Heatsink apparatus

a heatsink and apparatus technology, applied in mechanical apparatus, machines/engines, liquid fuel engines, etc., can solve the problems of insufficient heatsink cooling insufficient heatsink air cooling, and decline in reliability of impeller bearing structures, so as to improve overall cooling efficiency and maintain the temperature of heat-generating electronic components. , the effect of low thermal resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

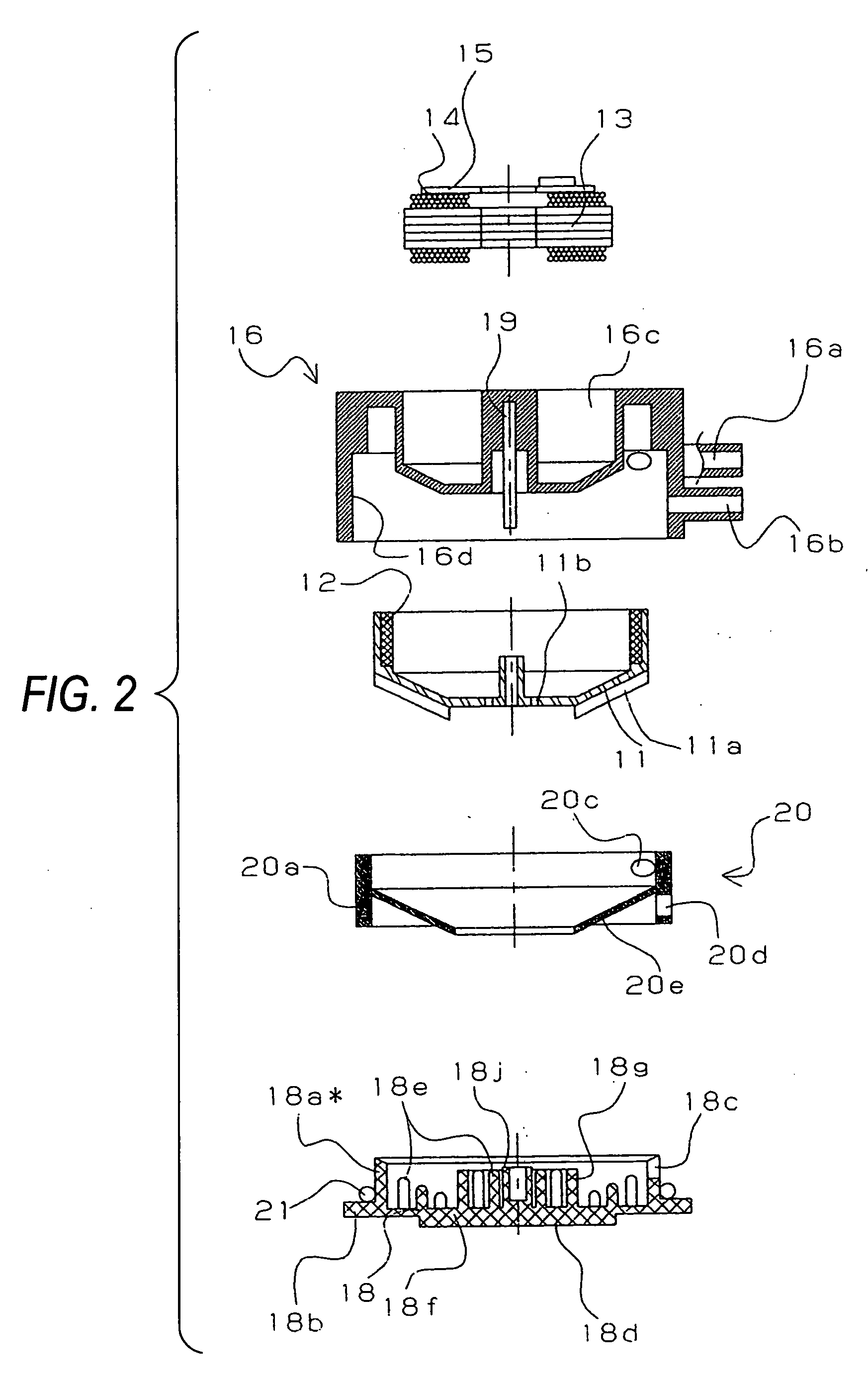

[0037] A centrifugal pump in a heatsink apparatus according to a first embodiment of the present invention is described below. FIG. 1 is a cross-sectional view of the centrifugal pump in the heatsink apparatus according to the first embodiment of the present invention; FIG. 2 is an exploded cross-sectional view of the centrifugal pump in the heatsink apparatus according to the first embodiment of the present invention; FIGS. 3 to 5 are perspective views of a lower casing according to the first embodiment of the present invention; FIG. 6 is a perspective view of a ring-shaped sealing member as a single unit according to the first embodiment of the present invention; and FIG. 7 illustrates a flow direction of a coolant in the centrifugal pump according to the first embodiment of the present invention. An overall structure of an electronic device having the heatsink apparatus according to the first embodiment is the same as that in the conventional art, thus FIGS. 16 and 17 are also re...

second embodiment

[0059] A centrifugal pump in a heatsink apparatus according to a second embodiment of the present invention is described below. FIG. 8 is a cross-sectional view of the centrifugal pump in the heatsink apparatus according to the second embodiment of the present invention; FIG. 9 is an exploded cross-sectional view of the centrifugal pump in the heatsink apparatus according to the second embodiment of the present invention; FIGS. 10 and 11 are perspective views of a lower casing according to the second embodiment of the present invention; FIG. 12 is a perspective view of a ring-shaped sealing member as a single unit according to the second embodiment of the present invention; and FIG. 13 illustrates a flow direction of a coolant in the centrifugal pump according to the second embodiment of the present invention. An overall structure of an electronic device having the heatsink apparatus according to the second embodiment is the same as that in the conventional art, thus FIGS. 16 and 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com