Defrosting system and refrigerator with same

An evaporator and main body technology, applied in the field of refrigerators, can solve the problems of not being able to fully guarantee defrosting, low heat exchange efficiency of the evaporator, and high energy consumption for defrosting, so as to shorten the defrosting time and ensure sufficient defrosting performance, the effect of reducing the amount of frosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

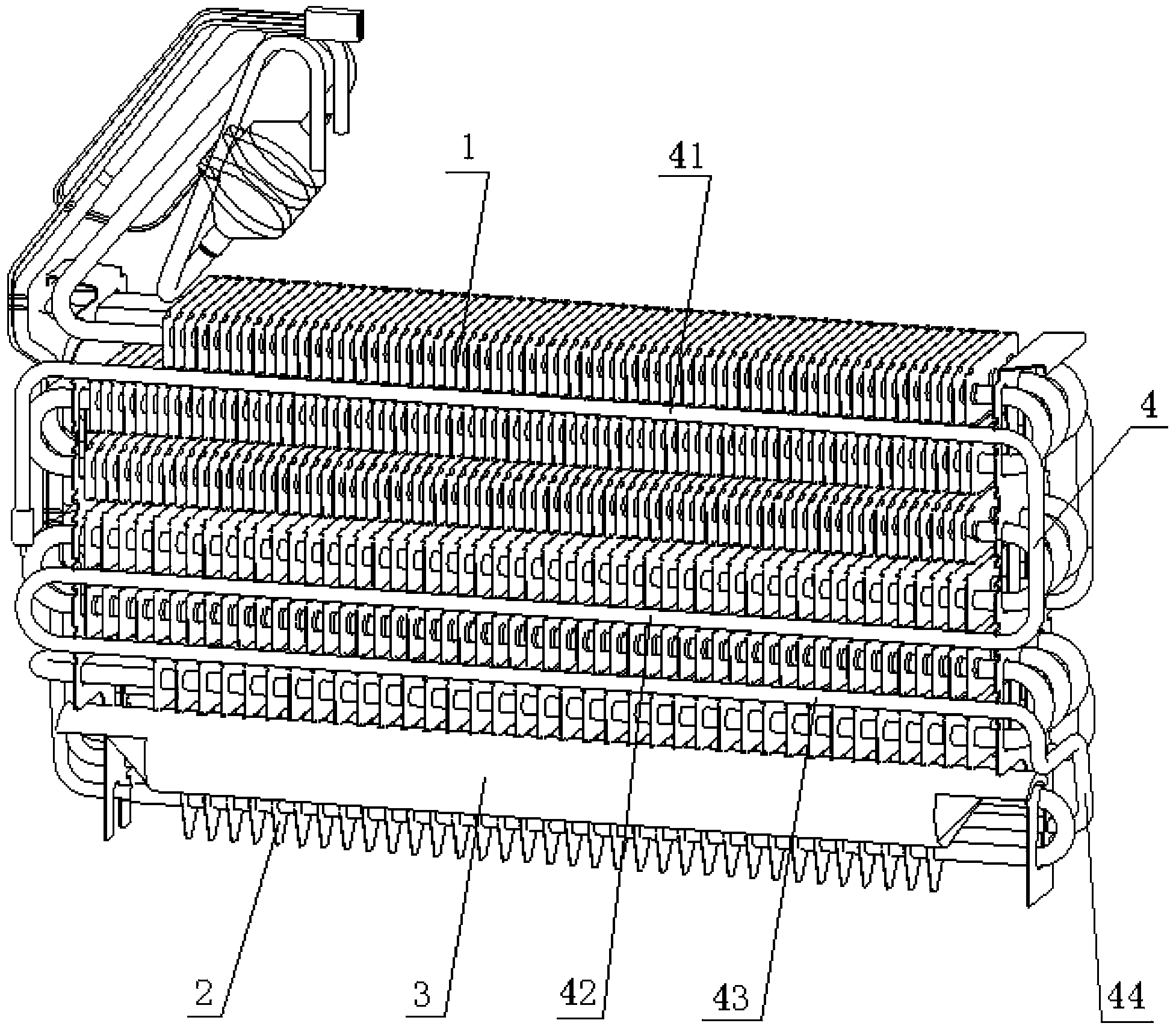

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

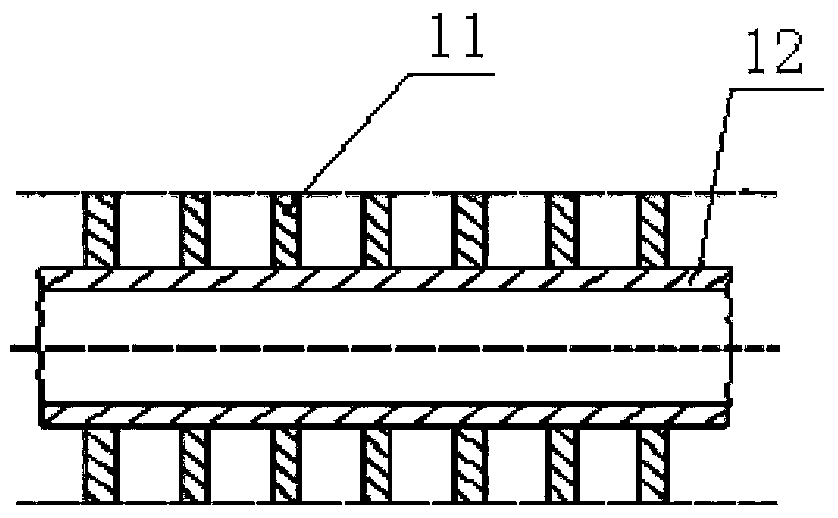

[0027] figure 1 It is a structural schematic diagram of the defrosting system provided by the specific embodiment of the present invention. Such as figure 1 As shown, this scheme starts from various aspects of design to form an efficient and reliable defrosting technology. The defrosting system includes an evaporator body 1 and a pre-cooling evaporator 2 arranged at the bottom of the evaporator body 1 for cooling and dehumidifying the high-temperature and high-humidity air returning from the return air outlet. The pre-cooling evaporator 2 One end communicates with the air return port, and the other end communicates with the main body 1 of the evaporator.

[0028] In the air-cooled refrigerator with the defrosting system of the present invention, the high-temperature and high-humidity air returned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com