Preparation method of titanium alloy bars

A technology for titanium alloy and rods, which is applied in the field of preparation of titanium alloy rods, can solve the problems of material plasticity reduction, uneven structure and performance of batch forgings, unqualified low-magnification structure, etc., and achieve high strength and fracture toughness. Convenient and plastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

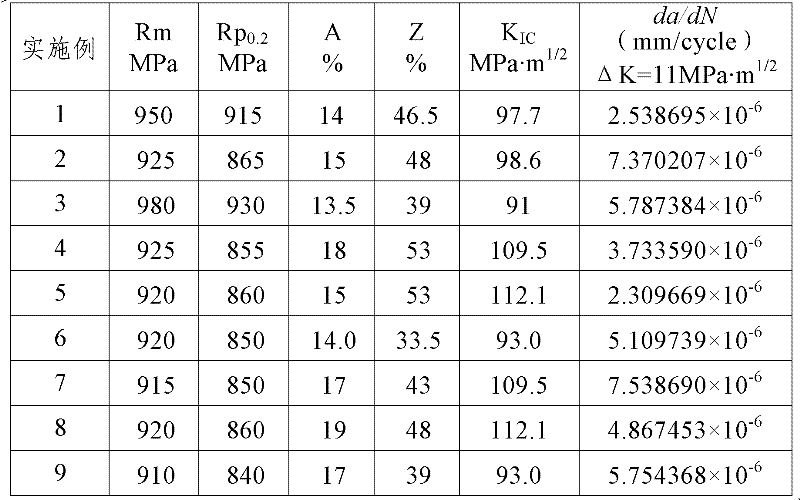

Examples

Embodiment 1

[0018] (1) Ingot smelting: 0-grade sponge titanium, Al-85V intermediate alloy and industrial pure aluminum are packaged into alloy packages, and then successively undergo electrode pressing, plasma welding and secondary vacuum consumable electric arc furnace melting to obtain specifications TC4-DT titanium alloy ingot of Φ570mm; the weight percentage of each component of TC4-DT titanium alloy ingot is Al: 6.34%, V: 4.21%, O: 0.09%, Fe: 0.05%, C: 0.02%, N : 0.012%, H: 0.007%, Ti is the balance;

[0019] (2) Using a resistance furnace, heat the TC4-DT titanium alloy ingot described in step (1) to 1200°C, and then use a 1600T fast forging machine to open and forge the titanium alloy ingot in the β-phase region for 2 fires to obtain forging For billets, the forging ratio per fire is not less than 1.3, and the final forging temperature is not less than 850°C; the phase transformation temperature T of the forged billets is β is 980°C;

[0020] (3) Adopt electric resistance furnace...

Embodiment 2

[0025] The preparation method of this example is the same as that of Example 1, except that the specification of TC4-DT titanium alloy ingot is Φ650mm; The β-phase zone is opened and forged for 3 times to obtain a forged billet; the forged billet is heated to T β After -35°C (945°C), repeat upsetting and elongating forging with a fast forging machine for 6 fires; the forging temperature of the forged billet after forging is T β -70°C (910°C), the system of double annealing treatment is: the first annealing at temperature T β Air cooling after heat preservation at -25°C (955°C) for 1 hour, and air cooling after heat preservation at 540°C for 8 hours for the second annealing; the specification of the finished titanium alloy rod prepared is Φ130 mm.

[0026] The titanium alloy bar prepared in this embodiment has good strength, high fracture toughness and low fatigue crack growth rate.

Embodiment 3

[0028] The preparation method of this example is the same as that of Example 1, except that the specification of TC4-DT titanium alloy ingot is Φ720mm; In the β phase zone, the billet is opened and forged for 2 fires to obtain the forged billet; the forged billet is heated to T β After -50°C (930°C), repeat upsetting and elongating forging with a fast forging machine for 3 times; the forging temperature of the forged billet after forging is T β -50°C (930°C), the system of double annealing treatment is: the first annealing at temperature T βAir-cooling after heat preservation at -50°C (930°C) for 1.5h, second annealing at 600°C for 4h and then air-cooling; the specification of the finished titanium alloy rod prepared is Φ300mm.

[0029] The titanium alloy bar prepared in this embodiment has good strength, high fracture toughness and low fatigue crack growth rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com