Design method of deep complex stratum well bore structure based on risk assessment

A wellbore structure and complex formation technology, applied in the field of oil and gas drilling, can solve the problems of reducing the comprehensive risk of the wellbore structure, and achieve the effect of reducing the comprehensive risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

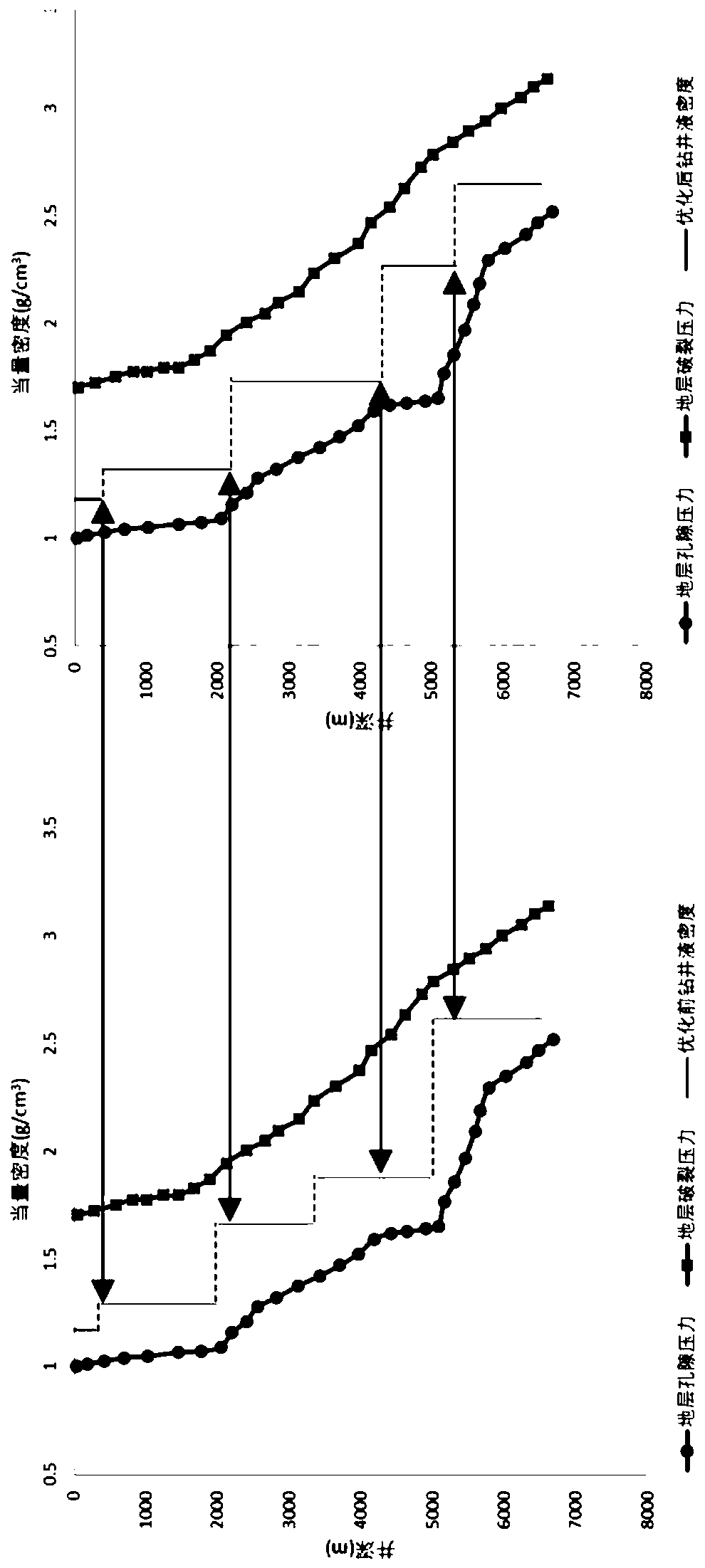

[0059] by Taking the well as an example, a specific implementation method is introduced. The design well depth is 6500 meters, and the well kick tolerance is S k =0.05g / cm 3 , Formation fracture pressure safety factor S f =0.04g / cm 3 , Additional drilling fluid density ρ=0.05g / cm 3 , Suction pressure coefficient S b =0.04g / cm 3 . Its formation pressure profile is as figure 1 shown.

[0060] According to steps 1)-3) of the present invention, a top-down method is adopted to preliminarily determine the wellbore structure scheme of the well.

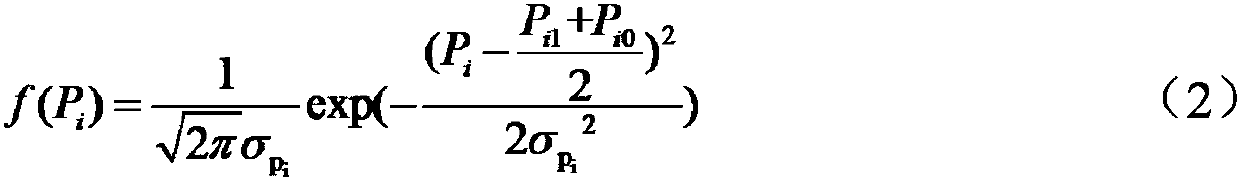

[0061] In step 2), take the standard deviation of formation pressure prediction error The error cumulative probability formulas of formation pore pressure and formation fracture pressure are obtained as follows:

[0062] Formation pore pressure:

[0063] Formation fracture pressure:

[0064] According to the drilling experience of adjacent wells in this area, kick and lost circulation are prone to occur downhole in the dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com