Oil pipe dragging fracturing pipe column with packer as bottom seal and fracturing method

A technology of fracturing strings and packers, which is applied in the directions of sealing/packing, earthwork drilling, mining fluids, etc., and can solve problems such as inability to pull out the string, incomplete unsealing, and failure of the rubber tube due to frictional damage. Achieve the effects of improving the efficiency of fracturing construction, facilitating the control of sealing, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

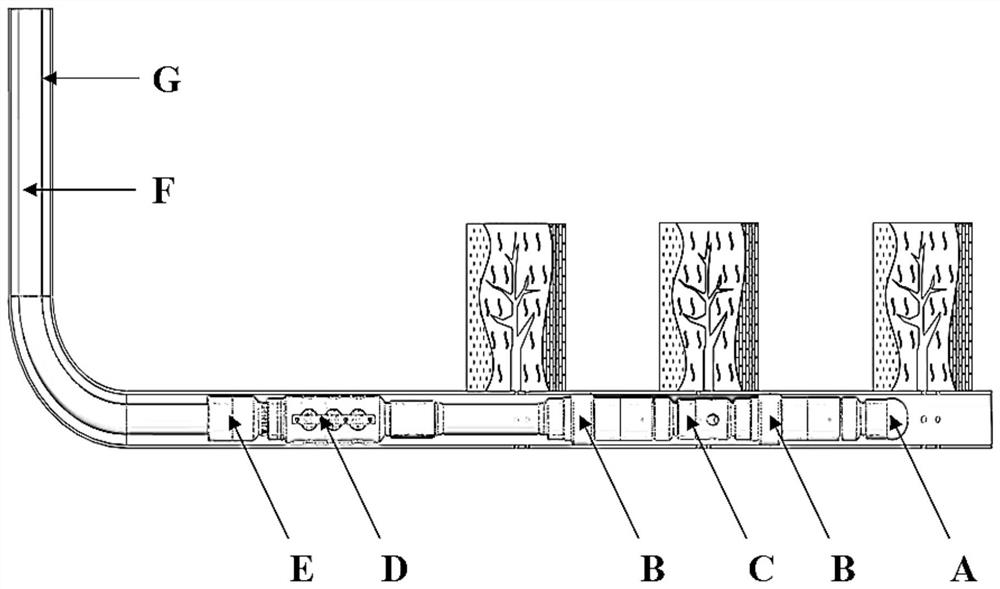

[0034] Such as figure 1 As shown, the tubing-driven fracturing string with the packer as the bottom seal includes a diversion ball seat A, a sand control hydraulic anchor B, an unthrottled self-unpacking packer C, and a hydraulic anchor connected sequentially from bottom to top. The injector D, and the hydraulic safety joint E connected above the hydraulic injector D through the 2-7 / 8" oil pipe, the above-mentioned connected tools are arranged inside the production casing G, and the top of the hydraulic safety joint E is also from bottom to top It is connected with 2-7 / 8″ oil pipe, oil pipe hanger and oil make-up distance.

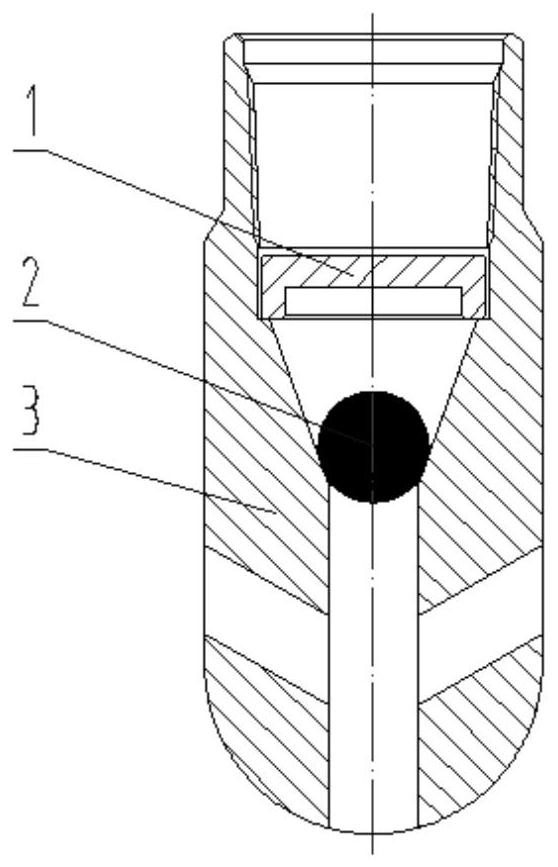

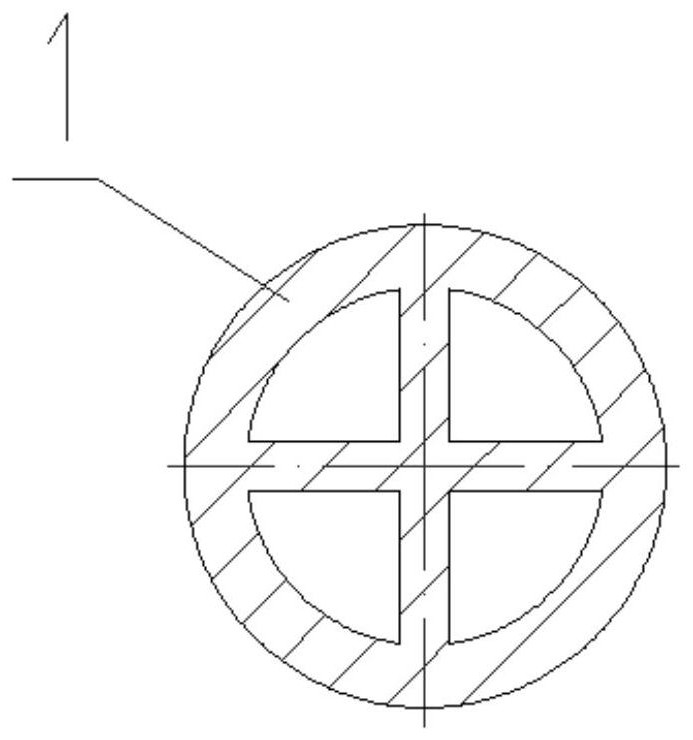

[0035] Such as figure 2 and image 3As shown, the guide ball seat includes a cylindrical body 3 and a valve ball 2 and a stop ring 1 arranged in the cylindrical body 3 from bottom to top; the inner diameter of the upper part of the cylindrical body 3 is larger than the inner diameter of the lower part, and the diameter change is the inner diameter The ...

Embodiment 2

[0047] A fracturing method using the oil tubing with the packer as the bottom seal to drag the fracturing string to implement, the specific steps are as follows:

[0048] S1. Run the fracturing string into the production casing of the oil and gas well, so that the nozzle of the hydraulic injector corresponds to the injection point of the first reservoir section;

[0049] S2. Pressurize from the oil pipe to make the diversion ball seat realize positive closing, and the pressure acts on the power piston 9 through the slit on the lower center pipe 11 of the unthrottle self-service unsealing packer C to push The power piston 9 goes up, compresses the spring 10, and pushes the spacer ring 7 up to compress the rubber tube 6. When the pressure reaches the preset value, the annular space between the oil pipe F and the production casing G is sealed. At this time, the non-throttle self-service Unpack the packer C to complete the initial seal, and continue to increase the pressure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com