Wear part intended for a crusher and a method of manufacturing the same

A technology of wear-resistant parts and crushers, which is applied in the field of wear-resistant parts and can solve problems such as difficult and time-consuming machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

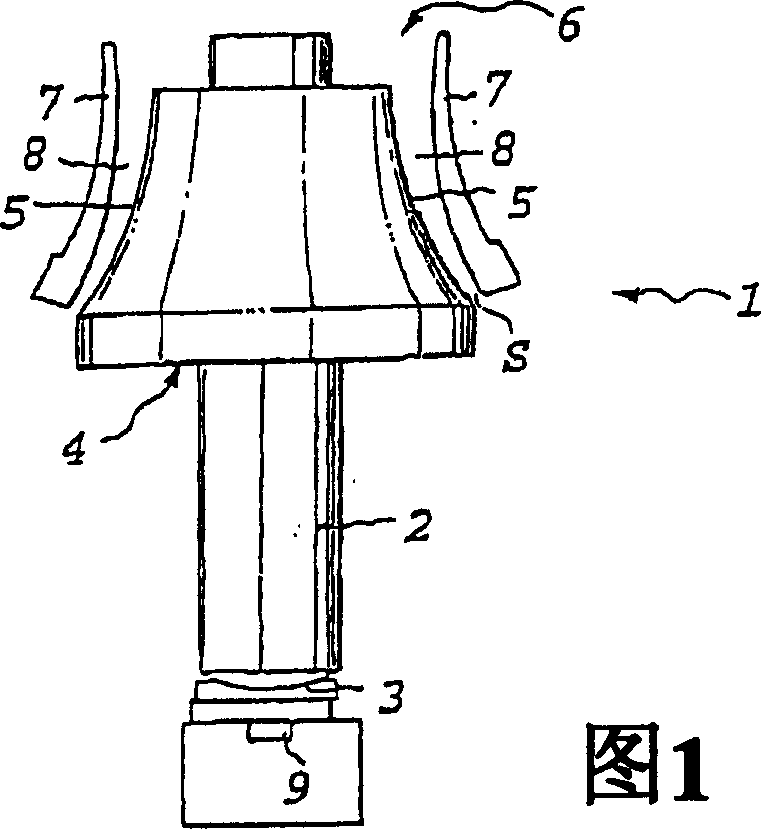

[0037] FIG. 1 shows a rotary crusher 1 . The crusher 1 has a crusher shaft 2 mounted eccentrically at its lower end 3 . On its upper side, the crusher shaft 2 has a crushing head 4 . The crushing head 4 has an inner shell 5 which crushes the material supplied to the upper part 6 of the crusher against an outer shell 7 in the continuous rotation and vibration of the crusher shaft 2 . A crushing chamber 8 is formed between the inner casing 5 and the outer casing 7 . In principle, the functionality of the crusher 1 is determined by the gap S as the minimum distance between the inner shell 5 and the outer shell 7 of the crusher 1 . The crusher shaft 2 can move in the vertical direction under the action of the adjusting device 9 . Thus, the gap S of the crushing chamber 8 can be adjusted so that the relationship between the amount of material crushed by the crusher 1 and the size of the crushed material can be set in a desired manner.

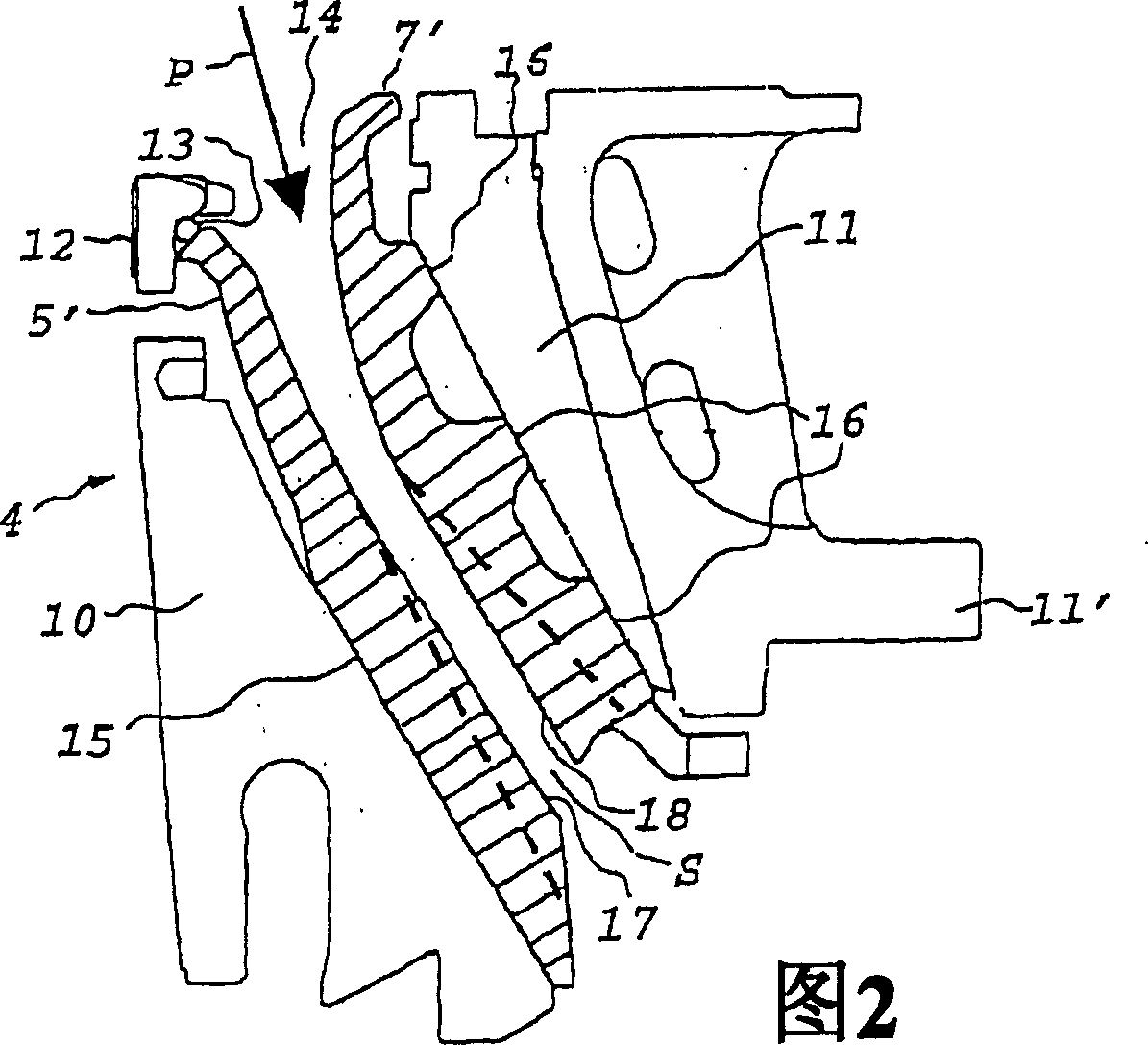

[0038] Figure 2 shows an inner shell 5' a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com