Terminal assembly for a coaxial cable

a technology of coaxial cable and terminal, which is applied in the direction of electrically conductive connections, coupling device connections, electrical apparatus, etc., can solve the problems of significant manual manipulation, laborious and sensitive techniques, and known methods for assembling terminals to coaxial cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

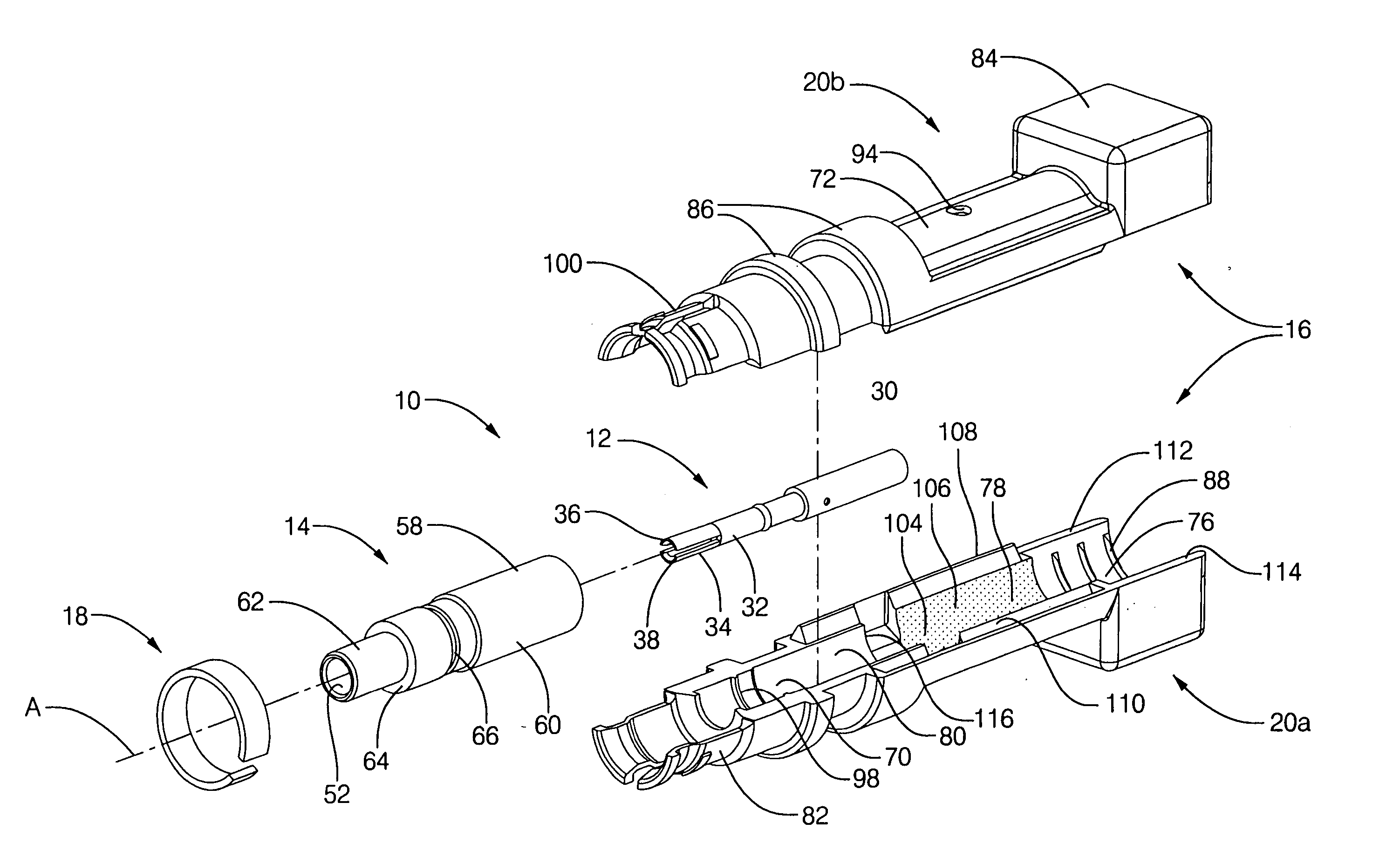

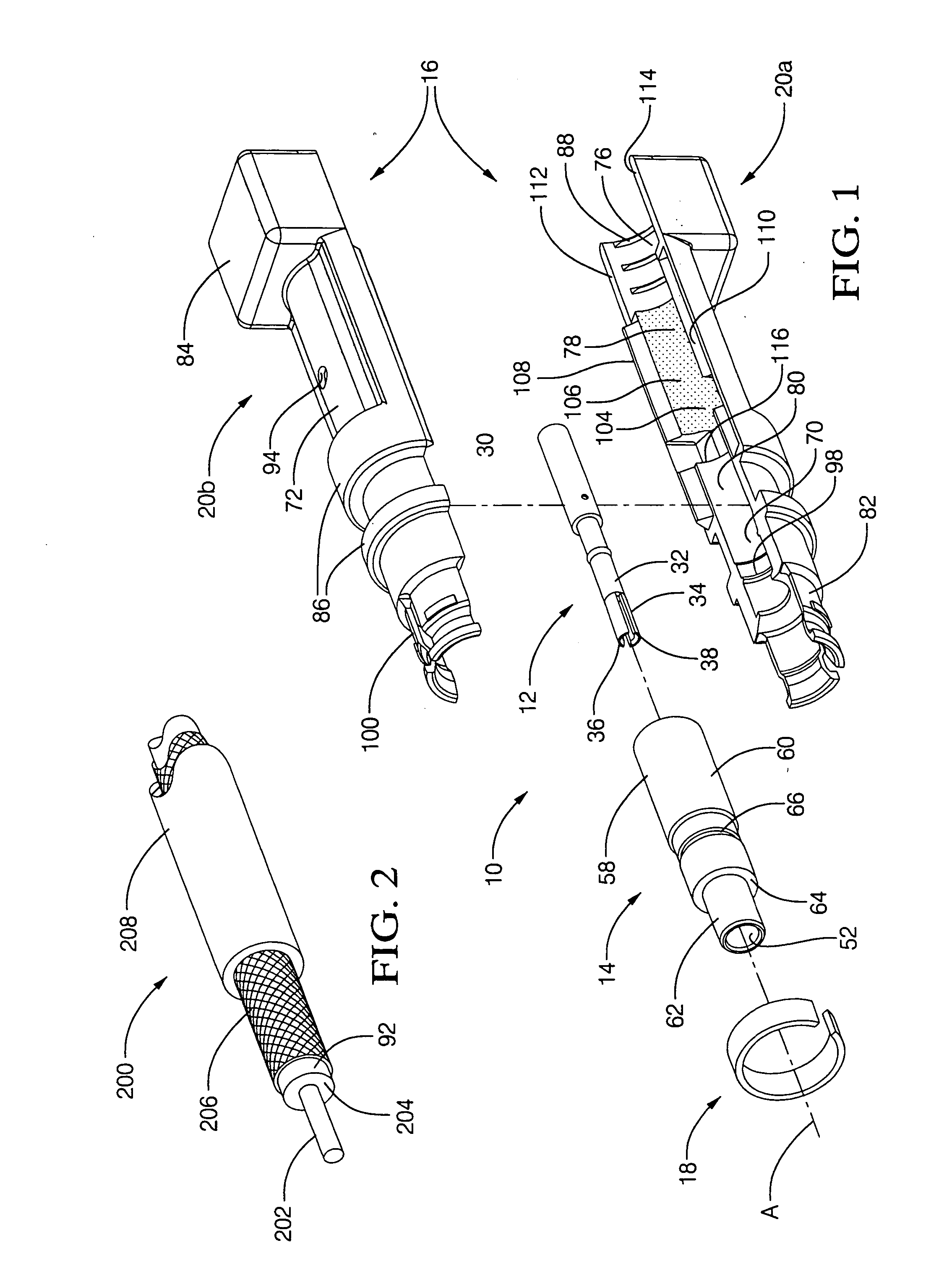

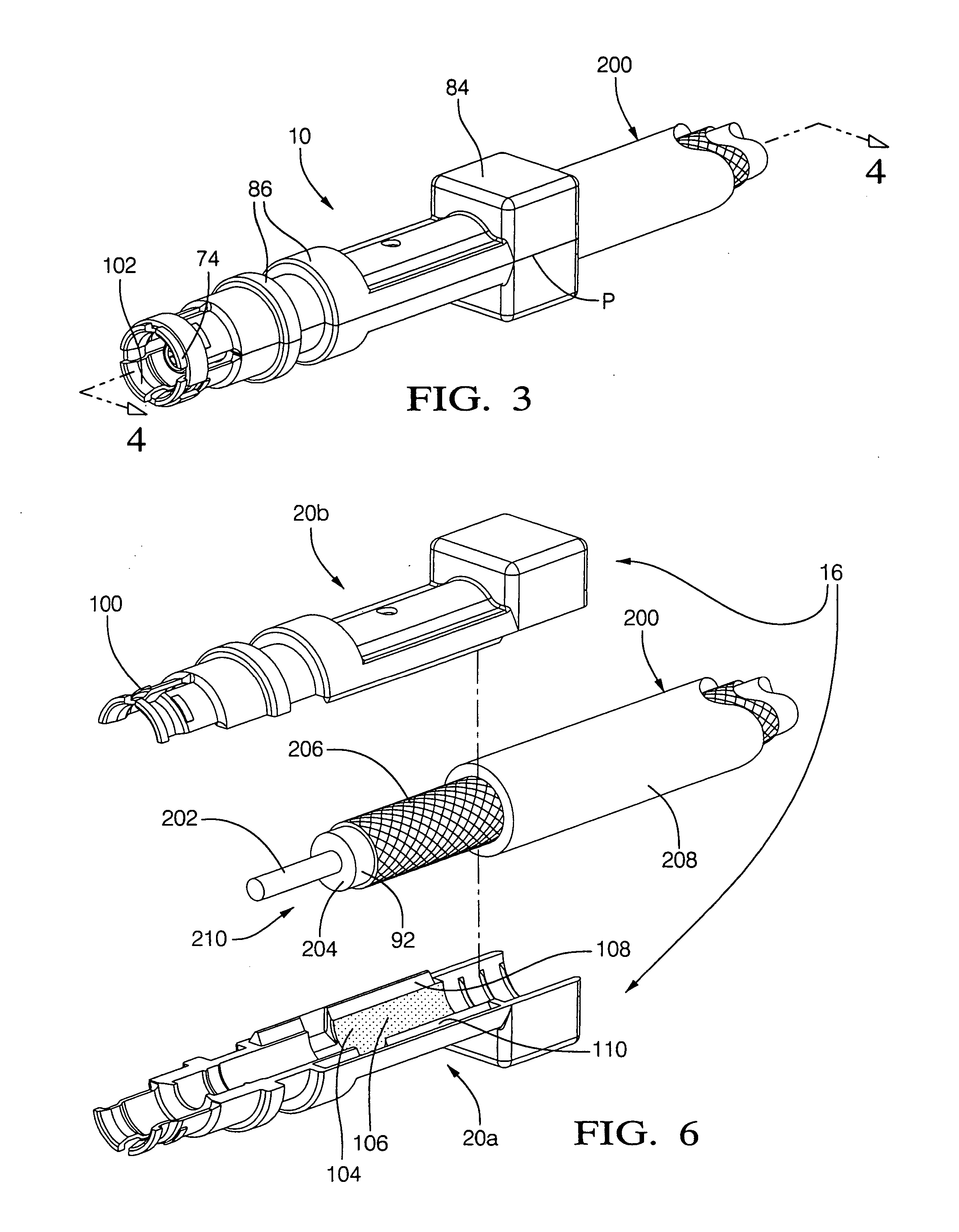

[0022] Referring to the figures wherein like numerals refer to like elements throughout the several views, FIGS. 1, 3, and 4 illustrate a preferred embodiment of an electrical terminal 10 of the present invention. The terminal 10 includes an electrically conductive core conductor 12, a dielectric member 14, a conductive ground shield 16, and a split ring support 18. The ground shield 16 is an assembly of two identical ground shield halves or housing members 20a, 20b. When joined, the ground shield housing members 20a, 20b define the completed ground shield 16. Each ground shield housing member 20a, 20b is preferably a rigid die cast member constructed of a nickel plated zinc alloy.

[0023]FIG. 2 illustrates a coaxial cable 200 which includes an inner conductor 202, an inner dielectric sheath 204 around the inner conductor 202, an outer conductor layer 206 having a cylindrical outer surface and concentrically surrounding the inner dielectric sheath 204 and the inner conductor 202, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com