Aqueous film-forming foam extinguishing agent special for fire extinguishing bullet and throwing type fire extinguisher

A technology of foam fire extinguishing agent and fire extinguisher, which is applied in the direction of fire prevention equipment, etc., can solve the problems of low fire extinguishing efficiency, fire extinguishing speed not meeting the requirements, and the urgent need to improve the anti-reburning performance, so as to achieve good fire extinguishing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

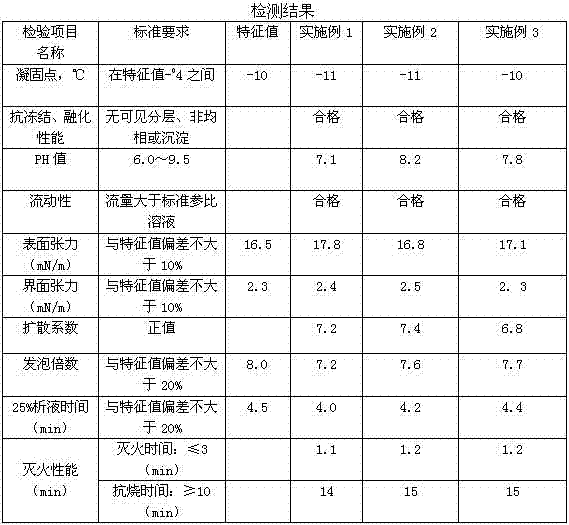

Embodiment 1

[0017] Take F1157N: 7.5kg, F1203: 2kg, Sodium Lauryl Sulfate: 5kg, Cocamidopropyl Betaine: 7.5kg, Ethylene Glycol: 4kg, Glycerol: 2.5kg, Ethylene Glycol Butyl Ether: 12.5 kg, xanthan gum: 0.2kg, urea: 12kg, ammonium polyphosphate: 3kg, water: 43.8kg, be placed in the container and stir evenly, promptly make the special aqueous film-forming foam fire extinguishing agent of fire extinguishing bomb and throwing type fire extinguisher of the present invention 100kg, the above aqueous film-forming foam fire extinguishing agent can be packaged in separate bottles to make a throwing fire extinguisher.

[0018] In this example, the distribution ratio of each component is as follows: 9.5% main blowing agent, 12.5% auxiliary blowing agent, 6.5% antifreeze, 12.5% cosolvent, 0.2% stabilizer, 12% anti-burning agent, flame retardant 3%, water 43.8%.

[0019] The specific proportions include: F1157N: 7.5%, F1203: 2.0%, Sodium Lauryl Sulfate: 5.0%, Cocamidopropyl Betaine: 7.5%, Ethylene ...

Embodiment 2

[0021] Take F1157N: 6.5kg, F1203: 4 kg, dodecyl dimethyl betaine: 15 kg, ethylene glycol: 2 kg, propylene glycol: 6 kg, diethylene glycol ether: 16 kg, xanthan gum: 0.1 kg, urea: 8 kg, ammonium dihydrogen phosphate: 2 kg, water: 40.4 kg, put them in a container and stir evenly to obtain 100 kg of special aqueous film-forming foam fire extinguishing agent for fire extinguishing bombs and throwing fire extinguishers of the present invention.

[0022] In this example, the distribution ratio of each component is as follows: main blowing agent 10.5%, auxiliary blowing agent 15.0%, antifreeze agent 8.0%, cosolvent 16.0%, stabilizer 0.1%, anti-burning agent 8.0%, flame retardant 2.0%, water 40.4%.

[0023] The specific ratio includes: F1157N: 6.5%, F1203: 4%, lauryl dimethyl betaine: 15%, ethylene glycol: 2%, propylene glycol: 6%, diethylene glycol ether: 16%, yellow Raw gum: 0.1%, urea: 8%, ammonium dihydrogen phosphate: 2%, water: 40.4%.

Embodiment 3

[0025] Take F1203: 3kg, F1460: 9 kg, alkyl glycoside: 8 kg, ethylene glycol: 2 kg, dodecyl alcohol: 6 kg, n-butanol: 16 kg, sodium alginate: 0.2 kg, urea: 16 kg, Ammonium polyphosphate: 5 kg, water: 34.8 kg, placed in a container and stirred evenly, promptly made 100 kg of special aqueous film-forming foam fire extinguishing agent for fire extinguishing bombs and throwing fire extinguishers of the present invention.

[0026] In this example, the distribution ratio of each component is as follows: main blowing agent 12.0%, auxiliary blowing agent 8.0%, antifreeze agent 2.0%, cosolvent 22.0%, stabilizer 0.2%, anti-burning agent 16.0%, flame retardant 5.0%, water 34.8%.

[0027] The specific ratio includes: F1203: 3%, F1460: 9%, alkyl glucoside: 8%, ethylene glycol: 2%, dodecyl alcohol: 6%, n-butanol: 16%, sodium alginate: 0.2%, Urea: 16%, ammonium polyphosphate: 5%, water: 34.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com