Medium production method of soilless lawn adaptive to arid area

A technology of soilless lawn and production method, applied in the direction of seed treatment method, botanical equipment and method, application, etc., can solve problems such as difficulty in maintenance and management of soilless lawn, drought stress of lawn grass, affecting lawn quality, etc., and achieves low cost Produce and beautify the urban environment, avoid drought stress, and reduce the effect of maintenance and management difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

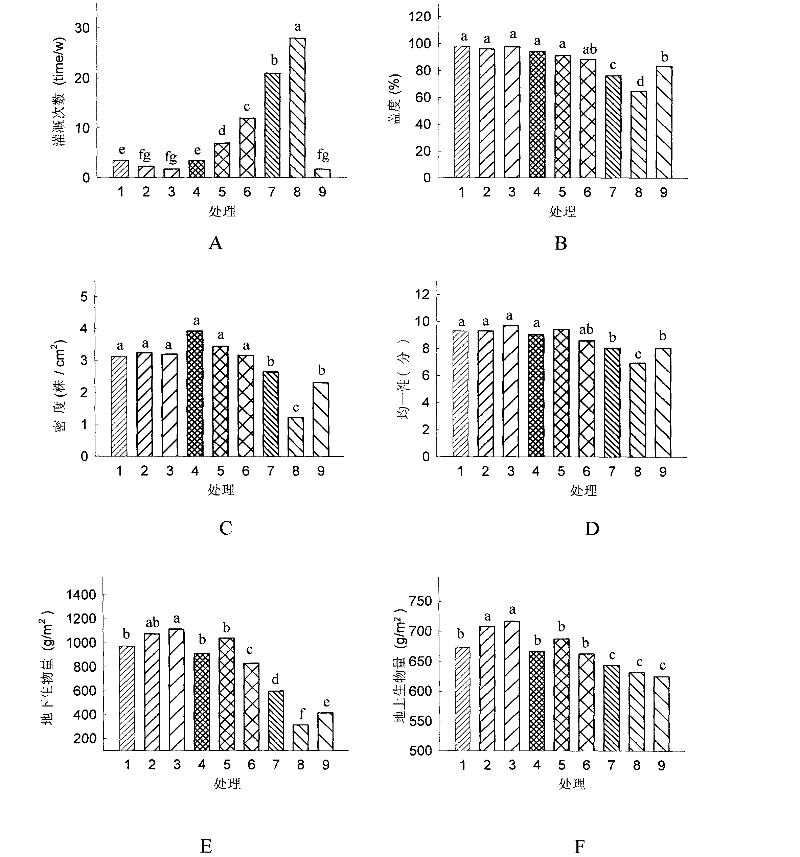

Image

Examples

Embodiment 1

[0090] Example 1 A substrate production method adapted to soilless lawns in arid areas includes the following steps:

[0091] (1) Choose cold-season turfgrass-Poa pratensis variety Midnight (provided by American Bailv Group) as seeds.

[0092] (2) Preparation of growth substrate layer: compost the slag and organic sludge in a volume ratio of 50:50 (m 3 / m 3 ) Mixed to form a growth substrate layer.

[0093] (3) Preparation of water-retaining nutrient slow-release material layer: the leftovers, sawdust, and straw powder from mushroom production are in a volume ratio of 35:35:30 (m 3 / m 3 ) After mixing, press per m 2 Add 25g of water-retaining agent and 35g of slow-release fertilizer to form a water-retaining nutrient slow-release material layer.

[0094] (4) Lay the plastic mulch on the ground as the isolation layer, and then lay the polypropylene shade net as the turf bottom layer above the isolation layer.

[0095] (5) On the turf bottom layer, a growth substrate layer with a thicknes...

Embodiment 2

[0100] Embodiment 2 A substrate production method adapted to soilless lawns in arid areas includes the following steps:

[0101] (1) Choose cold-season turfgrass-Poa pratensis variety Midnight as seeds.

[0102] (2) Preparation of growth substrate layer: compost the slag and organic sludge in a volume ratio of 60:40 (m 3 / m 3 ) Mixed to form a growth substrate layer.

[0103] (3) Preparation of the water-retaining nutrient slow-release material layer: the leftovers, sawdust, and straw powder from mushroom production are in a volume ratio of 45:25:30 (m 3 / m 3 ) After mixing, press per m 2 Add 25g of water-retaining agent and 45g of slow-release fertilizer to form a water-retaining nutrient slow-release material layer.

[0104] (4) Lay the plastic mulch on the ground as the isolation layer, and then lay the polypropylene shade net as the turf bottom layer above the isolation layer.

[0105] (5) On the turf bottom layer, a growth substrate layer with a thickness of 35mm is first laid, and...

Embodiment 3

[0110] Embodiment 3 A substrate production method adapted to soilless lawns in arid areas includes the following steps:

[0111] (1) Choose cold-season turfgrass-Poa pratensis variety Midnight as seeds.

[0112] (2) Preparation of growth substrate layer: compost slag and organic sludge in a volume ratio of 55:45 (m 3 / m 3 ) Mixed to form a growth substrate layer.

[0113] (3) Preparation of water-retaining nutrient slow-release material layer: the leftovers, sawdust, and straw powder from the mushroom production are in a volume ratio of 42:30:28 (m 3 / m 3 ) After mixing, press per m 2 Add 25g of water-retaining agent and 40g of slow-release fertilizer to form a water-retaining nutrient slow-release material layer.

[0114] (4) Lay the plastic mulch on the ground as the isolation layer, and then lay the polypropylene shade net as the turf bottom layer above the isolation layer.

[0115] (5) On the turf bottom layer, a growth substrate layer with a thickness of 20mm is first laid, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com