Cold plate with pins

a technology of cold plate and pin, which is applied in the direction of laminated elements, lighting and heating equipment, separation processes, etc., can solve the problems of plugging of cold plate, not being particularly clean,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

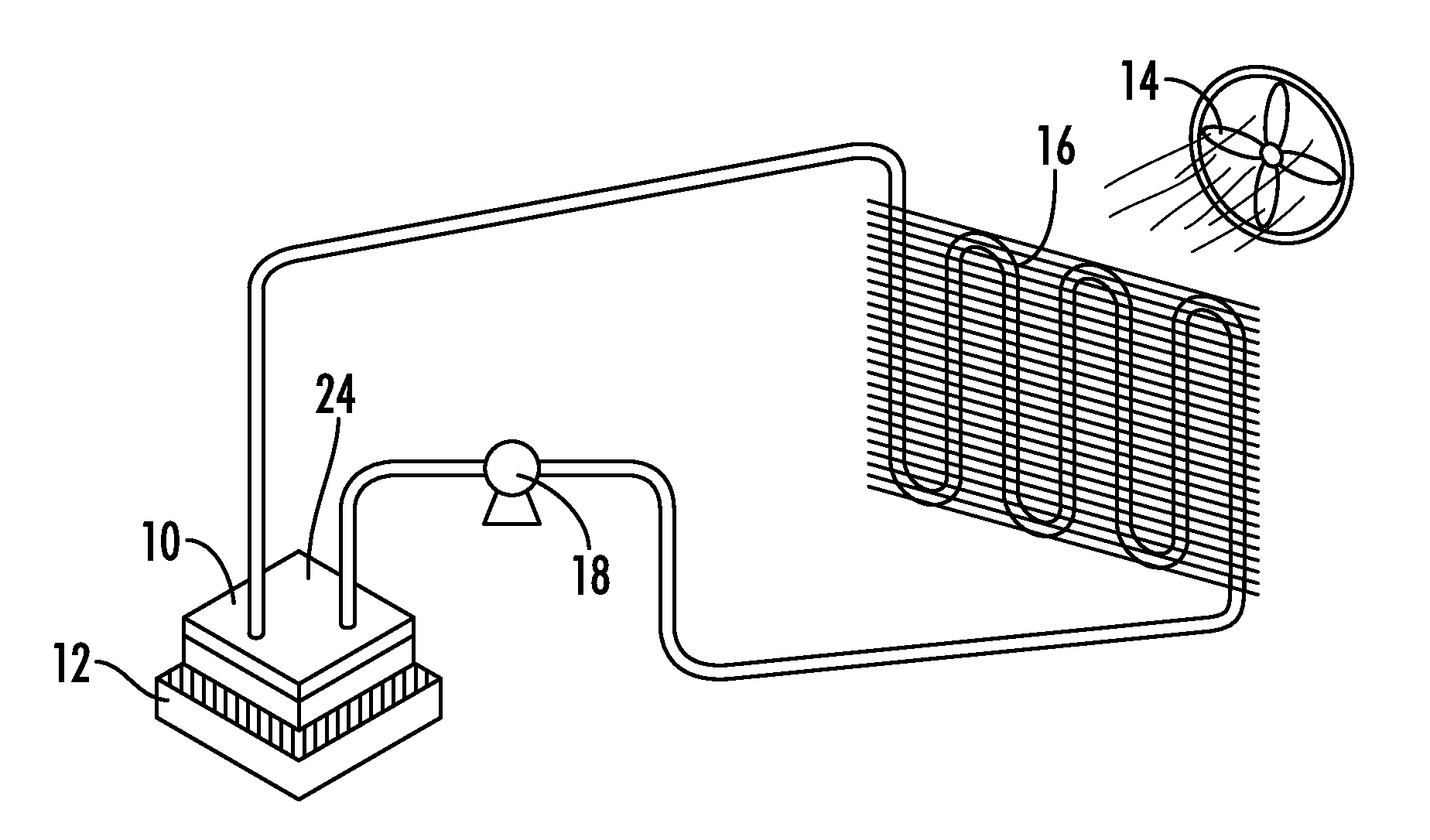

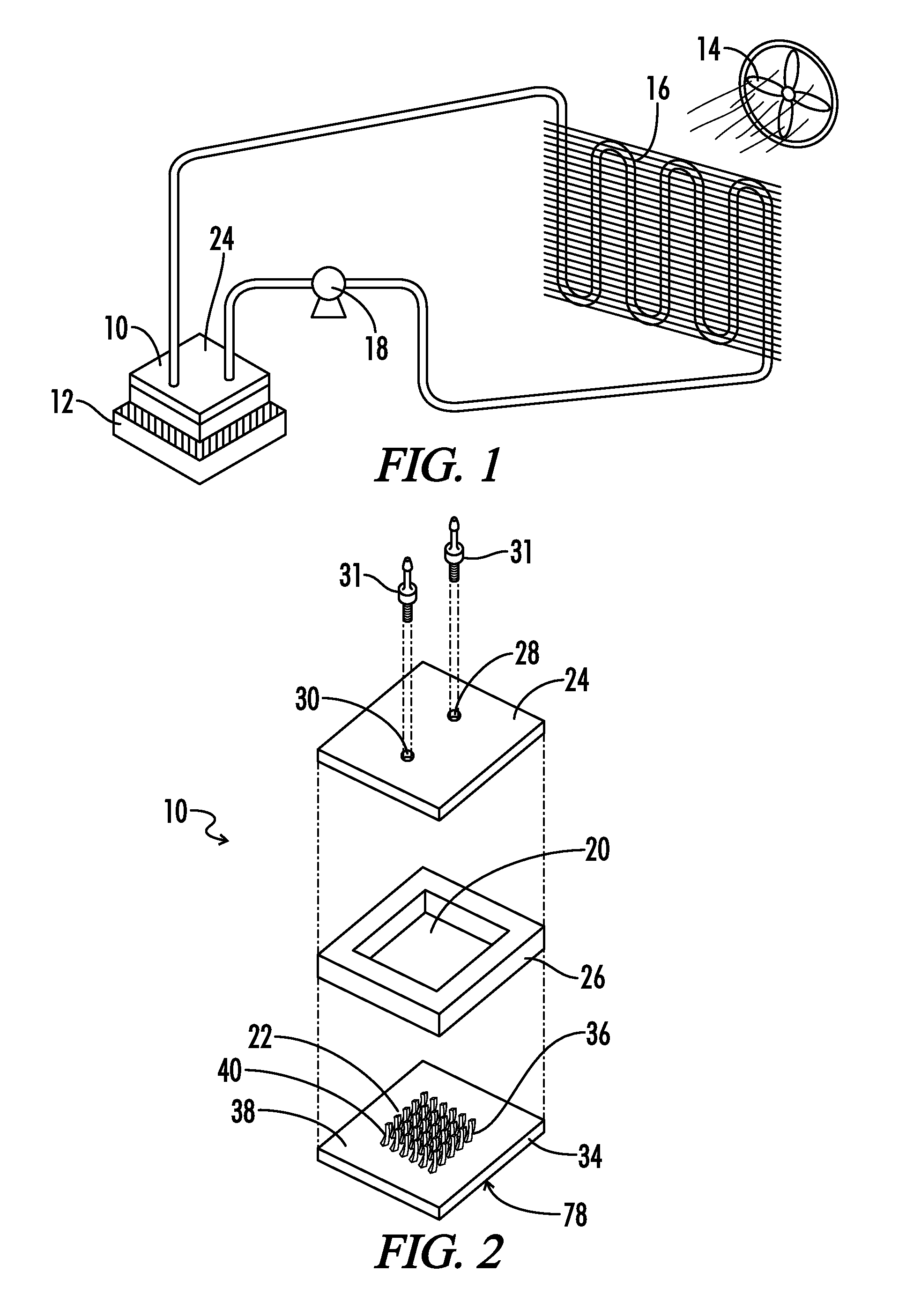

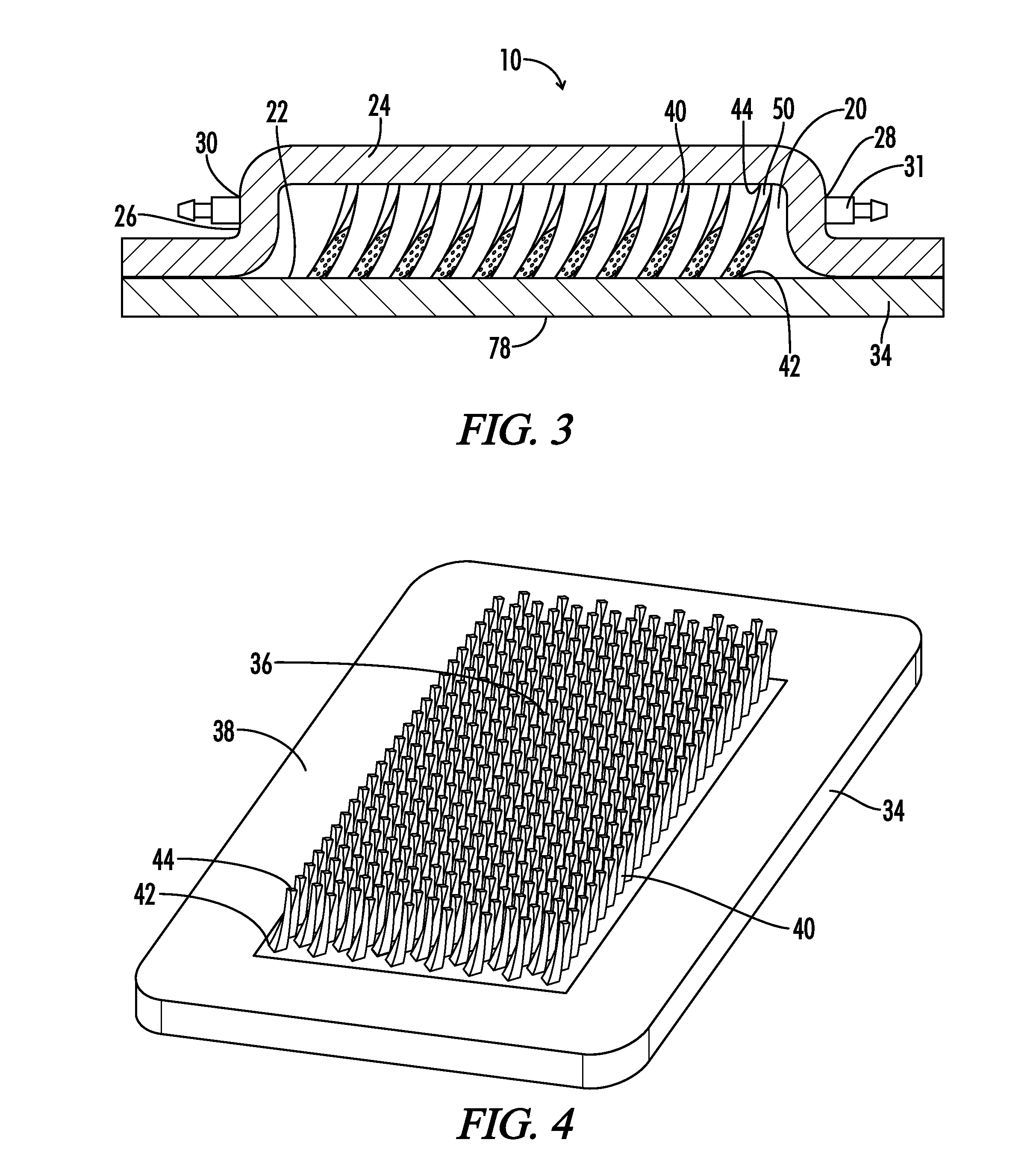

[0021]Some electronic components are limited by the heat they produce. Cooling can help to increase the utilization of some of these components. Different cooling techniques are more appropriate for different equipment or different circumstances. One cooling method uses fans to blow air over an electronic component for convection cooling. This technique is simple and safe, but does not provide the cooling potential of some other techniques. The utilization of a liquid coolant can provide more efficient cooling, but many electronic components can malfunction when splashed with a liquid, so some can be cautious when using liquid cooling. Nevertheless, liquid cooling can increase the overall efficiency of some electronic components, as well as providing certain other benefits. Secondary benefits can include decreased acoustical noise and superior temperature consistency in the electronic component.

Heat Transfer Fundamentals

[0022]This description will focus on single phase heat transfer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com