Heat radiation assembly and electric device

A technology for heat dissipation components and electronic equipment, which is applied in circuits, electrical components, electric solid devices, etc., and can solve problems such as poor heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

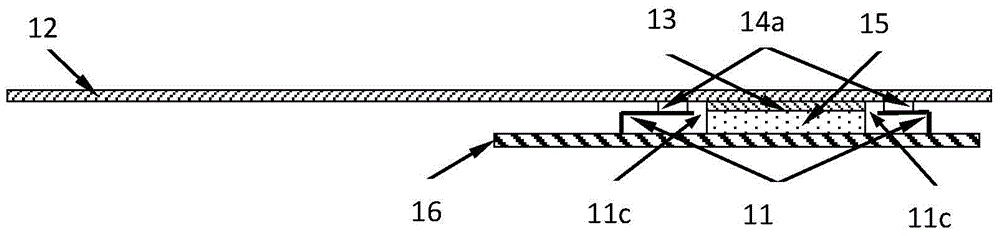

[0083] Please refer to figure 1 , the embodiment of the present application provides a heat dissipation assembly, the heat dissipation assembly includes:

[0084] A shielding element 11, the shielding element 11 is provided with a through hole 11c, the shielding element 11 is electrically connected to the ground copper of the PCB board 16, and the PCB board 16 is provided with a heating electronic element 15;

[0085] The heat pipe 12 is located on the through hole 11c, the heat pipe 12 is electrically connected to the shielding element 11, wherein the heat pipe 12, the PCB board 16 and the shielding element 11 form a heat pipe for accommodating the heat Electromagnetic shielding cover of electronic component 15;

[0086] The first elastic thermal interface material 13 is located between the heat pipe 12 and the heat-generating electronic component 15 , and adheres to the heat pipe 12 and the heat-generating electronic component 15 .

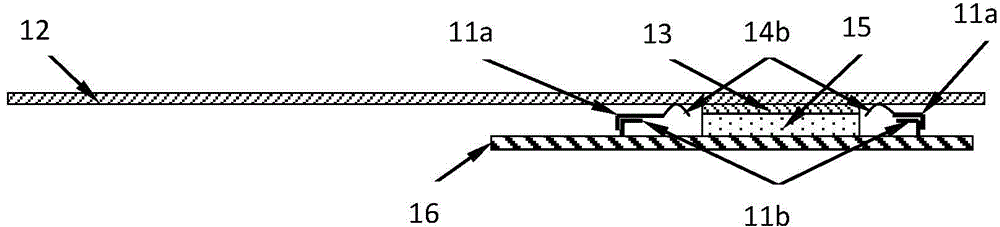

[0087] Please refer to figure 2 The s...

Embodiment 2

[0101] Please refer to Image 6 , the embodiment of the present application provides a heat dissipation assembly, the heat dissipation assembly includes:

[0102] A shielding element 11, the shielding element 11 is provided with a through hole 11c, the shielding element 11 is electrically connected to the ground copper of the PCB board 16, and the PCB board 16 is provided with a heating electronic element 15;

[0103] The elastic conductive thermal interface material 19 is located on the through hole 11c and is attached to the shielding element 11, wherein the elastic conductive thermal interface material 19, the PCB board 16 and the shielding element 11 form a An electromagnetic shielding cover for accommodating the heating electronic components 15;

[0104] The heat pipe 12 is located on the elastic conductive thermal interface material 19 and attached to the elastic conductive thermal interface material 19 .

[0105] like Image 6 As shown, the elastic conductive thermal...

Embodiment 3

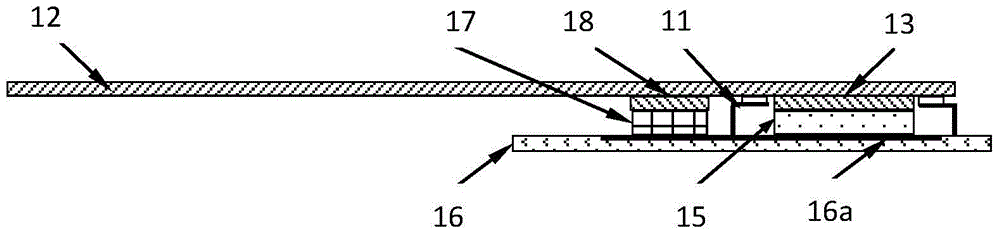

[0112] Please refer to Figure 8 , the embodiment of the present application provides a heat dissipation assembly, the heat dissipation assembly includes:

[0113] The heat-conducting metal block 17 is arranged on the PCB board 16, and is connected to the heating electronic component 15 provided on the PCB board 16 through the heat-conducting layer 16a on the PCB;

[0114] An elastic thermal interface material 18 is pasted on the heat-conducting metal block 17;

[0115] The heat pipe 12 is pasted on the elastic thermal interface material 13 .

[0116] During practical application, since the PCB board 16 is provided with many copper layers and thermal holes, most of the heat of many heat-generating electronic components 15 is transferred to the PCB board 16 . Therefore, in the embodiment of the present application, for the case where the main heat is transferred to the PCB board 16, a heat-conducting metal block 17 is arranged on the PCB board 16 adjacent to the heating elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com