Thick steel plate for nuclear power plant containment and manufacture method thereof

A nuclear power plant containment and manufacturing method technology, which is applied in the field of thick steel plate and its manufacturing, can solve the problems that cannot fully meet the requirements of the new containment, and achieve the effects of good toughness, good weldability, and fine and uniform grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

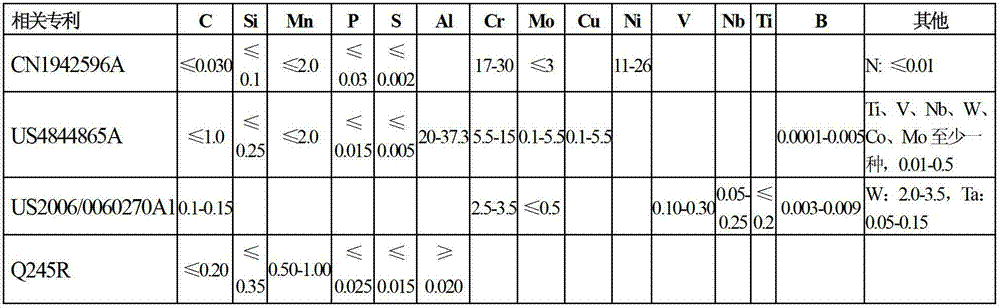

[0041] The technical solution of the present invention will be further described below in conjunction with Examples 1-10, but this description does not constitute a limitation of the present invention.

[0042] Manufacture thick steel plates for nuclear power plant containment according to the present invention according to the following steps (see Table 2 for the chemical element ratio of each steel plate in Examples 1-10, and see Table 3 for specific process parameters in Examples 1-10):

[0043] 1) Smelting and casting;

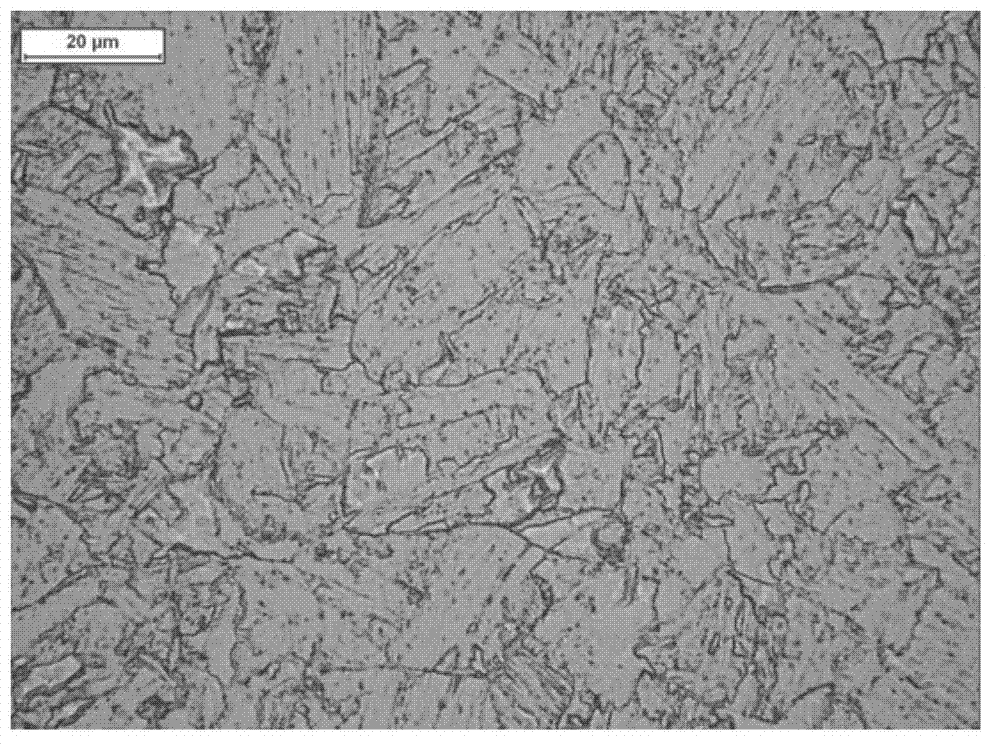

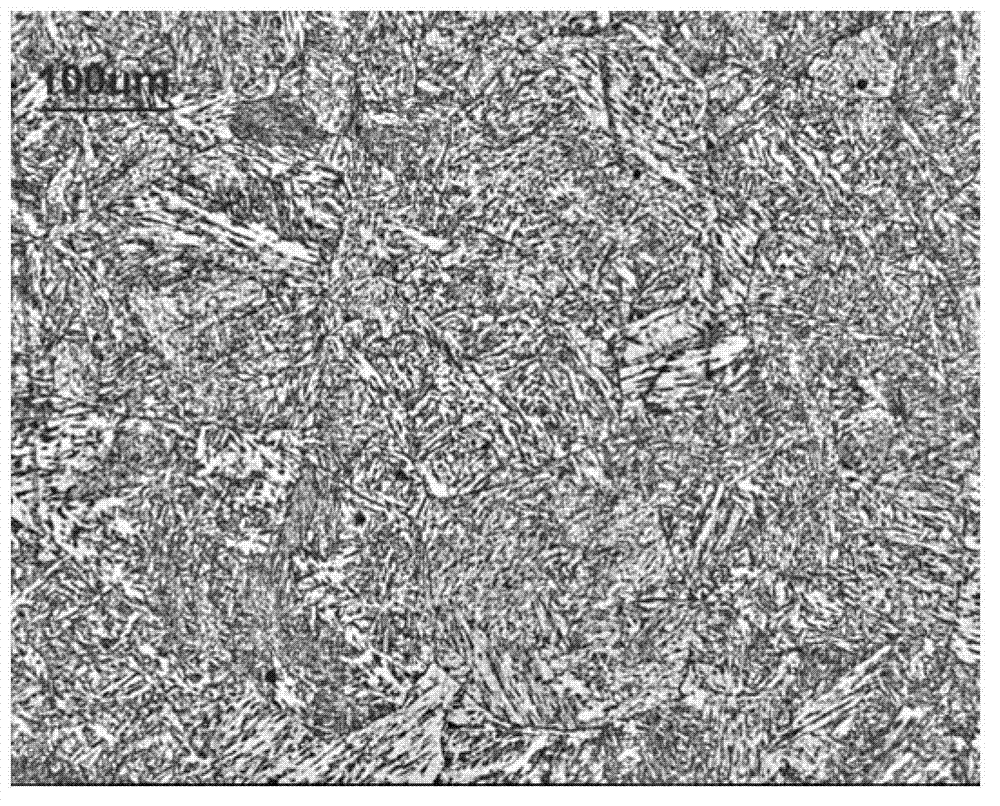

[0044] 2) Heating the billet to 1100-1250°C for austenitization, and controlling the time when the center of the billet is above 900°C for not less than 120 minutes.

[0045] 3) Rolling: the total deformation is greater than 80%, and the deformation per pass is greater than 8%;

[0046] 4) Quenching: The quenching temperature is 880-960°C, and the heat preservation is sufficient to make the temperature of the inside and outside of the steel plate consiste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com