Integrated window sidetrack drilling tool

A window-opening sidetracking, integrated technology, applied in drilling equipment, earth-moving drilling, drilling equipment and methods, etc., can solve problems such as wellbore scrapping, difficulty in milling and reduction of operation efficiency, and reduce construction costs. and labor intensity, avoid false setting accidents, and improve the effect of work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

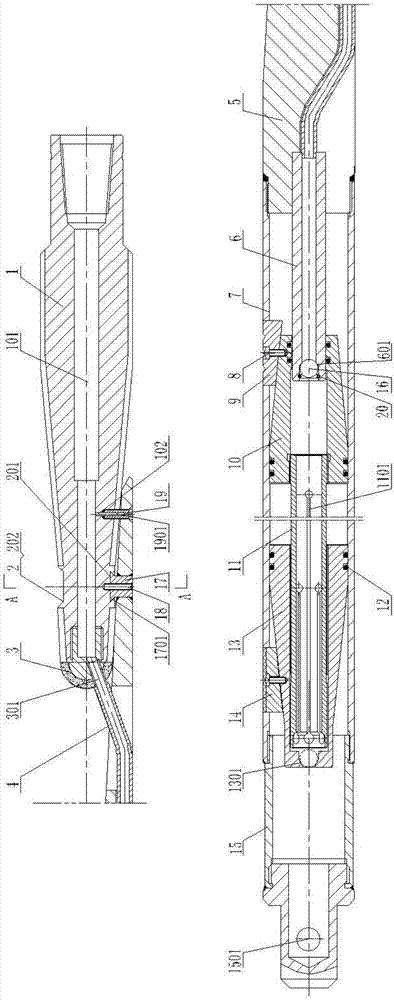

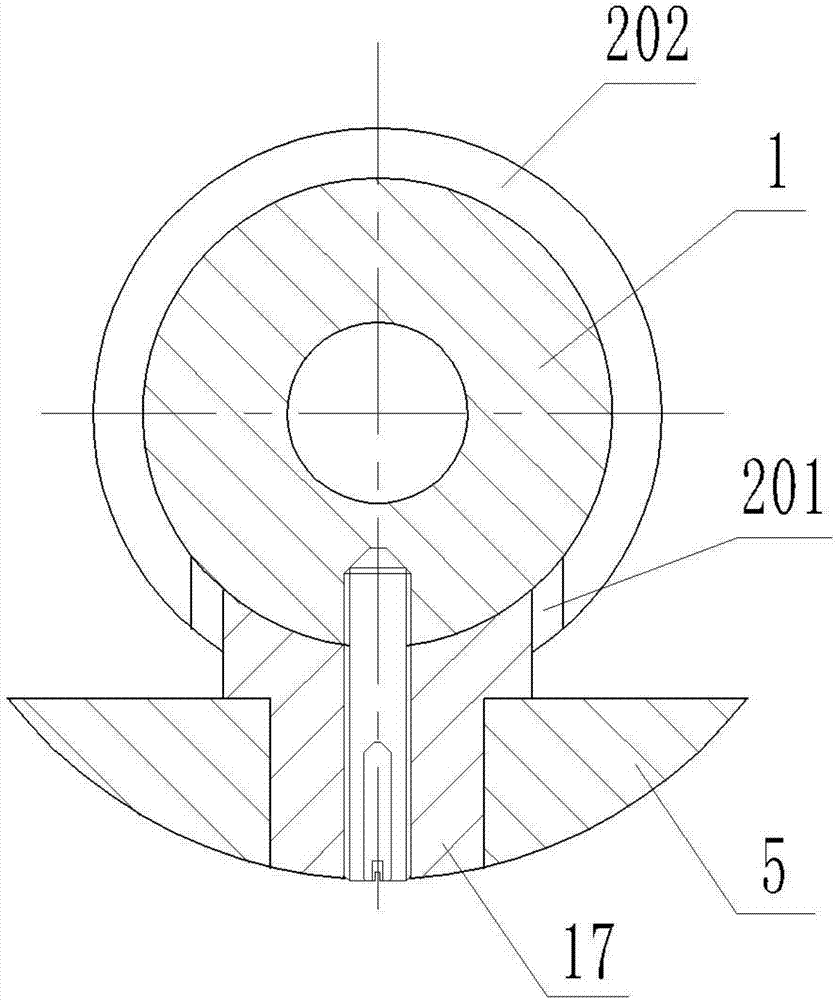

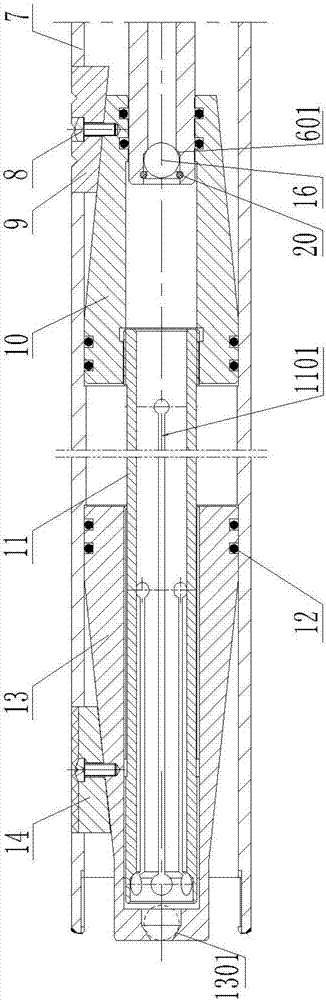

[0028] Such as Figure 1-Figure 3 As shown, the integrated window sidetracking tool includes a hollow milling cone 1, a deflector slant iron 5 connected to the lower part of the milling cone 1, and a setting anchor device fixedly connected to the lower end of the deflection deflector slant 5. In the inclined iron 5 of the deflection guide, there is a catheter 4 connected to the inner hole of the milling cone 1 and the inner cavity of the setting anchoring device. There is a nozzle hole 301 communicating with the milling cone inner hole 101, and the upper end of the liquid guide pipe 4 is drawn out from the top of the slope of the inclined iron 5 of the deflector and inserted into the nozzle hole 301 for welding.

[0029] The lower part of the milling cone 1 is pressed on the upper inclined surface of the inclined iron 5 of the inclined guide, and an annular groove 2 is processed in the lower part of the milling cone 1 along the circumferential direction, and the annular groove 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com