Double-seal straddle test string

A technology for testing tubes and spans, which is applied in the field of downhole testing equipment and double-sealed spanning test strings, and can solve the problems of multiple procedures, low testing efficiency, and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

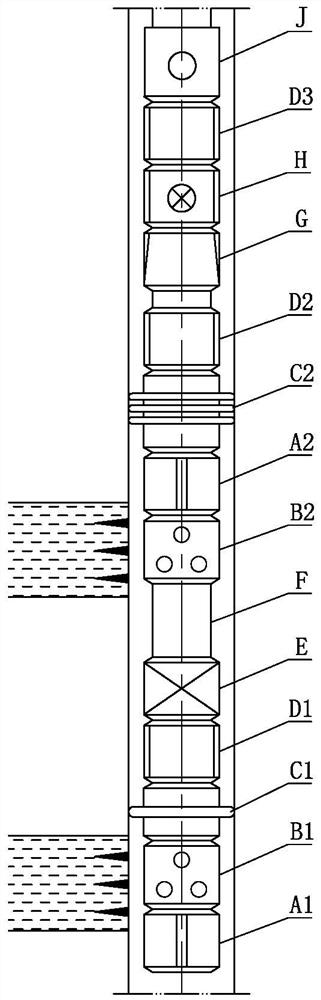

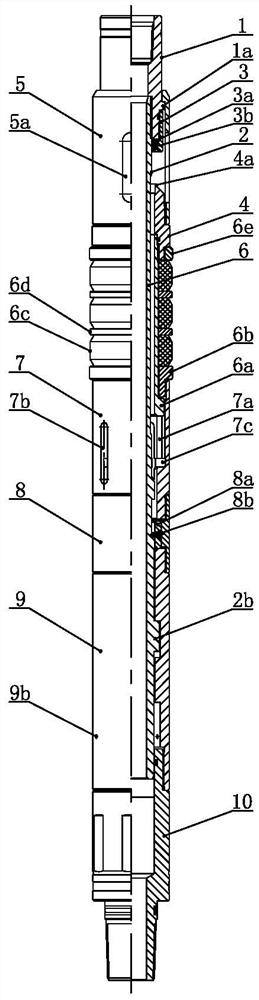

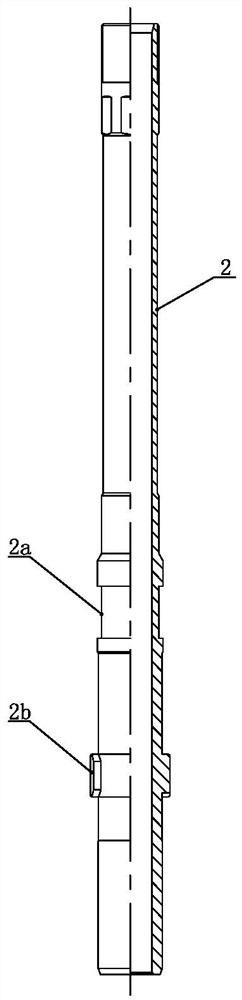

[0040] Such as figure 1 As shown, the double-sealed spanning test string of the present invention includes screen one B1 corresponding to the first formation and screen two B2 corresponding to the second formation, and a pressure gauge support is screwed below the screen one B1 Slip packer C1, lifting nipple 1 D1 and plug E are arranged in sequence above cylinder 1 A1 and screen 1 B1. The upper end of wire plug E is connected to the bottom of screen 2 B2 through adjusting nipple F. The second B2 is connected upwardly with the second pressure gauge holder A2, the span packer C2, the second lifting sub D2, the mechanical lock G, the tester H, the third lifting sub D3 and the circulation valve J.

[0041] After the first formation is tested by the traditional test method, if it is judged that the first formation has mining value, then the test string of the present invention is lowered to a predetermined position, and the passage in the pipe string below the plug E is closed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com