Method for preparing carbon nitride quantum dots

A technology of quantum dots and carbon nitride, which is applied in the field of material preparation, can solve the problems of restricting mass production and application of products, unsatisfactory uniformity, and low yield of preparation technology, and achieves low cost, good dispersion, and water solubility. good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

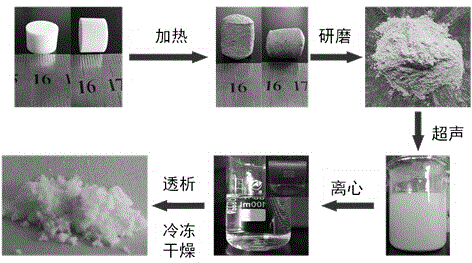

[0026] The preparation method of the carbon nitride quantum dot of the present embodiment comprises the following steps:

[0027] (1) Material preparation: Weigh 1 g of melamine and 3 g of sodium chloride crystals (that is, the mass ratio of melamine and sodium chloride crystals is 1:3), and dissolve melamine and sodium chloride crystals in 30 g of deionized water;

[0028] (2) Drying and tableting: Freeze-dry the aqueous solution obtained in step (1) at -30°C for 24 hours to constant weight, place it in a mold, and press it into a sheet with a thickness of 1cm under a pressure of 10MPa using a tablet press;

[0029] (3) Heating: Put the sheet obtained in step (2) in a porcelain boat, place it in a tube furnace, pass nitrogen gas at a flow rate of 5ml / min, raise the temperature to 600°C at a rate of 10°C / min and keep it warm for 2h , cooled to room temperature with the furnace;

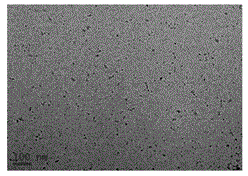

[0030] (4) Separation: Grind the product obtained in step (3) for 20 minutes in a mortar, then di...

Embodiment 2

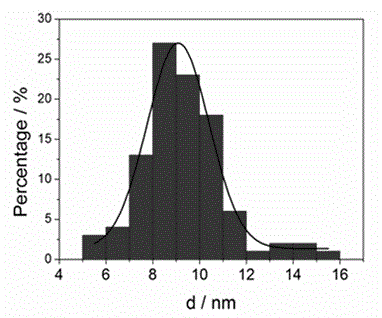

[0034] The only difference from Example 1 is that the mass ratio of melamine and sodium chloride crystals in this example is 1:1, that is, 1 g of melamine and 1 g of sodium chloride crystals are weighed in step (1), and the melamine and sodium chloride crystals are weighed Dissolved in 10g of deionized water, step (4) was also dissolved in 10g of deionized water, the others were the same as in Example 1.

[0035] The diameter of the nitrided quantum dots obtained in this example is 5-16nm (8.8nm on average), and the specific surface area is 300 m 2 / g, the productive rate is 92wt%.

Embodiment 3

[0037] The only difference from Example 1 is that the mass ratio of melamine and sodium chloride crystals in this example is 1:5, that is, 1 g of melamine and 5 g of sodium chloride crystals are weighed in step (1), and the melamine and sodium chloride crystals are weighed Dissolved in 50g of deionized water, step (4) was also dissolved in 50g of deionized water, the others were the same as in Example 1.

[0038] The diameter of the nitrided quantum dots obtained in this example is 4-13nm (7.3nm on average), and the specific surface area is 310 m 2 / g, the productive rate is 94wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com