Construction waste comprehensive treatment method

A construction waste, comprehensive treatment technology, applied in construction waste recycling, recycling technology, solid waste removal and other directions, can solve problems affecting the processing and final quality of building materials products, unreasonable arrangement of magnetic separation steps, uneven particle size of recycled aggregates problems, to achieve the effect of high product strength, complete crushing and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

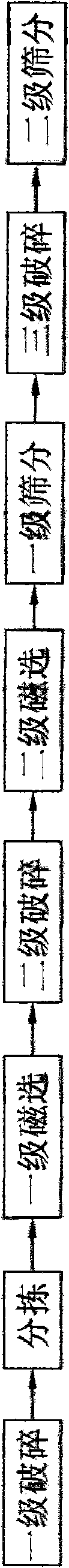

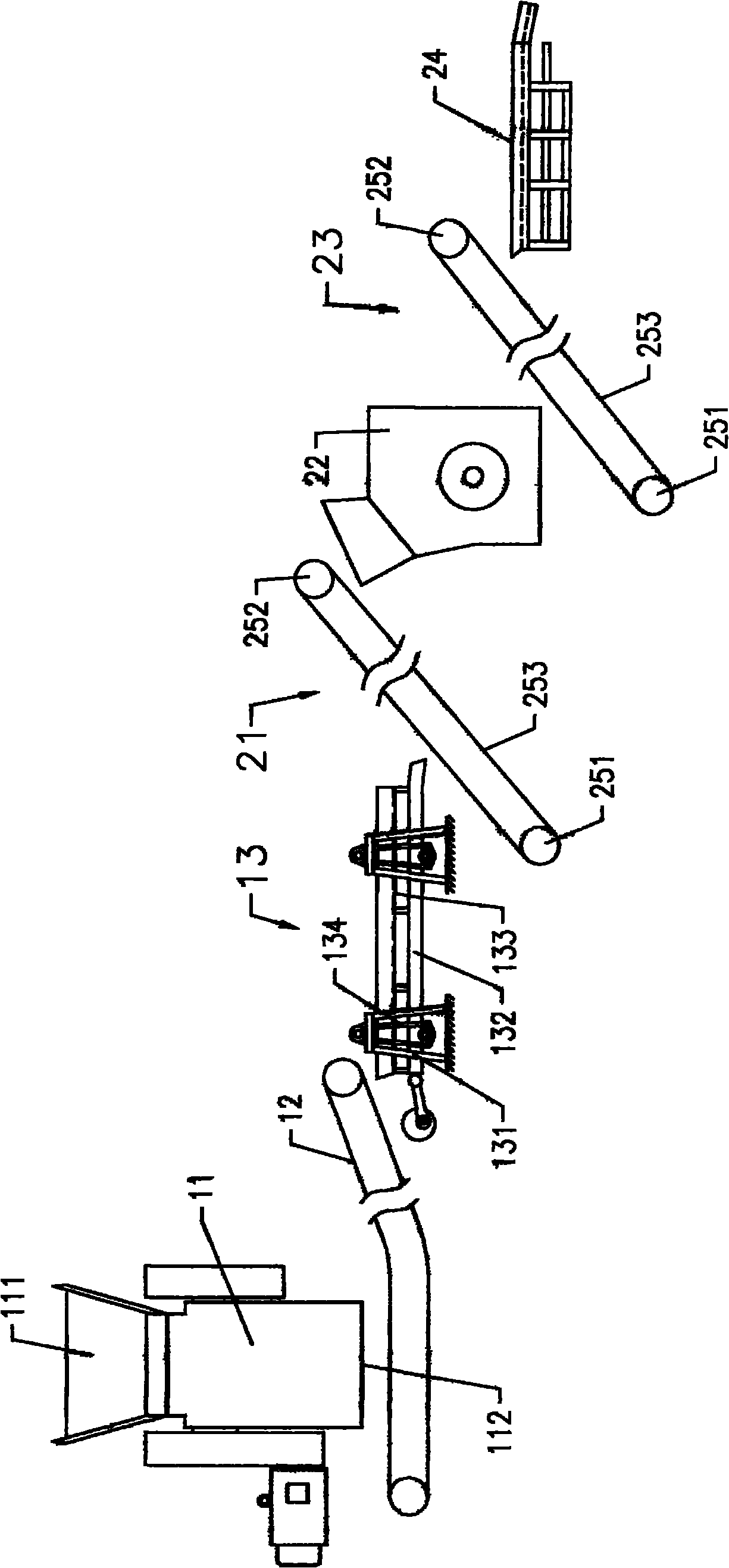

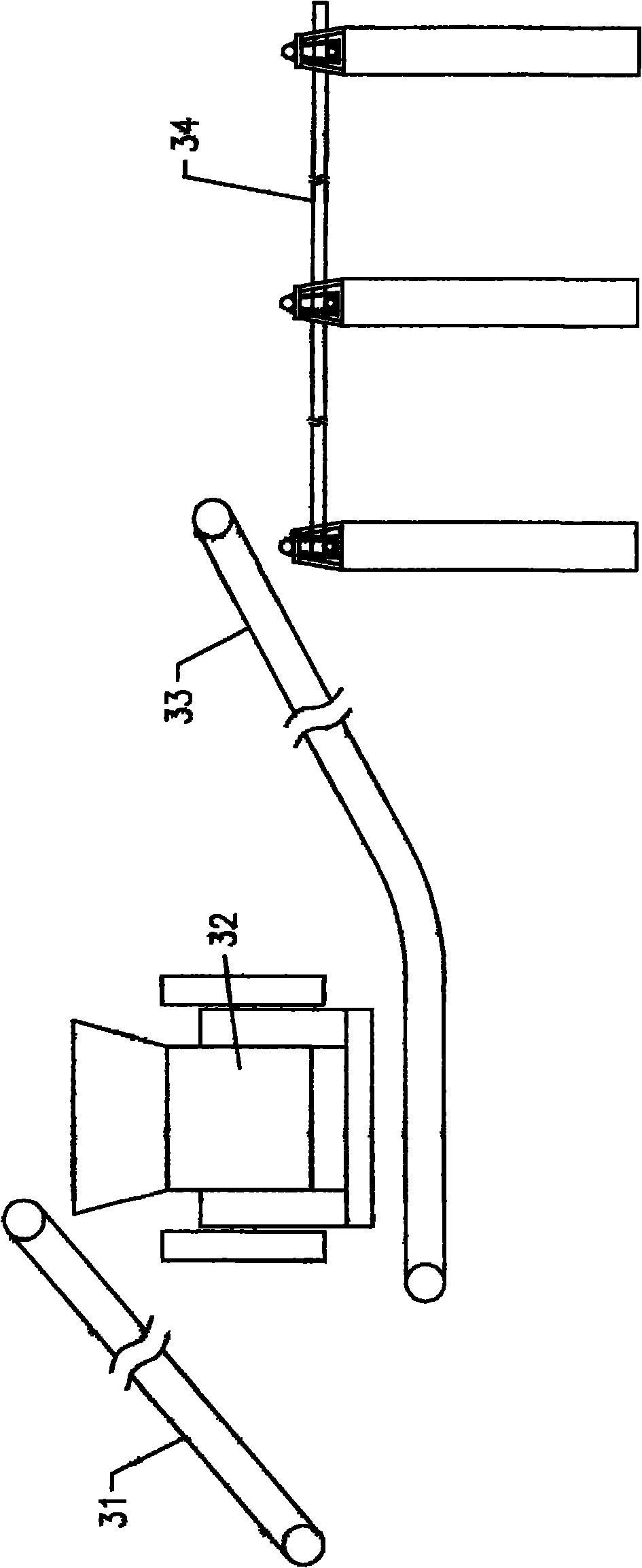

[0034] Such as Figure 1 to Figure 3 Commonly shown, a comprehensive processing method for construction waste, which includes the following processing steps:

[0035] (1) Primary crushing: The construction waste raw materials are sent to the primary crusher 11 for crushing, and then output to the sorting device through the discharge port 112 of the primary crusher 11 . Among them, the primary crusher 11 is preferably a jaw crusher, which can crush relatively large construction waste, and the particle size of the recycled aggregate after crushing is relatively uniform. The primary crusher 11 is provided with an inclined feeding port 111, and the construction waste can be directly fed into the feeding port 111 through the loader.

[0036] (2) Sorting: the sorting device sorts and removes the metal, bamboo and wood and plastic debris in the construction waste, and outputs the sorted construction waste to the primary magnetic separation device 21 . Wherein, the sorting device in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com