Method for achieving separated layer water distribution by pressure pulse

A technology of pressure pulse and water distribution, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of long time, control failure, and large difference in water absorption capacity, etc., achieve high success rate, improve efficiency, The effect of saving labor time and construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

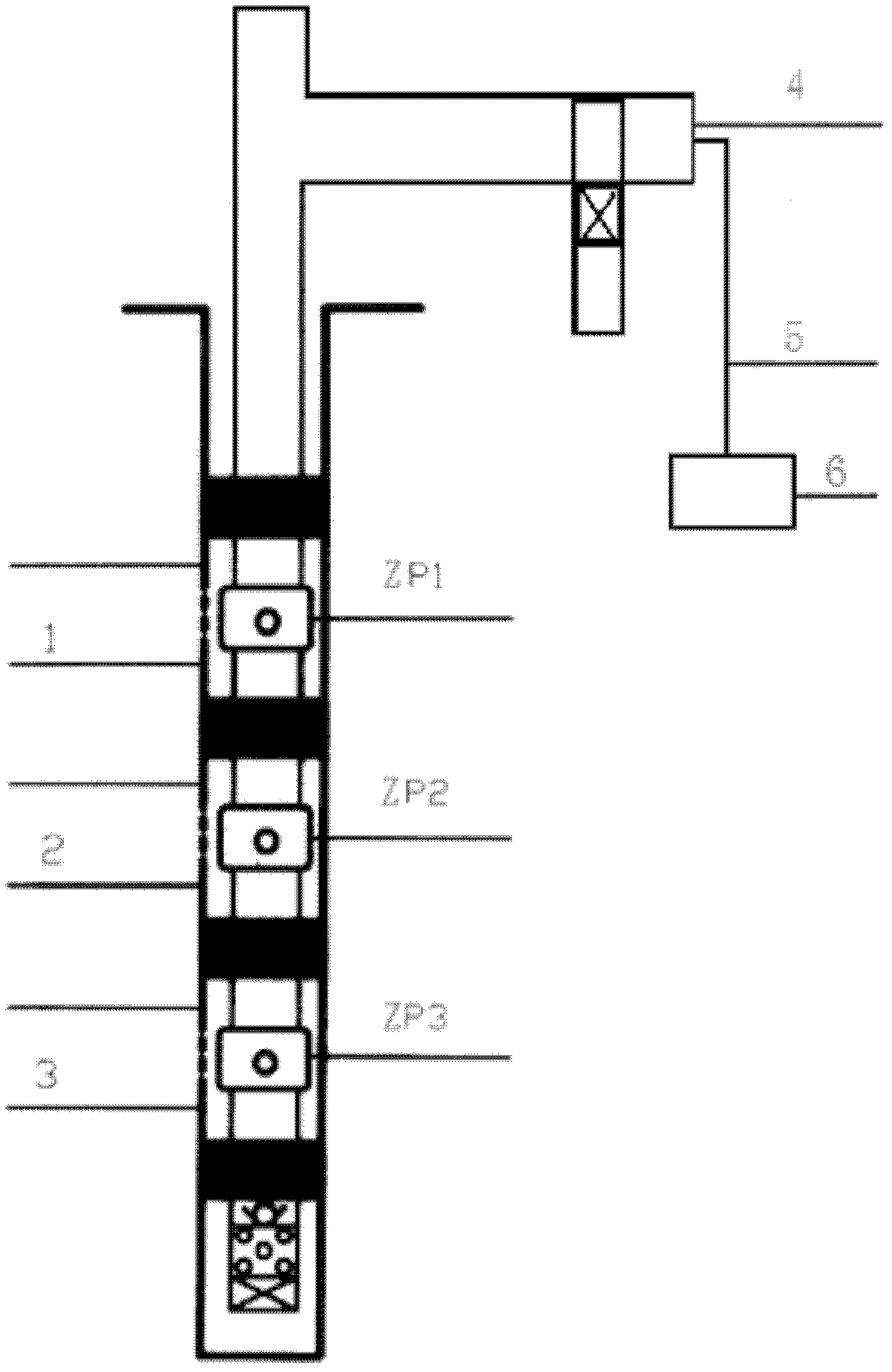

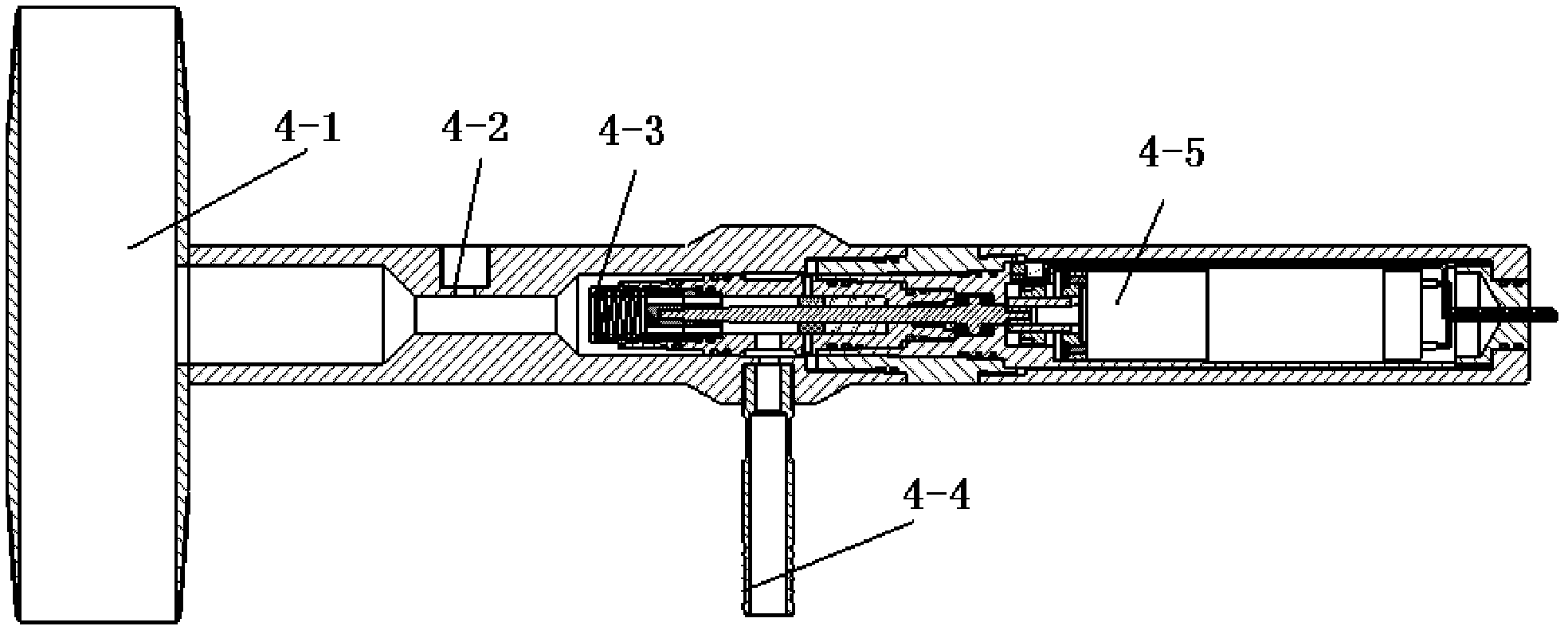

[0030] A method for realizing stratified water distribution with pressure pulses, the method utilizes a wellhead pressure pulse program-controlled generator 4 and a stratified water injection string equipped with an intelligent water distributor to realize stratified water distribution; the method includes the following steps:

[0031] (1) An intelligent water distributor ( figure 1 ZP1, ZP2 and ZP3 in the wellhead), the wellhead pressure pulse program-controlled generator 4 is installed at the wellhead; the wellhead pressure pulse program-controlled generator 4 is connected with the computer 6 by the communication cable 5;

[0032] (2) The computer 6 sends an instruction signal to the wellhead pressure pulse program-controlled generator 4. After the wellhead pressure pulse program-controlled generator 4 receives the instruction signal, the program control generates a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com