Intelligent gravel aggregate production line

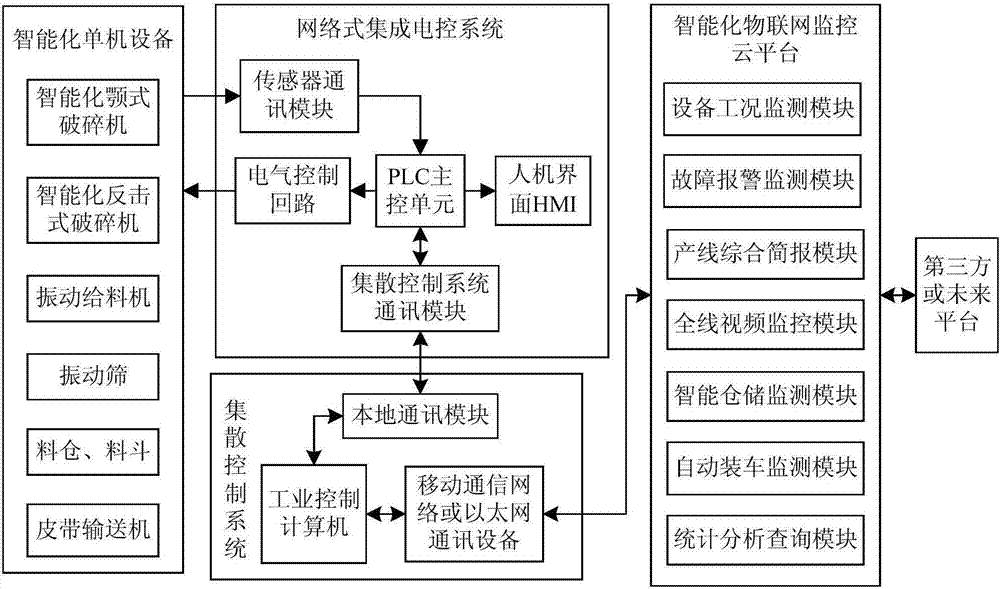

A production line and aggregate technology, applied in the direction of comprehensive factory control, instrumentation, comprehensive factory control, etc., can solve problems such as insufficient research on state monitoring and fault diagnosis, lack of data accumulation and application services, and low degree of single-machine intelligence and informatization , to achieve the effect of realizing automatic adjustment control, improving the level of automation, and reducing the number of on-site operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

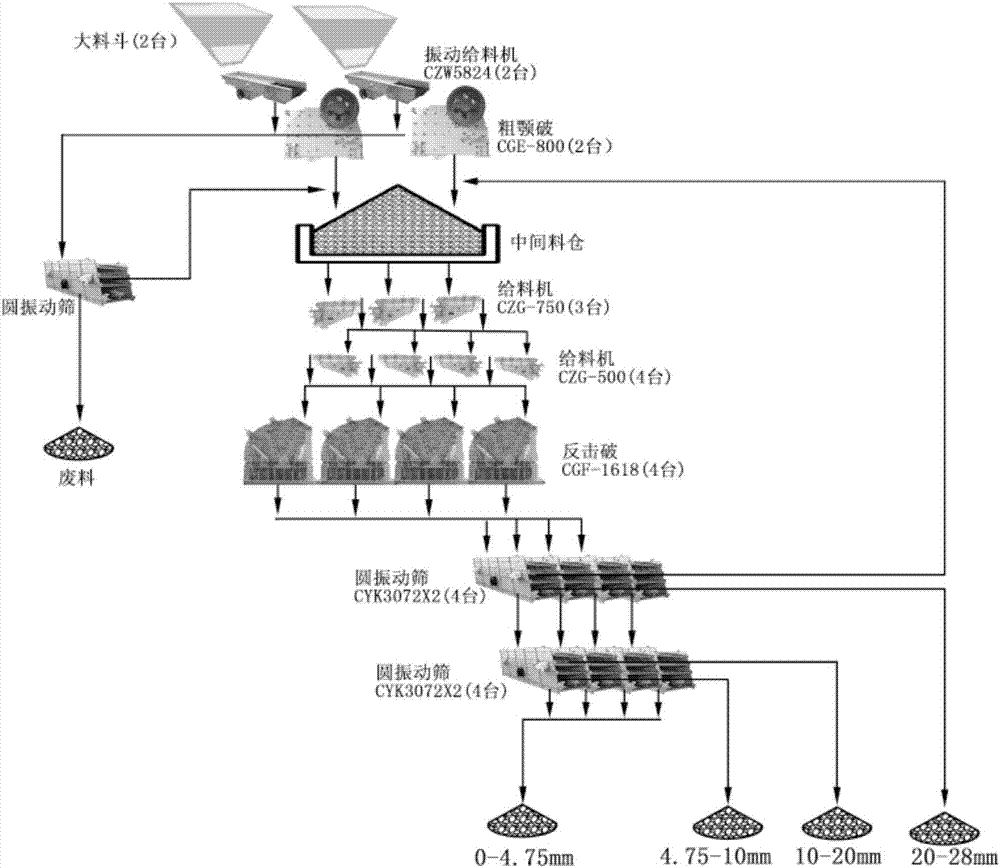

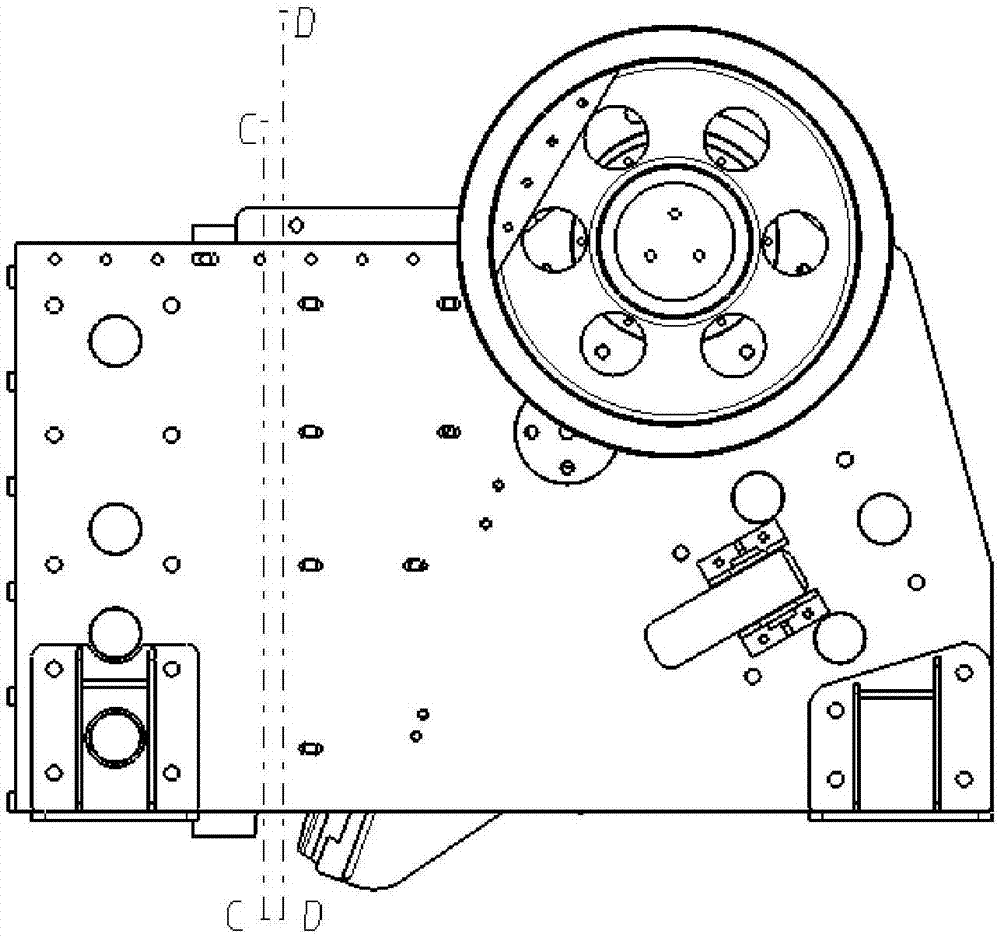

[0050] In this embodiment, the production process of sand and gravel aggregate is as follows figure 1 As shown, the material is unloaded from the truck, enters the sand and gravel aggregate production line from the large hopper, and is transported to the intelligent jaw crusher by the vibrating feeder for coarse crushing, and then transported to the intermediate silo by the belt conveyor. After falling from the intermediate silo, it is transported to the intelligent impact crusher by the vibrating feeder for medium and fine crushing, and finally through the belt conveyor and two vibrating screen screening procedures to obtain four different specifications of finished sand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com