Method for manufacturing building material from building garbage

A construction waste and construction material technology, which is applied in construction waste recycling, chemical instruments and methods, mechanical material recycling, etc., can solve the problem of occupying a large space, and achieve the effects of reducing emissions, strong adhesion, and less consumption

Inactive Publication Date: 2008-08-13

BEIJING HENGYECUN S&T

View PDF0 Cites 45 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the non-degradability of construction waste, the accumulation of construction waste will occupy a large amount of space and cause problems such as blowing sand

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0025] Example 2: 10kg of fiber material, 40kg of mineral material, 30kg of low-water cement, and 30kg of fly ash.

Embodiment 3

[0026] Example 3: 7kg of fiber material, 50kg of mineral material, and 25kg of low-water cement.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Login to View More

Abstract

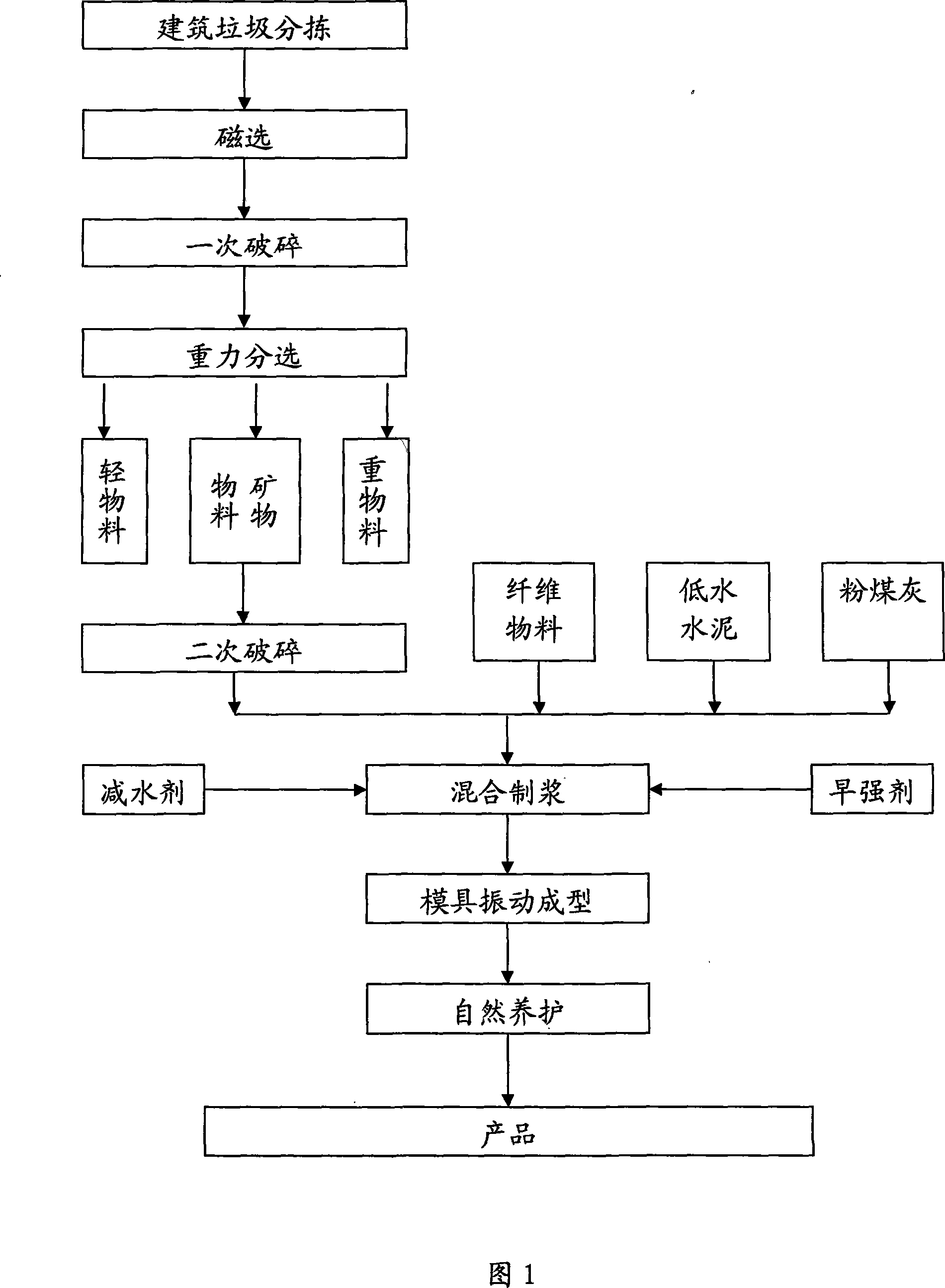

The present invention relates to a method for manufacturing the building material with the building garbage, the method executes sorting, magnetic separation, primary crushing and gravity sorting to the city building material, and the building material is separated to heavy material, light material and mineral material, the mineral material is used for manufacturing the building material after the secondary crushing, and the raw material of the building material comprises the following components: fiber material 5-10 parts, mineral material 40-60 parts, low-water cement 20-30 parts and other material 0-30 parts, the production process of the building material comprises the steps of mixing the fiber material, mineral material and other material to uniform, then adding the low-water cement for mixing to uniform, adding water and stirring to slurry, placing into the mold for jolt molding or extrusion molding, and forming the building used sheet material after natural curing. The method of the invention has the advantages of full utilization of the mineral material comprising the major component of the building garbage, saving the material resource, reducing the final discharging amount of the building garbage, and the method can be used for manufacturing the building materials such as hollow brick, hollow block, partition plate and the like.

Description

technical field [0001] The invention relates to a method for manufacturing building materials by using construction waste, and belongs to the fields of environmental protection and building materials. Background technique [0002] Construction waste is mainly inorganic mineral-based waste generated in the process of building renovation and demolition of buildings. According to existing regulations, these wastes should be concentrated in a special treatment site for treatment. There are two common ways to deal with them. One is to be piled into the garbage dump; the other is to be used as a cushion for temporary construction roads, and finally to be removed to the garbage dump. Due to the non-degradability of construction waste, the accumulation of construction waste will occupy a large amount of space and cause problems such as blowing sand. On the other hand, due to the continuous development of the construction industry, the production of building materials needs to consu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/02C04B18/16

CPCC04B28/02B09B3/0041C04B18/16B03B9/065Y02W30/58Y02W30/52Y02W30/91B09B3/25C04B14/42C04B18/08C04B20/026C04B40/0028C04B40/0259C04B40/0067C04B18/24C04B20/02

Inventor 王丽

Owner BEIJING HENGYECUN S&T

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com