Treating method for oily sludge

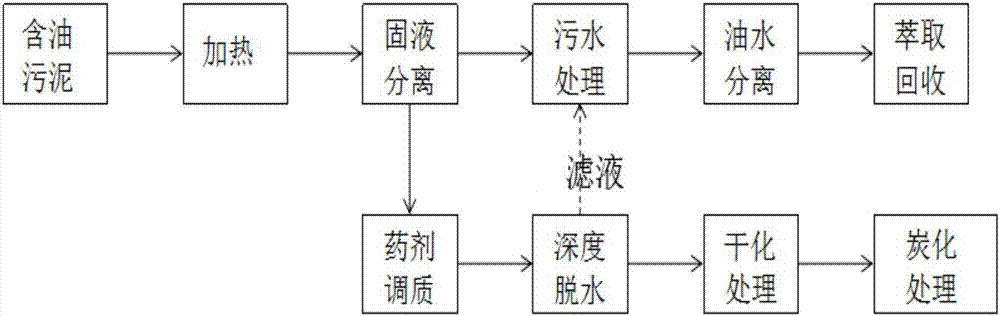

A treatment method and sludge technology, which are applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of high energy consumption, secondary pollution, complicated treatment, etc. To achieve the effect of simple flue gas treatment, less pollutants, and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The treatment method of the present embodiment oily sludge comprises the following steps:

[0026] S1. Heat and stir the oily sludge, the heating temperature is 40°C, the stirring speed is 30r / min, stirring for 10min, and after standing for 0.5h, solid-liquid separation is carried out to obtain oily sludge and oily liquid;

[0027] S2, passing the oily liquid obtained in step S1 into a sewage treatment system for oil-water separation, and extracting and purifying the separated oil;

[0028] S3, adding medicament to the oily sludge obtained in step S1 for conditioning, the amount of medicament added is 1% of the absolute dry weight of the oily sludge, and the medicament is polyaluminum chloride accounting for 0.5% of the absolute dry weight of the oily sludge and accounting for 0.5% of the absolute dry weight of the oily sludge It is compounded with sodium persulfate with an absolute dry weight of 0.5%. After adding the medicament, stir at 30r / min for 5 minutes. The cond...

Embodiment 2

[0033] The treatment method of the present embodiment oily sludge comprises the following steps:

[0034] S1. Heat and stir the oily sludge, the heating temperature is 120°C, the stirring speed is 130r / min, stirring for 60min, and after standing for 4h, solid-liquid separation is carried out to obtain oily sludge and oily liquid;

[0035] S2, passing the oily liquid obtained in step S1 into a sewage treatment system for oil-water separation, and extracting and purifying the separated oil;

[0036] S3. Add medicament to the oil sludge obtained in step S1 for conditioning. The medicament is polyacrylamide accounting for 5‰ of the absolute dry weight of oily sludge, ferrous sulfate accounting for 2.5% of the absolute dry weight of oily sludge, and accounting for 2.5% of the absolute dry weight of oily sludge. 5% of polyaluminum chloride, 4% of polyferric sulfate by weight of absolute dry weight of oily sludge, 1% of chitosan by weight of absolute dry weight of oily sludge, and 3%...

Embodiment 3

[0041] The treatment method of the present embodiment oily sludge comprises the following steps:

[0042]S1. Take 100L of oil sludge with a moisture content of 96.3% and an oil content of 1.8%, heat it to 70°C, stir and maintain it for 20 minutes, and the stirring speed is 120r / min. A large amount of oily matter is floating on the water surface. After standing for 1 hour, solidify liquid separation to obtain sludge and oily liquid;

[0043] S2, passing the oily liquid obtained in step S1 into a sewage treatment system for oil-water separation, and extracting and purifying the separated oil;

[0044] S3. Add medicaments to the oily sludge obtained in step S1 for conditioning. The medicaments are cationic polyacrylamide accounting for 1‰ of the absolute dry weight of the oily sludge, 5% polyferric chloride accounting for the absolute dry weight of the oily sludge, and 5% of the absolute dry weight of the oily sludge. It is compounded with 2% surfactant in absolute dry weight. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com