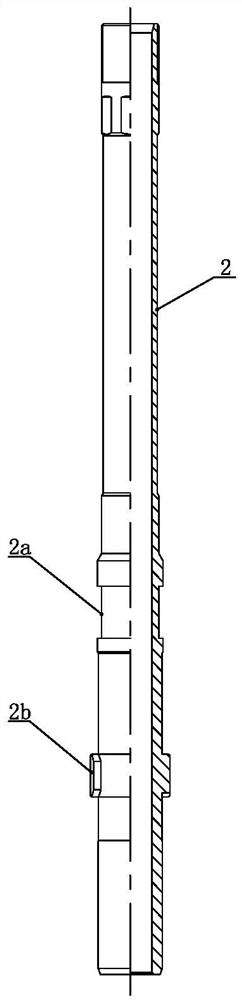

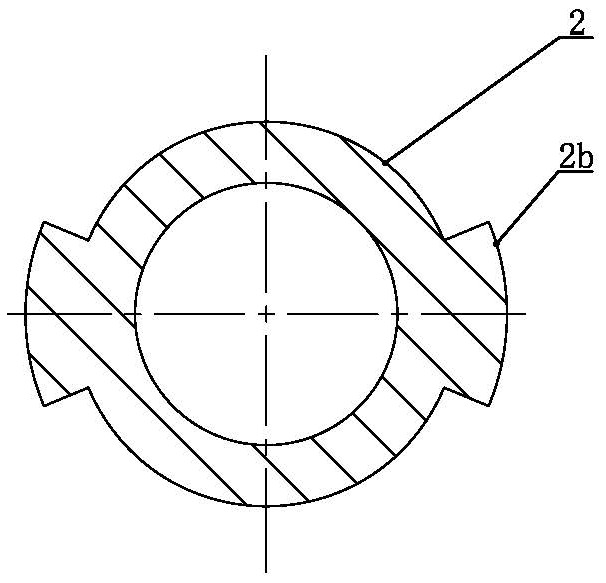

String bearing module and string

PendingCN109653695AIncrease elasticityAvoid getting stuckDrilling rodsFluid removalElastic componentEngineering

The invention discloses a string bearing module and a string and belongs to the field of petroleum and natural gas sand control completion. The string comprises a setting device and a packer which areconnected through the string bearing module; the string bearing module comprises an elastic clamp, bearing lugs, pin shafts and elastic components, wherein the elastic clamp comprises an elastic clamp body and a plurality of elastic claws, which are connected with each other, and the elastic clamp body is provided with a plurality of lug grooves for accommodating the elastic lugs; mandrel holes penetrating through the lug grooves are formed in the elastic clamp body in the axial direction of the elastic clamp body; every bearing lug comprises a bearing lug body, a first protrusion and a second protrusion, wherein the first protrusion and the second protrusion are formed on the bearing lug body, a grove is formed between the first protrusion and the second protrusion, the bearing lug bodyis provided with an elastic component hole, which corresponds to the groove and is used for accommodating the corresponding elastic component; the pin shafts sequentially penetrate through the mandrelholes and the grooves; one end of every elastic component abuts against the corresponding pin shaft.

Owner:DRIPRO

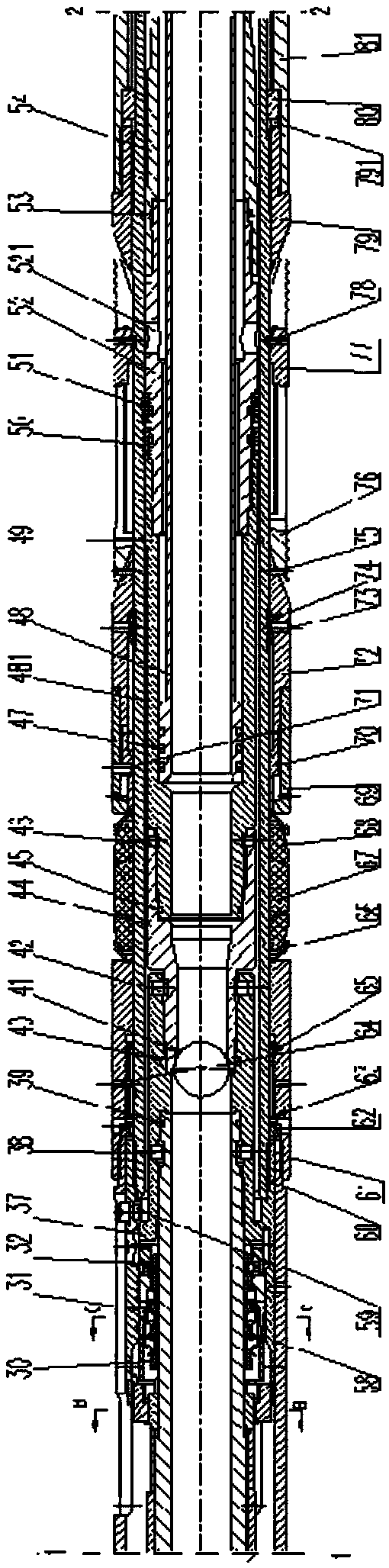

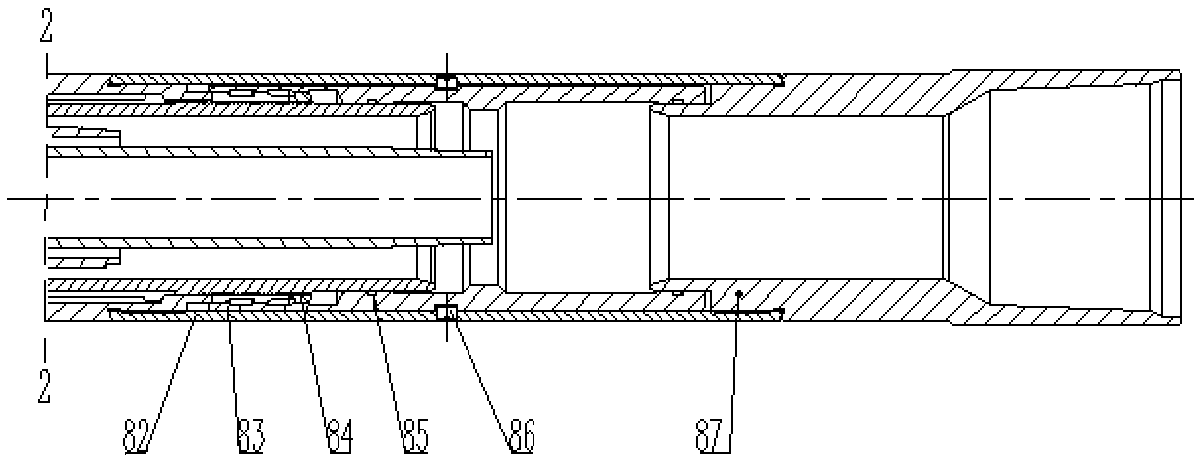

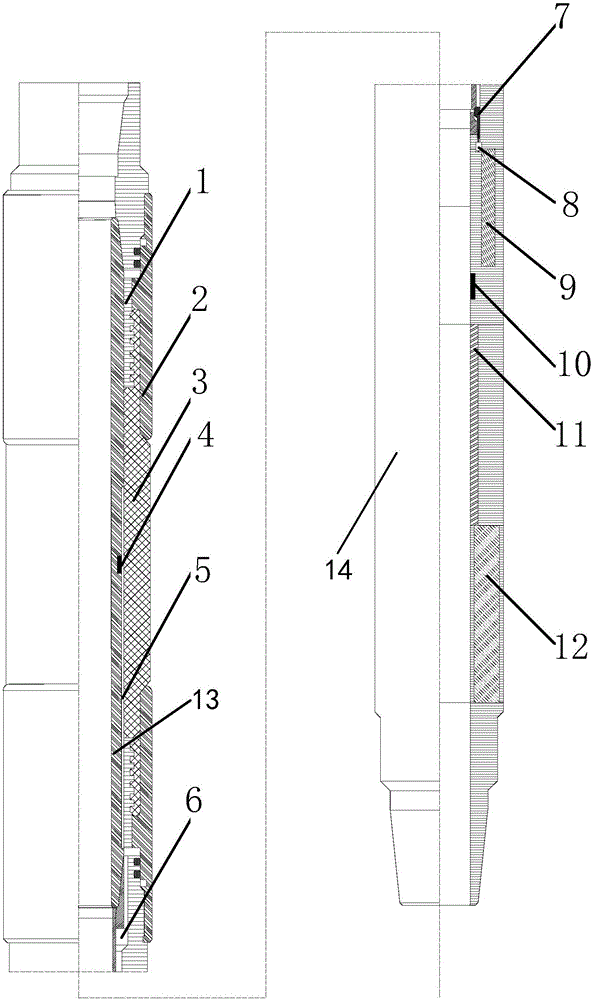

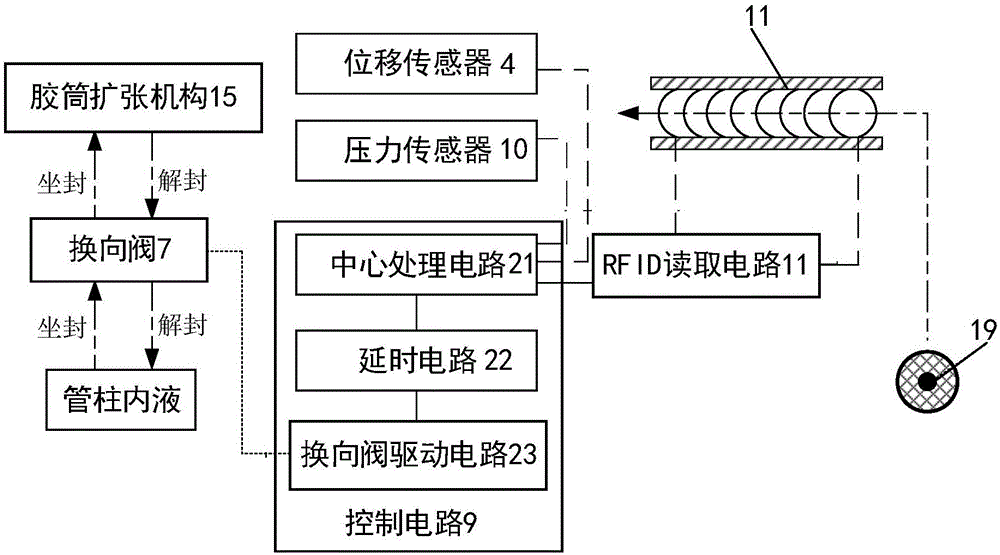

Remote controlled packer capable of preventing pre-mature packing

InactiveCN105134126AGuaranteed normal readPrevent pre-settingSealing/packingRemote controlEngineering

The invention discloses a remote controlled packer capable of preventing pre-mature packing. A main body inner liner is arranged in a rubber cylinder, and a displacement sensor is installed on the outer wall of the main body inner liner to detect the expansion and contraction of the rubber cylinder and send the expansion and contraction to a control circuit. A reversing valve is arranged on an oil path between an oil source and a rubber cylinder expansion mechanism, and a pressure sensor is installed on the inner wall of the main body to detect the pressure in a tubing string and send the pressure information to the control circuit. An RFID reading circuit reads information carried by an RFID label in the tubing string and sends the information to the control circuit. The control circuit controls the reversing valve to switch to the first valve position when the pressure value received by the pressure sensor remains greater than a preset pressure for a preset time period continuously, switch to the third valve position when the displacement received by the displacement sensor remains greater than a preset displacement, and switch to the second valve position when a releasing command is received by the RFID reading circuit. Premature packing of the packer can be prevented.

Owner:CNPC BOHAI DRILLING ENG

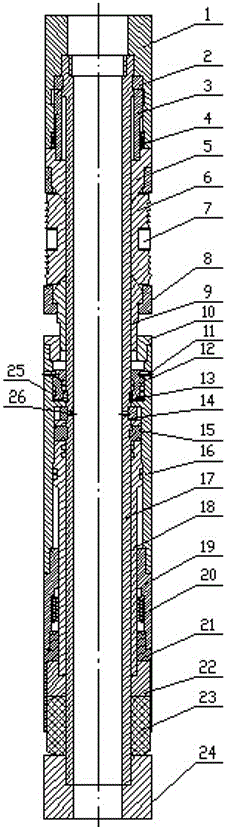

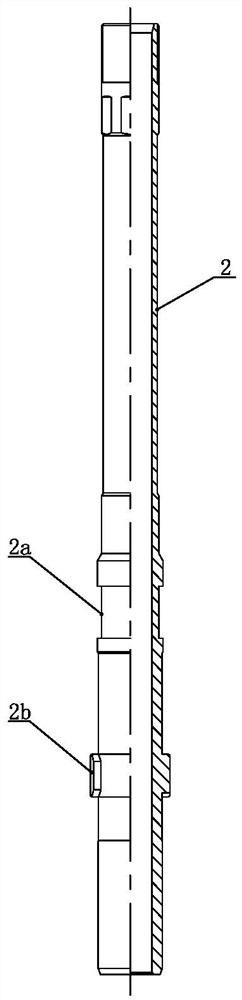

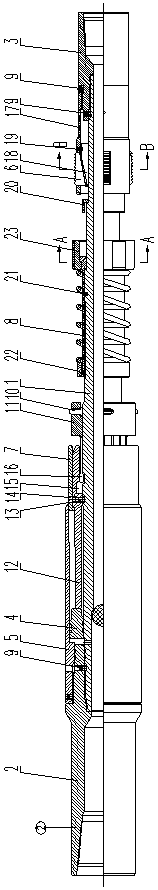

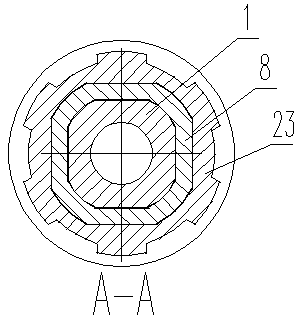

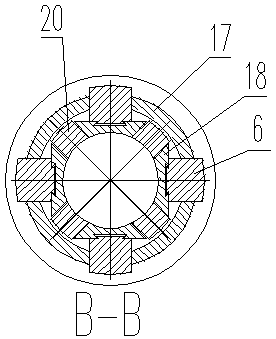

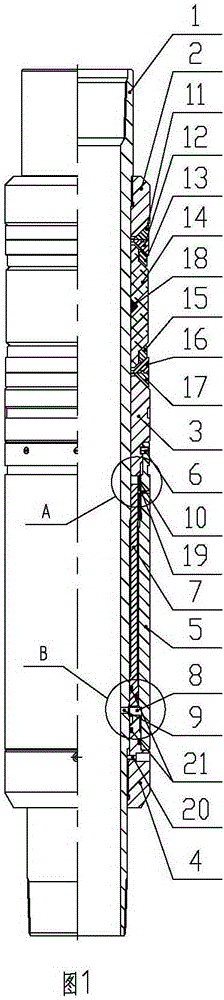

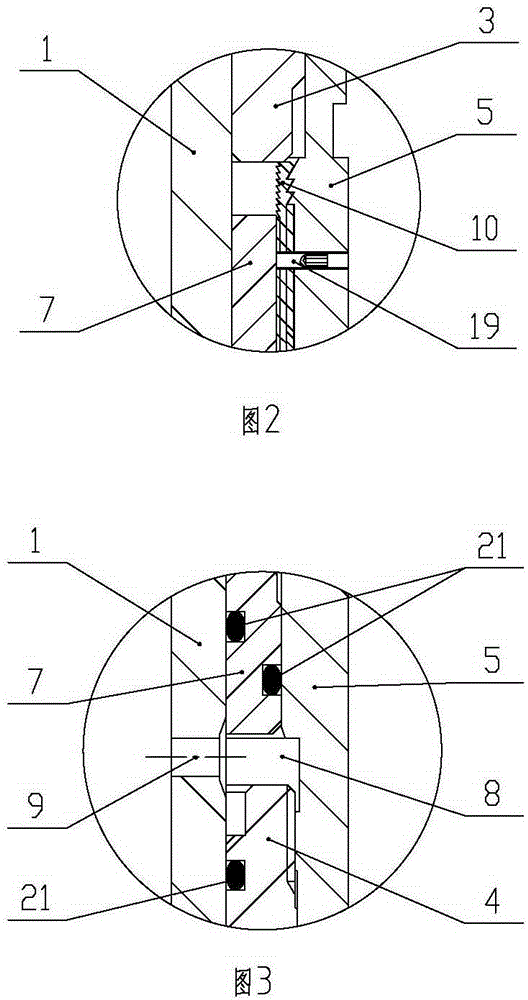

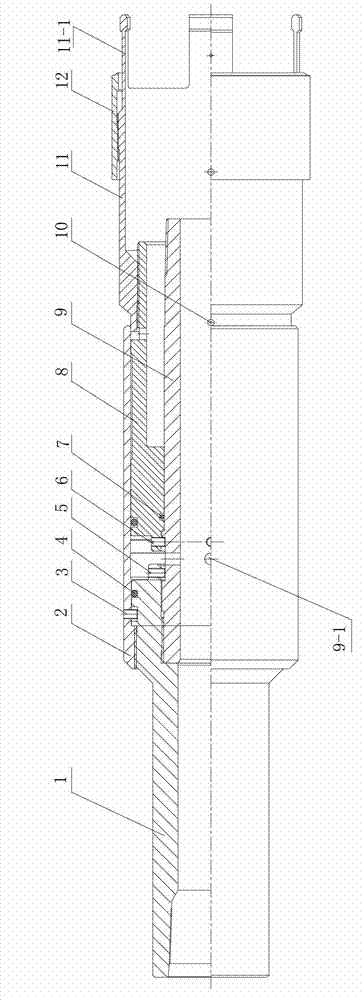

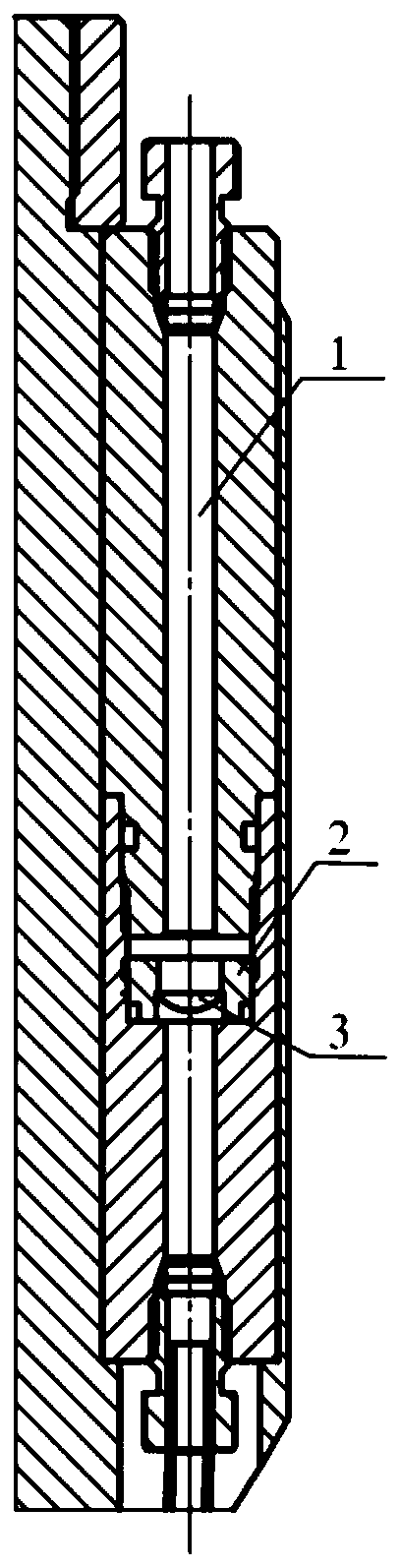

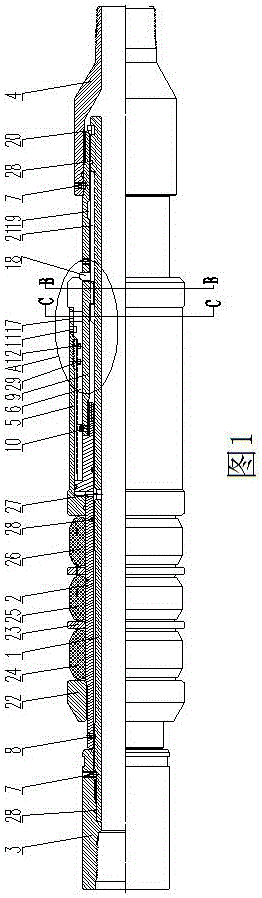

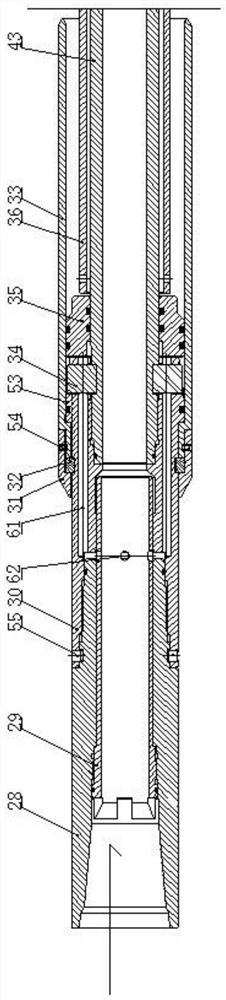

Hydraulic setting and rotating unlocking packer

The invention relates to a hydraulic setting and rotating unlocking packer, and belongs to the field of oil gas well underground working tools. The packer comprises an inner central pipe, an outer central pipe, an upper connector, a lower connector, a piton sleeve and a release sleeve. The upper connector is arranged at one end of the inner central pipe in a threaded mode. An outer central pipe is arranged on the portion, on one side of the upper connector, of the inner central pipe. A middle connector is arranged on the portion, on one side of the outer central pipe, of the inner central pipe. One end of the middle connector is connected with the outer central pipe in a threaded mode, and the other end of the middle connector is provided with the lower connector in a threaded mode. The packer is compact in structure; a setting mechanism and an unlocking mechanism are exquisite in design; by means of a shearing pin arranged in the setting mechanism, setting conducted in advance can be effectively prevented; the setting force is locked and kept through a locking ring after setting is conducted, and setting is durable and effective; the defects caused when multiple packers are unlocked by providing large torque are effectively avoided. The packer is particularly suitable for production, water (gas) injection, interlayer packing, separated injection and production, multi-layer testing and yield increase work of vertical shafts and small-inclination wells.

Owner:荆州市赛瑞能源技术有限公司

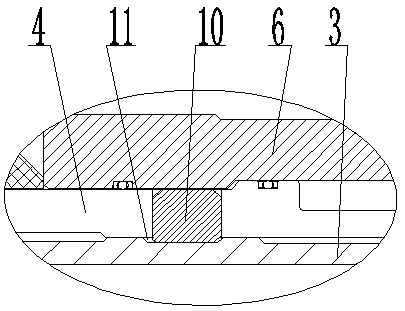

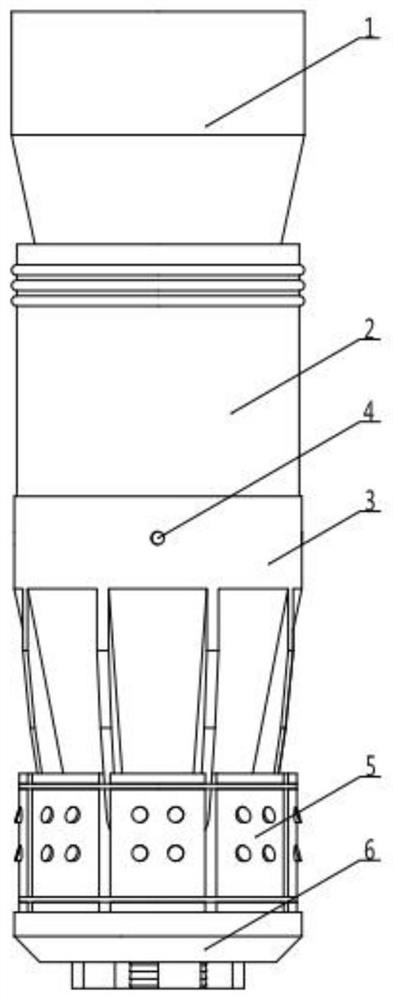

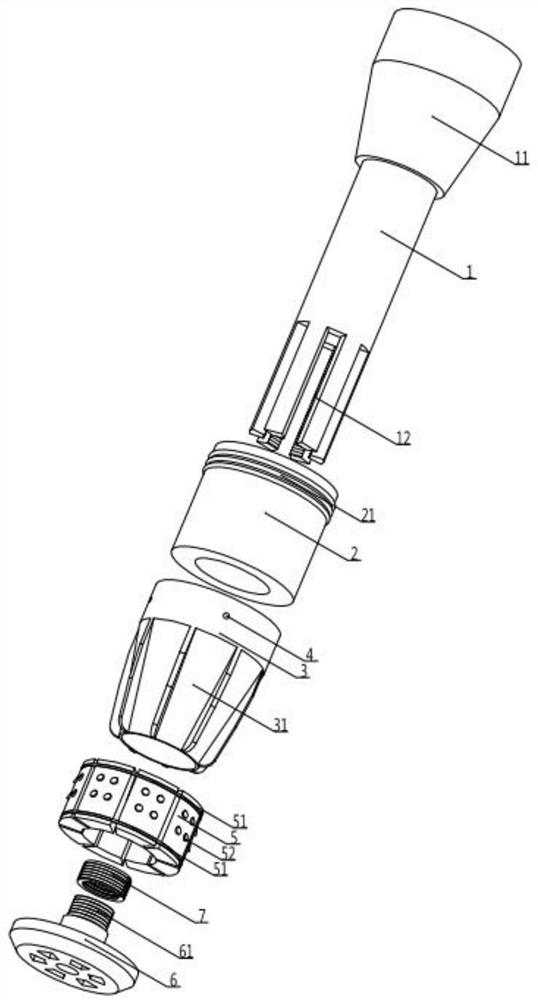

All-metal double-slip soluble large-drift-diameter bridge plug

The invention discloses an all-metal double-slip soluble large-drift-diameter bridge plug comprising an adapter. The bridge plug is characterized in that the adapter is connected with one end of the bridge plug and penetrates through a center pipe; the bridge plug comprises a push ring (2), an upper slip (3), a cone (4), a lower slip (5), a joint (6), a fixed wire (7), a center pipe (8), a shear pin (9) and a friction bean (12). The shear pin (9) is connected with the adapter (1) and a center pipe (10). The fixed wire (7) is connected with the joint (6) and the center pipe (10). The all-metaldouble-slip soluble large-drift-diameter bridge plug has the advantages that magnesium-lithium cone replaces traditional rubber sealing material, cost is reduced, green and environmental protection effects are achieved, the structure is simple, and the size becomes smaller.

Owner:陕西海格瑞恩实业有限公司

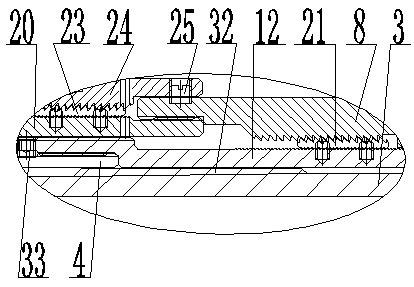

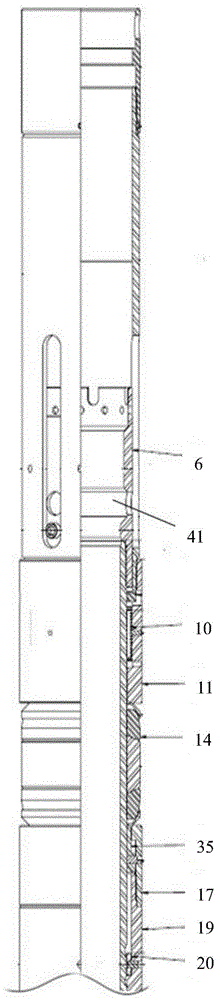

Hydraulic packer for preventing resistance encountering

The invention relates to a hydraulic packer for preventing resistance encountering, and belongs to the technical field of downhole operation tools. The hydraulic packer is composed of an upper joint,a lower joint, an inner central tube, an outer central tube, an upper cone and a lower cone; one end of the inner central tube is connected with the upper joint, the other end of the inner central tube is connected with the lower joint, the outer central tube is movably mounted on the inner central tube, one end of the outer central tube is connected with an upper guiding ring, and the other end of the outer central tube is in threaded connection with a releasing sleeve; the lower cone is mounted at one end of the releasing sleeve; a lower guiding ring is movably mounted on the outer central tube, the other end of the lower guiding ring is in threaded connection with a piston sleeve, and an upper piston and a lower piston are movably mounted in the piston sleeve; and an upper piston retaining ring is fixedly mounted on the position, between the upper piston and the lower piston, of the outer central tube. The hydraulic packer is simple in structure and ingenious in design, the problemthat an existing pack is extremely prone to setting in advance is solved, and the demands of oilfield use are met.

Owner:荆州市赛瑞能源技术有限公司

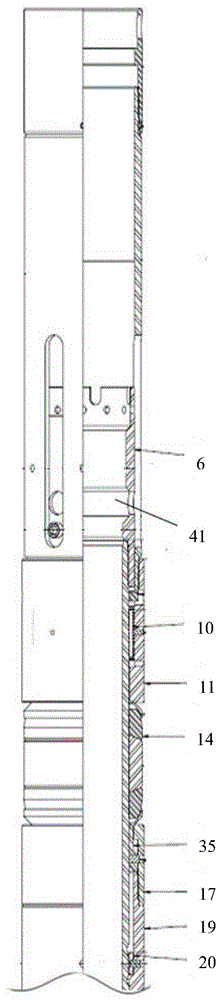

Anti-scouring packer

ActiveCN105696966AAvoid breakingPrevent eccentric wear damageSealing/packingHydraulic cylinderLower limit

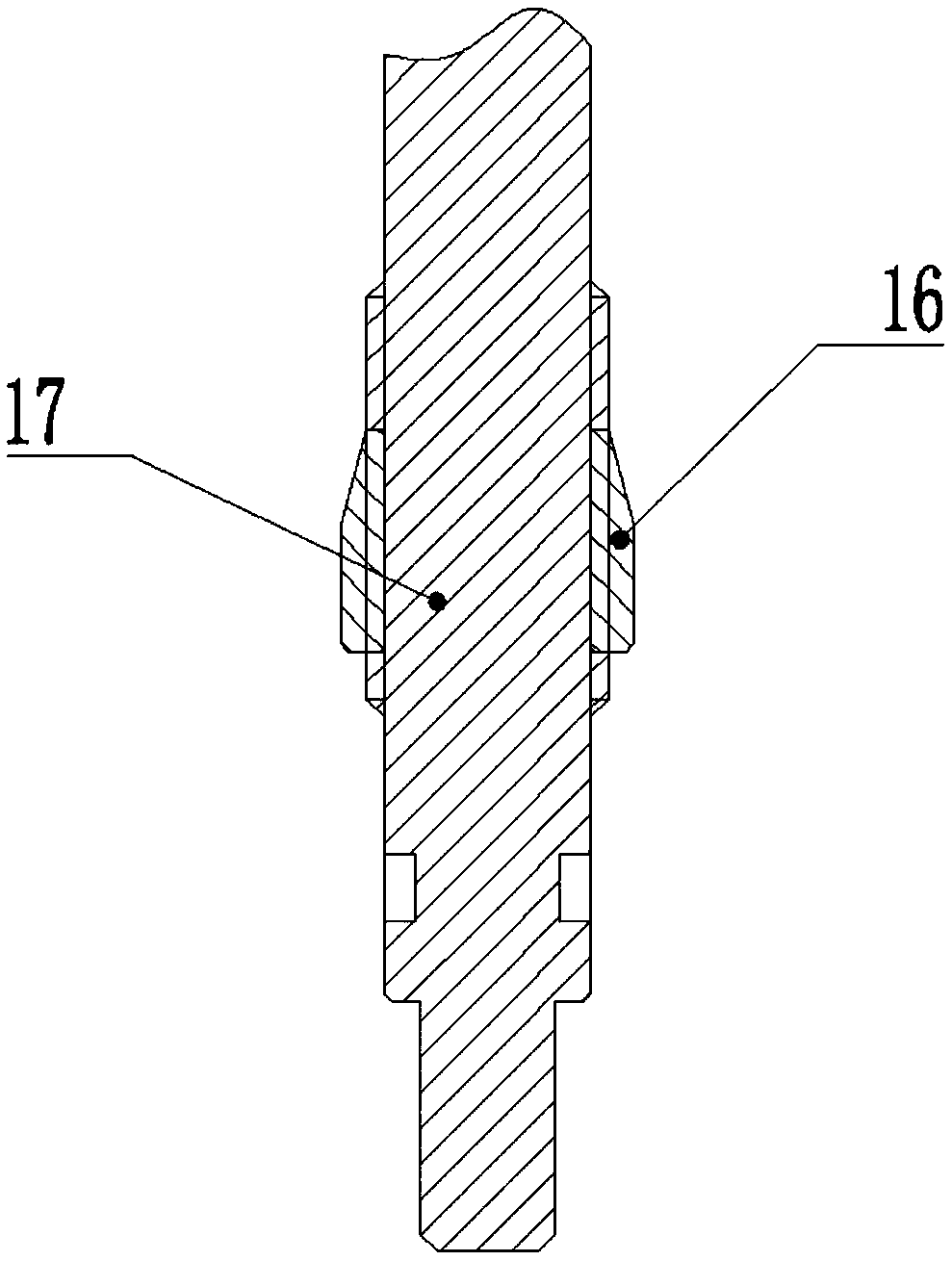

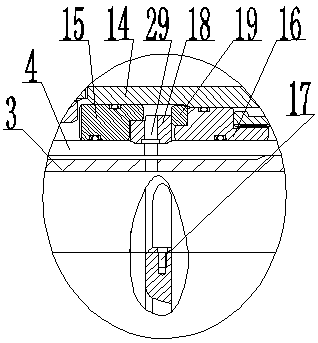

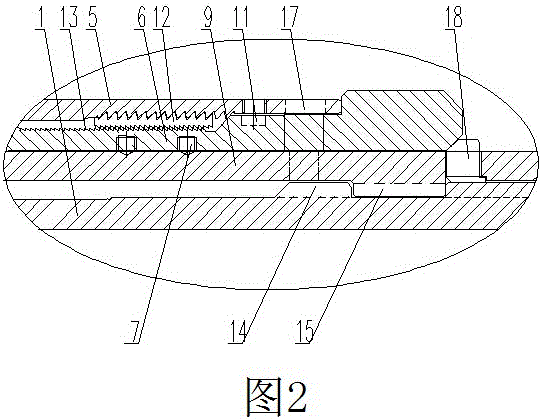

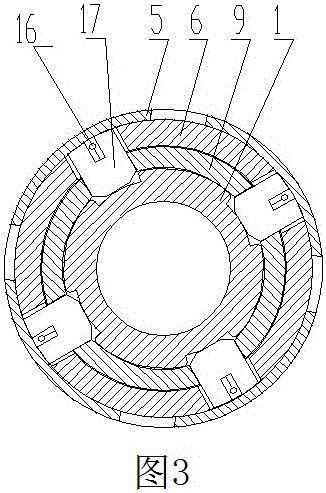

An anti-scouring packer comprises an unpacking joint, an unpacking ring, a connecting joint, a stopping ring, an upper taper 5, a slip, a leaf spring, a slip cover, a lower taper, an upper pressing cap, a setting pin, a piston, an upper limit ring, a lower limit ring, a locking block, a spindle, a pressure transmitting inner sleeve, a pressure transmitting sleeve, a locking ring, a rubber cylinder protecting cover, a sliding joint, a rubber cylinder and a lower joint, wherein the spindle is mounted and connected between the interior of the unpacking joint and the interior of the lower joint; the unpacking ring, the connecting joint, the upper taper, the slip, the slip cover, the lower taper, the upper pressing cap, the piston, a hydraulic sleeve, the pressure transmitting inner sleeve, the pressure transmitting sleeve, the rubber cylinder protecting cover, the sliding joint and the rubber cylinder are sequentially mounted on and connected with the outer side of the spindle. The anti-scouring packer has the characteristics that eccentric wear damage is not prone to occur when normal-circulation mud displacement or reverse-circulation large-displacement backwashing is performed in a straight well, an inclined well or a horizontal well, and when the rubber cylinder passes through an inclined well section, setting cannot appear in advance during scraping on the well wall; a single hydraulic cylinder structure is adopted, the anti-scouring capacity is high, the service life of the rubber cylinder is long, and the like, therefore, the packer is widely applied to downhole operation processes for oil exploitation.

Owner:DONGYING FLUID SCI & TECH

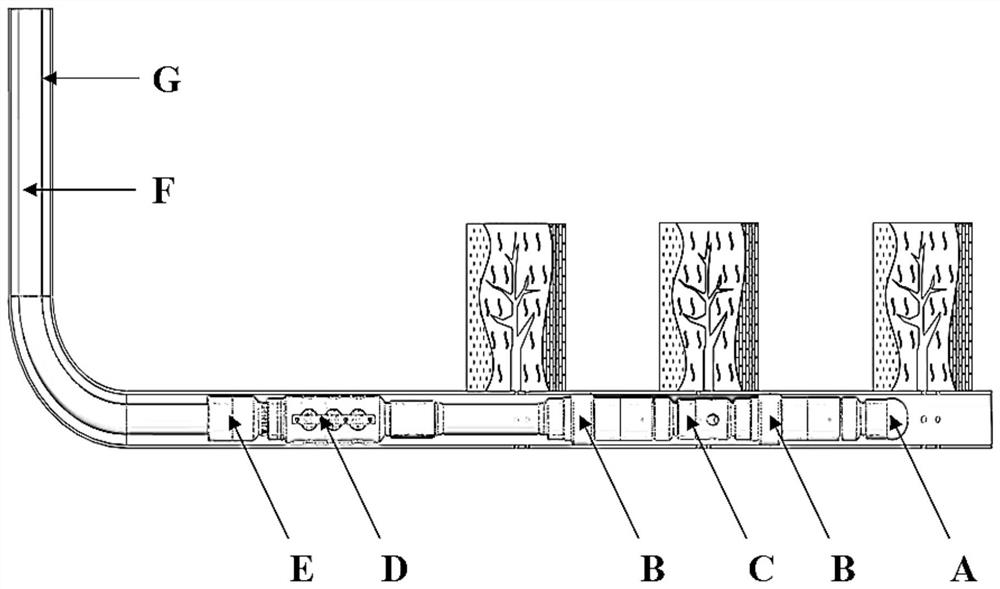

Oil pipe dragging fracturing pipe column with packer as bottom seal and fracturing method

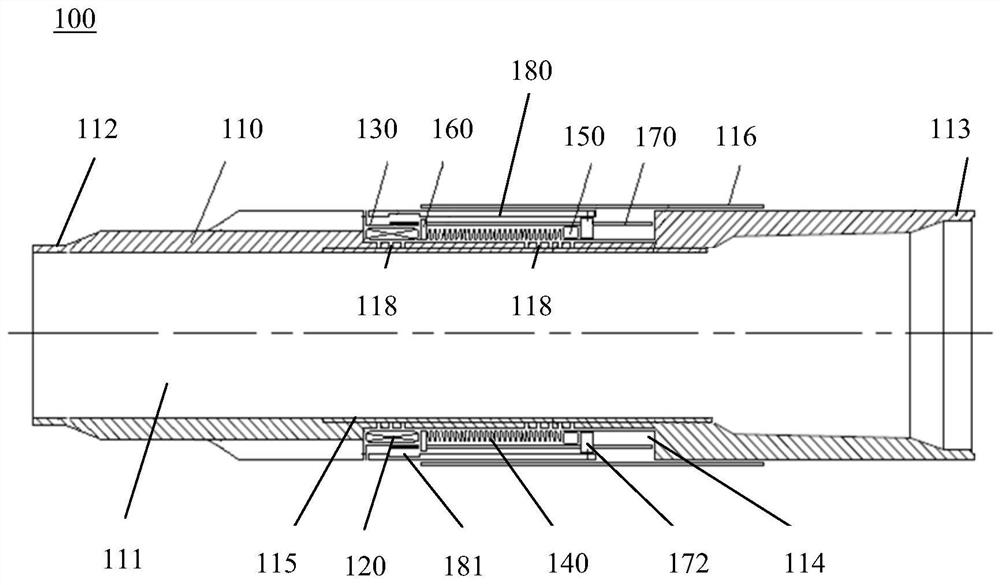

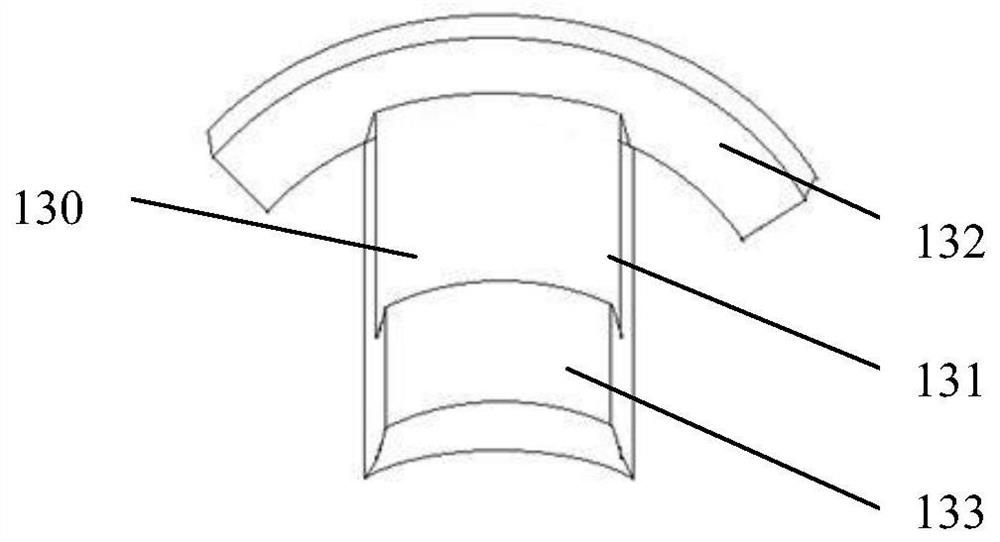

InactiveCN112523734APrevent pre-settingImprove securityFluid removalSealing/packingHorizontal wellsTripping

The invention discloses an oil pipe dragging fracturing pipe column with a packer as a bottom seal and a fracturing method. The oil pipe dragging fracturing pipe column comprises a flow guide ball seat, a sand prevention hydraulic anchor, a throttling-free self-service unsetting packer, a hydraulic ejector and a hydraulic safety connector connected to the upper part of the hydraulic ejector through an oil pipe, wherein the flow guide ball seat, the sand prevention hydraulic anchor, the throttling-free self-service unsetting packer and the hydraulic ejector are sequentially connected from bottom to top. The flow guide ball seat comprises a cylindrical body, a valve ball and a baffle ring, wherein the valve ball and the baffle ring are arranged in the cylindrical body from bottom to top; andthe packer comprises a pipe body structure, a sealing mechanism and a power mechanism, wherein the sealing mechanism and the power mechanism sleeve the pipe body from bottom to top, and a compressionspring is arranged in the power mechanism and can move upwards under the hydraulic action to compress the sealing mechanism to form setting. According to the oil pipe dragging fracturing pipe columnwith the packer as the bottom seal and the fracturing method, the tripping-in safety of the fracturing tubular column can be improved, setting and unsetting are achieved through pressure changes in the fracturing tubular column, throttling is not needed, the tripping-in and tripping-out processes of the tubular column are convenient to operate, the fracturing operation efficiency is high, the costis low, the risk is small, and the oil pipe dragging fracturing pipe column can be applied and popularized on vertical wells and horizontal wells.

Owner:CNPC BOHAI DRILLING ENG +1

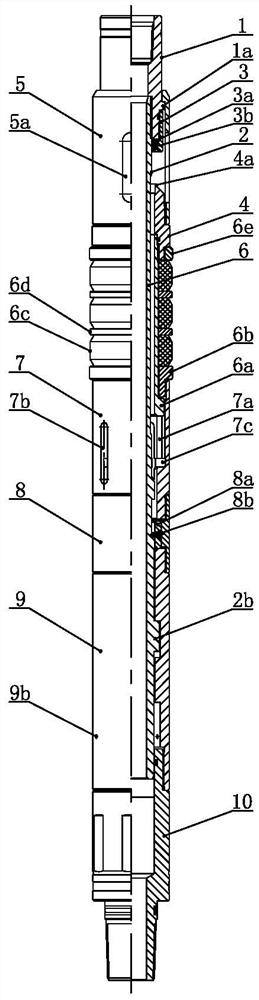

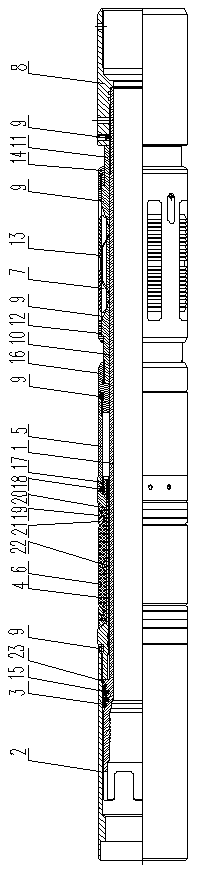

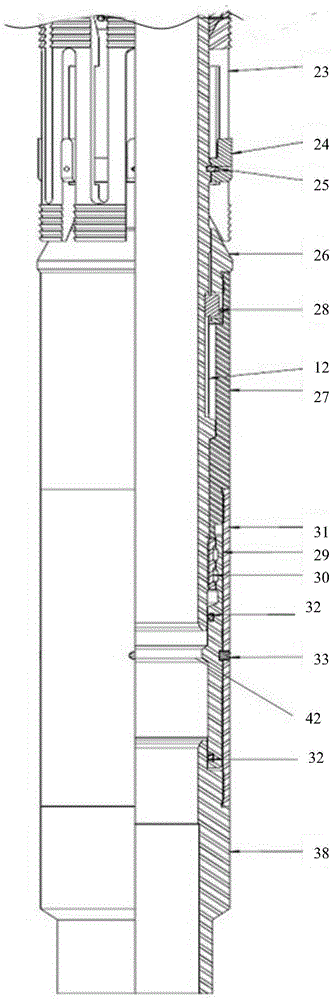

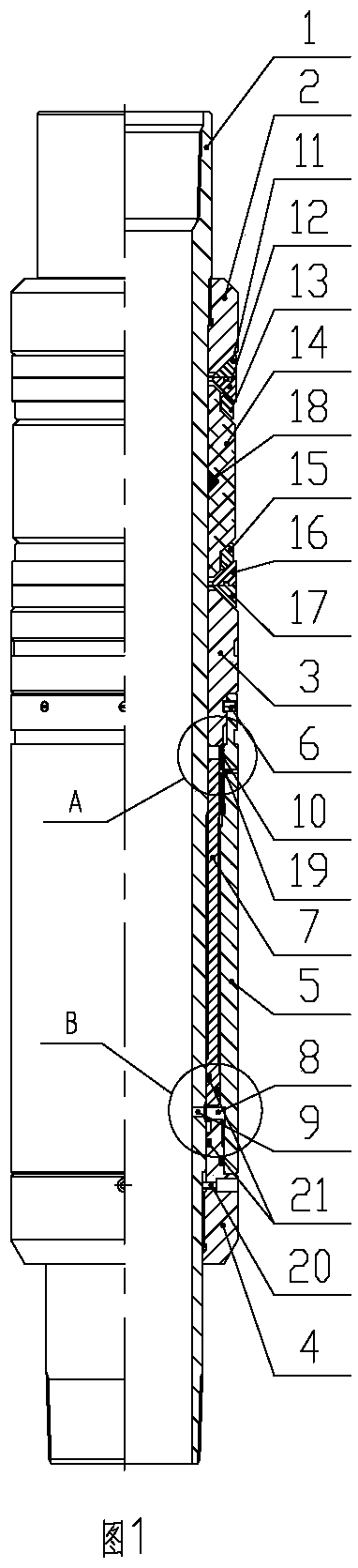

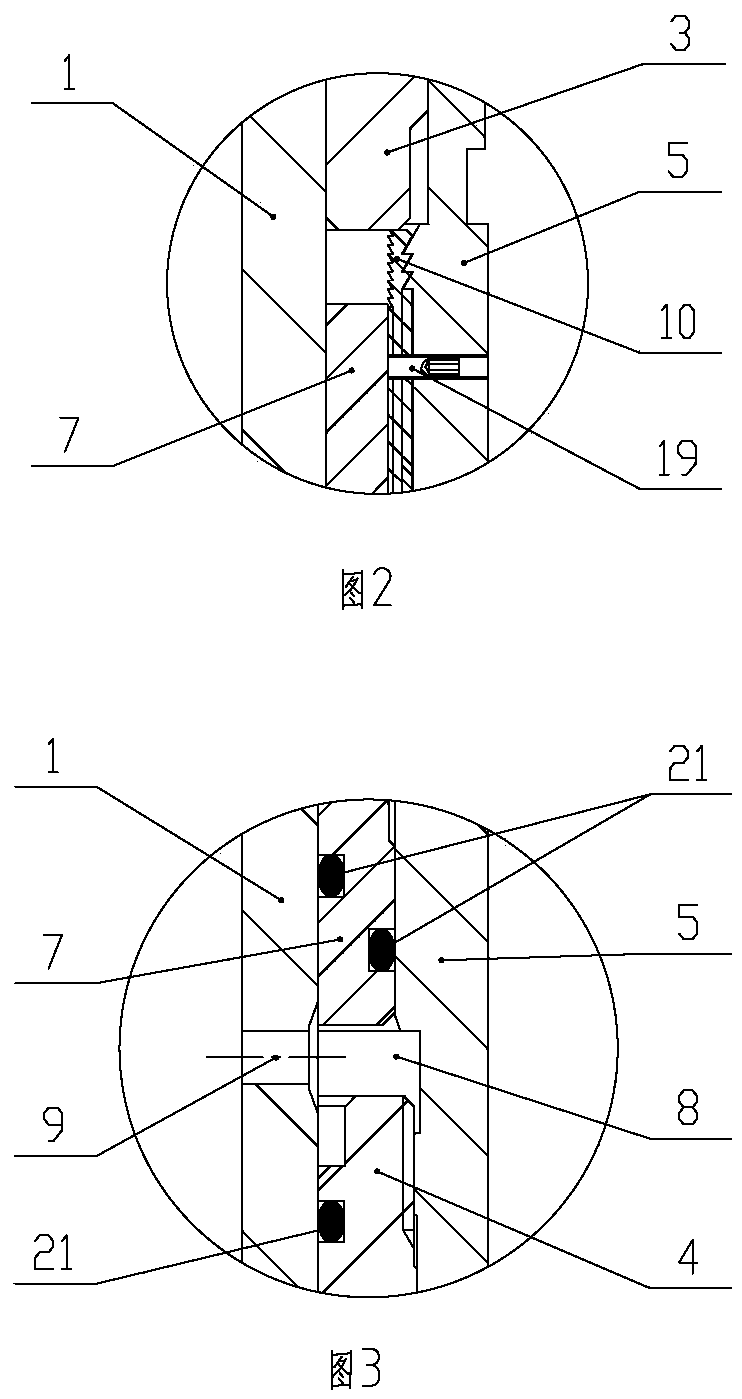

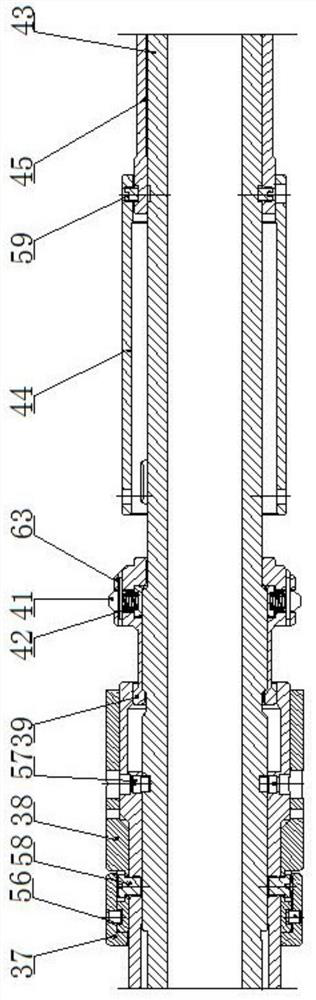

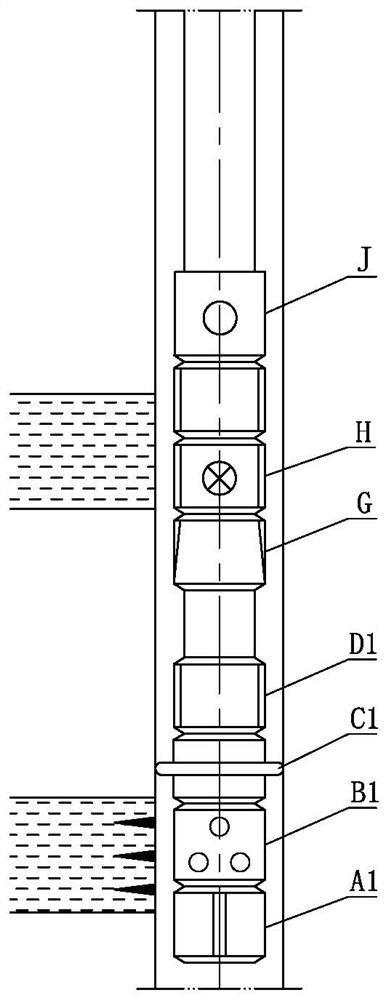

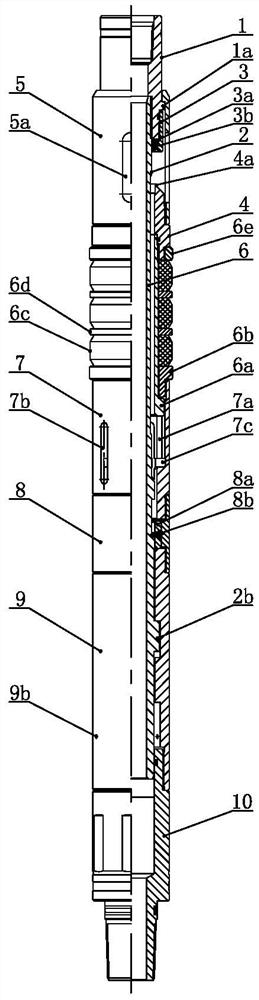

Packer for formation testing and method for performing formation testing by adopting packer

ActiveCN111911110APrevent pre-settingGood for walkingWell/borehole valve arrangementsSealing/packingUpper jointEngineering

The invention relates to a packer for formation testing and a method for performing formation testing by adopting the packer. The packer comprises an upper joint, wherein a conical female thread is formed in the upper end of the upper joint, a core pipe extending downwards is screwed in an internal thread in the lower end of the upper joint, and the lower end of the core pipe is inserted into an upper port of a lower joint and is sealed through an O-shaped ring; a conical male thread is formed in the lower end of the lower joint; and a bypass mechanism capable of communicating upper liquid flow and lower liquid flow of the packer is arranged on the periphery of the core pipe and below the upper joint, a setting mechanism is arranged below the bypass mechanism, a shear pin mechanism is arranged below the setting mechanism, and a transposition mechanism for controlling bypass and setting is arranged below the shear pin mechanism. During well descending, the bypass is opened to communicate upper and lower annuluses, after in place, the core pipe is rotated, the bypass is closed, setting is performed, stratum fluid enters a string, then the bypass is opened, unsetting is performed, andthe string is lifted. In the drilling process, it is ensured that the straddle packer cannot be set in advance, so that packer rubber sleeves are effectively protected, and the straddle test successrate is practically increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Suspension packer

The invention relates to a suspension packer. The suspension packer comprises a mandrel, wherein the upper side of the mandrel is connected with a top joint; the lower end of the top joint is connected with a rubber sleeve component having a rubber sleeve; a slip component is arranged below the rubber sleeve component; an unpacking component for conveniently recovering the packer is arranged below the slip component, wherein a first key slot for fitting an outer-layer key on a packer sending tool to rotate a packer pipe column in the down-pass process is formed in the top joint; a pressure transfer hole of the packer sending tool is separated from the packer pipe column by a ball seat and a sealing rubber ring thereof; the unpacking component comprises an unpacking sleeve; and a second key slot for fitting a key block on a packer recovering tool to lift up the packer pipe column is formed in the unpacking sleeve. The suspension packer can rotate in the down-pass process of the tools without setting beforehand, and can realize the recovery.

Owner:PETRO KING ENERGY TECH HUIZHOU CO LTD

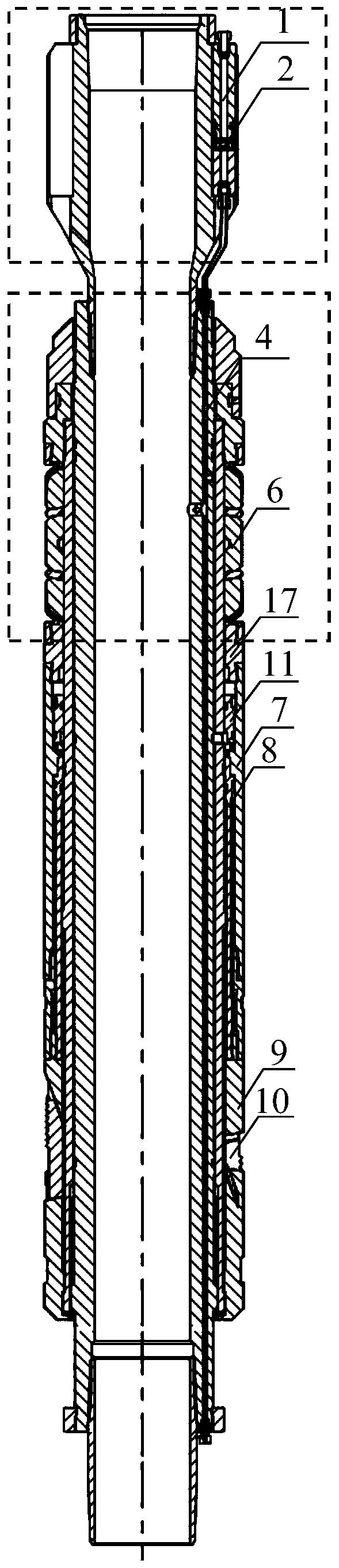

Hydraulic Setting Tool

InactiveCN103206182BShear value stablePrevent pre-settingBorehole/well accessoriesUpper jointEngineering

The invention relates to a hydraulic setting tool which comprises an upper joint and a mandrel connected with the upper joint. The hydraulic setting tool is characterized by further comprising a piston pushing mechanism and a converting mechanism which are arranged outside the mandrel, the piston pushing mechanism comprises a piston hermetically sleeved outside the mandrel, a converting sleeve connected with the outside of one end of the piston, and a sliding sleeve connected with the upper joint, the mandrel and the piston are fixed through a shearing pin, the sliding sleeve and the upper joint are fixed circumferentially, the converting mechanism comprises a piston and an adjusting sleeve sleeved outside the converting sleeve, and at least four pressure transmitting holes are arranged on the mandrel. The hydraulic setting tool has the advantages that by matching the shearing pin between the mandrel and the piston and the converting sleeve and the adjusting sleeve of the setting tool with a packer at the top, setting of the packer in advance can be effectively prevented to enable setting operations to be reliable and effective. The hydraulic setting tool can be matched with various packers such as a packer at the top of an outer-layer sand prevention tool and a sand setting packer, and is low in manufacturing cost, simple in assembly program, and convenient, safe and reliable in on-site operation process.

Owner:CHINA NAT OFFSHORE OIL CORP +1

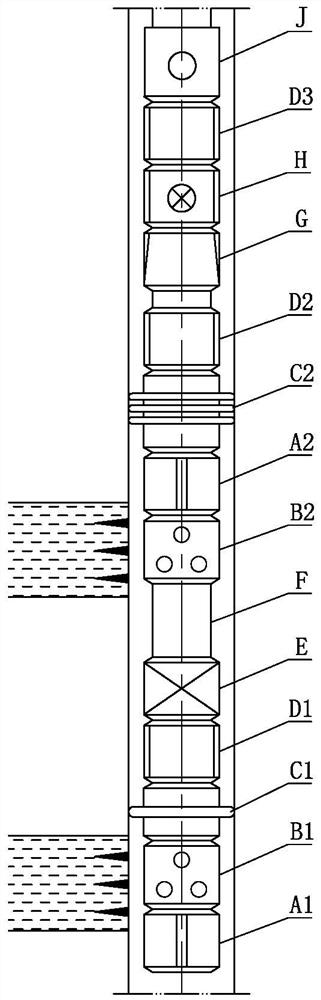

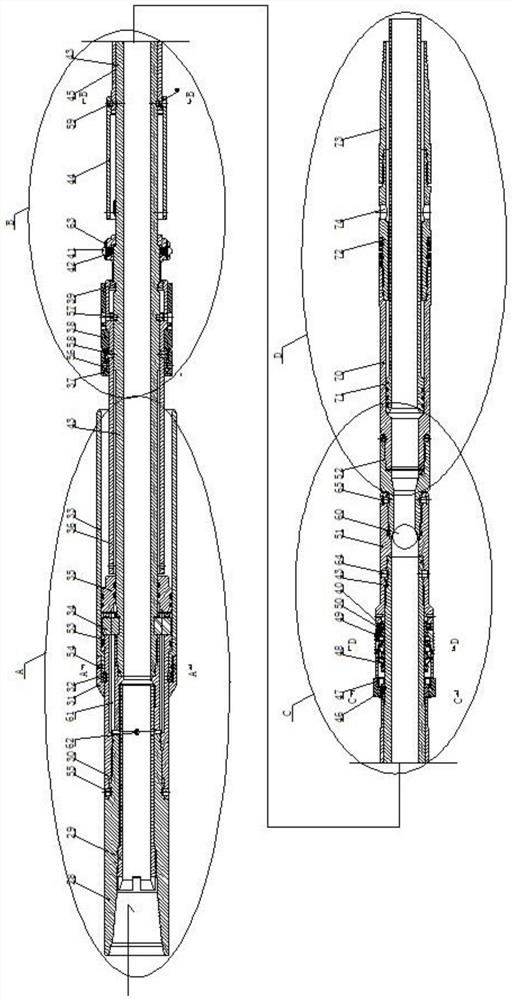

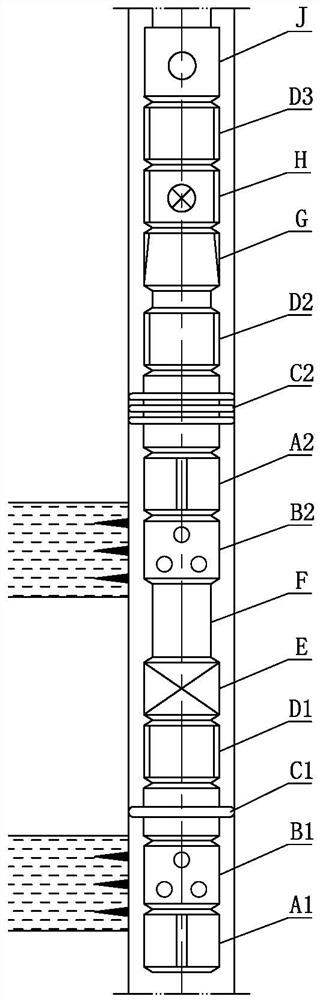

Double-seal straddle test string

The invention relates to a double-seal straddle test string. The double-seal straddle test string comprises a screen pipe I corresponding to a first stratum and a screen pipe II corresponding to a second stratum, wherein a pressure gauge supporting cylinder I is connected to the lower part of the screen pipe I in a screwed mode, a slip packer, a lifting short section I and a screwed plug are sequentially arranged above the screen pipe I, and the upper end of the screwed plug is connected with the bottom of the screen pipe II through an adjusting short section. The screen pipe II is upwards connected with a pressure gauge supporting cylinder II, a straddle packer, a lifting short section II, a mechanical lock, a tester, a lifting short section III and a circulating valve in sequence; and the straddle packer comprises a bypass mechanism, wherein a setting mechanism is arranged below the bypass mechanism, a shear pin mechanism is arranged below the setting mechanism, and a transposition mechanism for controlling bypass and setting is arranged below the shear pin mechanism. The double-seal straddle test string disclosed by the invention can be used for continuously testing two well sections in sequence, so that the test time is greatly shortened, the test efficiency is improved, and the test accuracy is high. In the well descending process, it is ensured that the straddle packer cannot be set in advance, and the success rate of straddle testing is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

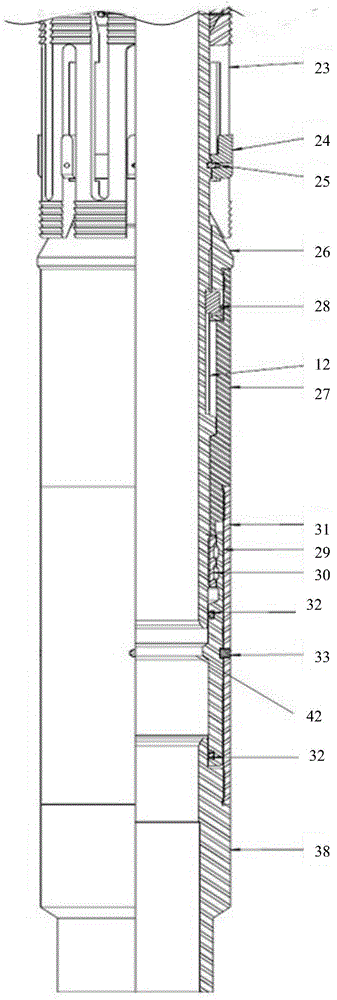

A hanger feeding tool with linked hands

ActiveCN105840126BWith emergency drop functionEasy for emergency machinery to dropBorehole/well accessoriesEngineeringCam

The invention relates to a linked-release hanger delivery tool and belongs to the field of oil-gas well down-hole operation tools. The delivery tool comprises a central tube, an upper connector, a lower connector, a piston, a cylinder sleeve, a clamping bush, a setting sleeve and a spring sleeve, wherein the upper connector is mounted at one end of the central tube; a cam block is mounted on the central tube on one side of the upper connector; an elastic claw is mounted on the cam block; the piston is mounted between the elastic claw and the upper connector; a piston extending sleeve is arranged on one side of the piston; the setting sleeve is mounted on the piston extending sleeve; the piston extending sleeve is fixedly connected with the setting sleeve via a releasing pin. The tool is capable of hydraulically releasing; the piston is against an ejection sleeve under the action of the hydraulic pressure, then an inclined body is pushed to move down; a dovetail groove in the inclined body drives the dovetail on the clamping bush to fall back; a special anti-setting device is designed at the upper end of the tool; the elastic claw is hooped on the central tube; the cam block is fixed in a square groove of the elastic claw and supports a guide body of a packer, thereby preventing the packer from setting in advance after meeting with barriers in the well.

Owner:荆州市赛瑞能源技术有限公司

External casing packer

ActiveCN105257239AAvoid situations that hinder the passage of the inner sleevePrevent retractionSealing/packingMechanicsShear pin

The invention relates to the technical field of oil field packers, in particular to an external casing packer. The external casing packer comprises a spindle, an upper connector, a middle connector, a lower connector, an outer cylinder and a rubber cylinder assembly, wherein the upper connector and the lower connector are respectively fixedly mounted on the outer side of the upper portion of the spindle and on the outer side of the lower portion of the spindle, the middle connector sleeves the outer side of the middle portion of the spindle, and the outer cylinder is fixedly mounted on the outer side of the upper portion of the lower connector. The external casing packer has the advantages that the external casing packer is reasonable and compact in structure, convenient to use, simple in structure, easy to mount and high in reliability; high-pressure fluid enters a sealing cavity to push an inner slide sleeve to move upwards so as to cut off a shear pin to push the rubber cylinder to perform expansion sealing, rubber cylinder contraction is prevented through two-way inverted teeth, and the outer cylinder is fixed during the whole setting process; a two-way inverted-tooth ring with a facture is meshed with the inner side of the outer cylinder, and the radial expandability of the two-way inverted-tooth ring guarantees that the inner slide sleeve passes smoothly; the packer can be effectively prevented from getting caught and stuck, setting in advance can be effectively prevented, and the situation that the two-way inverted-tooth ring blocks the passage of the inner slide sleeve can be avoided.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Hydraulic setting tool

InactiveCN103206182AShear value stablePrevent pre-settingBorehole/well accessoriesUpper jointEngineering

The invention relates to a hydraulic setting tool which comprises an upper joint and a mandrel connected with the upper joint. The hydraulic setting tool is characterized by further comprising a piston pushing mechanism and a converting mechanism which are arranged outside the mandrel, the piston pushing mechanism comprises a piston hermetically sleeved outside the mandrel, a converting sleeve connected with the outside of one end of the piston, and a sliding sleeve connected with the upper joint, the mandrel and the piston are fixed through a shearing pin, the sliding sleeve and the upper joint are fixed circumferentially, the converting mechanism comprises a piston and an adjusting sleeve sleeved outside the converting sleeve, and at least four pressure transmitting holes are arranged on the mandrel. The hydraulic setting tool has the advantages that by matching the shearing pin between the mandrel and the piston and the converting sleeve and the adjusting sleeve of the setting tool with a packer at the top, setting of the packer in advance can be effectively prevented to enable setting operations to be reliable and effective. The hydraulic setting tool can be matched with various packers such as a packer at the top of an outer-layer sand prevention tool and a sand setting packer, and is low in manufacturing cost, simple in assembly program, and convenient, safe and reliable in on-site operation process.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Controllable hydraulic setting crossing packer

The invention discloses a controllable hydraulic setting crossing packer. The controllable hydraulic setting crossing packer comprises a packer body. The packer body comprises a central pipe and a hydraulic assembly which sleeves the central pipe. At least one hydraulic control pipeline is arranged between the central pipe and the hydraulic assembly. Rupture disks are arranged at the liquid inletends of the hydraulic control pipelines, and rupture disk bursting discs are arranged on the rupture disks and are used for bearing static pressure above the hydraulic control pipelines. When the hydraulic pressure in the hydraulic control pipelines rises, the rupture disk bursting discs rupture, and the hydraulic pressure is transmitted to the hydraulic assembly through a pressure transmission hole, so that setting is achieved. The controllable hydraulic setting crossing packer has two alternative setting systems, the controllable hydraulic setting crossing packer can be set either by the central pipe or by hydraulic pipelines. According to the controllable hydraulic setting crossing packer, the setting mode can be independently selected, the downhole setting position is accurately controlled, and the using performance of the packer is optimized.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Spiral underground packing tool

PendingCN114439407AGuaranteed uniformityImprove the sealing pressure bearing effectSealing/packingStructural engineeringPipe

The invention relates to the field of petroleum underground construction, in particular to a spiral underground packing tool which comprises a central pipe with a conical outer surface, an anchoring sealing structure is arranged on the outer surface of the central pipe in a matched and sleeved mode, the anchoring sealing structure is provided with a first sealing section and an anchoring section, and the anchoring section comprises a plurality of slips. The plurality of slips and the plurality of first spiral sealing rings are in one-to-one correspondence and respectively form an integrated structure; a locking structure matched with the locking main body is arranged on the central pipe, the locking main body comprises a plurality of spiral locking rings, and the plurality of slips and the plurality of spiral locking rings are in one-to-one correspondence and respectively form an integral structure. The multiple slips are evenly unfolded in the radial direction, the slips are evenly distributed in the circumferential direction, the slips are evenly anchored on the inner wall of a whole shaft, the uniformity of the pressure bearing capacity of an underground packing tool in the radial direction is guaranteed, and the sealing pressure bearing effect is improved. In addition, the spiral locking ring is matched with the locking structure in a locking mode, so that the anchoring sealing structure is prevented from falling off from the central pipe.

Owner:VERTECHS PETROLEUM TECH INNOVATION & EQUIP MFG CO LTD

A Disposable Permanent Packer

ActiveCN106089144BAvoid the risk of early fiefdomAvoid getting stuckSealing/packingEngineeringHydraulic pressure

The invention relates to a permanent packer capable of being released and belongs to the field of underground operation tools for oil and gas wells. The permanent packer comprises a central pipe, a setting sleeve, a lock ring, a lining, a connecting sleeve, a rubber cylinder and a slip. A lower connector is installed at one end of the central pipe in a threaded mode. An upper conical body and a lower conical body are symmetrically arranged on the portion, on one side of the lower connector, of the central pipe. The slip is installed between the upper conical body and the lower conical body through a slip protection sleeve and a leaf spring. The other end of the central pipe is sleeved with the setting sleeve. The portion, on one side of the setting sleeve, of the central pipe is provided with the lining. The lining is in threaded connection with the setting sleeve. The slip of the packer is pressed by the leaf spring when entering a well and only stretches out when being pressed by the conical bodies under the action of hydraulic pressure, and the advanced setting risk of a conventional packer is effectively avoided. Firm anchorage can be guaranteed through the slip of the packer, the downward tooth shape can bear loads from the upper portion of the packer, and the upward tooth shape can bear loads from the lower portion of the packer. The slip is specially designed to be located below the rubber cylinder and used for blocking scraps, and the situation that the slip is jammed by the scraps during operation is avoided.

Owner:荆州市赛瑞能源技术有限公司

Anti-blocking bridge plug

PendingCN112780220APrevent pre-settingSmoothly in placeDrilling rodsSealing/packingEngineeringStructural engineering

The invention discloses an anti-blocking bridge plug. The anti-blocking bridge plug comprises a central pipe, an anchoring device and a protective sleeve, wherein an adjusting short section is arranged at the upper end of the central pipe, a guide shoe is arranged at the lower end of the central pipe, the anchoring device is arranged in the middle of the central pipe, the anchoring device comprises an upper slip and an upper cone which are arranged at the upper part of the central pipe in a sleeving manner, and a lower slip and a lower cone which are arranged at the lower part of the central pipe in a sleeving manner, the protective sleeve is detachably connected to the upper end of the central pipe in a sleeving mode, and the protective sleeve is arranged outside the adjusting short section and the upper slip in a sleeving mode, when the lower cone and the lower slip move relatively, the lower slip is pushed to be opened and anchored to a casing pipe, and after the protective sleeve is detached, the upper cone and the upper slip move relatively to push the upper slip to be opened and anchored on the casing pipe, According to the anti-blocking bridge plug, the slip can be prevented from being accidentally opened through the protective sleeve, and the situation that the bridge plug is blocked and blocked before entering a preset position, and setting is conducted in advance is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

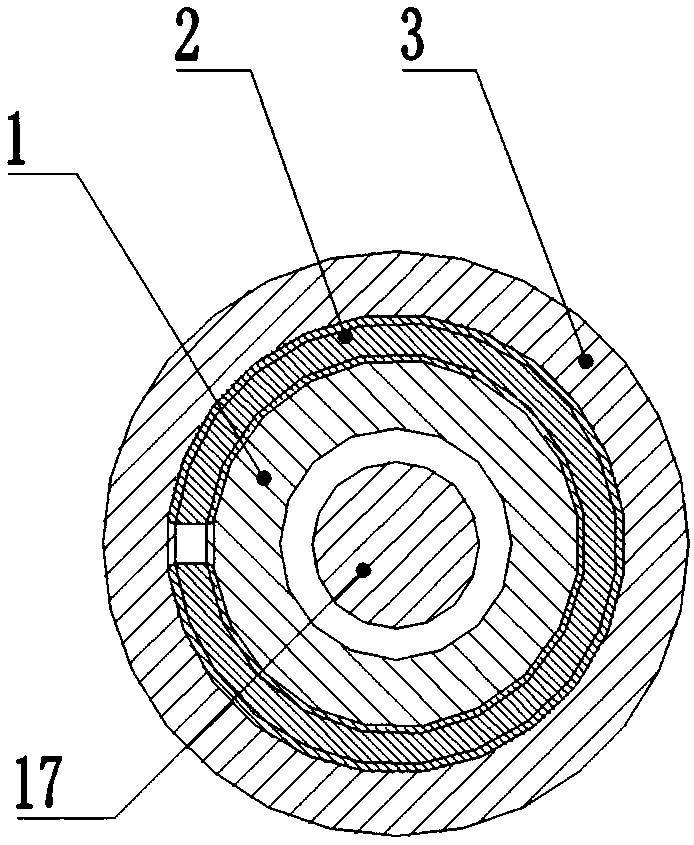

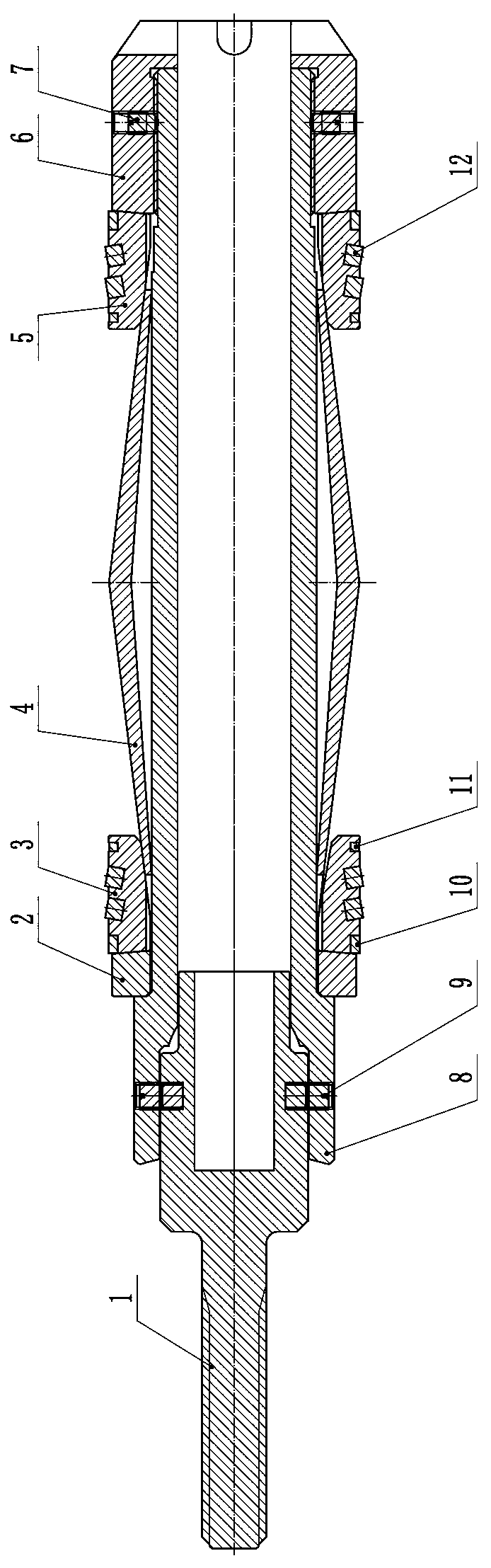

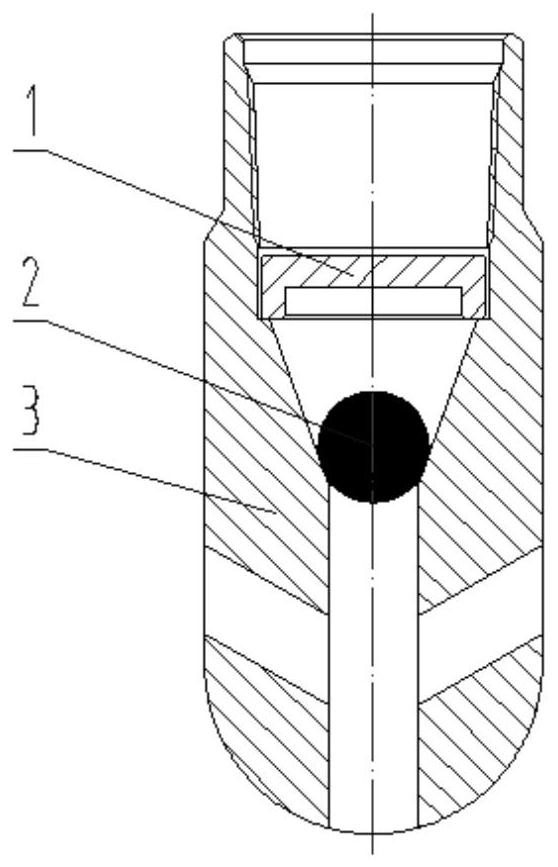

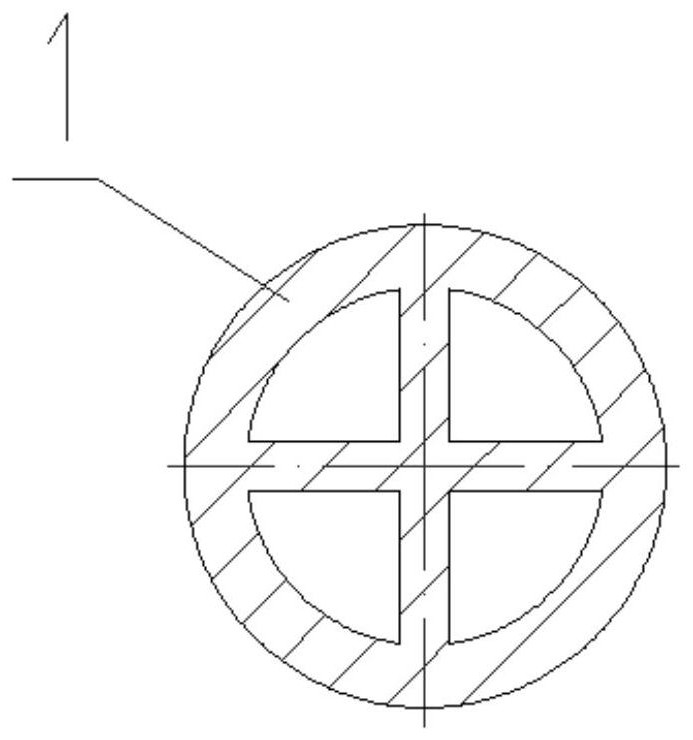

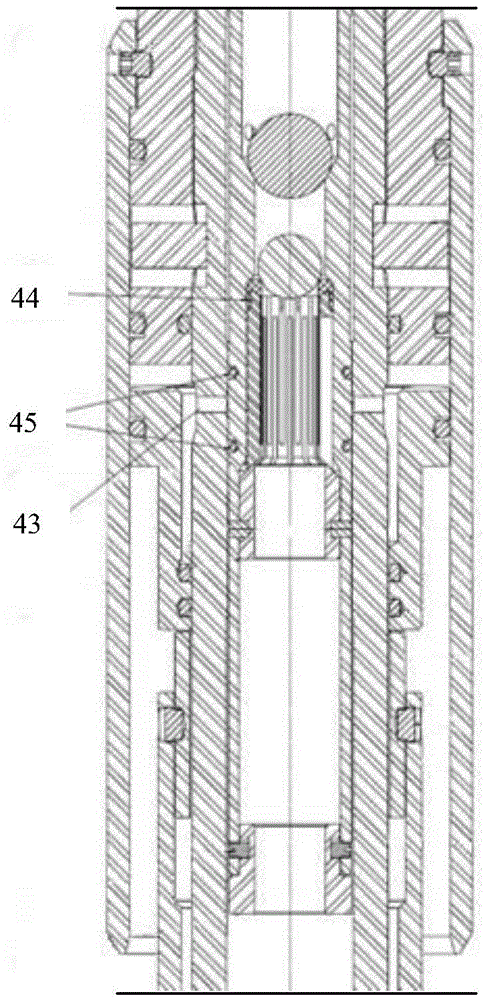

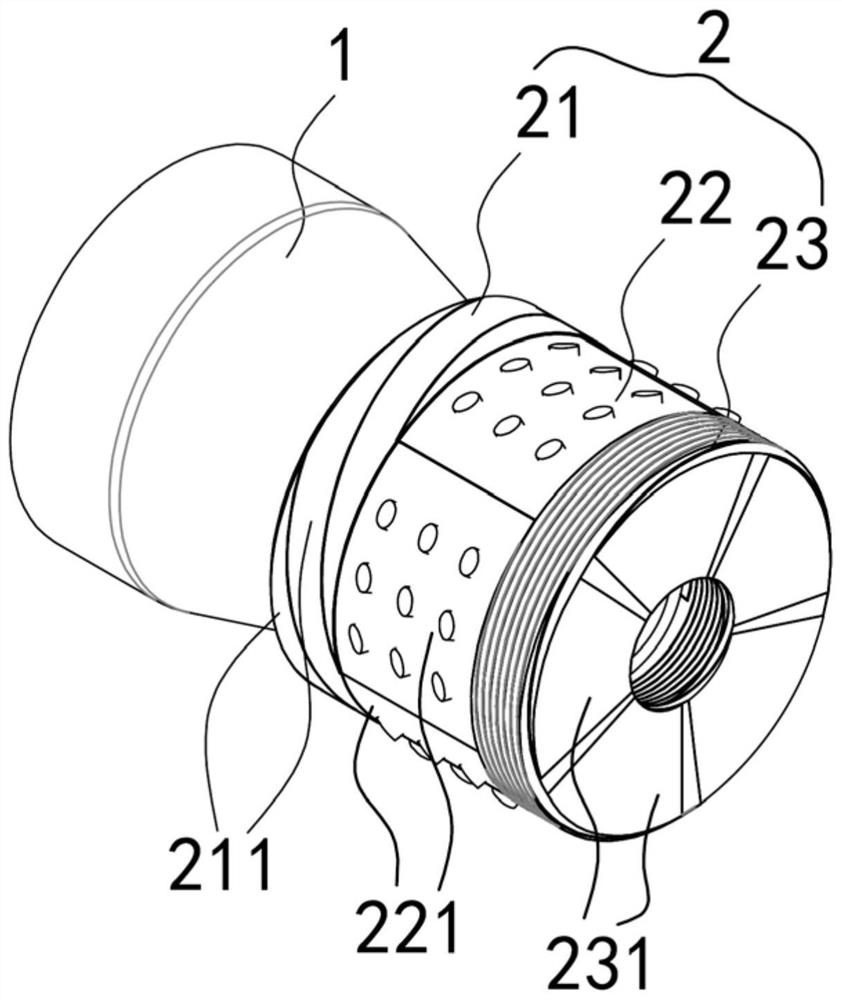

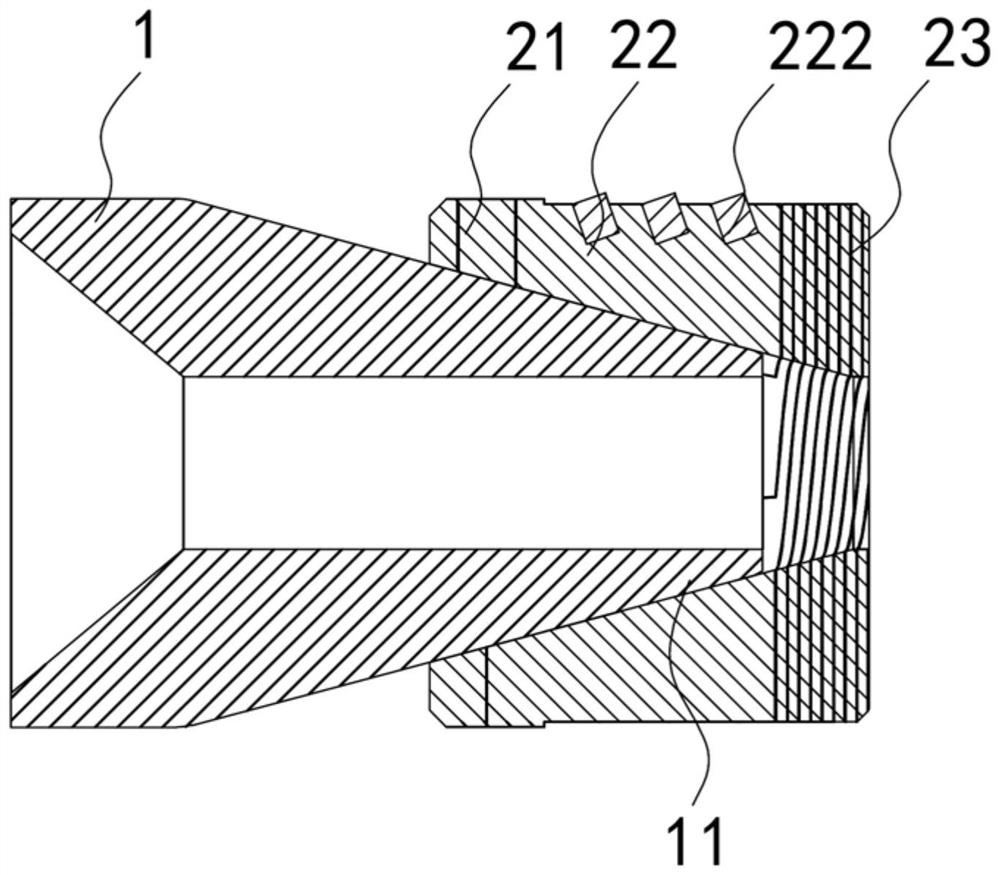

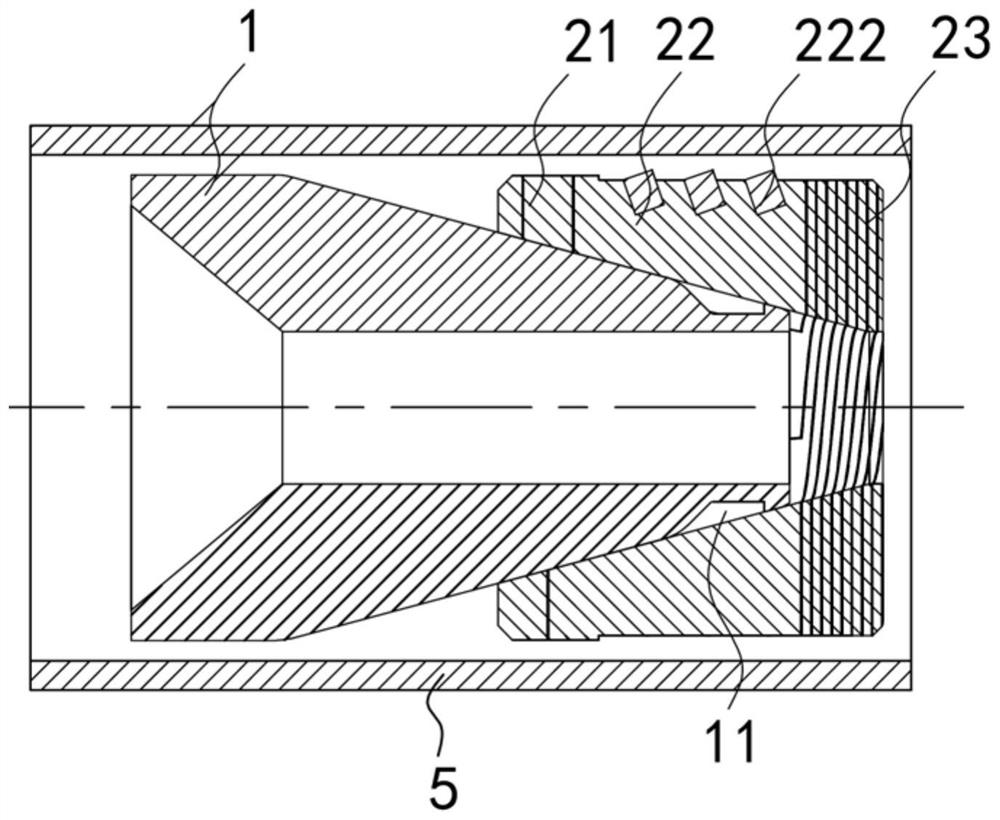

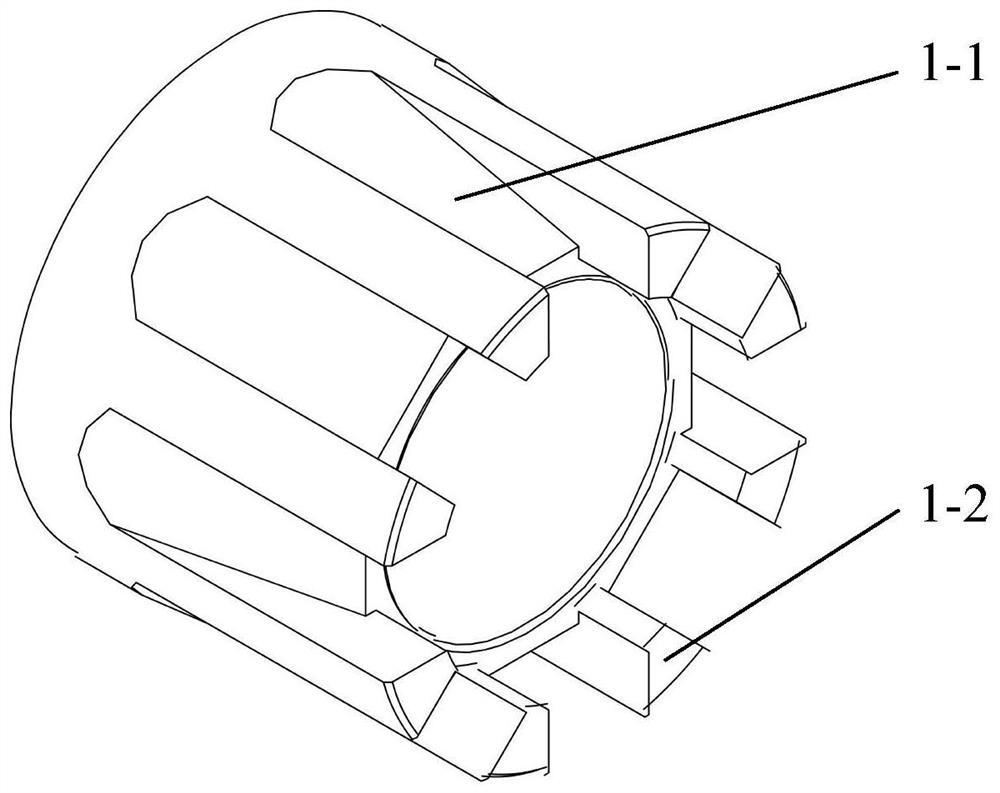

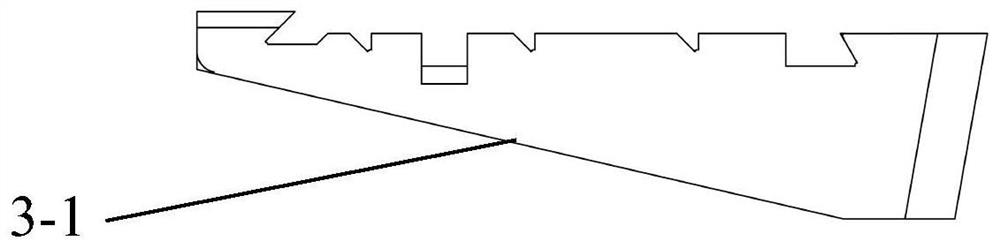

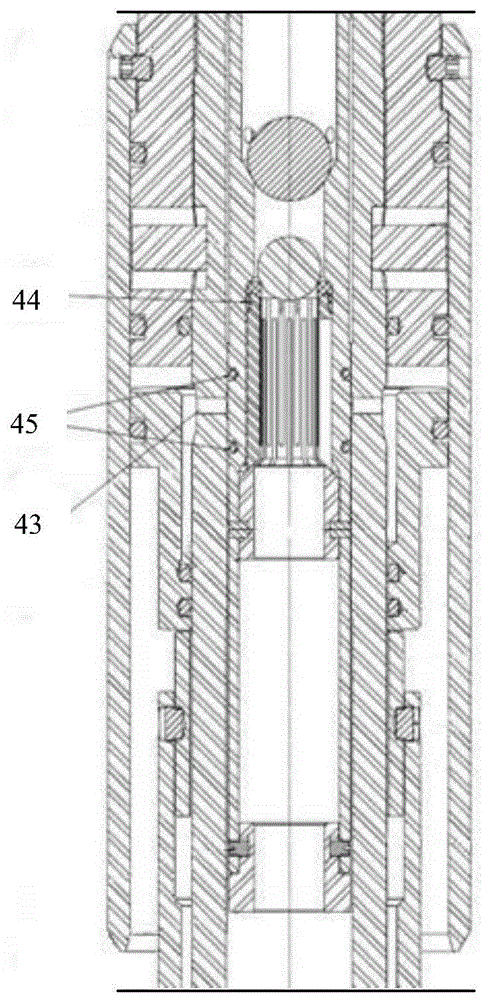

A fast millable slip assembly for downhole tools

The invention relates to the field of oilfield oil production engineering, and belongs to a slip component which can be quickly milled and milled for downhole tools. The invention solves the problem that the integral slips and segmented slips used on common bridge plugs are not easy to be milled, and includes: a cone (1), a main assembly and an italic body (5). Expand and support the slip base (3) during setting, while limiting the circumferential displacement of the slip base (3); the main body assembly is inserted and installed between the cone (1) and the italic body (5); the italic body (5) It is used to support the tail of the slip base (3); the main body assembly includes a fixing ring (2), a slip base (3), and a slip sheet (4); wherein the fixing ring (2) attaches the slip base ( 3) Hoop into a circle, and insert the slip sheet (4) on the upper surface of the slip base (3). The invention has the advantages of simple structure, safety and reliability, rapid milling and small volume of the remaining part of the slip base after milling.

Owner:PETROCHINA CO LTD +1

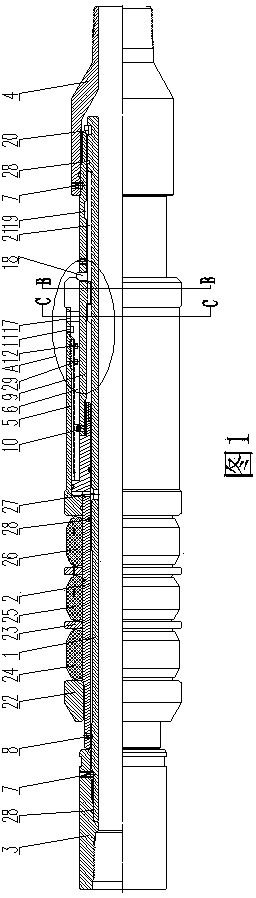

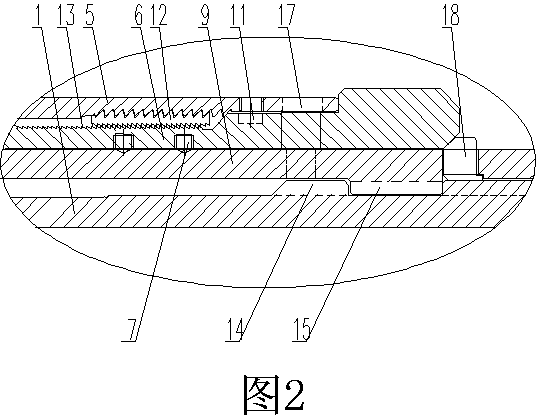

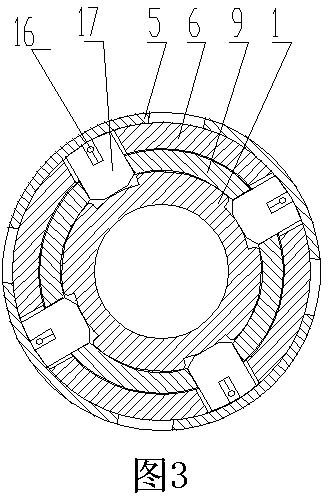

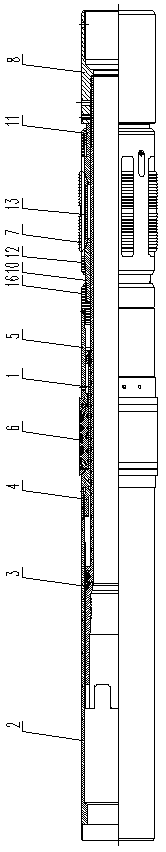

A packer with hydraulic setting and rotary unsealing

The invention relates to a hydraulic setting and rotating unlocking packer, and belongs to the field of oil gas well underground working tools. The packer comprises an inner central pipe, an outer central pipe, an upper connector, a lower connector, a piton sleeve and a release sleeve. The upper connector is arranged at one end of the inner central pipe in a threaded mode. An outer central pipe is arranged on the portion, on one side of the upper connector, of the inner central pipe. A middle connector is arranged on the portion, on one side of the outer central pipe, of the inner central pipe. One end of the middle connector is connected with the outer central pipe in a threaded mode, and the other end of the middle connector is provided with the lower connector in a threaded mode. The packer is compact in structure; a setting mechanism and an unlocking mechanism are exquisite in design; by means of a shearing pin arranged in the setting mechanism, setting conducted in advance can be effectively prevented; the setting force is locked and kept through a locking ring after setting is conducted, and setting is durable and effective; the defects caused when multiple packers are unlocked by providing large torque are effectively avoided. The packer is particularly suitable for production, water (gas) injection, interlayer packing, separated injection and production, multi-layer testing and yield increase work of vertical shafts and small-inclination wells.

Owner:荆州市赛瑞能源技术有限公司

a hanging packer

The invention relates to a suspension packer. The suspension packer comprises a mandrel, wherein the upper side of the mandrel is connected with a top joint; the lower end of the top joint is connected with a rubber sleeve component having a rubber sleeve; a slip component is arranged below the rubber sleeve component; an unpacking component for conveniently recovering the packer is arranged below the slip component, wherein a first key slot for fitting an outer-layer key on a packer sending tool to rotate a packer pipe column in the down-pass process is formed in the top joint; a pressure transfer hole of the packer sending tool is separated from the packer pipe column by a ball seat and a sealing rubber ring thereof; the unpacking component comprises an unpacking sleeve; and a second key slot for fitting a key block on a packer recovering tool to lift up the packer pipe column is formed in the unpacking sleeve. The suspension packer can rotate in the down-pass process of the tools without setting beforehand, and can realize the recovery.

Owner:PETRO KING ENERGY TECH HUIZHOU CO LTD

Outer tube packer

ActiveCN105257239BAvoid situations that hinder the passage of the inner sleevePrevent retractionSealing/packingEngineeringHigh pressure

The invention relates to the technical field of oil field packers, in particular to an external casing packer. The external casing packer comprises a spindle, an upper connector, a middle connector, a lower connector, an outer cylinder and a rubber cylinder assembly, wherein the upper connector and the lower connector are respectively fixedly mounted on the outer side of the upper portion of the spindle and on the outer side of the lower portion of the spindle, the middle connector sleeves the outer side of the middle portion of the spindle, and the outer cylinder is fixedly mounted on the outer side of the upper portion of the lower connector. The external casing packer has the advantages that the external casing packer is reasonable and compact in structure, convenient to use, simple in structure, easy to mount and high in reliability; high-pressure fluid enters a sealing cavity to push an inner slide sleeve to move upwards so as to cut off a shear pin to push the rubber cylinder to perform expansion sealing, rubber cylinder contraction is prevented through two-way inverted teeth, and the outer cylinder is fixed during the whole setting process; a two-way inverted-tooth ring with a facture is meshed with the inner side of the outer cylinder, and the radial expandability of the two-way inverted-tooth ring guarantees that the inner slide sleeve passes smoothly; the packer can be effectively prevented from getting caught and stuck, setting in advance can be effectively prevented, and the situation that the two-way inverted-tooth ring blocks the passage of the inner slide sleeve can be avoided.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

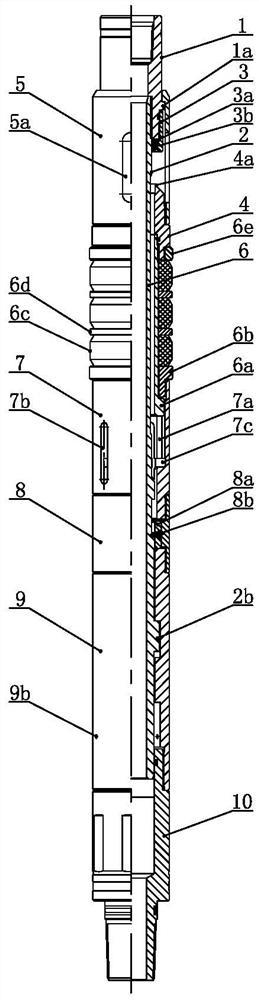

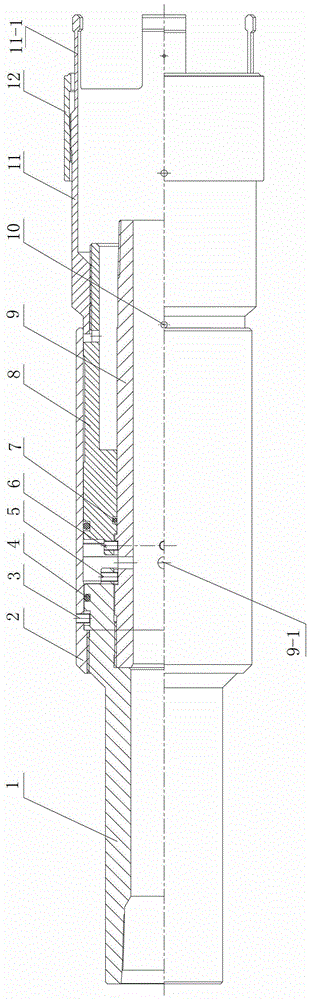

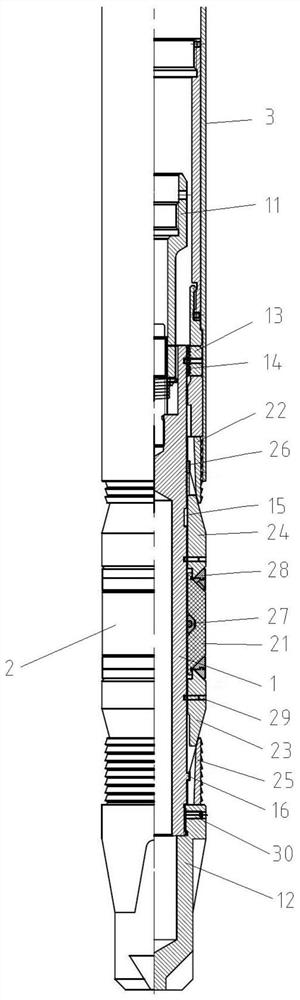

A hydraulically and mechanically releasable setting tool

ActiveCN111706279BRealize mechanical releaseGood for fallingBorehole/well accessoriesSet screwUpper joint

The invention relates to a hydraulically and mechanically releasable setting tool, which belongs to the field of downhole operation tools for oil and gas wells. The setting tool includes a mandrel, a setting pup joint, an upper joint and a ball seat pup joint; one end of the upper joint is installed with a setting pup joint, the inner thread of the upper joint is equipped with a protective cover, and the seat on one side of the end of the protective cover is installed. There is a mandrel installed on the internal thread of the sealing pup, and a lock block is installed between the mandrel and the setting pup. On one side of the lock block, a piston is installed on the mandrel at the end of the setting pup. The setting tool can be repeated many times. In use, the outer cylinder of the piston is fixed by a step that is short-circuited between the separation ring and the setting seal. During maintenance, the set screw fixed between the pressure caps of the outer cylinder can be directly removed to realize the operation. Compared with the traditional fixed piston outer cylinder through threaded connection, it can prevent the repeated disassembly and wear of the connecting thread during tool maintenance, resulting in the problem that the parts cannot be used, and the operation is simple, which increases the reliability of the setting tool.

Owner:杨国 +1

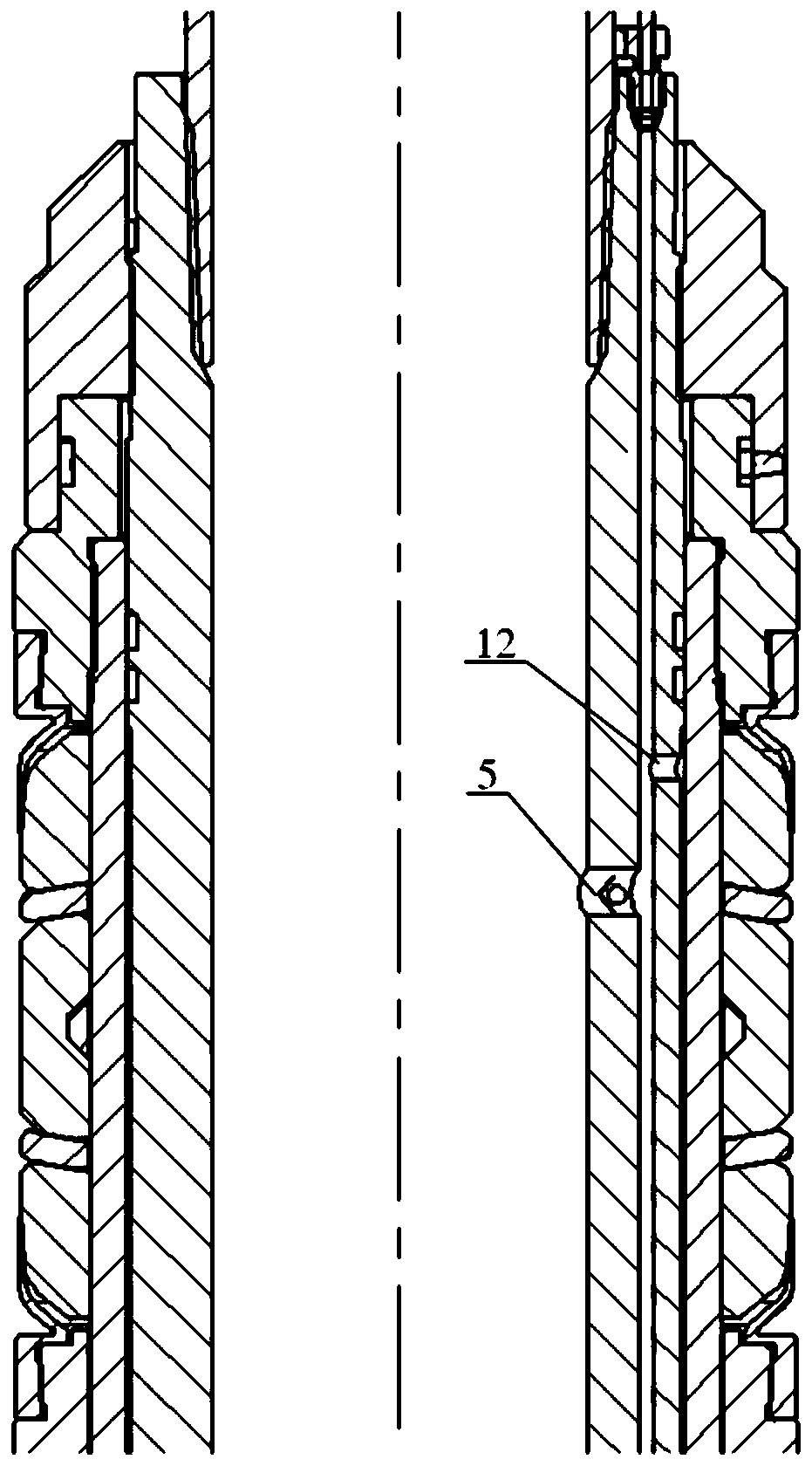

A soluble metal sealing fracturing bridge plug

ActiveCN110905443BPrevent pre-settingReduce the risk of problems in downhole operationsFluid removalSealing/packingScrew threadMetal

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Anti-scouring packer

ActiveCN105696966BAvoid breakingPrevent eccentric wear damageSealing/packingHydraulic cylinderLower limit

An anti-scouring packer comprises an unpacking joint, an unpacking ring, a connecting joint, a stopping ring, an upper taper 5, a slip, a leaf spring, a slip cover, a lower taper, an upper pressing cap, a setting pin, a piston, an upper limit ring, a lower limit ring, a locking block, a spindle, a pressure transmitting inner sleeve, a pressure transmitting sleeve, a locking ring, a rubber cylinder protecting cover, a sliding joint, a rubber cylinder and a lower joint, wherein the spindle is mounted and connected between the interior of the unpacking joint and the interior of the lower joint; the unpacking ring, the connecting joint, the upper taper, the slip, the slip cover, the lower taper, the upper pressing cap, the piston, a hydraulic sleeve, the pressure transmitting inner sleeve, the pressure transmitting sleeve, the rubber cylinder protecting cover, the sliding joint and the rubber cylinder are sequentially mounted on and connected with the outer side of the spindle. The anti-scouring packer has the characteristics that eccentric wear damage is not prone to occur when normal-circulation mud displacement or reverse-circulation large-displacement backwashing is performed in a straight well, an inclined well or a horizontal well, and when the rubber cylinder passes through an inclined well section, setting cannot appear in advance during scraping on the well wall; a single hydraulic cylinder structure is adopted, the anti-scouring capacity is high, the service life of the rubber cylinder is long, and the like, therefore, the packer is widely applied to downhole operation processes for oil exploitation.

Owner:DONGYING FLUID SCI & TECH

A kind of anti-blocking hydraulic packer

The invention relates to a hydraulic packer for preventing resistance encountering, and belongs to the technical field of downhole operation tools. The hydraulic packer is composed of an upper joint,a lower joint, an inner central tube, an outer central tube, an upper cone and a lower cone; one end of the inner central tube is connected with the upper joint, the other end of the inner central tube is connected with the lower joint, the outer central tube is movably mounted on the inner central tube, one end of the outer central tube is connected with an upper guiding ring, and the other end of the outer central tube is in threaded connection with a releasing sleeve; the lower cone is mounted at one end of the releasing sleeve; a lower guiding ring is movably mounted on the outer central tube, the other end of the lower guiding ring is in threaded connection with a piston sleeve, and an upper piston and a lower piston are movably mounted in the piston sleeve; and an upper piston retaining ring is fixedly mounted on the position, between the upper piston and the lower piston, of the outer central tube. The hydraulic packer is simple in structure and ingenious in design, the problemthat an existing pack is extremely prone to setting in advance is solved, and the demands of oilfield use are met.

Owner:荆州市赛瑞能源技术有限公司

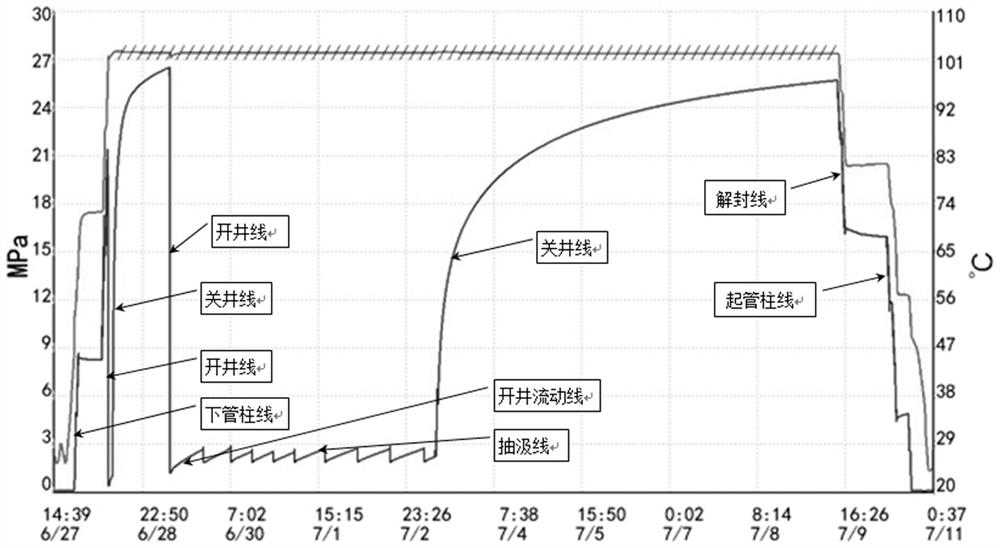

Double-seal straddle formation testing method

The invention relates to a double-seal straddle formation testing method. The method comprises the following steps of (1) performing perforation on a first testing well section; (2) assembling a single-seal testing string into a well; (3) performing pulling out after completing the test of the first testing well section; (4) performing perforation on a second testing well section; (5) assembling adouble-seal straddle testing string into the well; (6) setting an anchor packer above a corresponding first stratum in a sleeve, then setting a straddle packer, and then performing mechanical lockingand anchoring to the sleeve; (7) opening a tester, enabling formation fluid of the second testing well section to enter a test string from a screen pipe II, and enabling the formation fluid to flow upwards through the tester; (8) performing pumping analysis; (9) closing the tester, and enabling second formation fluid to remain in the string; (10) lifting the string, unanchoring mechanical locking, and then sequentially unsetting the straddle packer and the anchor packer; and (11) lifting oil pipes one by one, and performing sampling when the second formation fluid in the string is seen. According to the testing method, two well sections can be continuously tested in sequence, the testing time is greatly shortened, and the testing efficiency is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Formation test packer and method for formation test using same

ActiveCN111911110BPrevent pre-settingEasy to walkWell/borehole valve arrangementsSealing/packingUpper jointEngineering

The invention relates to a packer for formation testing and a method for using the same for formation testing. The packer includes an upper joint, the upper end of the upper joint is provided with a tapered female thread, and the inner thread at the lower end of the upper joint is screwed with a downward Extended core tube, the lower end of the core tube is plugged into the upper port of the lower joint and sealed by an O-ring, the lower end of the lower joint is provided with a tapered male thread; the outer circumference of the core tube and the lower part of the upper joint are provided with a communication seal The bypass mechanism for the upper and lower liquid flow of the spacer, the setting mechanism is arranged under the bypass mechanism, the shear pin mechanism is arranged under the setting mechanism, and the transposition mechanism for controlling bypass and setting is arranged under the shear pin mechanism. When going downhole, the bypass is opened to connect the upper and lower annulus; when in place, the core pipe is rotated, the bypass is closed and set, the formation fluid enters the pipe string, and then the bypass is opened and unsealed, and the pipe string is lifted. The invention ensures that the straddling packer will not be set in advance during the drilling process, thereby effectively protecting the packer rubber cylinder and effectively improving the success rate of the straddling test.

Owner:CHINA PETROLEUM & CHEM CORP +1

An automatic packing device for casing

ActiveCN112096339BGood sealingEasy to operateCleaning apparatusSealing/packingStructural engineeringMechanical engineering

The invention provides an automatic packing device for a casing, comprising: a body with a central flow channel, an annular groove on the outer surface of the body; an expansion sleeve installed in the annular groove , a number of scrapers uniformly distributed in the circumferential direction are arranged on the outer peripheral surface of the expansion sleeve; an isolation mechanism arranged in the annular groove for driving the scrapers to clean the inner wall of the outer casing, It includes an elastic member, a first sleeve and a second sleeve sequentially arranged on the radially outer side of the elastic member, wherein, the side wall of the body is provided with a plurality of holes that allow the fluid in the central channel to enter the The through hole of the annular groove, the expansion sleeve expands radially outward under the action of the fluid, and the isolation mechanism is configured to drive the scraper to clean the inner wall of the outer casing, so that the expansion sleeve The barrel is fully expanded to contact the inner wall of the outer casing, thereby completing the containment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com