Electrically-heatable low-emissivity coated laminated glass

A low-emissivity coating and laminated glass technology, which is applied in the field of automobile windshields, can solve the problems such as the unsatisfactory electrical connection between the low-emissivity film and the busbar, and achieve the effects of simplifying the production process, good electrical contact performance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

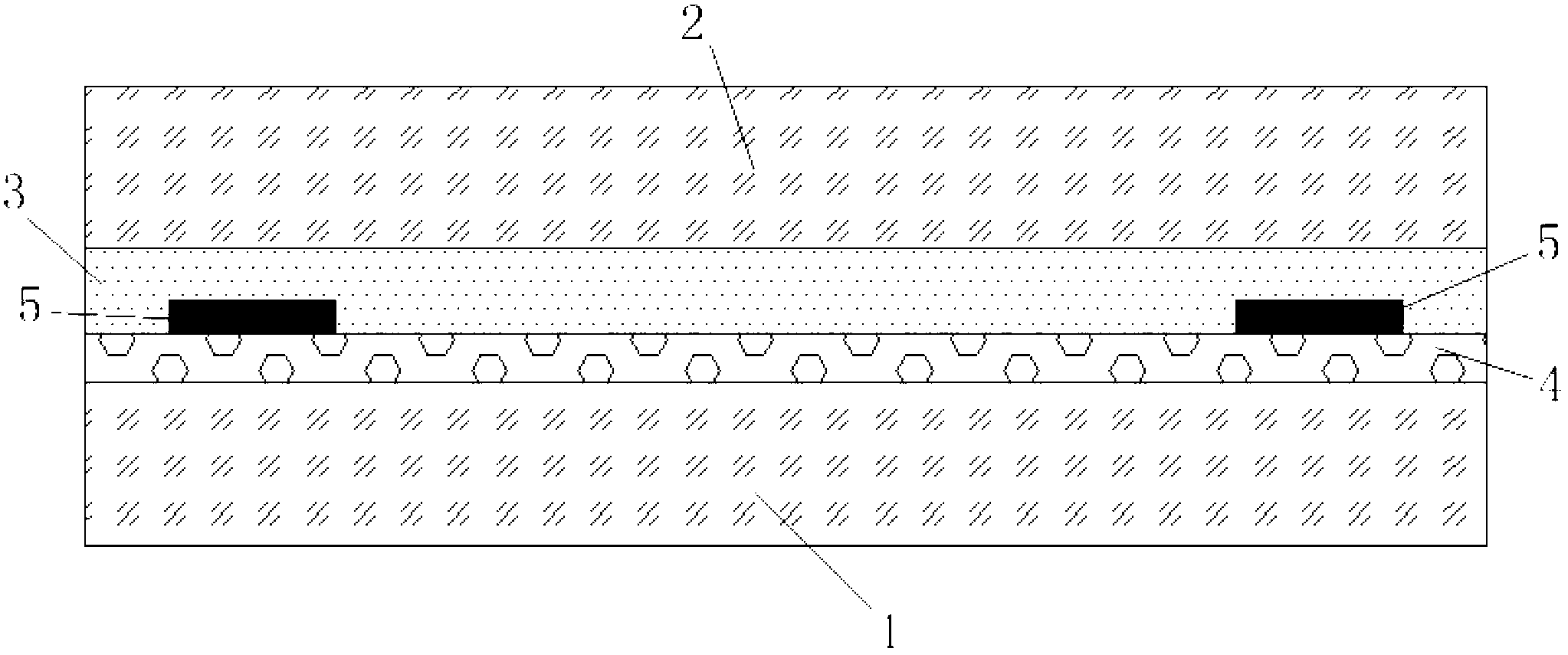

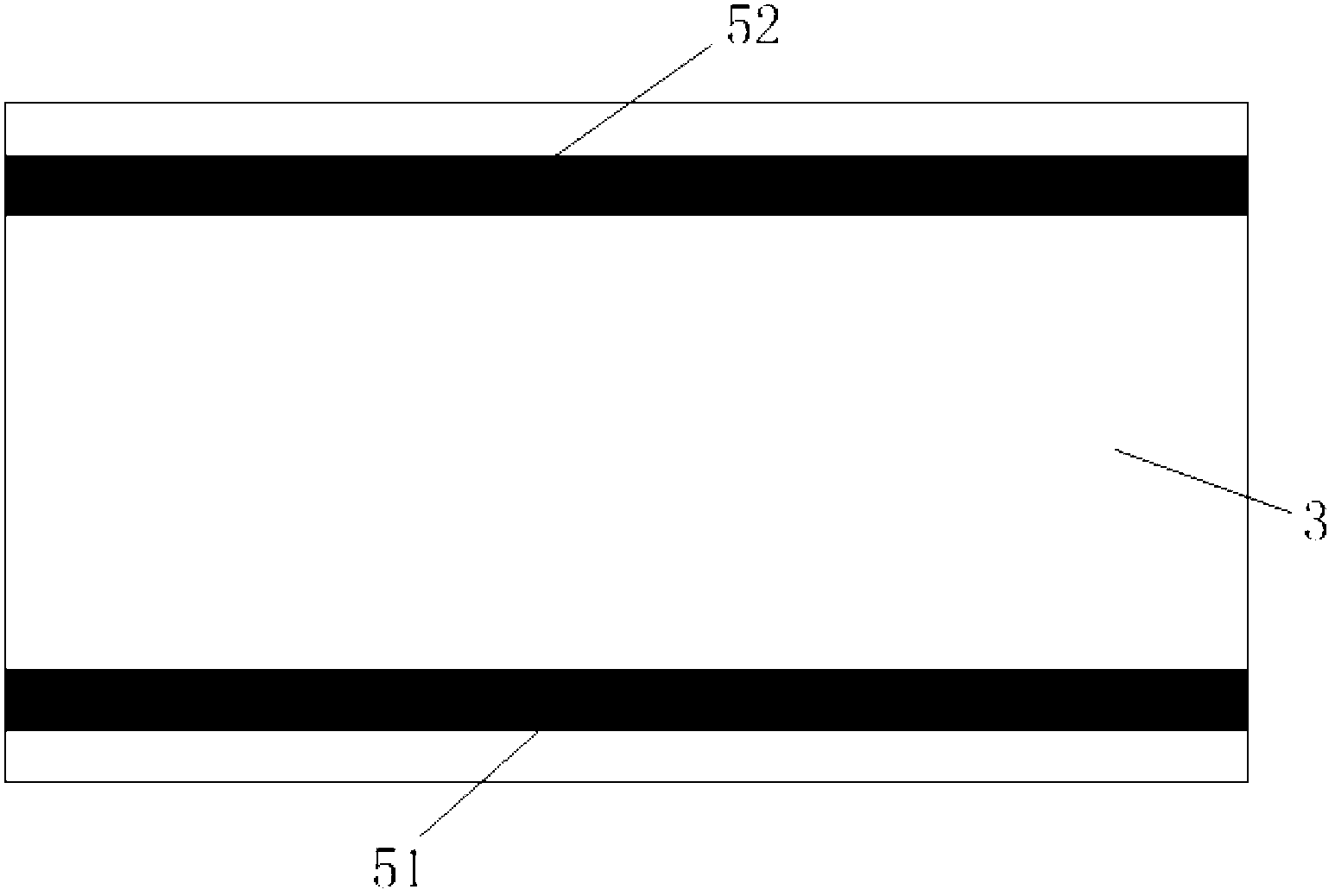

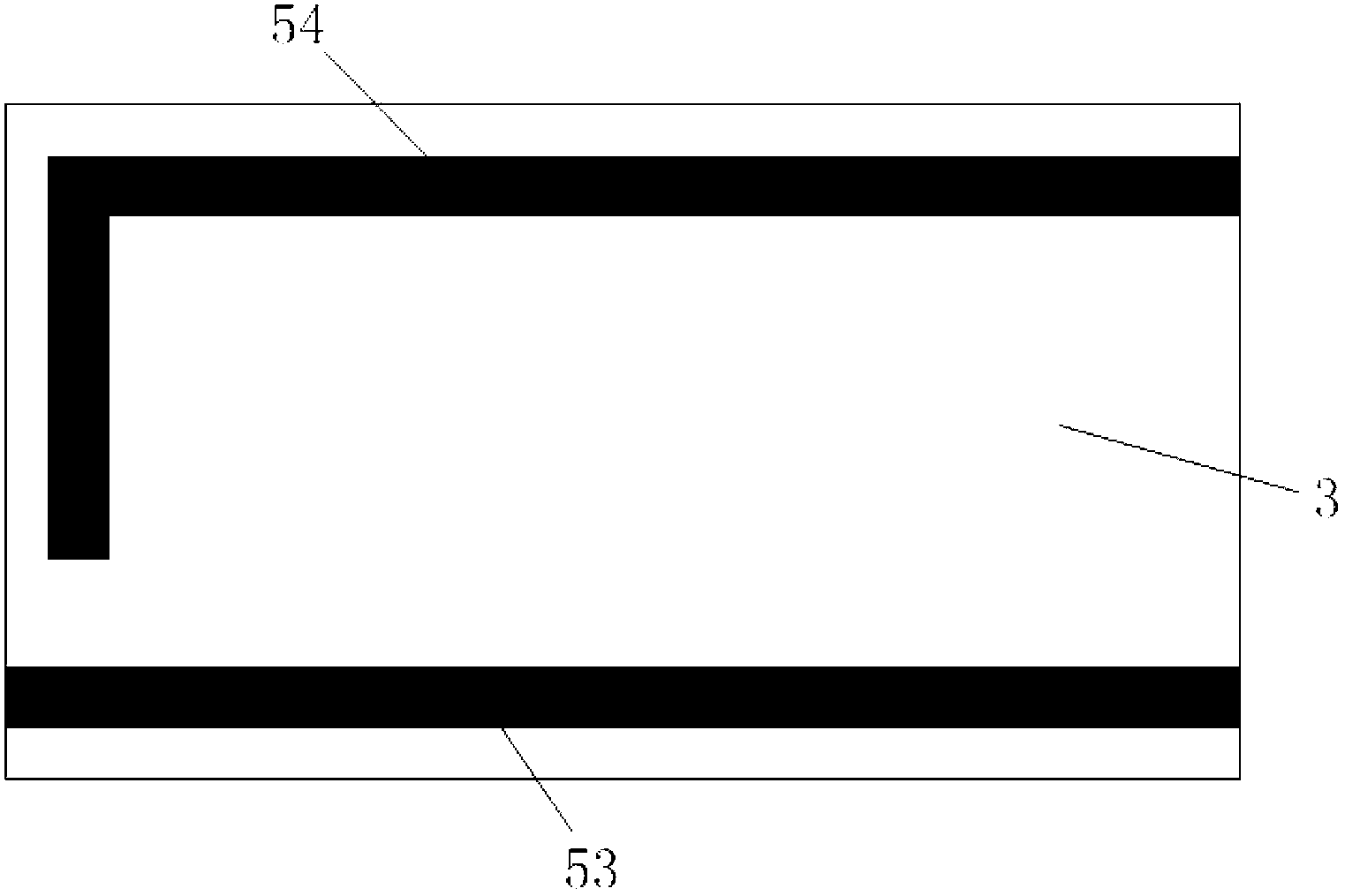

[0049] A low-emissivity film 4 is arranged on a surface of the glass substrate 1 in contact with the intermediate polymer 3, such as Figure 5 As shown, in this embodiment, the low-emissivity film 4 includes a silver layer and its outermost layer is an ITO layer, and its specific film layer structure is: glass substrate│SiNx│TiOx│ZnO│Ag│NiCrOx│ZnO│ ZnSnOx│ITO, 101 is a SiNx layer, 102 is a TiOx layer, 103 is a ZnO layer, 104 is an Ag layer, 105 is a NiCrOx layer, 106 is a ZnO layer, 107 is a ZnSnOx layer, and 108 is an ITO layer; Manufacture of horizontal continuous magnetron sputtering coating equipment, the background vacuum reaches 1×10 -4 Below Pa, the sputtering vacuum degree is not lower than 6×10 -1 Pa, the temperature range in the vacuum chamber is 20-50°C; the sputtering of the ITO film layer uses a ceramic target as a raw material, and the weight ratio of the Sn element in the material is in the range of 1-15%, preferably 5-10%. In this embodiment 10% in the middle...

Embodiment 2

[0053] A low-emissivity film 4 is arranged on a surface of the glass substrate 1 in contact with the intermediate polymer 3, such as Image 6As shown, in this embodiment, the low-emissivity film 4 includes two silver layers and its outermost layer is an ITO layer, and its specific film layer structure is: glass substrate│SiNx│TiOx│ZnO│Ag│NiCrOx│ZnSnOx │ZnO│Ag│NiCrOx│SiNx│ITO, 201 is SiNx layer, 202 is TiOx layer, 203 is ZnO layer, 204 is Ag layer, 205 is NiCrOx layer, 206 is ZnSnOx, 207 is ZnO layer, 208 is Ag layer, 209 is a NiCrOx layer, 210 is a SiNx layer, and 211 is an ITO layer; the low-emissivity film is manufactured by horizontal continuous magnetron sputtering coating equipment, and the background vacuum reaches 1×10 -4 Below Pa, the sputtering vacuum degree is not lower than 6×10 -1 Pa, the temperature range in the vacuum chamber is 20-50°C; the sputtering of the ITO film layer uses a ceramic target as a raw material, and the weight ratio of the Sn element in the ma...

Embodiment 3

[0057] A low-emissivity film 4 is arranged on a surface of the glass substrate 1 in contact with the intermediate polymer 3, such as Figure 7 As shown, in this embodiment, the low-emissivity film 4 includes three silver layers and its outermost layer is an ITO layer, and its specific film layer structure is: glass substrate│SiNx│TiOx│ZnO│Ag│NiCrOx│ZnSnOx │ZnO│Ag│NiCrOx│ZnSnOx│ZnO│Ag│

[0058] NiCrOx│SiNx│ITO, 301 is SiNx layer, 302 is TiOx layer, 303 is ZnO layer, 304 is Ag layer, 305 is NiCrOx layer, 306 is ZnSnOx layer, 307 is ZnO layer, 308 is Ag layer, 309 is NiCrOx layer , 310 is a ZnSnOx layer, 311 is a ZnO layer, 312 is an Ag layer, 313 is a NiCrOx layer, 314 is a SiNx layer, 315 is an ITO layer; the low-emissivity film is manufactured by horizontal continuous magnetron sputtering coating equipment, and the background Vacuum up to 1×10 -4 Below Pa, the sputtering vacuum degree is not lower than 6×10 -1 Pa, the temperature range in the vacuum chamber is 20-50°C; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square resistance | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com