High-performance polyimide molding powder material suitable for 3D printing and 3D printing molding method

A polyimide and powder material technology, applied in the direction of liquid material additive processing, processing and manufacturing, etc., can solve the problems of few types of polymers, low temperature resistance, low product strength, etc., to broaden the range of options and improve viscosity The effect of junction strength and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

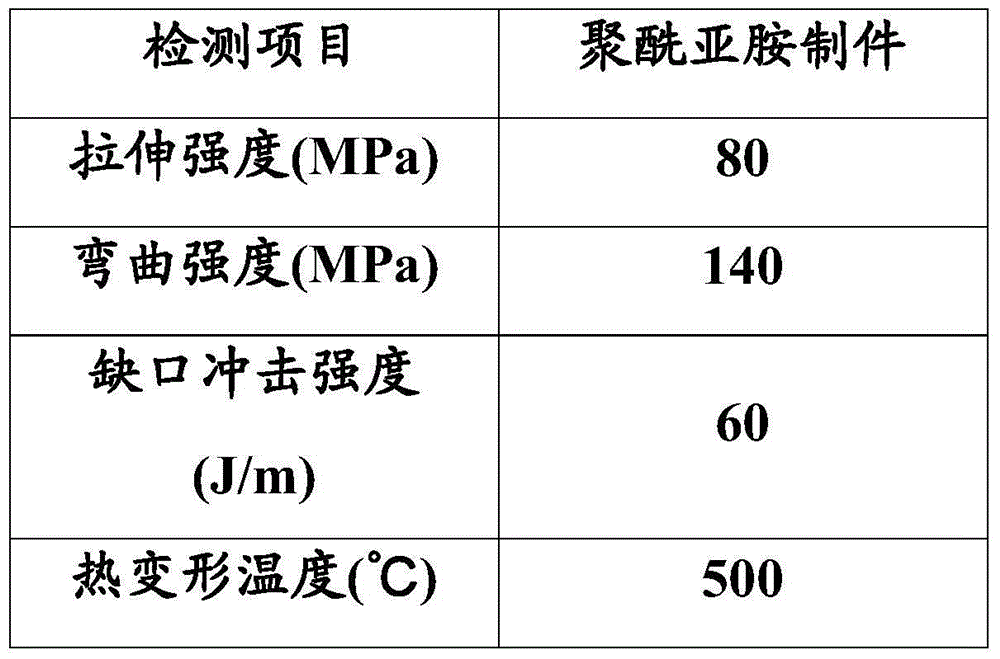

Embodiment 1

[0037] A high mechanical strength, high temperature resistant polyimide powder 3D printing method, the preparation method is as follows:

[0038] (1) According to the set space spraying forming sequence, after computer-aided (CAD) design, the CAD model size of the workpiece is l5mm×15mm×15mm. Through the system model and the forming machine data exchange interface program, the computer terminal outputs instructions to directly control the 3D printing forming machine to operate and prepare according to the forming parameters.

[0039] (2) Polyacrylate of 100 parts by weight, carbon black of 5 parts by weight, light calcium carbonate of 5 parts by weight, polyamide of 3 parts by weight, simethicone oil of 0.8 parts by weight, polyphosphoric acid of 2 parts by weight The salt is fully mixed at 35°C and 800r / min for 0.5h before discharging;

[0040] (3) pave one deck of phthalic anhydride type polyimide molding powder, 0.5 parts by weight heat stabilizer 1010, 5 parts by weight o...

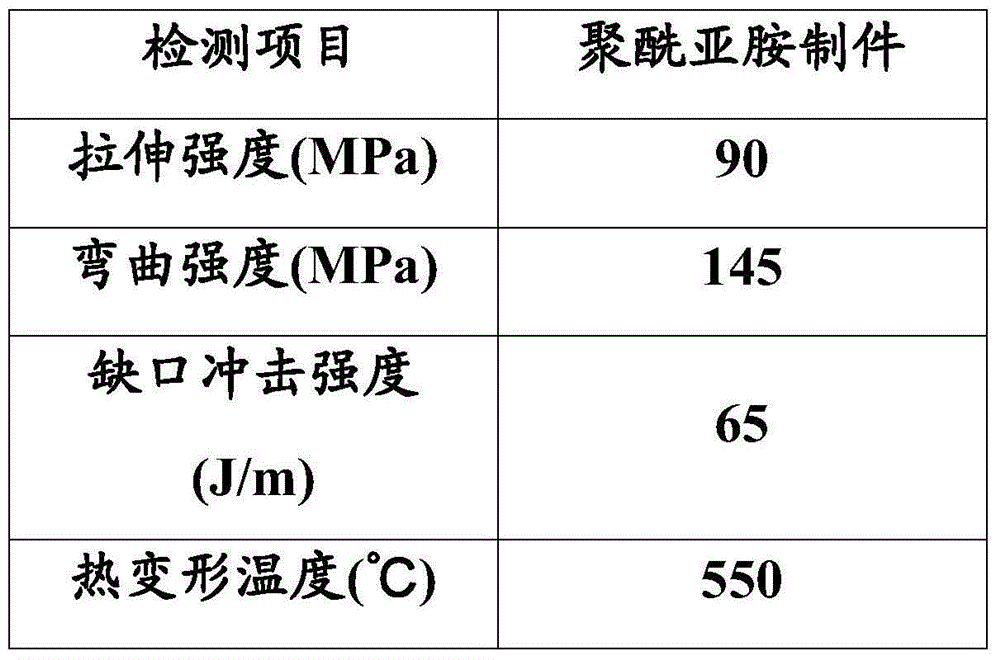

Embodiment 2

[0046] A high mechanical strength, high temperature resistant polyimide powder 3D printing method, the preparation method is as follows:

[0047] (1) According to the set space spraying forming sequence, after computer-aided (CAD) design, the CAD model size of the workpiece is l5mm×15mm×15mm. Through the system model and the forming machine data exchange interface program, the computer terminal outputs instructions to directly control the 3D printing forming machine to operate and prepare according to the forming parameters.

[0048] (2) 100 parts by weight of polyurethane, 5 parts by weight of titanium dioxide, 5 parts by weight of talcum powder, 3 parts by weight of polyvinyl alcohol, 0.8 parts by weight of polyether modified polysiloxane, 2 parts by weight of silicon The acid salt is fully mixed at 35°C and 800r / min for 0.5h before discharging;

[0049] (3) Spread one layer of ether anhydride type polyimide molding powder, 0.7 parts by weight heat stabilizer 168, 7 parts b...

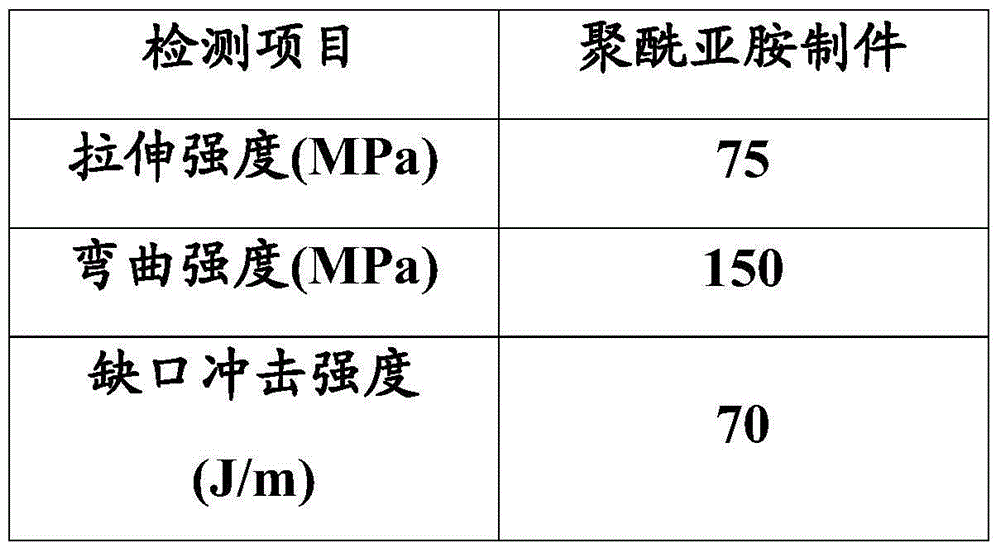

Embodiment 3

[0055] A high mechanical strength, high temperature resistant polyimide powder 3D printing method, the preparation method is as follows:

[0056] (1) According to the set space spraying forming sequence, after computer-aided (CAD) design, the CAD model size of the workpiece is l5mm×15mm×15mm. Through the system model and the forming machine data exchange interface program, the computer terminal outputs instructions to directly control the 3D printing forming machine to operate and prepare according to the forming parameters.

[0057] (2) 100 parts by weight of epoxy resin, 5 parts by weight of iron red, 5 parts by weight of kaolin, 3 parts by weight of nano-titanium dioxide, 0.8 parts by weight of polyacrylic acid, 2 parts by weight of polycarboxylate at 35 ° C, 800r Under the condition of rotating speed of / min, it is fully mixed for 0.5h and then discharged;

[0058] (3) Spread a layer of polyimide molding powder, 1 part by weight of heat stabilizer 1096, and 10 parts by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com