Spiral underground packing tool

A helical and helical sealing technology, which is applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of uneven deployment and anchoring, reduced pressure bearing capacity of downhole isolation tools, and isolation failure, etc. problems, to achieve the effect of improving the anti-pre-set sealing effect, improving the sealing pressure bearing effect, and ensuring the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

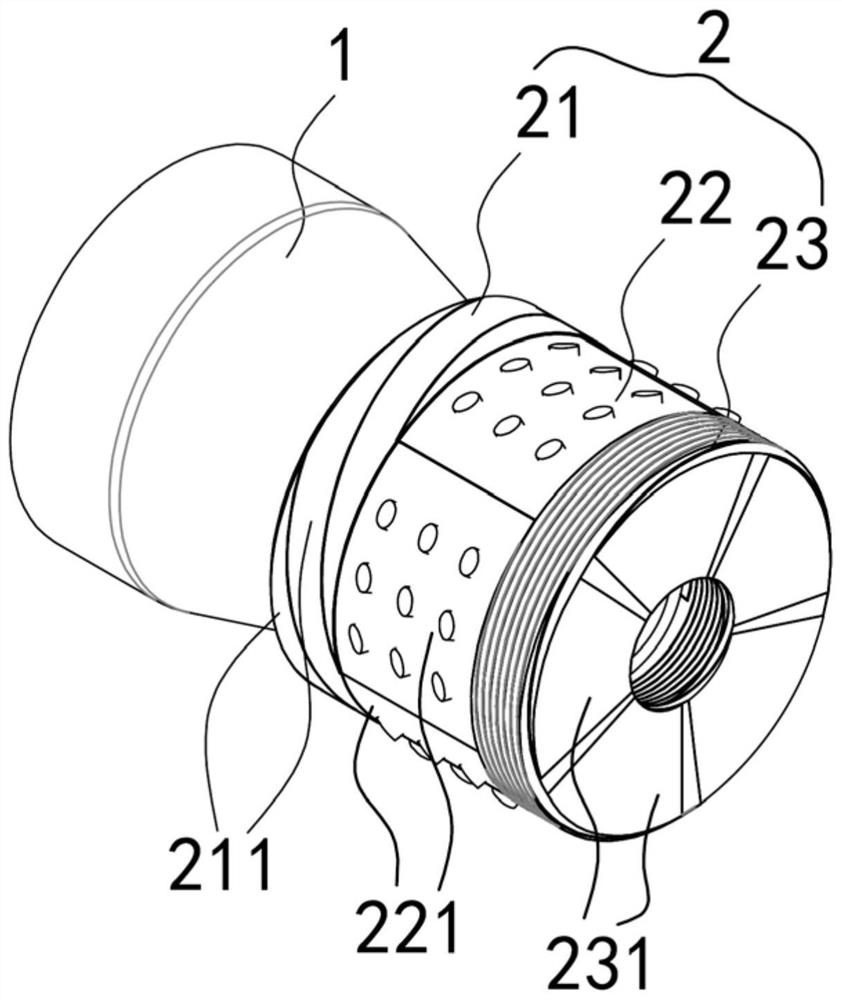

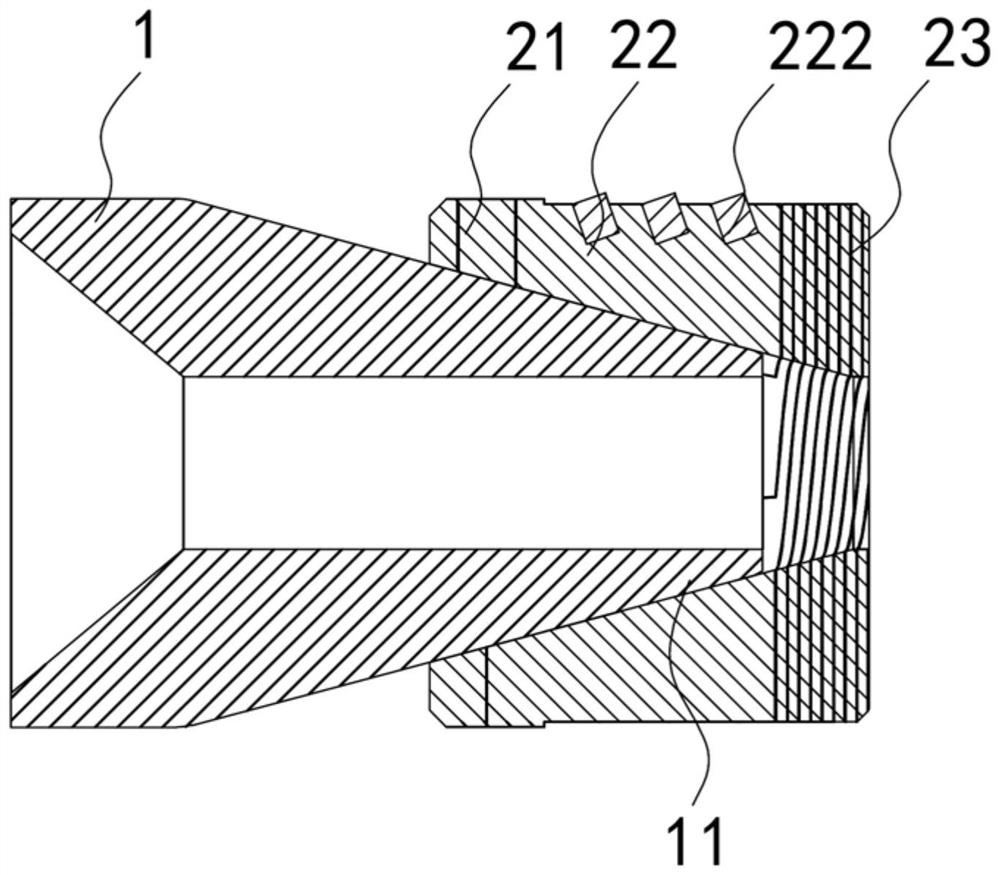

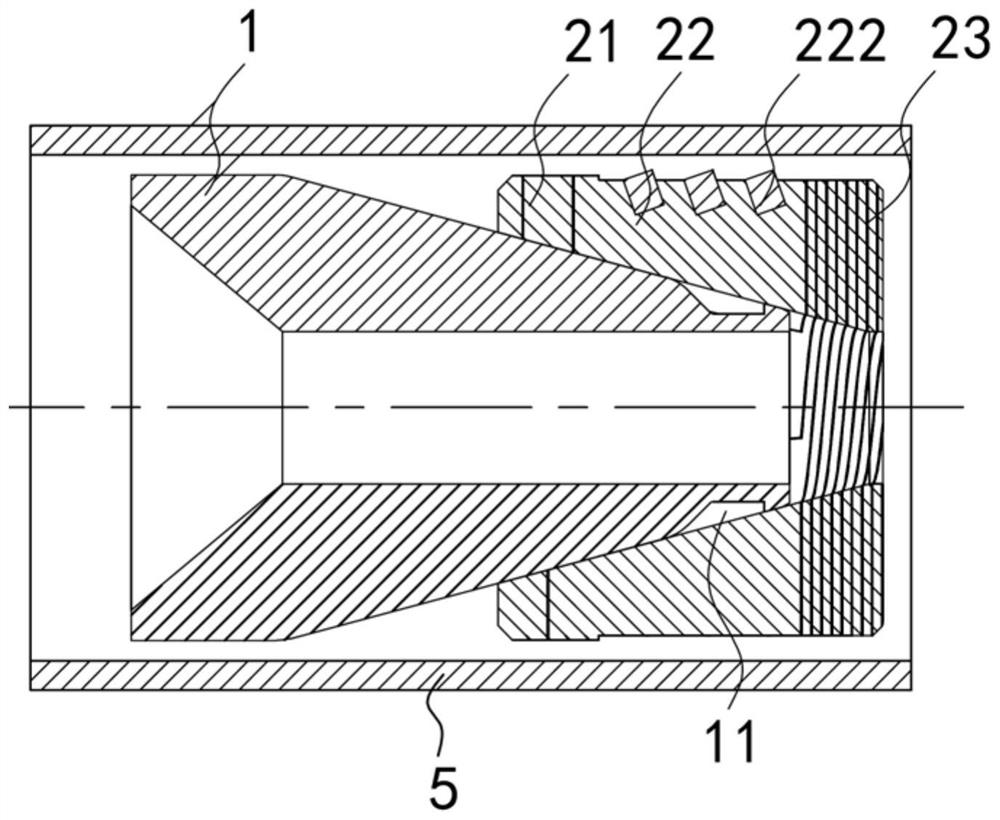

[0055] For a structural schematic diagram of Embodiment 1 of the spiral downhole isolation tool of the present invention, see Figure 1 to Figure 4 .

[0056] A spiral downhole isolation tool, comprising: a center pipe 1 with a tapered outer surface, and the center pipe 1 has an axial through hole.

[0057] An anchor sealing structure 2, the anchor sealing structure 2 is matched and sleeved on the outer surface of the central pipe 1, the anchor sealing structure 2 has a first sealing section 21 and an anchoring section 22, the first sealing section 21 is located on the center pipe 1 At the big end, the anchoring section 22 includes a plurality of slips 221, the first sealing section 21 includes a plurality of first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com