Liquid cooling jacket

a technology of liquid cooling jacket and cooling jacket, which is applied in the direction of metal-working equipment, basic electric elements, semiconductor devices, etc., can solve the problems of large pressure loss of cooling liquid, increased pump output power, and inability to efficiently cool liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

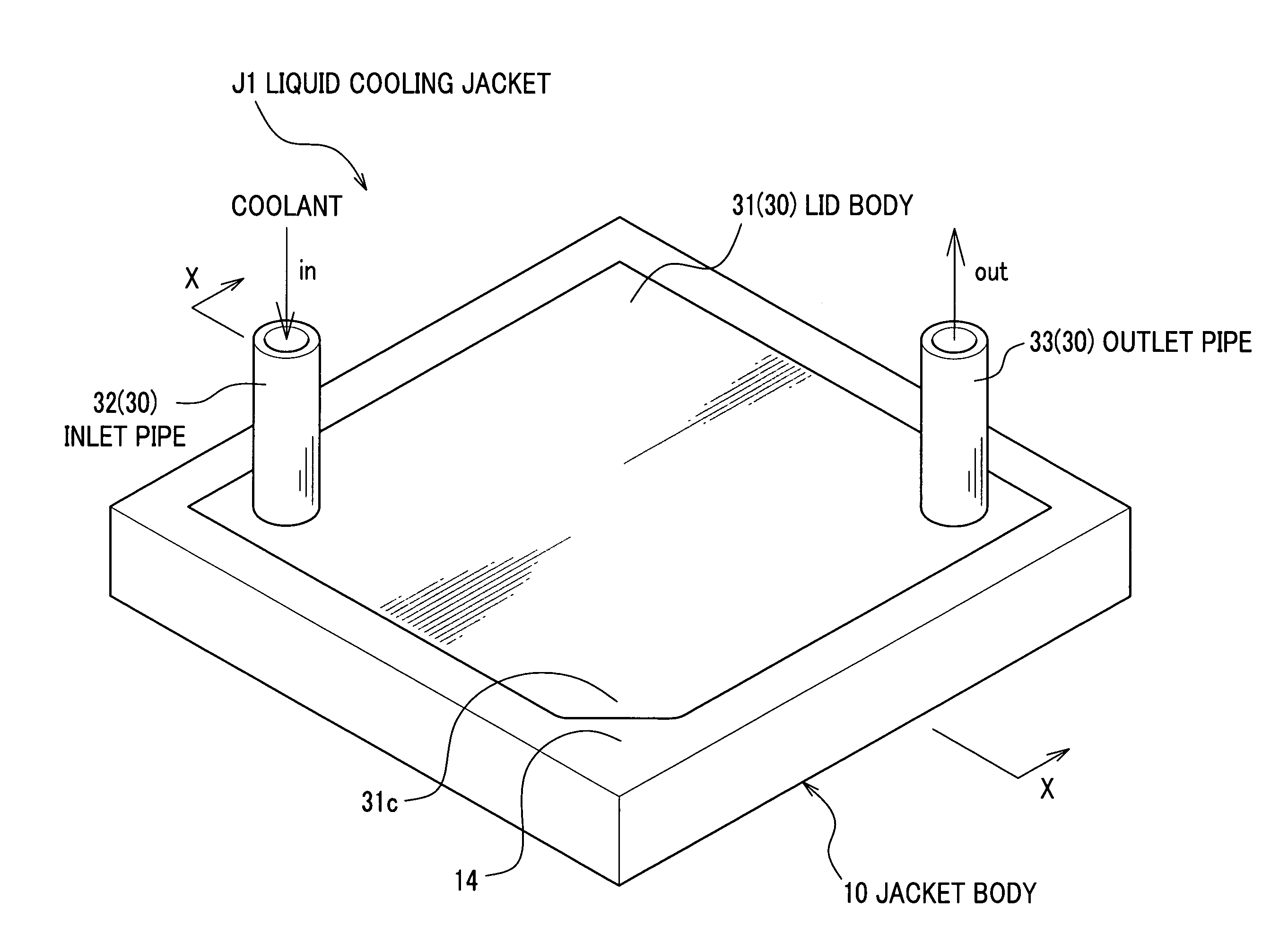

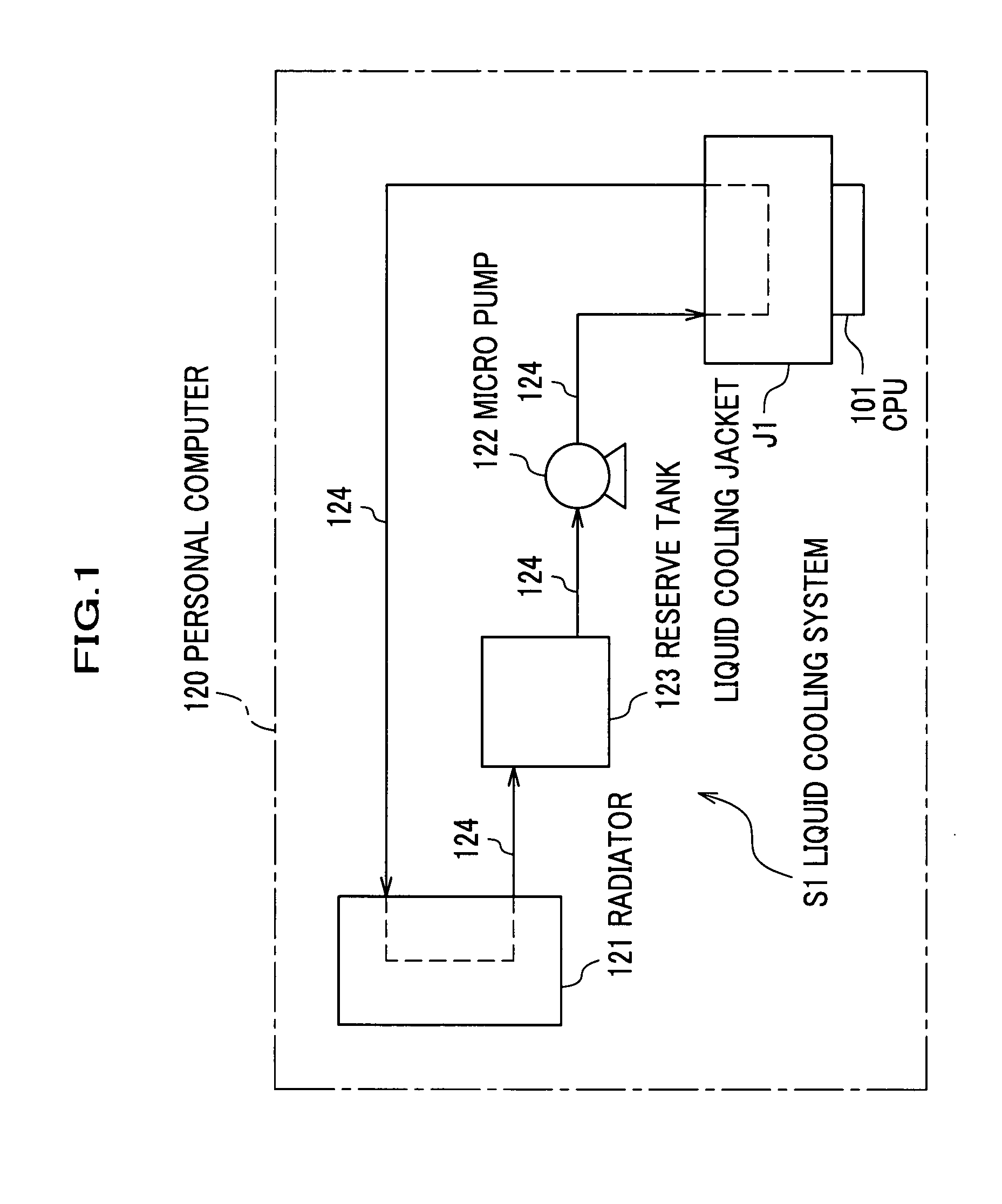

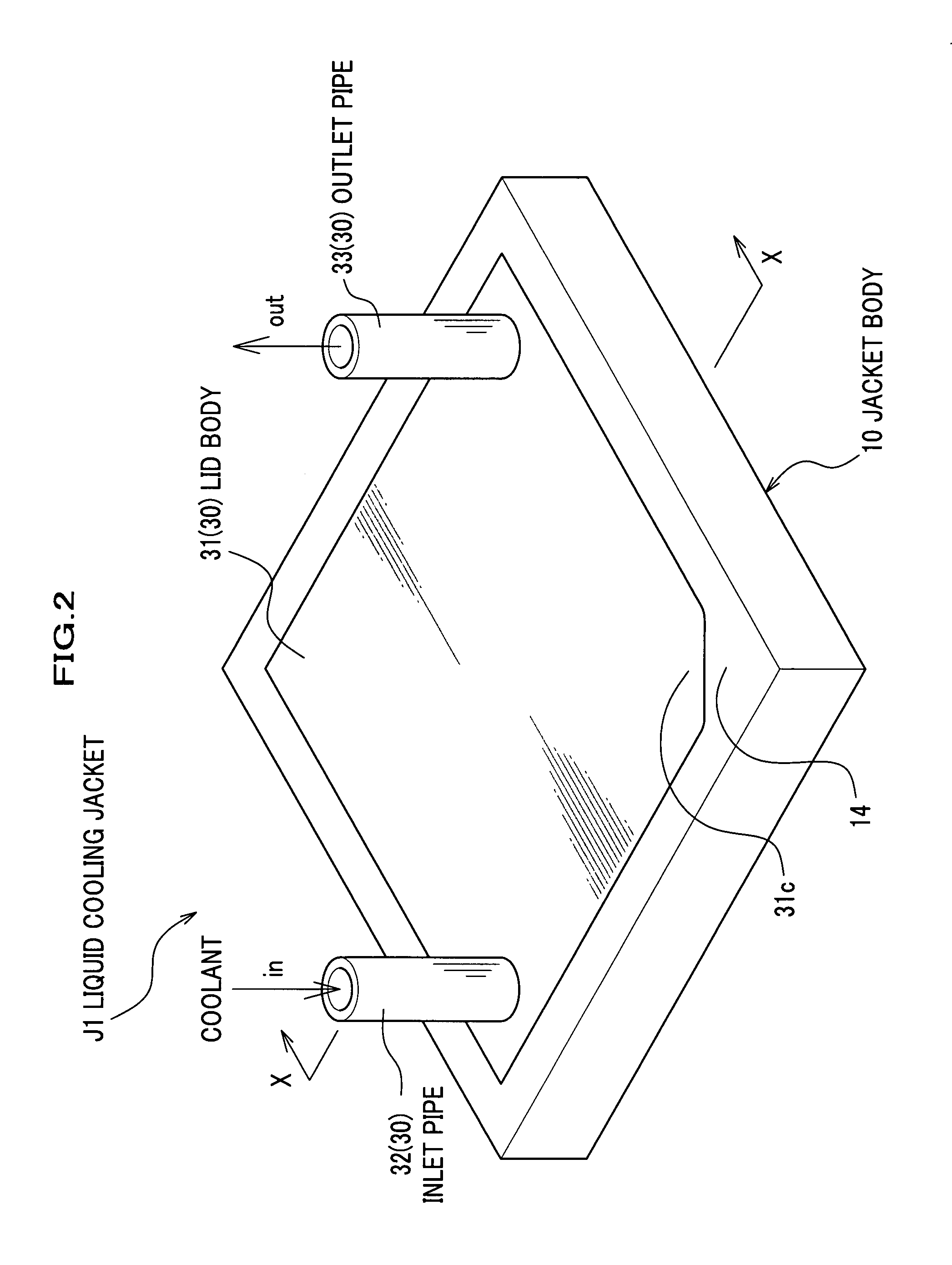

[0139]A liquid cooling system and a liquid cooling jacket according to a first embodiment are now described with reference to FIG. 1 to FIG. 8. FIG. 1 is a block diagram of the liquid cooling system according to the first embodiment. FIG. 2 is a perspective view of a liquid cooling jacket according to the first embodiment. FIG. 3 is a bottom perspective view of the liquid cooling jacket according to the first embodiment. FIG. 4 is a perspective view of the liquid cooling jacket according to the first embodiment, in which a lid unit is omitted. FIG. 5 is a plain view of the liquid cooling jacket according to the first embodiment, in which an inlet pile and an outlet pipe are omitted. FIG. 6 is a cross-sectional view of the liquid cooling jacket according to the first embodiment along a line X-X shown in FIG. 2. FIG. 7 is an exploded perspective view of the liquid cooling jacket according to the first embodiment. FIG. 8 is a graph schematically showing an effect of the liquid cooling ...

second embodiment

[0179]A liquid cooling jacket according to a second embodiment is now described with reference to FIG. 9 and FIG. 10. FIG. 9 is a perspective view of a liquid cooling jacket J2 according to the second embodiment, in which a lid unit is omitted.

FIG. 10 is a cross-sectional view of the liquid cooling jacket J2 according to the second embodiment along a line Y-Y shown in FIG. 9.

[0180]As shown in FIG. 9 and FIG. 10, the liquid cooling jacket J2 according to the second embodiment comprises a flat tube bundle 23 instead of the flat tube bundle 20 of the liquid cooling jacket J1 according to the first embodiment. Although the flat tube bundle 23 is the same as the flat tube bundle 20 in outside dimension, the flat tube bundle 23 is formed by bundling a plurality of laminar flat tubes 24 (three laminar flat tubes in FIG. 9 and FIG. 10). Each of the flat tubes 24 comprises a plurality of inner holes (12 inner holes in FIG. 9 and FIG. 10) inside thereof. Each of the inner holes is a second fl...

third embodiment

[0182]A liquid cooling jacket according to a third embodiment is now described with reference to FIG. 11 and FIG. 12. FIG. 11 is a perspective view of the liquid cooling jacket according to the third embodiment. FIG. 12 is a plain view of the liquid cooling jacket according to the third embodiment.

Configuration of the Liquid Cooling Jacket

[0183]As shown in FIG. 11 and FIG. 12, the liquid cooling jacket J3 according to the third embodiment comprises a lid body 34 on which an inlet 34a and an outlet 34b are disposed in positions different from those of the liquid cooling jacket J1 according to the first embodiment.

[0184]The inlet 34a communicates with substantially center of the space 10a (first flow passage A1). The coolant is supplied to the substantially center of the space 10a. The outlet 34b communicates with substantially center of the space 10c (third flow passage C1). The coolant is discharged from the substantially center of the space 10c. The inlet 34a and outlet 34b are dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com