Automatic chemical feeding device and method in foam-drainage gas recovery well

A technology of foam drainage and automatic chemical dosing, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of insufficient drainage, increased drainage burden, rapid water flooding of gas wells, etc., and achieve improved automation Management level, avoiding water flooding of gas wells, and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

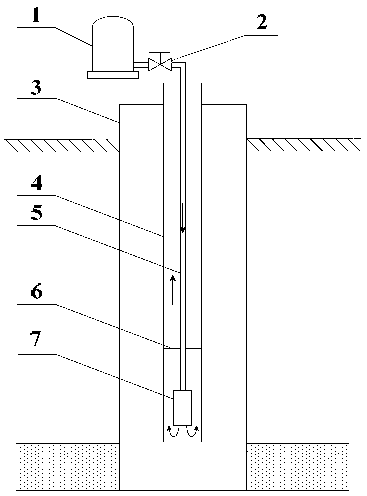

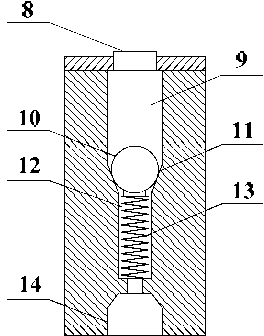

[0014] Such as figure 1 , figure 2 As shown, an automatic dosing device for foam drainage and gas recovery in the present invention is mainly composed of a medicine storage tank 1, a thin tube 5, a differential pressure control valve 7, an oil pipe 4, and a casing 3. The medicine storage tank 1, thin tube valve 2, thin tube 5, and differential pressure control valve 7 are sequentially connected in series from top to bottom to form a medicine adding channel. An annular drainage channel is formed between the thin tube 5 and the oil tube 4 . The differential pressure control valve 7 is mainly composed of a drug inlet 8, an upper chamber 9, a valve core ball 10, a conical valve seat 11, a lower chamber 12, a spring 13, and a drug outlet 14. The medicine inlet 8 is connected with the thin tube 5, and the medicine outlet 14 is communicated with the oil pipe 4; the spring 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com