Process for producing sweet gas for poor-quality gasoline distillate

A technology of inferior gasoline and distillate, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of unqualified mercaptan sulfur and reducing sulfur content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

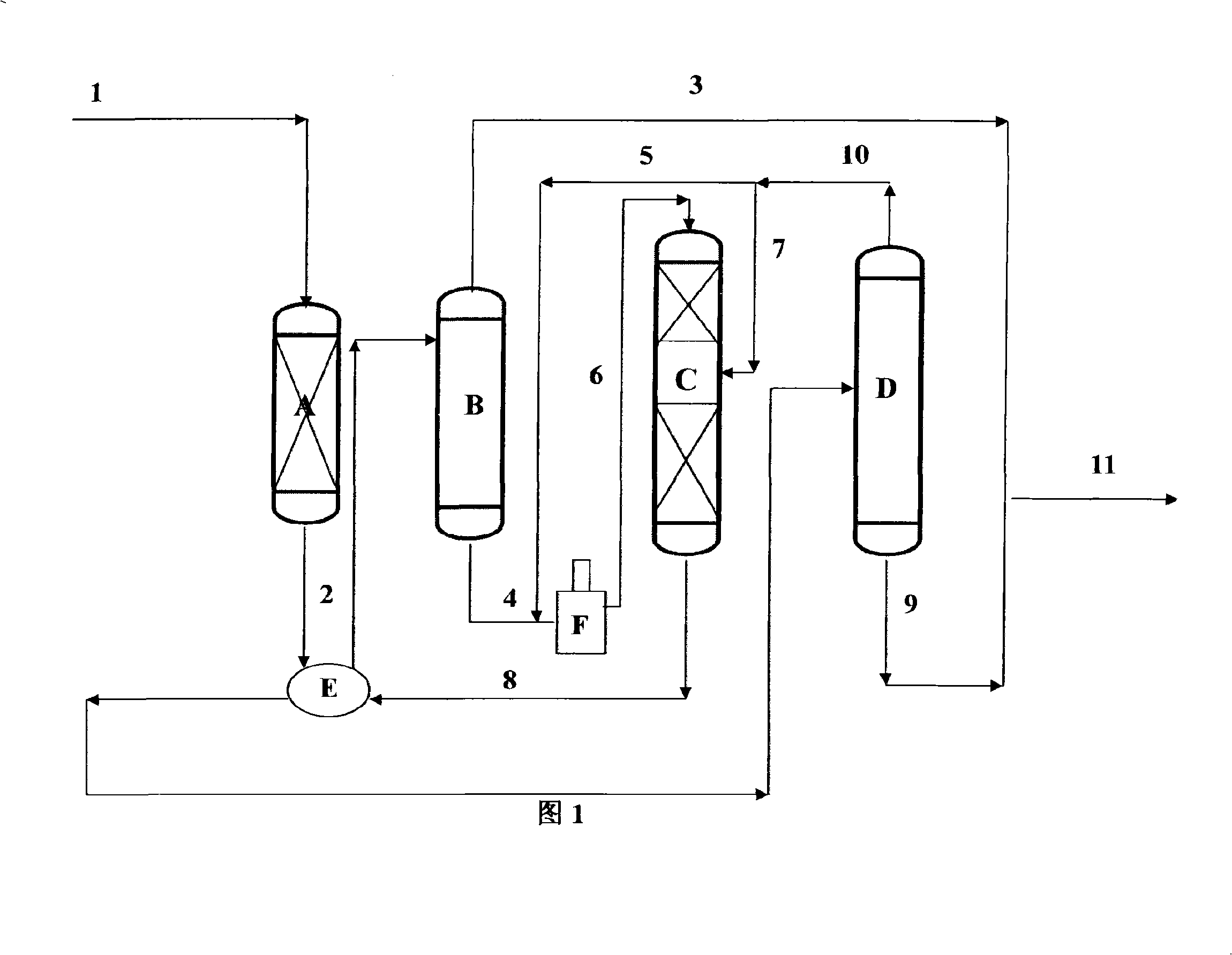

Method used

Image

Examples

example 1

[0038] This example prepares a kind of highly active MoO by step-by-step impregnation method 3 (13.0wt%)-CoO(4.0wt%)-P 2 o 5 (1.5wt%)-K 2 O-(2.0wt%) / Al 2 o 3 catalyst.

[0039] Take by weighing 1000g pseudo-thin water aluminum hydroxide powder (Al 2 o 3 Dry basis content is 78wt%), adding accounted for Al 2 o 3 Dry basis 5wt% squash powder extrusion aid, mass concentration 10% nitric acid aqueous solution 200ml, mix and roll and mix into plastic powder, use extruder to prepare cylindrical strips with a diameter of 1.5mm, dry at 120°C 8 hours, calcination at 500°C for 5 hours to prepare a catalyst carrier;

[0040] Press Catalyst on P 2 o 5 The content is 1.5wt%, K 2 O content is 2.0wt%, take quantitative phosphoric acid, potassium nitrate, add deionized water, be made into 120ml impregnating solution, then, spray on the above-mentioned catalyst carrier of 160g. P 2 o 5 (1.5wt%)-K 2 O-(2.0wt%) / Al 2 o 3 Catalyst intermediate.

[0041] MoO on Catalyst 3 The co...

example 2

[0043] This example co-impregnation method to prepare a low activity MoO 3 (3.0wt%)-CoO(1.0wt%)-K 2 O(2.0wt%) / Al 2 o 3 catalyst.

[0044] The catalyst carrier was prepared with reference to Example 1.

[0045] MoO on Catalyst 3 content of 3.0wt%, CoO content of 1.0wt% and K 2 O content is 2.0wt%, take quantitative ammonium molybdate, cobalt nitrate and potassium nitrate, add deionized water, be made into 110ml impregnation liquid, then, spray on the above-mentioned catalyst carrier of 165g. Drying at 120°C for 8 hours and calcining at 500°C for 4 hours prepared MoO 3 (3.0wt%)-CoO(1.0wt%)-K 2 O(2.0wt%) / Al 2 o 3 catalyst. The catalyst is referred to as LAC, and the specific surface area and pore volume properties of the catalyst are shown in Table 1 by low-temperature nitrogen adsorption BET method.

[0046] The physical property of table 1 example 1~instance 2 catalyst

[0047] project

[0048] Specific surface area, m 2 / g

example 3

[0050] This example shows the desulfurization effect of inferior FCC gasoline.

[0051] (1), raw oil sweetening

[0052] The sweetening oxidant of feedstock oil adopts commercial AFS-12 catalyst (purchased from Petroleum University), at a pressure of 0.5MPa, a temperature of 35°C-45°C, and a volume space velocity of 2.0h -1 , Gas-oil volume ratio (air / catalyst) 4:1 for deodorization.

[0053] (2) Cutting of raw oil light distillate and heavy distillate

[0054] With 50°C as the cut point temperature, FCC gasoline is separated into 50°C heavy fraction. Table 2 lists the properties of FCC gasoline, 50°C heavy fraction.

[0055] Properties of FCC gasoline, light ends and heavy ends in Table 2 Example 3

[0056] project

[0057] (3) Hydrodesulfurization of heavy fractions >50°C

[0058] The evaluation tests were carried out on a fixed bed reactor setup charged with 50 ml of a high activity HAC and a low activity LAC catalyst. The volume ratio of the former to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com