Toughening method for casting high-boron wear-resistant alloy

A wear-resistant alloy, high-boron technology, applied in the direction of manufacturing tools, heat treatment equipment, heat treatment process control, etc., can solve the problem of low impact toughness of high-boron wear-resistant alloys, and achieve the effect of improving impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

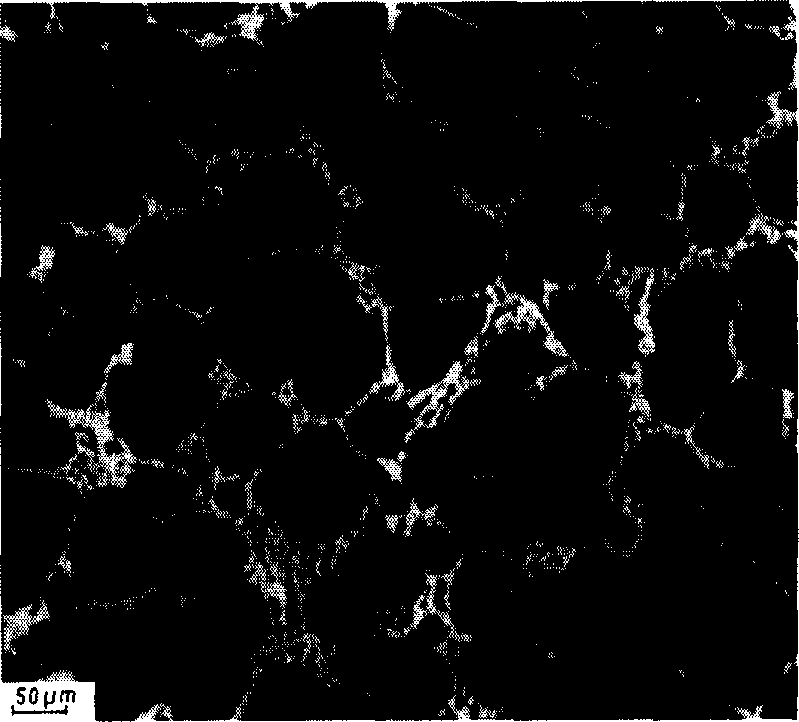

[0029] The chemical composition is 0.31 wt% C, 1.0 wt% B, 0.66 wt% Si, 0.82 wt% Mn. Modified with 2.5wt% FeTi30, the test block was water quenched at 1020 ° C for 3 hours, and then tempered at 200 ° C for 2 hours, the eutectic boride was broken, and it was isolated and granular. Wire cut 10mm×10mm×55mm standard specimen impact energy A k It is 8.5J and the hardness is 51HRC.

Embodiment 2

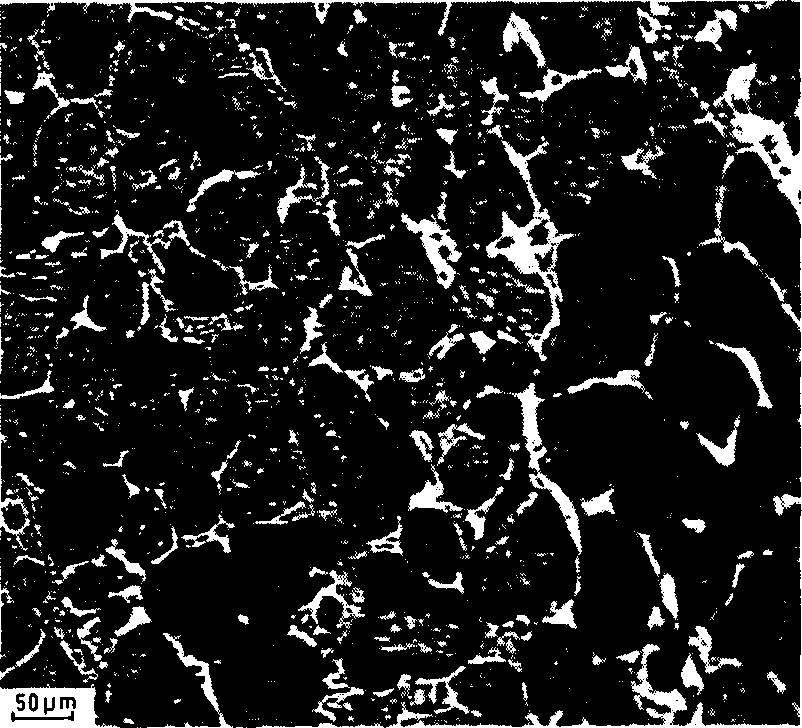

[0031] The chemical composition is 0.32wt% C, 1.0wt% B, 0.80wt% Si, 0.85wt% Mn. Modified with 3.2wt% FeTi30, the test block was water quenched at 1020 ° C for 3 hours, and then tempered at 200 ° C for 2 hours, the eutectic borides were broken, and they were isolated and granular. Wire cut 10mm×10mm×55mm standard specimen impact energy A k It is 8J and the hardness is 52HRC.

Embodiment 3

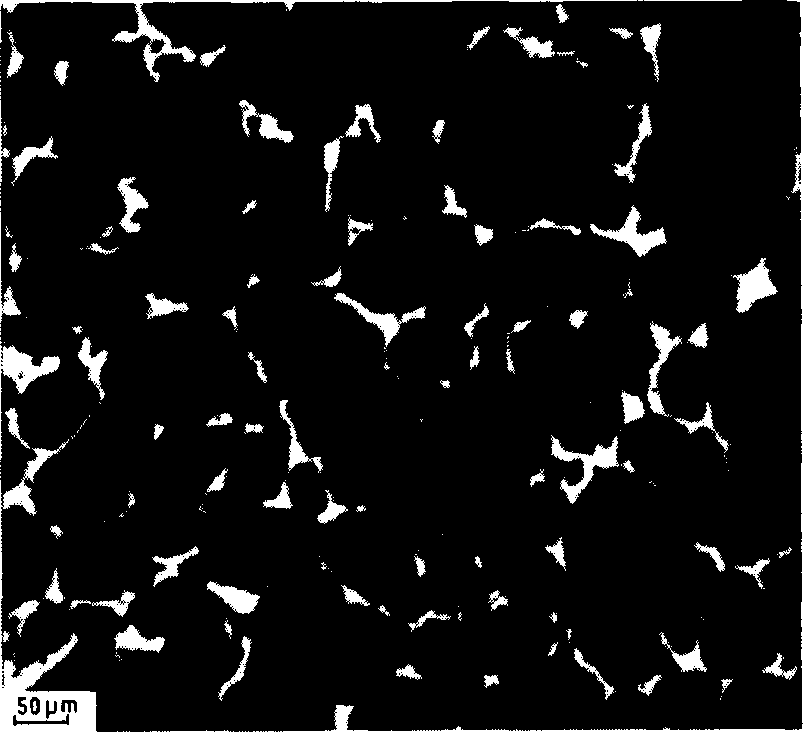

[0033] The chemical composition is 0.32wt% C, 1.0wt% B, 0.80wt% Si, 0.85wt% Mn. Modified with 3.2wt% FeTi30, the test block was water quenched at 1040 ° C for 3 hours, and then tempered at 200 ° C for 2 hours, the eutectic boride was completely broken, and it was isolated and granular. Wire cut 10mm×10mm×55mm standard specimen impact energy A k It is 10J and the hardness is 51.5HRC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com