Powder-based electrode forming method

A molding method and powder technology, applied in the field of powder-based electrode molding, can solve the problems of low production efficiency, large energy consumption, affecting the performance of electrochemical devices, etc., and achieve short mixing time, good uniformity and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

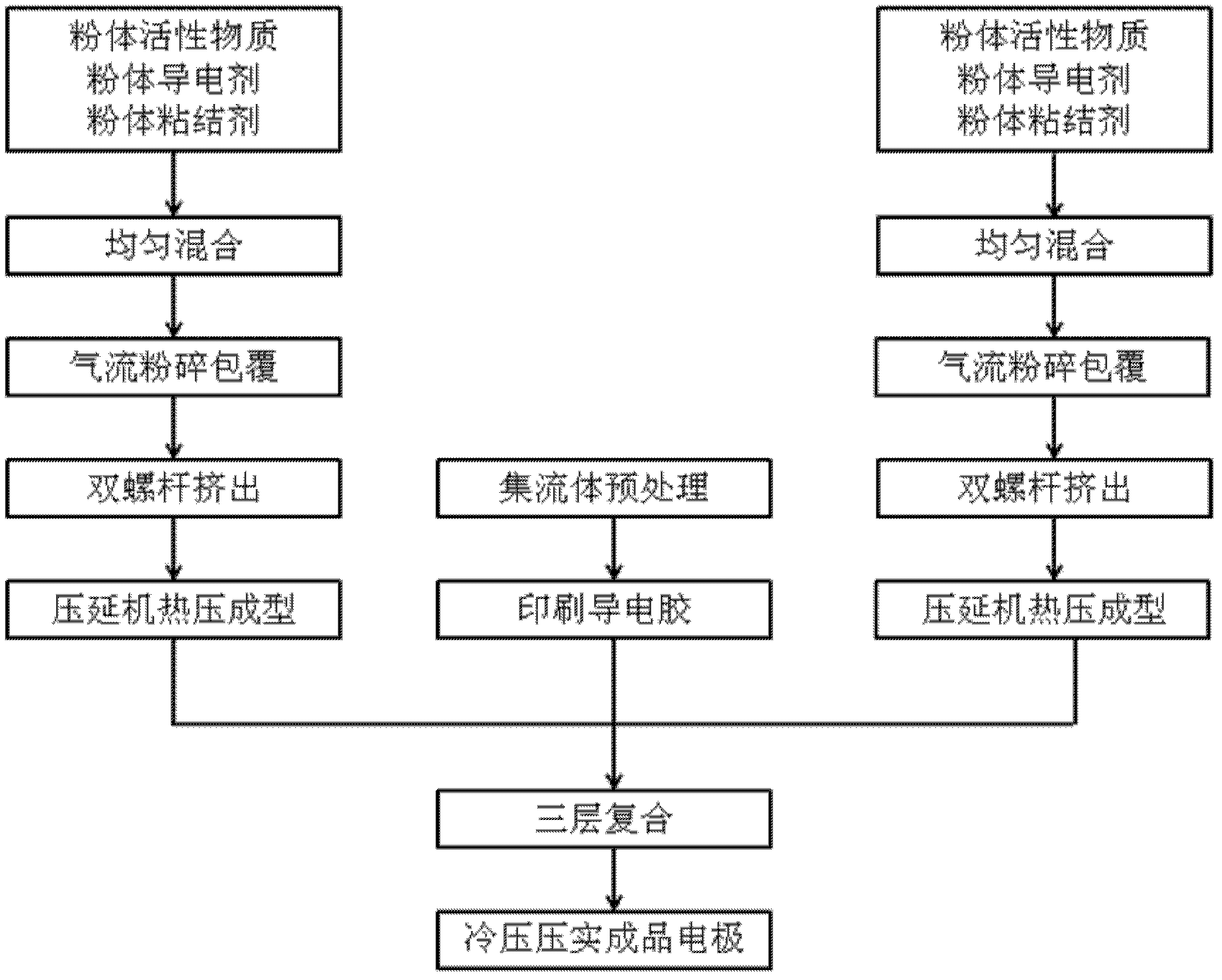

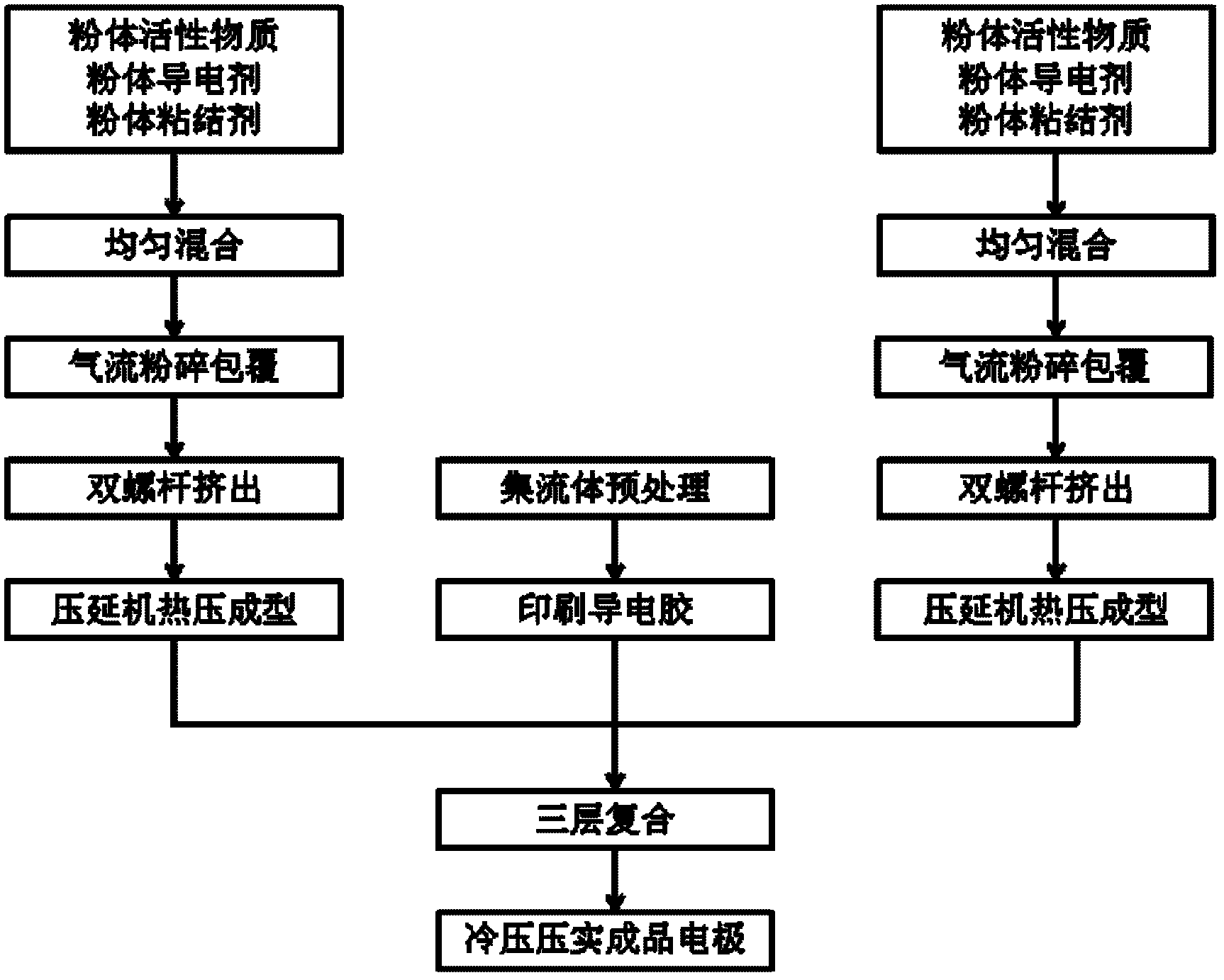

[0037] Such as figure 1 As shown, a powder-based electrode forming method includes the following steps:

[0038] (1) Select activated carbon YP50 from Kuraray Company of Japan as the powder active material, select Super P from Temico Company as the powder conductive agent, and select DuPont Company’s polytetrafluoroethylene as the powder binder. Three kinds of powders The mass ratio is 80:5:15;

[0039](2) Add the powder weighed in step (1) to the three-dimensional mixer for the first step of mixing, so that various powders are evenly distributed, the mixing speed is 30 rpm, and the processing time is 10 minutes ;

[0040] (3) Transport the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com