Method for preparing gasified coal water slurry by utilizing lignite

A technology of gasifying coal water slurry and coal water slurry, which is applied in the direction of granular/powder fuel gasification, special form dry distillation, liquid carbon-containing fuel, etc., can solve the problems of fragility, combustion, and low ignition point of lignite, and achieve improvement The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

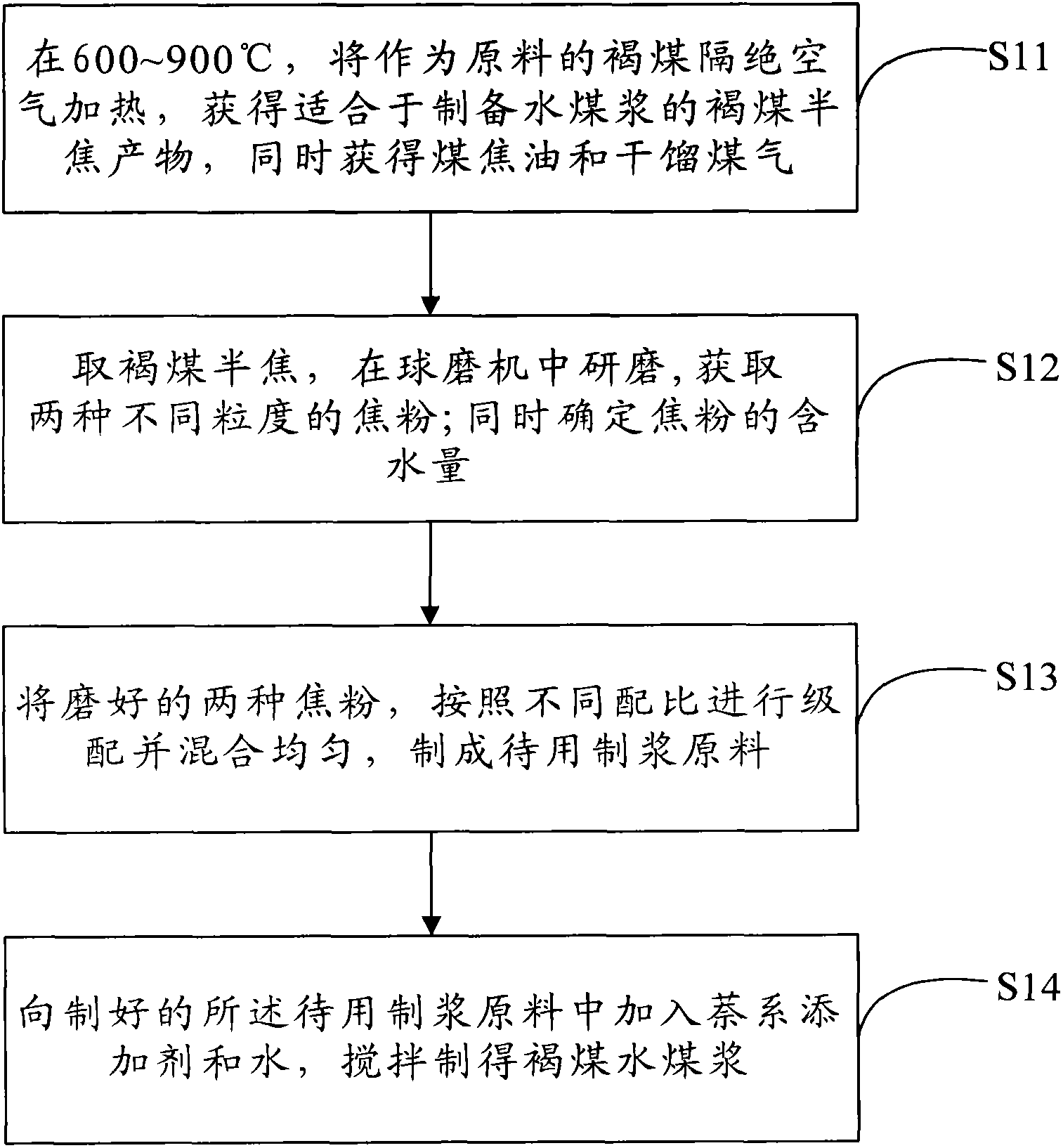

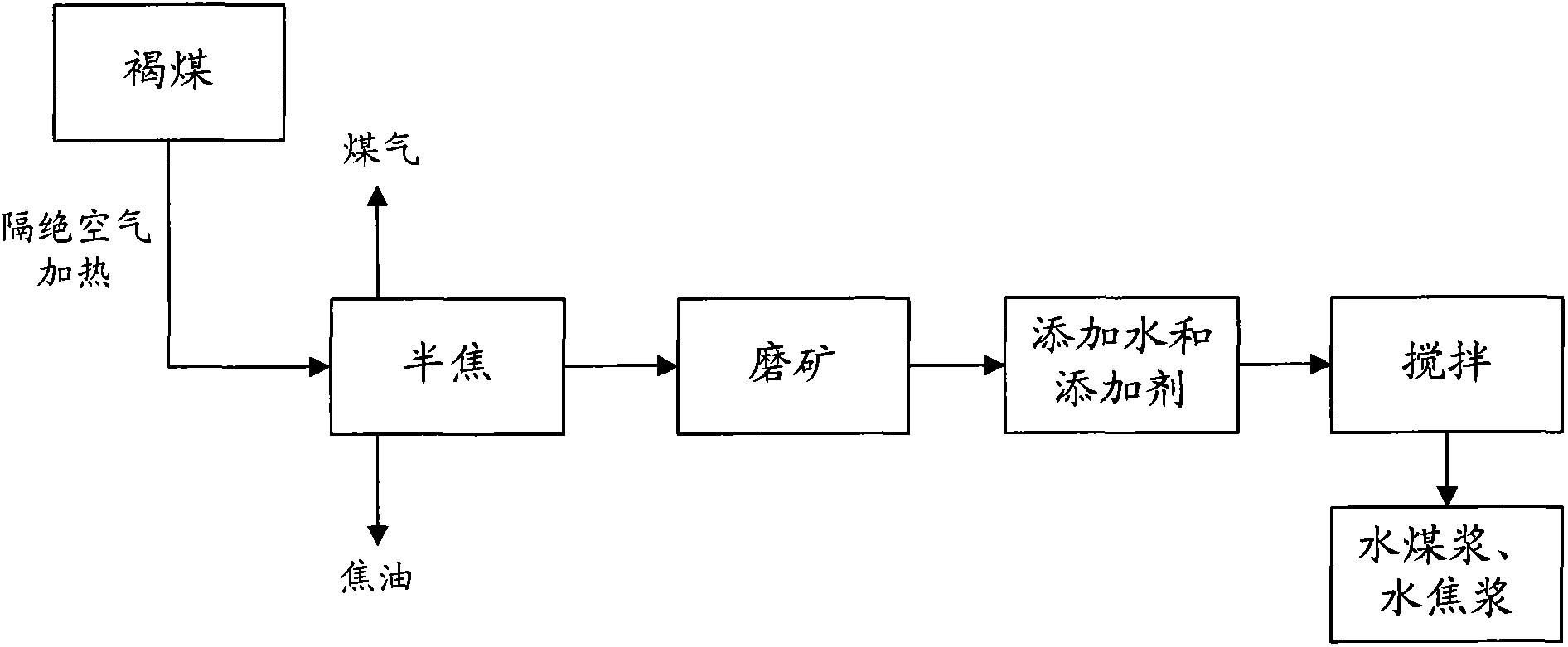

[0019] In order to make the above objects, features and advantages of the present invention more clearly understood, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

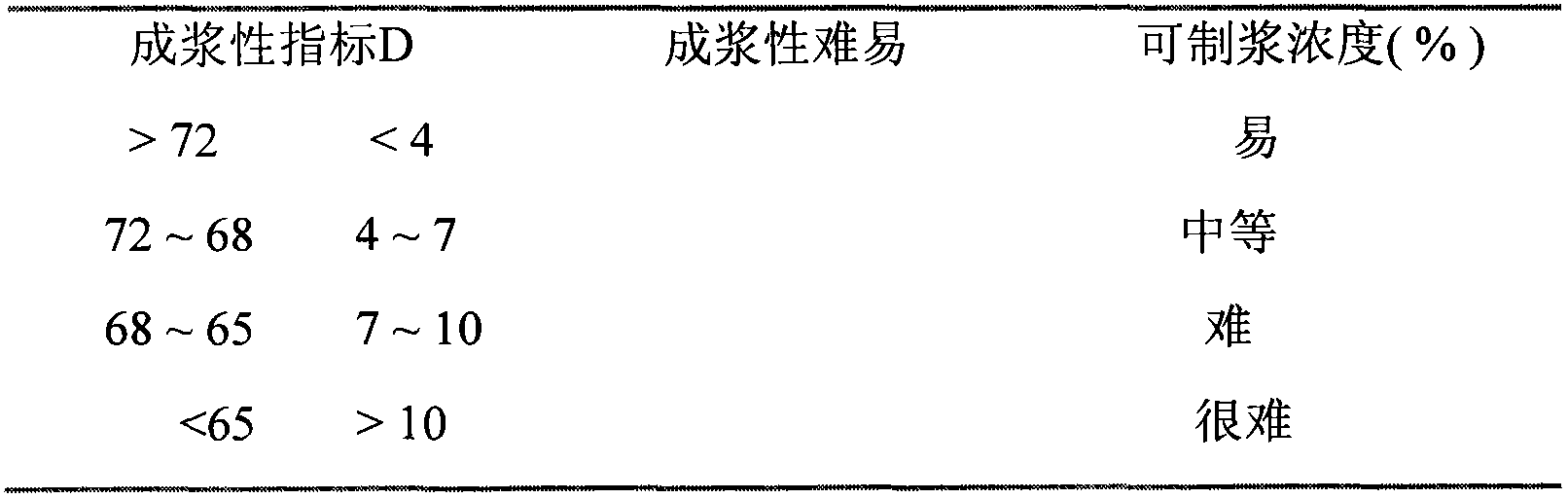

[0020] Coal water slurry is a new type of coal-based fuel that replaces oil with coal. It is mainly used to replace heavy oil for industrial boilers and kilns. The preparation of fuel coal-water slurry generally adopts bituminous coal and anthracite coal with good slurrying properties. However, bituminous coal is more expensive, making the cost of CWS too high. Anthracite is not only expensive, but also has poor combustibility of coal-water slurry. Therefore, the application of coal-water slurry is limited at present. First, a description of the relevant terminology:

[0021] coal water slurry

[0022] Coal water slurry is to use coal with abundant reserves and low price as the main raw material, and use flotation clean coal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com