Combined additive and subtractive manufacturing machine tool

A technology of additive manufacturing and material addition and subtraction, which is applied in the field of additive and subtractive composite manufacturing machine tools to achieve the effect of ensuring manufacturing accuracy and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

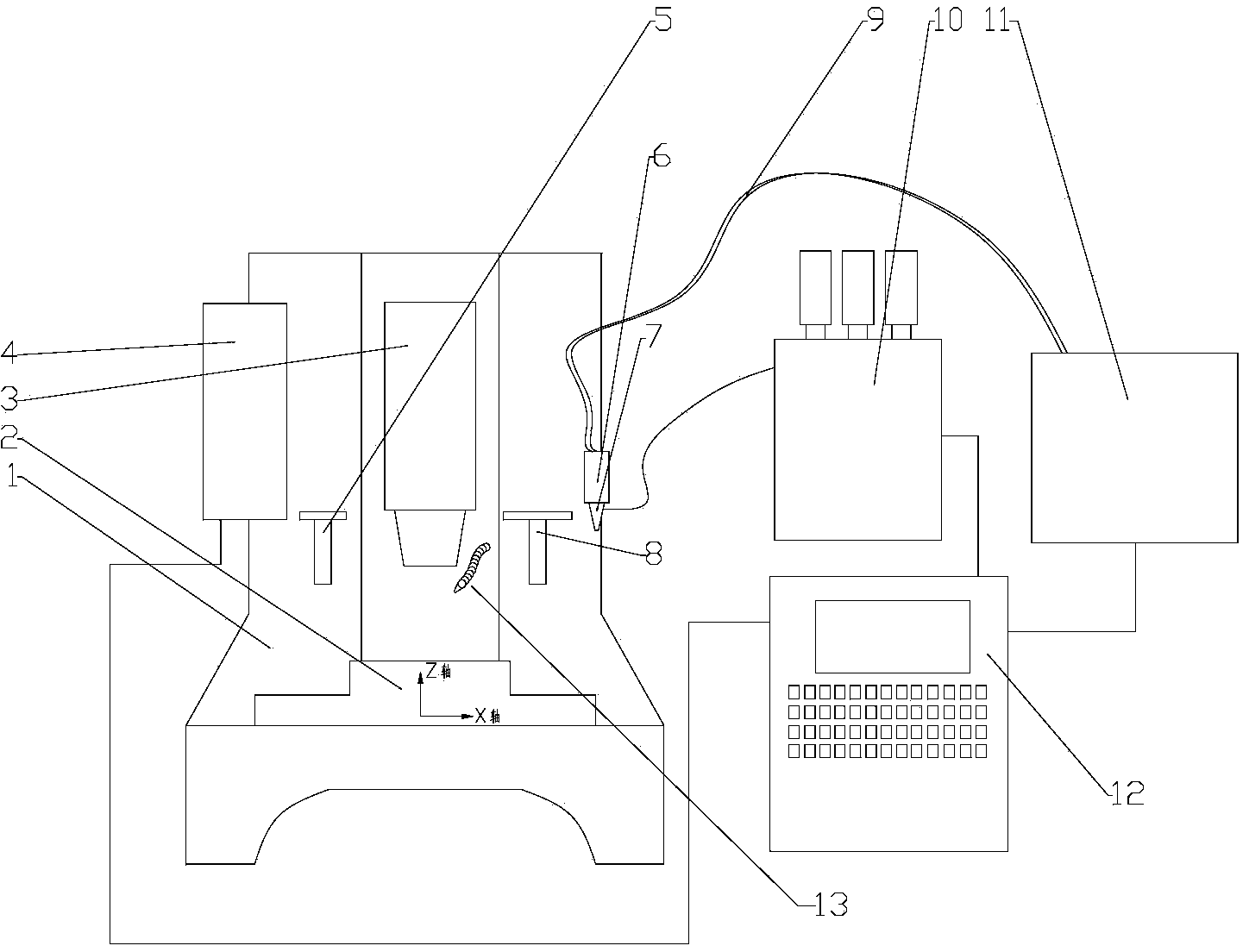

[0013] Below in conjunction with accompanying drawing, the present invention is described in detail by giving examples, embodiment:

[0014] An additive-subtractive composite manufacturing machine tool includes a bed 1, a workbench 2, a spindle 3, a subtractive machining module, an additive manufacturing module, and a numerical control system 12, wherein the subtractive machining module includes a tool magazine 4, tool clamping and ultrasonic vibration Mechanism 5; the additive manufacturing module includes a laser head 6, a nozzle 7, a laser head clamping mechanism 8, an optical fiber 9, a powder feeder 10, a laser 11 and a cooling gas nozzle 13. The workbench 2 is located in the middle of the bed 1, and is connected to the bed through two rotating shafts that can rotate around the X-axis and the Z-axis respectively, and then can rotate along the X-axis and the Z-axis; the main shaft 3 passes through two The linear guide rail whose axis direction is parallel to the Z-axis dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com