Preparation method of low-cost porous graphene

A porous graphene, low-cost technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of restricting the application and promotion of porous graphene, difficult mass production, and many product defects. The effect of large-scale production, less structural defects, and abundant sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

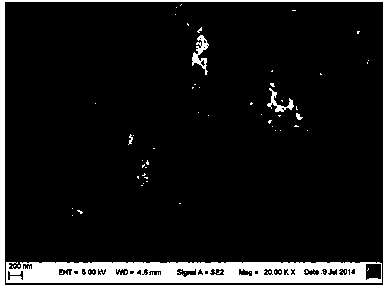

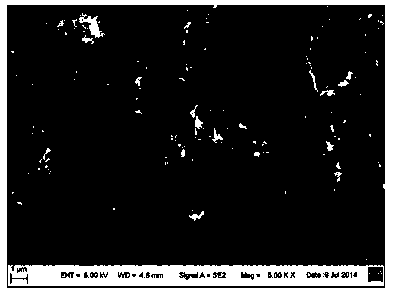

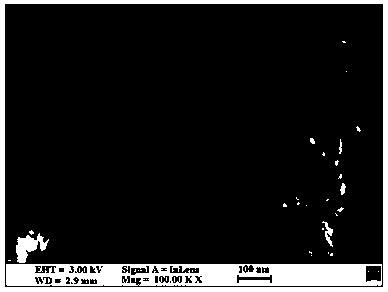

Image

Examples

Embodiment 1

[0027] 1) Raw material mixing: Weigh the water-based mesophase pitch and aluminum acetate according to the mass ratio of 100:100, use deionized water as the solvent, and the mass ratio of the raw material to the solvent is 1:10; mix the two evenly by mechanical stirring, and stir The temperature is 25°C, and the stirring time is 0.5h; after stirring evenly, the solvent is distilled off under reduced pressure, and placed in a 60°C vacuum oven (1.0×10 -1 Pa) dried for 4 hours, cooled to room temperature;

[0028] 2) Carbonization: place the dried sample in an atmosphere furnace, pass in argon gas (the flow rate of argon gas is 100mL / min), raise the temperature to 1800°C at 10°C / min, keep it warm for 2 hours, cool to room temperature and take it out;

[0029] 3) Pickling: Place the carbonized product in a hydrochloric acid solution (the molar concentration of the acid solution is 1mol / L), stir for 4 hours at a stirring speed of 120r / min, filter and separate, wash with deionized w...

Embodiment 2

[0032] 1) Mixing of raw materials: Weigh sucrose and aluminum sulfate according to the mass ratio of 100:50, use acetone as the solvent, and the mass ratio of raw materials to solvent is 1:3; mix the two evenly by mechanical stirring, and the stirring temperature is 30°C. Stirring time is 1h; after stirring evenly, the solvent is distilled off under reduced pressure, and placed in a vacuum oven at 35°C (1.0×10 -1 Pa) dry for 2 hours and cool to room temperature;

[0033] 2) Carbonization: place the dried sample in an atmosphere furnace, pass in nitrogen gas (nitrogen flow rate is 50mL / min), raise the temperature to 1400°C at 5°C / min, keep it warm for 1h, cool to room temperature and take it out;

[0034] 3) Pickling: Place the carbonized product in a sulfuric acid solution (the molar concentration of the acid solution is 0.5mol / L), stir for 2 hours at a stirring speed of 60r / min, filter and separate, wash with deionized water to neutrality; place in vacuum drying box (1.0 x 1...

Embodiment 3

[0037] 1) Mixing of raw materials: Weigh polystyrene and aluminum isopropoxide according to the mass ratio of 100:70, use N,N-dimethylformamide as the solvent, and the mass ratio of raw materials to solvent is 1:5; through mechanical stirring Mix the two evenly, the stirring temperature is 120°C, and the stirring time is 1.5h. After stirring evenly, the solvent was distilled off under reduced pressure and placed in a vacuum oven at 80°C (1.0×10 -1 Pa) dried for 10 hours, cooled to room temperature;

[0038] 2) Carbonization: place the dried sample in an atmosphere furnace, pass in argon gas (the flow rate of argon gas is 120mL / min), raise the temperature to 2000°C at 15°C / min, keep it warm for 0.5h, cool to room temperature and take it out;

[0039] 3) Pickling: Place the carbonized product in an oxalic acid solution (the molar concentration of the acid solution is 2mol / L), stir for 3 hours at a stirring speed of 80 rpm, filter and separate, wash with deionized water until ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com