Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

167 results about "Co injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

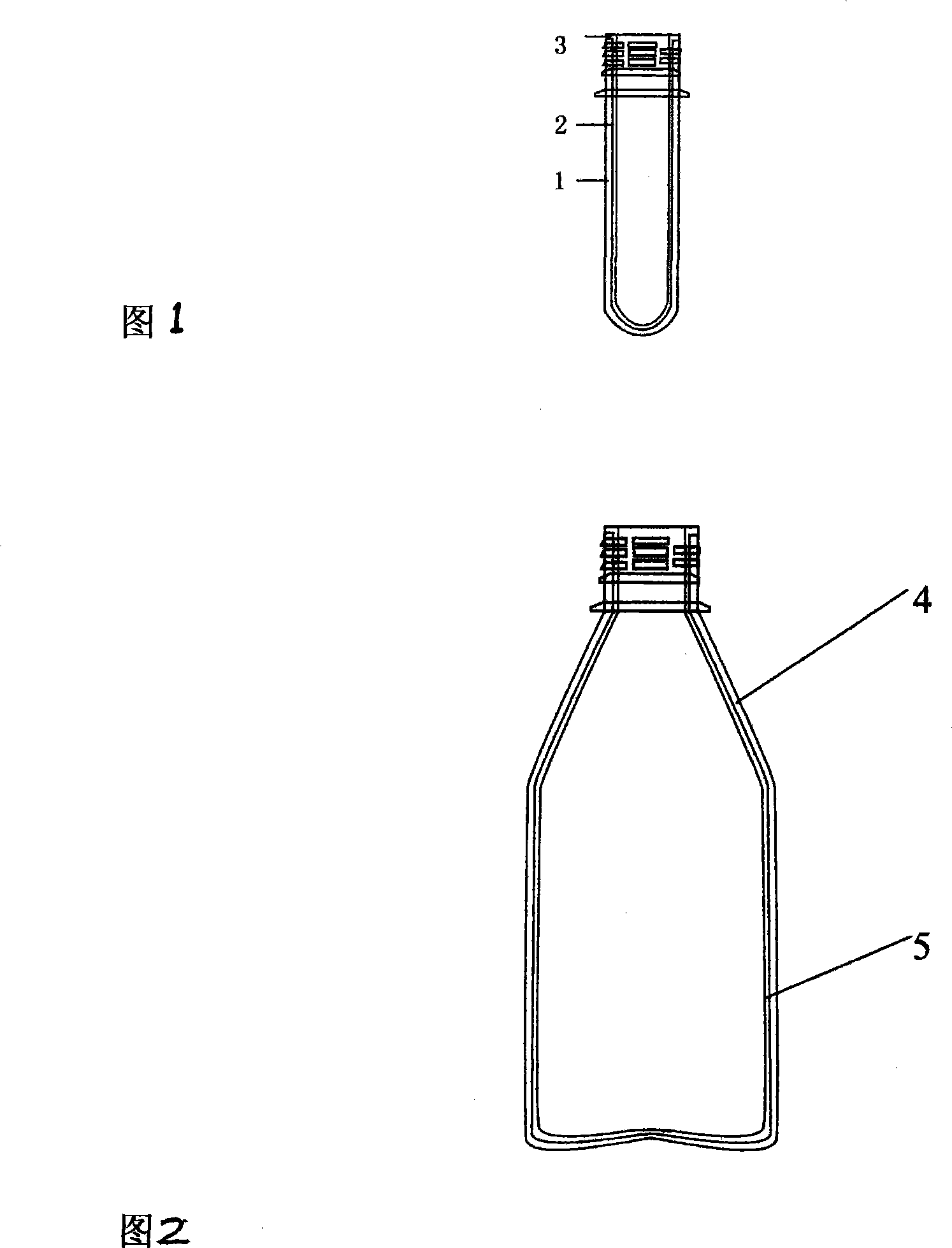

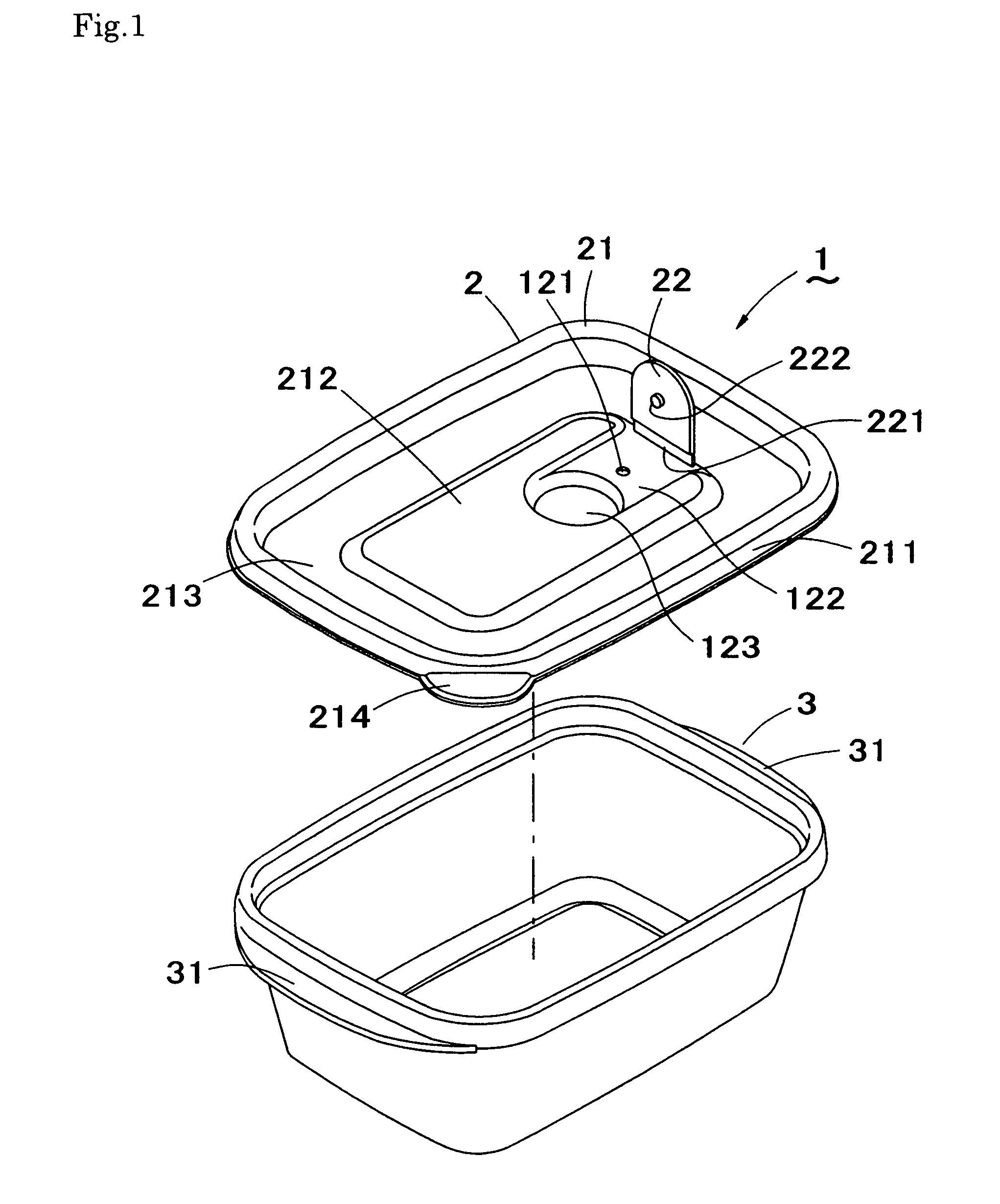

Multilayer containers and process for forming multilayer containers

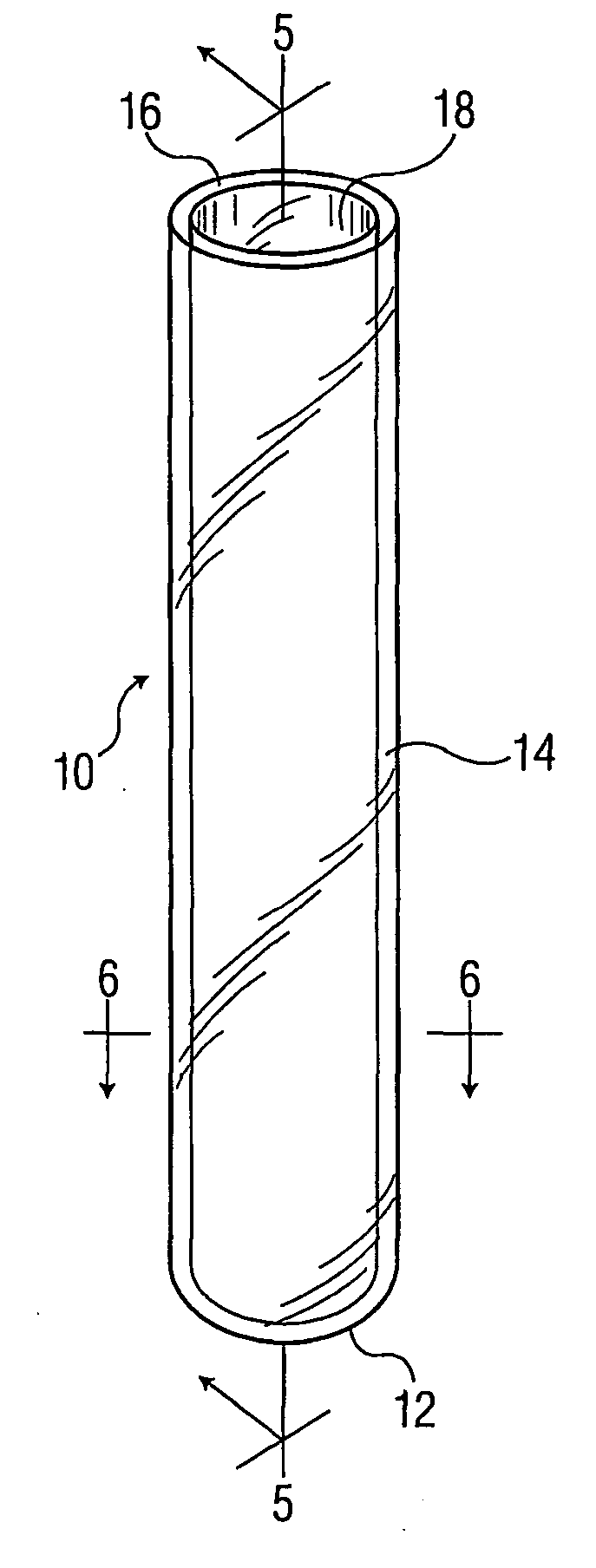

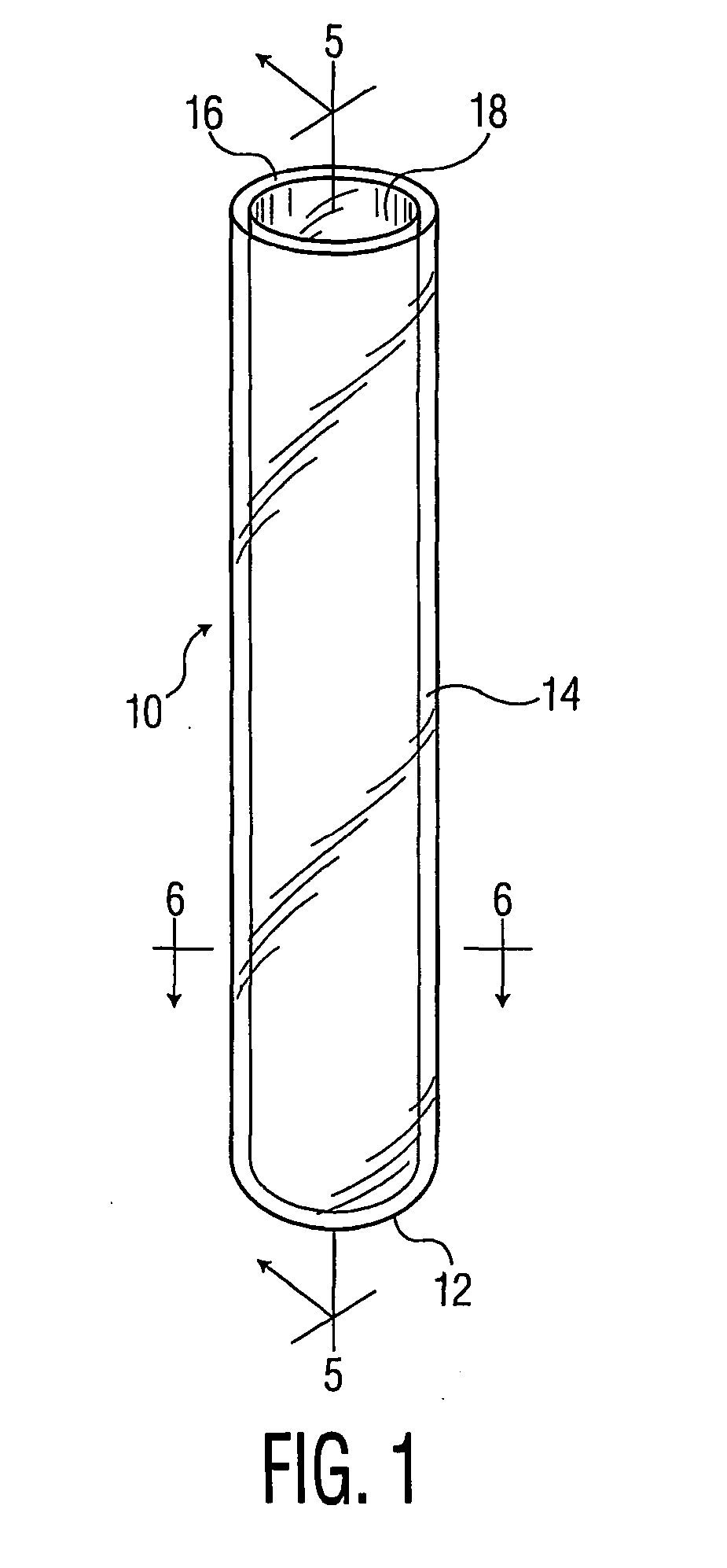

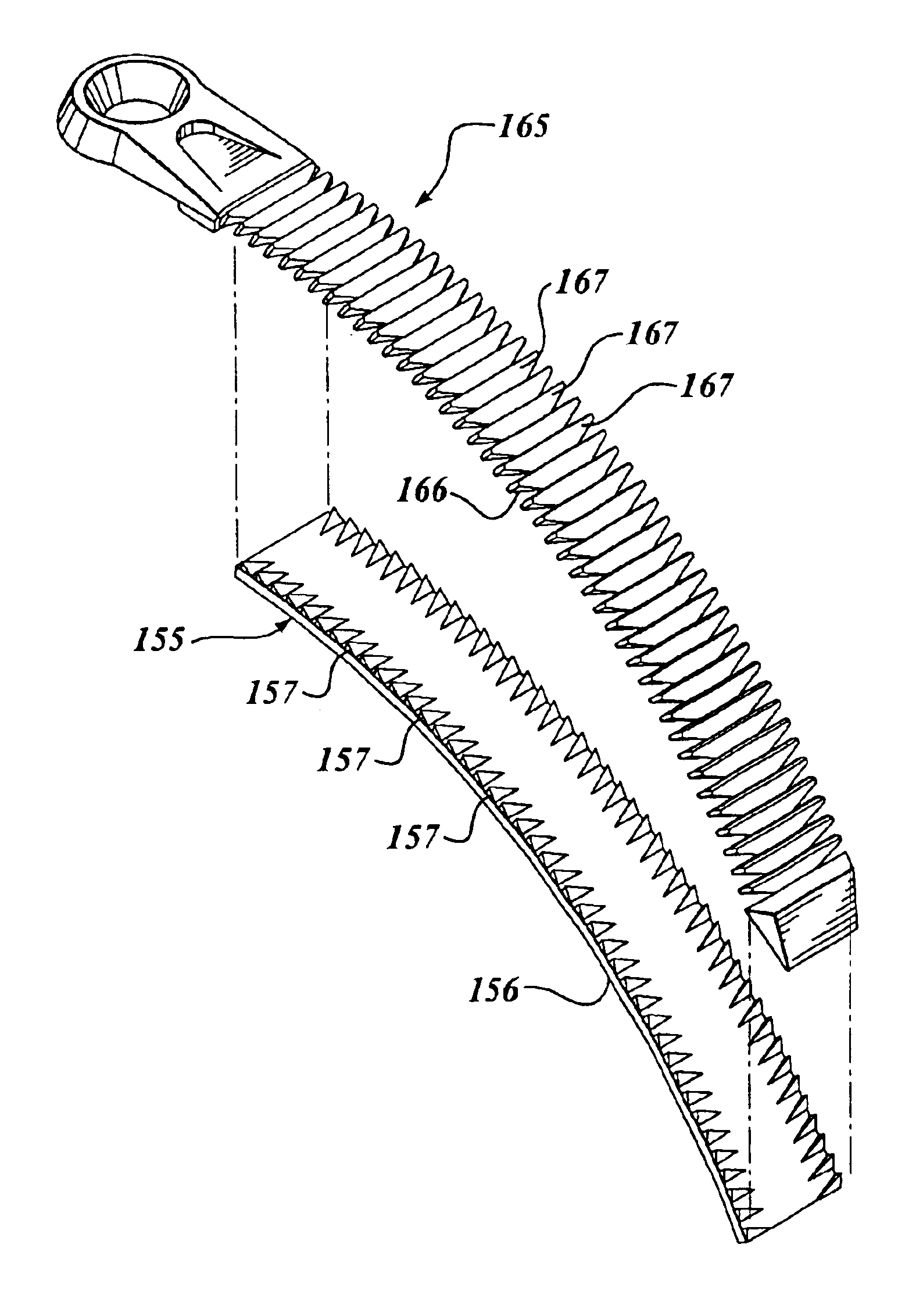

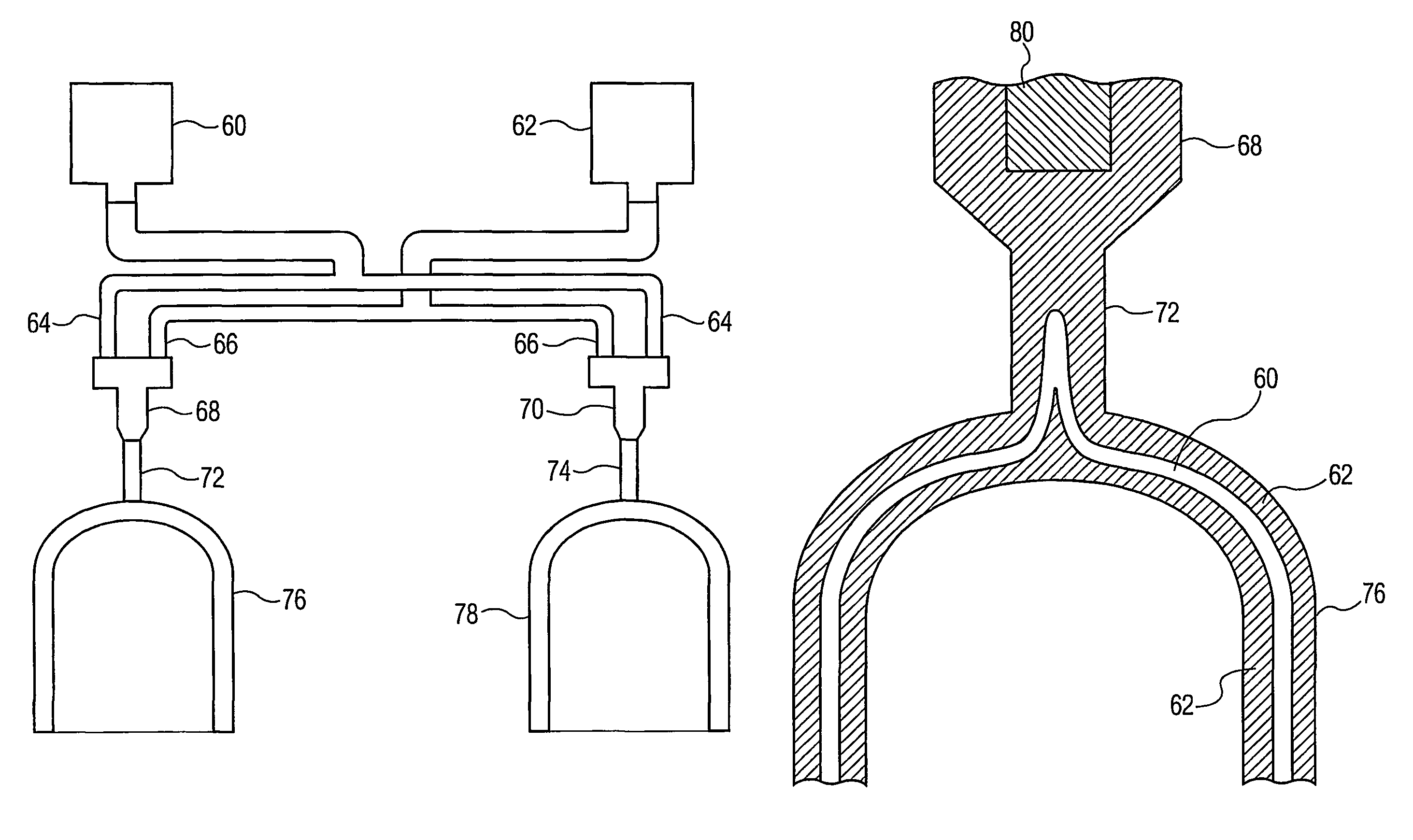

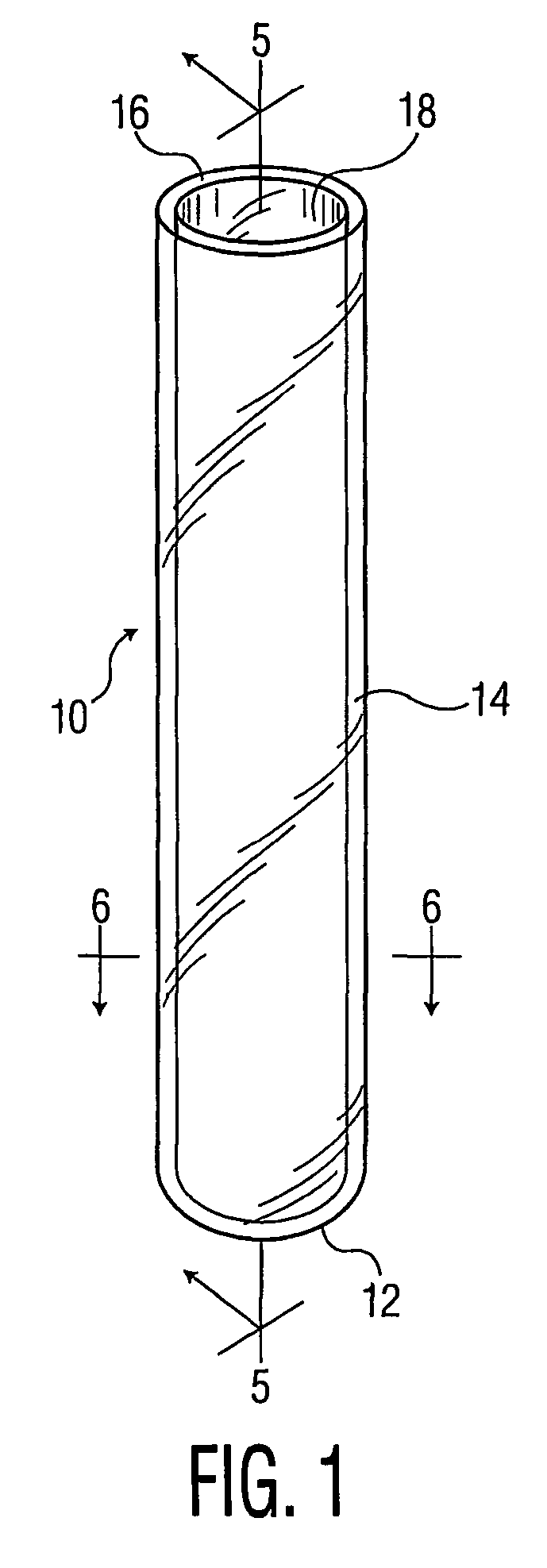

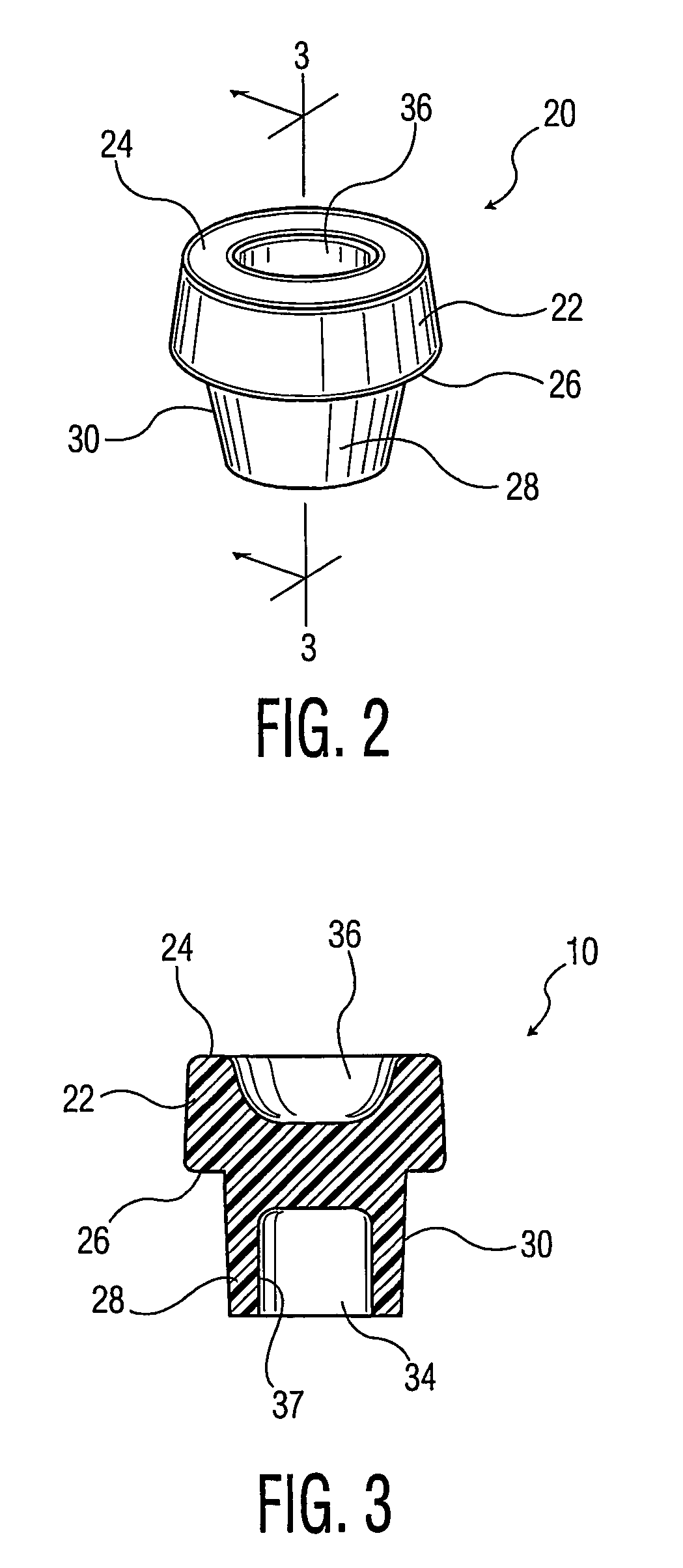

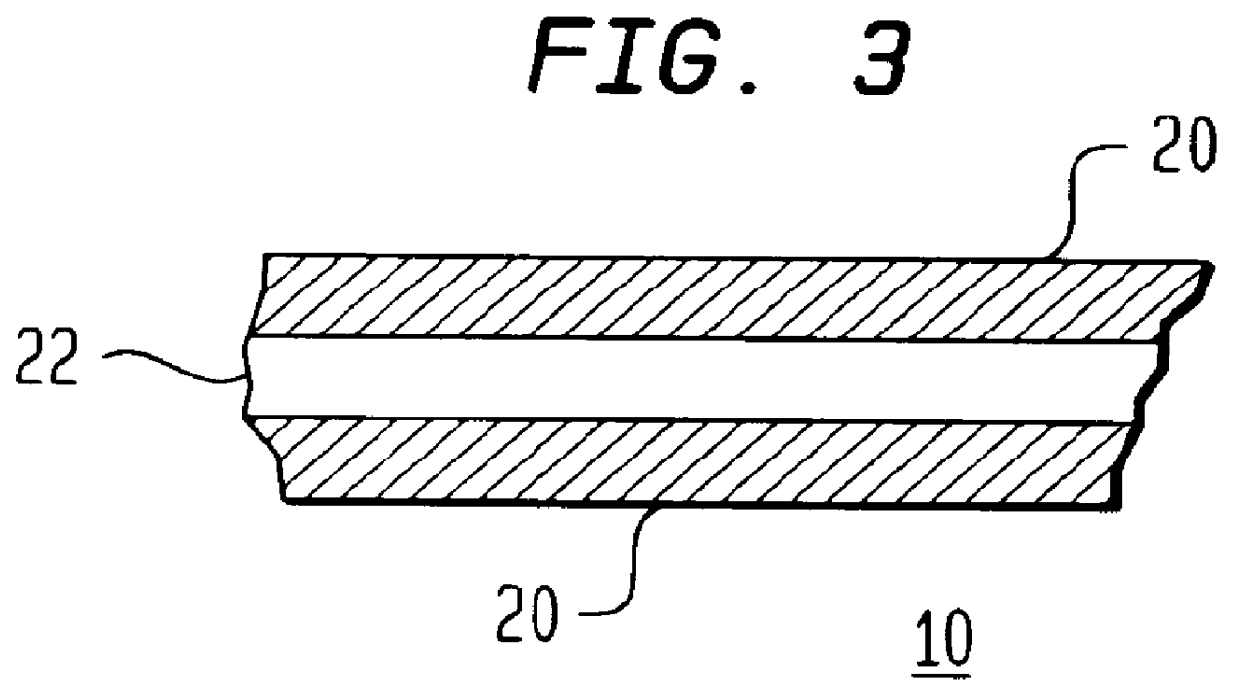

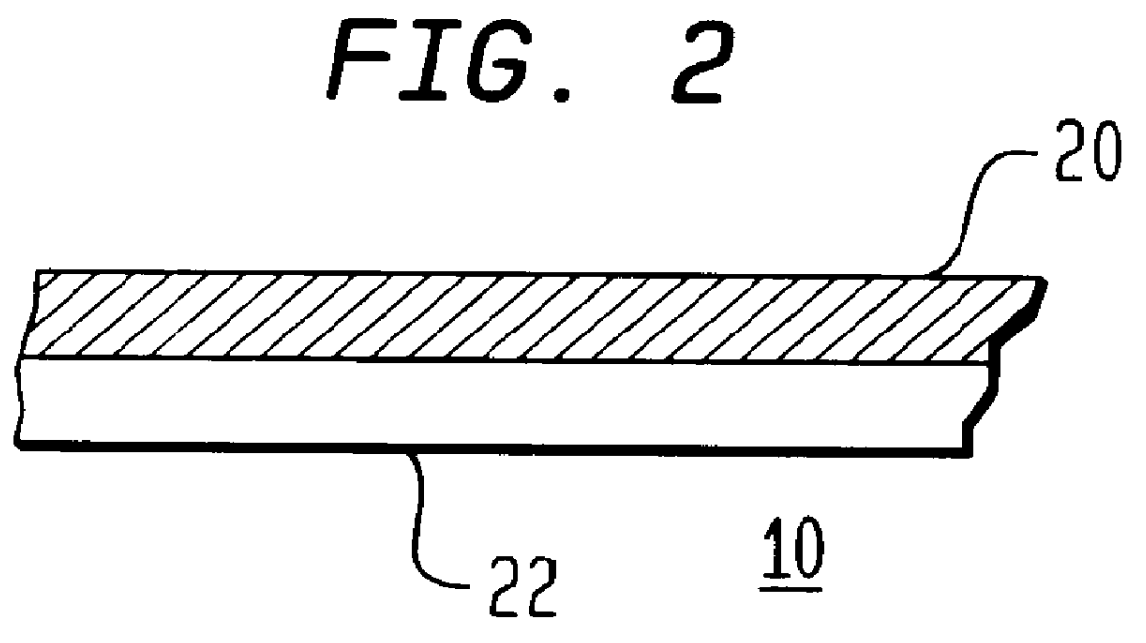

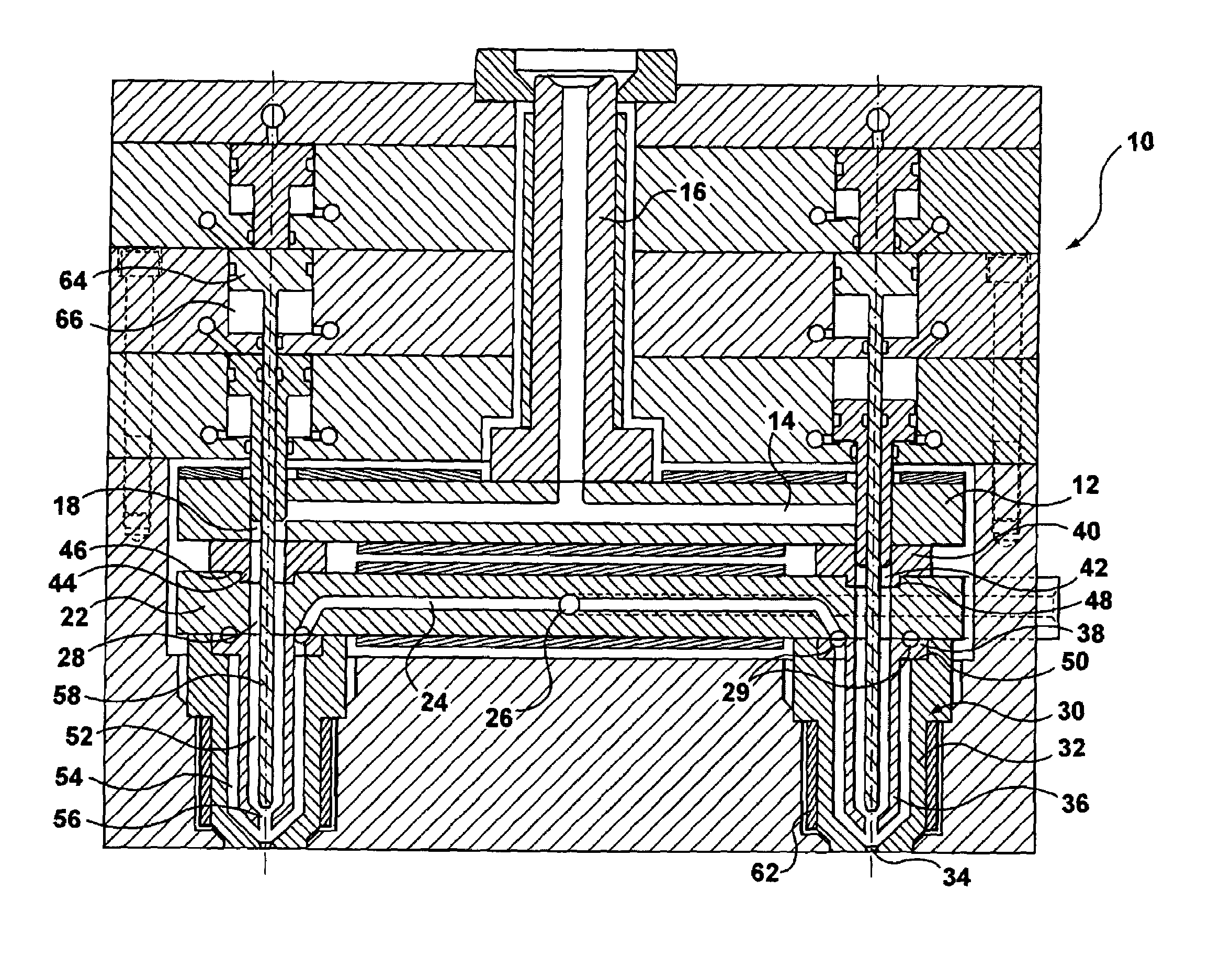

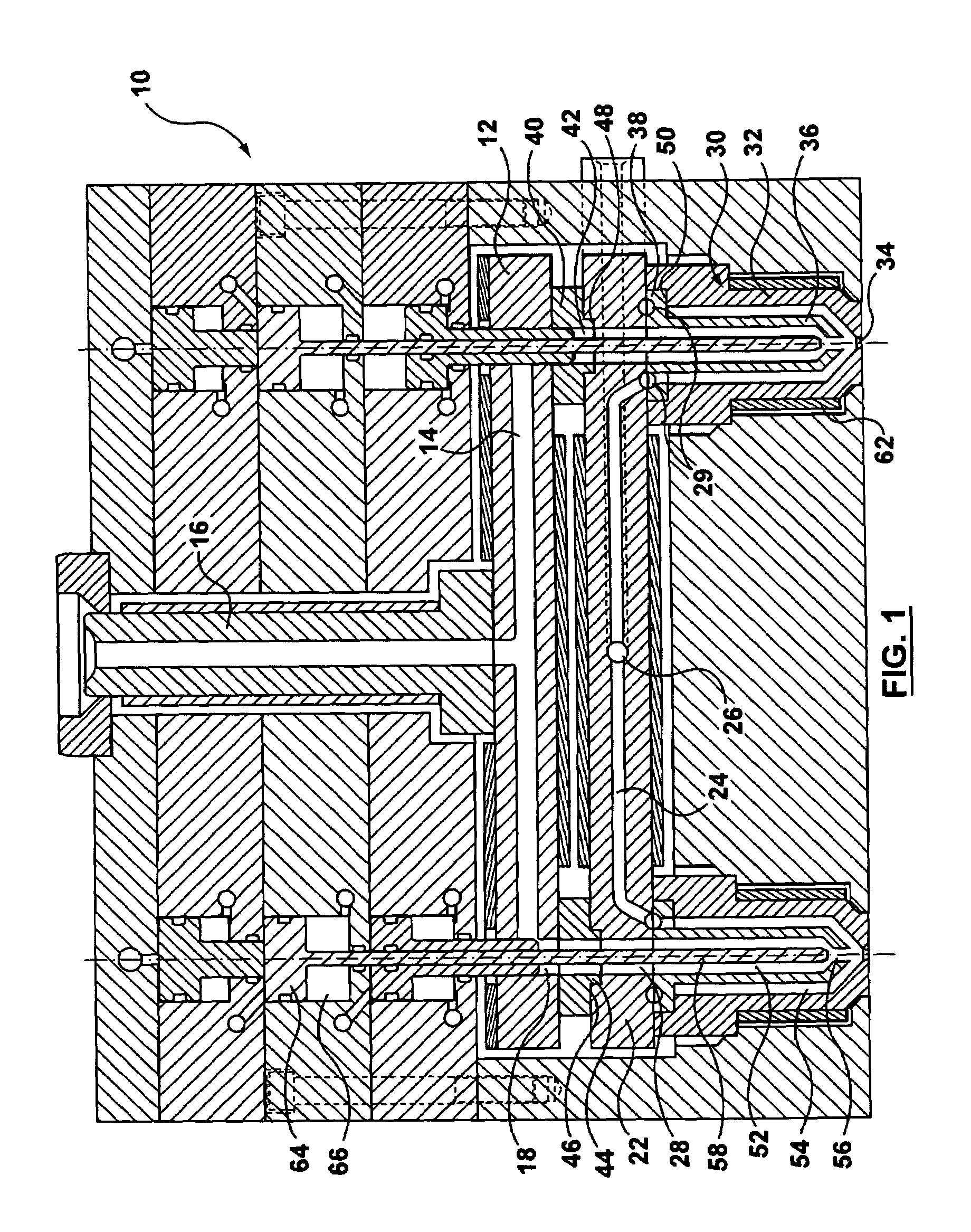

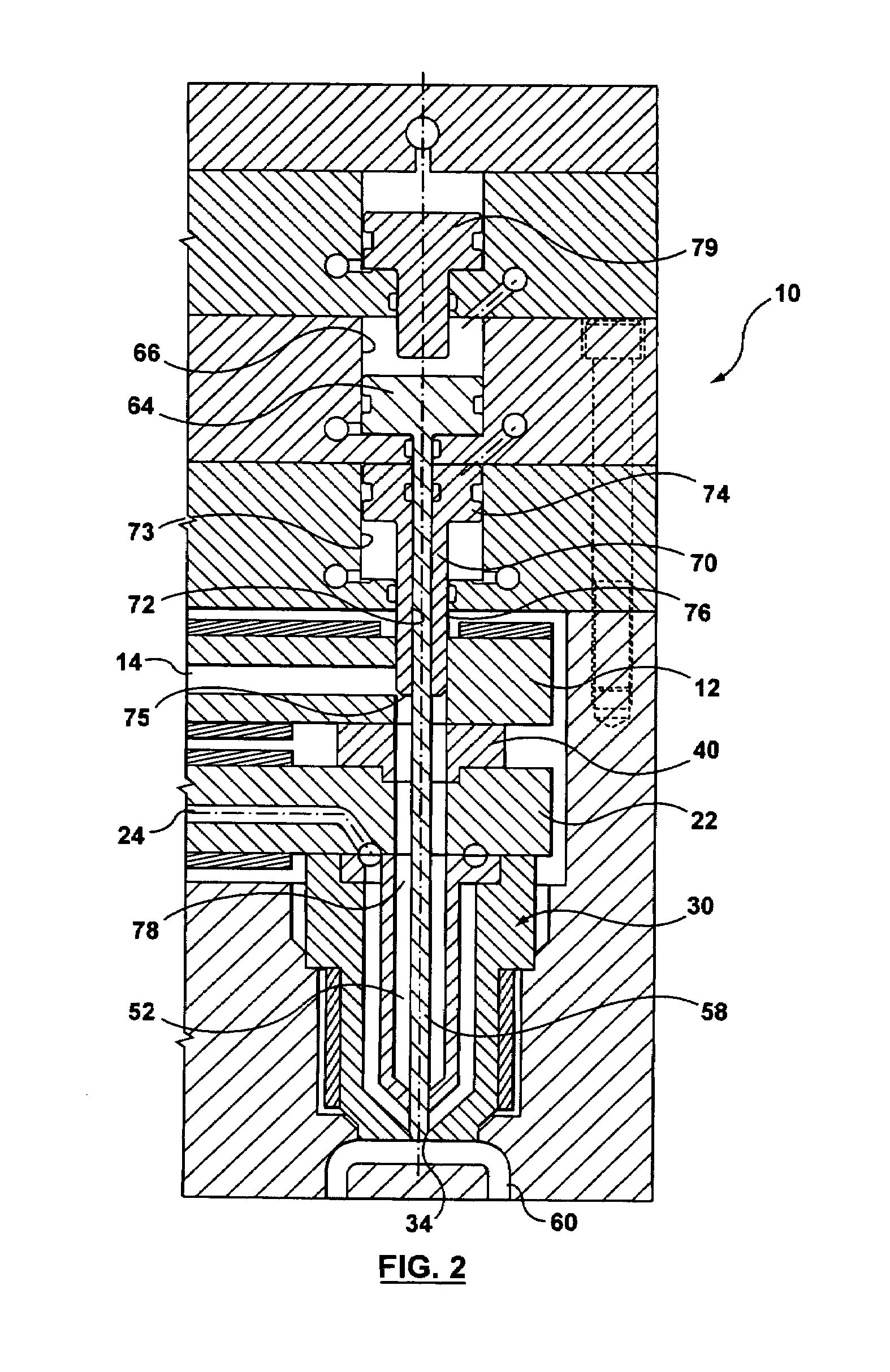

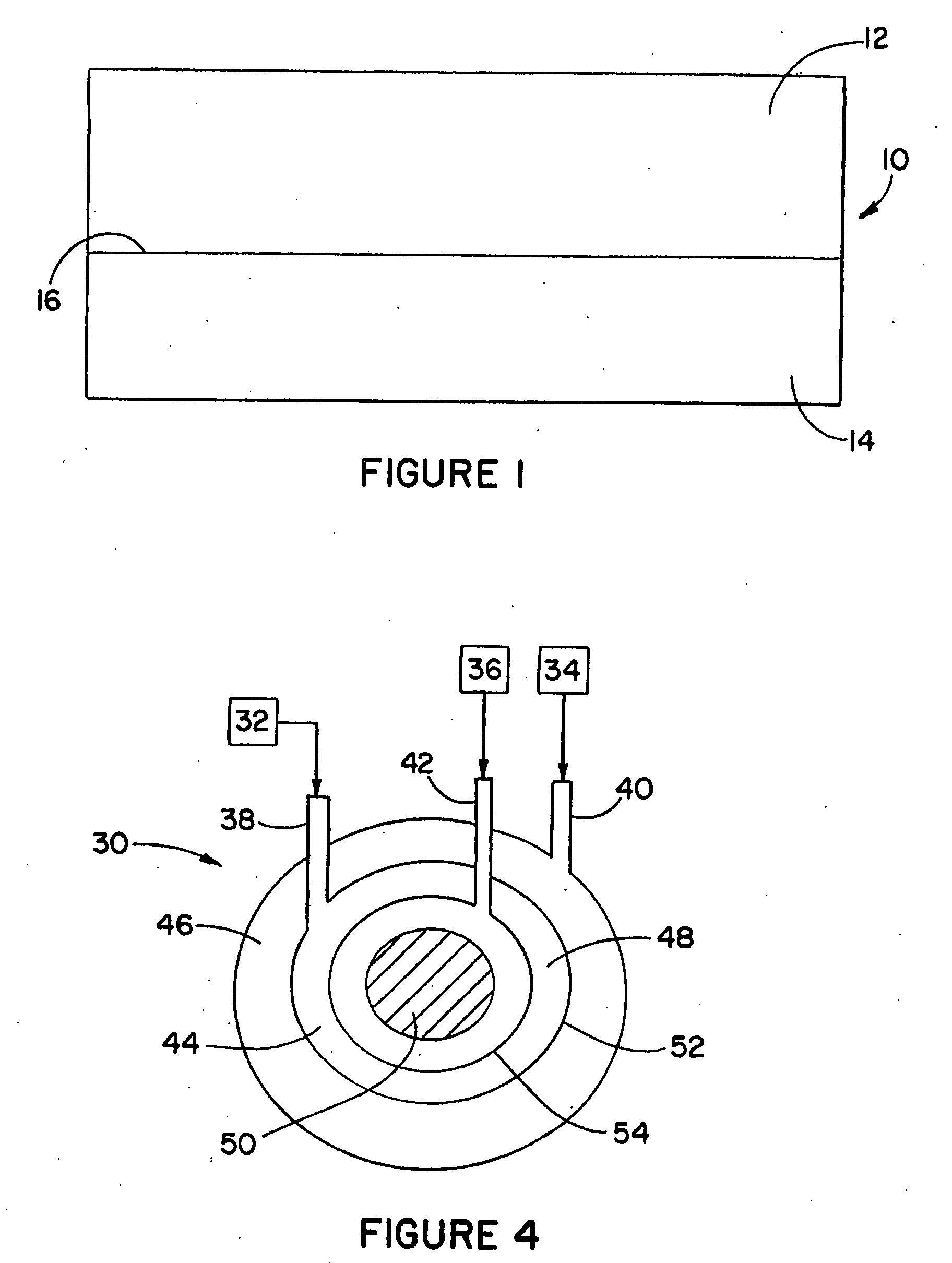

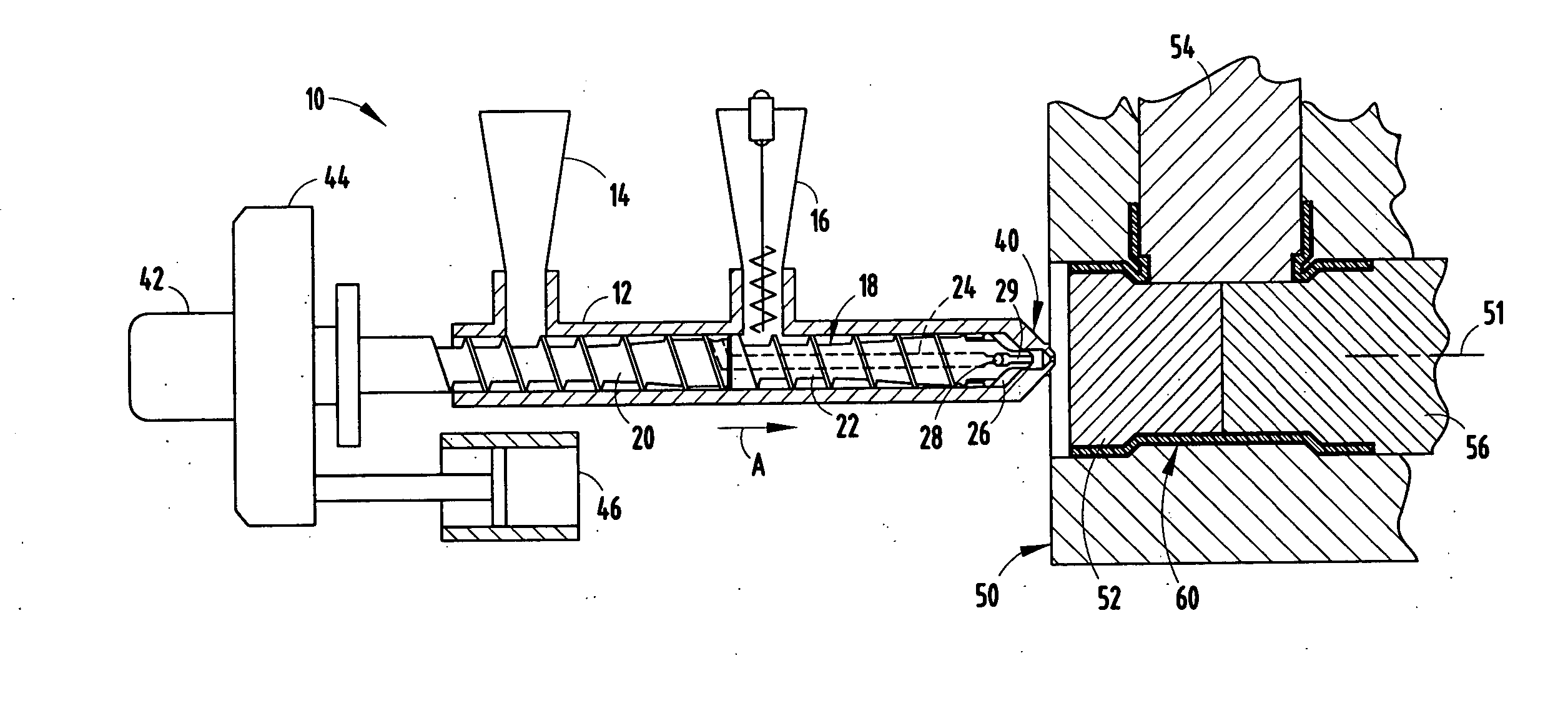

A co-injection process is provided for fabricating improved multi-layer containers, including but not limited to blood collection tubes, evacuated blood collection tubes, culture bottles, centrifuges tubes, and syringe barrels. The container includes a tube (10) having a bottom wall (12) and a side wall (14) with an open end (18). The container can be provided with a stopper having an upper portion (22) and a skirt with an outside portion (30), a well (34) and a cavity (36). The tube and stopper assembly can be used for medical purposes including containing a blood sample within an enclosed interior space (40).

Owner:BECTON DICKINSON & CO

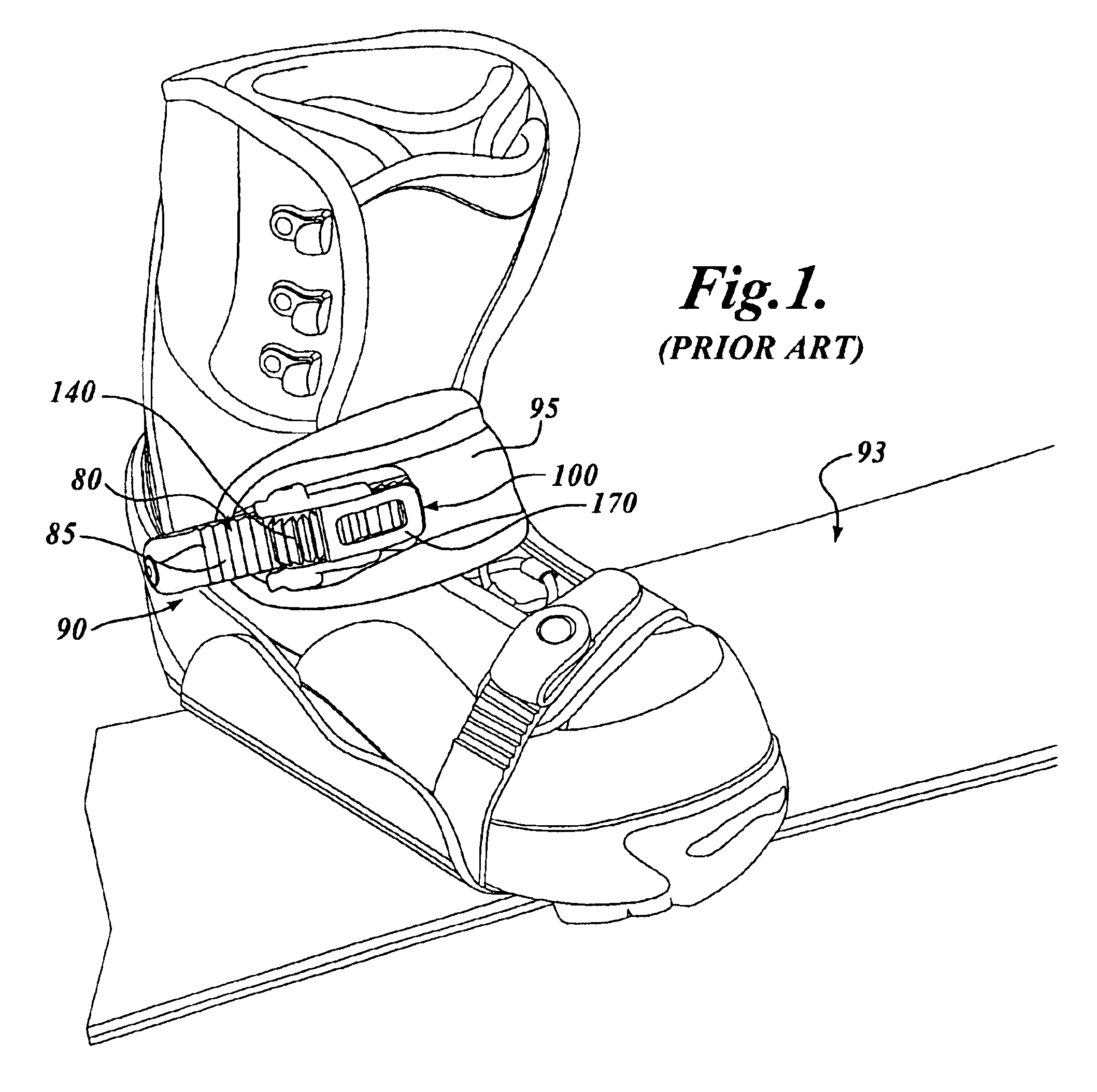

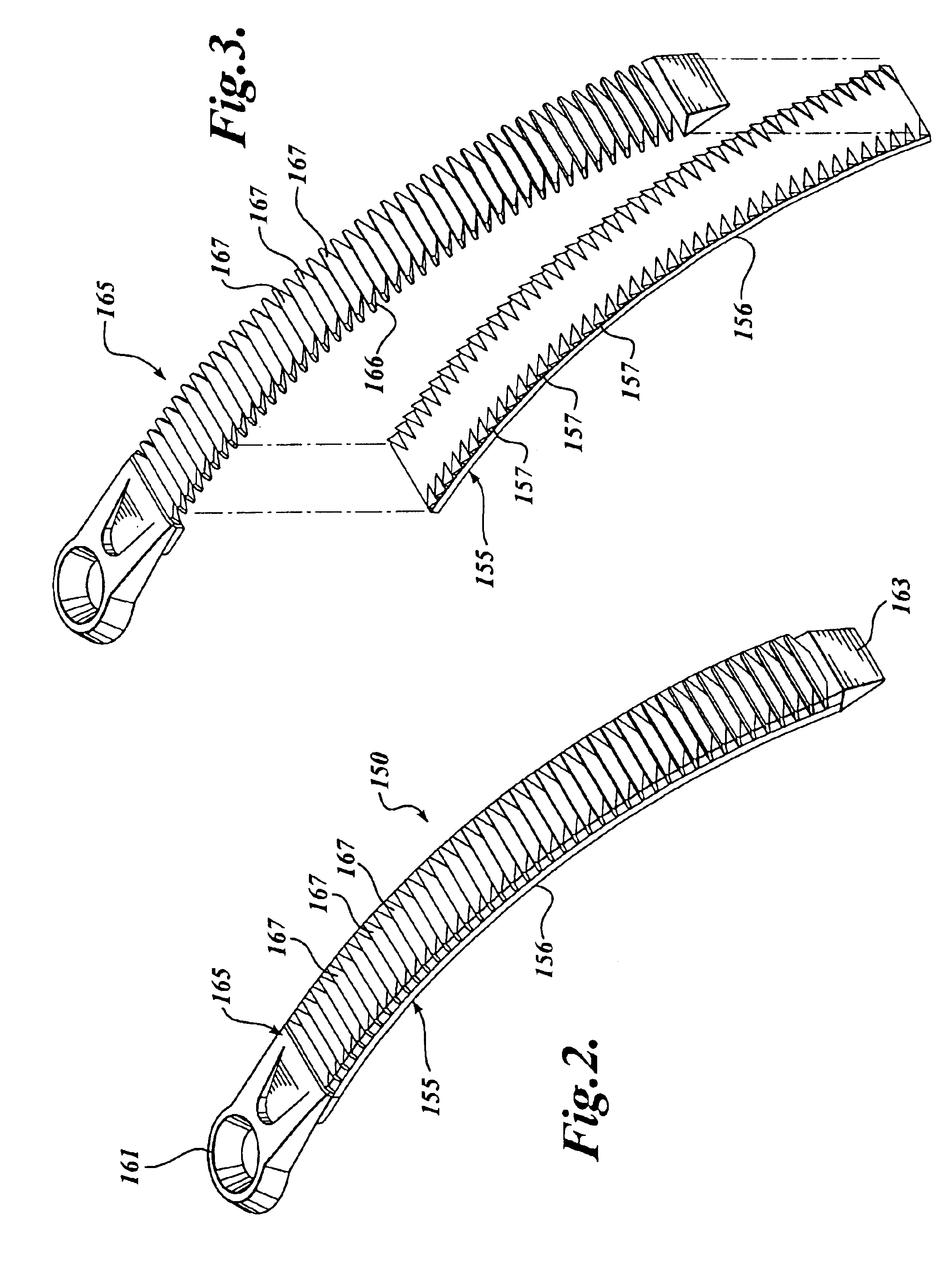

Co-molded ladder strap

InactiveUS6898826B2Desired flexibilityDesired hardness characteristicSnap fastenersSki bindingsShell moldingThermoplastic polyurethane

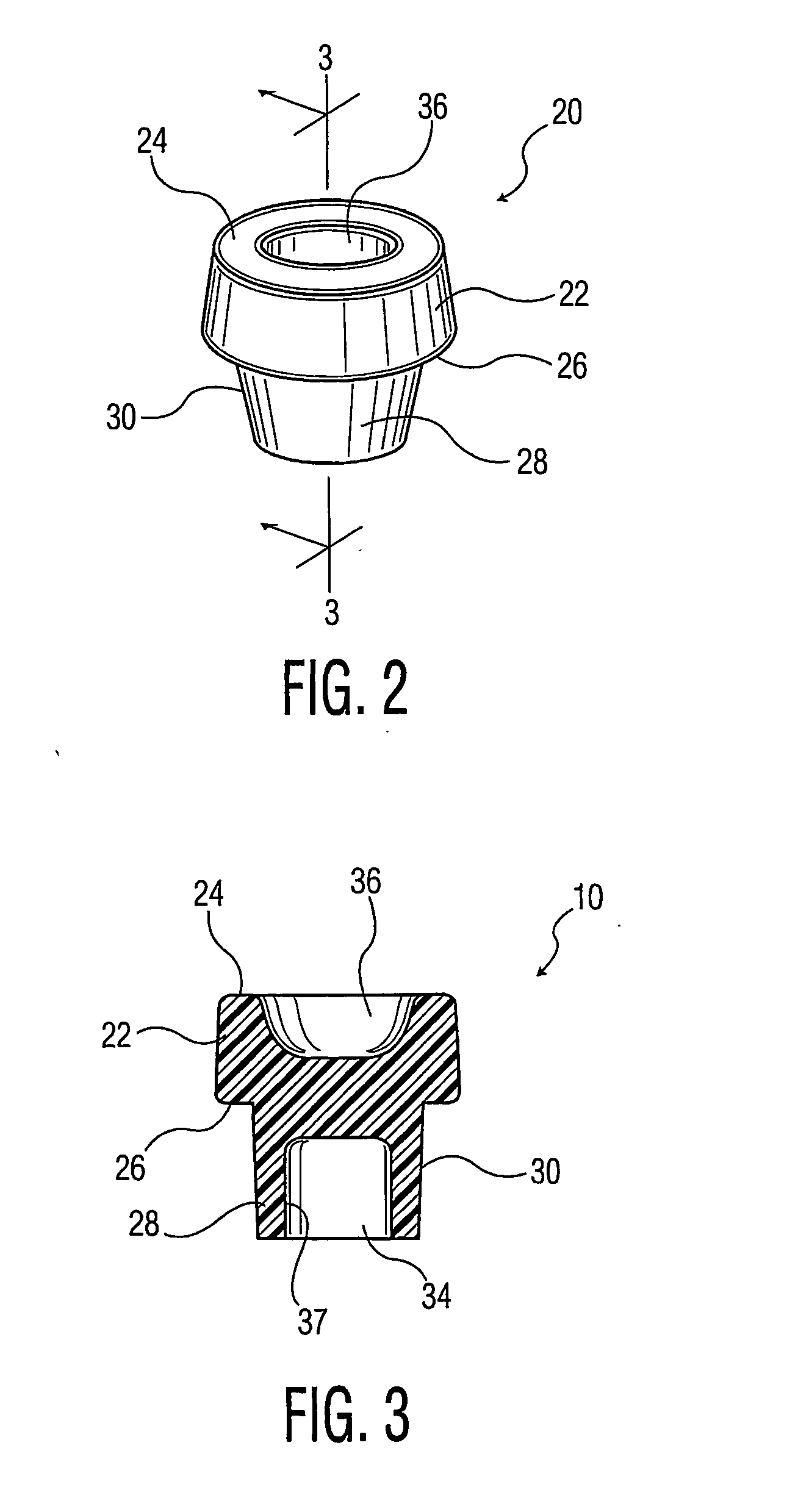

A ladder strap (150) is made by joining—for example, by co-molding—a first, relatively supple material, defining a lower strap portion (155) with a second, relatively hard material defining an upper strap portion (165). The teeth (167) of the ladder strap are comprises substantially of the harder, second material. In a preferred embodiment, the first and second materials are thermoplastic urethanes, and the co-molding is done using an injection molding process. The co-molding process may be accomplished with co-injection, wherein the two materials are injected at about the same time, or the first material may be injected into a first mold cavity and allowed to partially set, after which the cavity is modified to accommodate the second material.

Owner:K 2 CORP

Preparation method of hollow-structure metal or ceramic part

InactiveCN102351542AShort cycleShorten the production cycleCeramic shaping apparatusAdhesiveCo injection

The invention relates to a preparation method of a hollow-structure metal or ceramic part, which comprises the following steps: selecting metal or ceramic powder as the raw material, mixing, and granulating to obtain a feed material; selecting a core material; injecting the core material into a die by co-injection molding to obtain a core in hollow shape, and injecting the metal or ceramic feed material to be completely coated on the core, thereby obtaining a green body; and carrying out solvent extraction and heating on the green body to remove the adhesive and core, and sintering to obtain the hollow-structure product. The invention implements one-step molding of the hollow metal or ceramic part; from the raw material to the product, the production cycle is short, and the automation degree of equipment is high, thereby greatly enhancing the efficiency and forming a randomly complex and completely hollow die cavity; and thus, the invention can be used for preparing a completely hollow part with no joint, greatly lowers the cost of the product, and is especially suitable for preparing hollow metal and ceramic parts.

Owner:CENT SOUTH UNIV

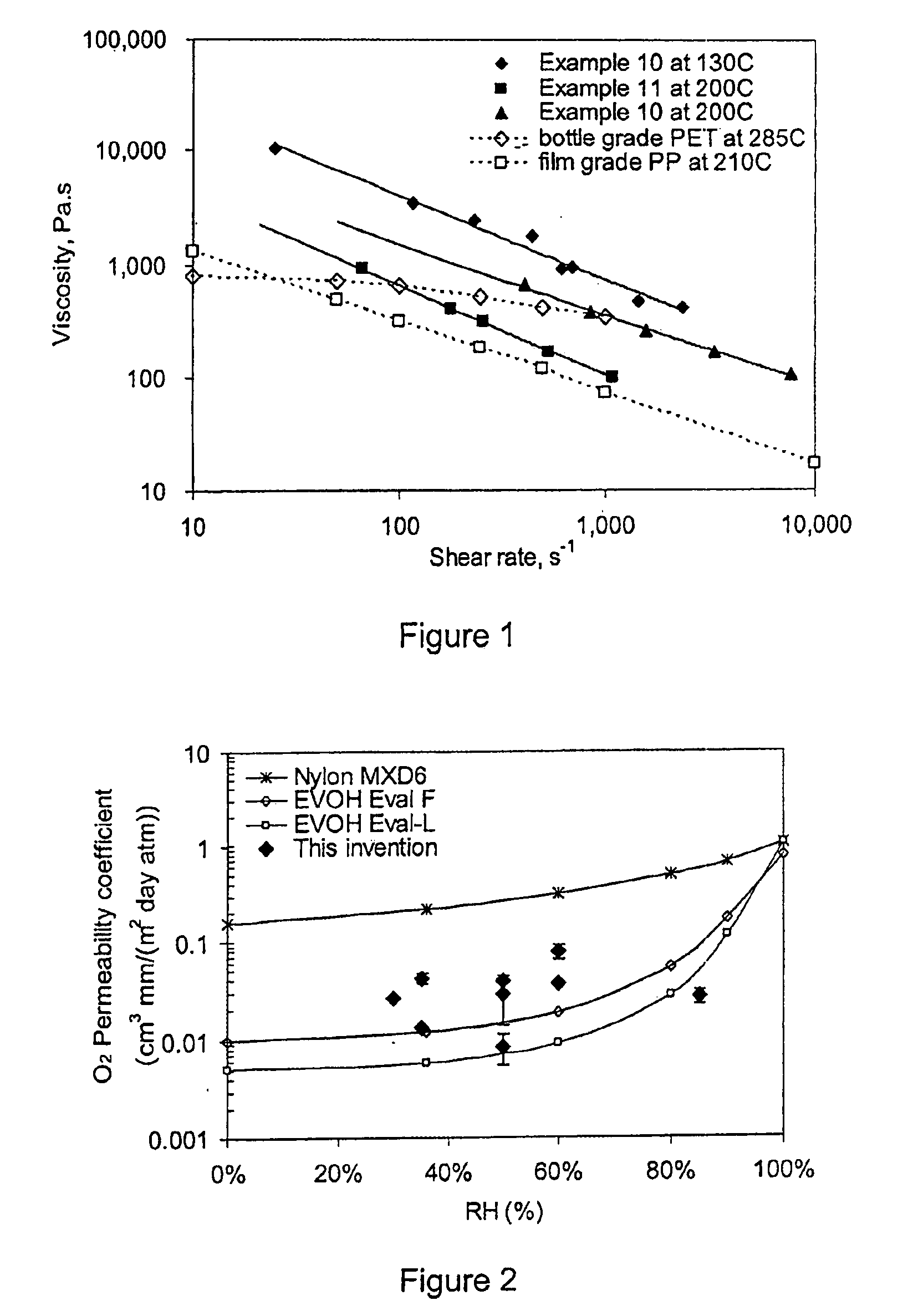

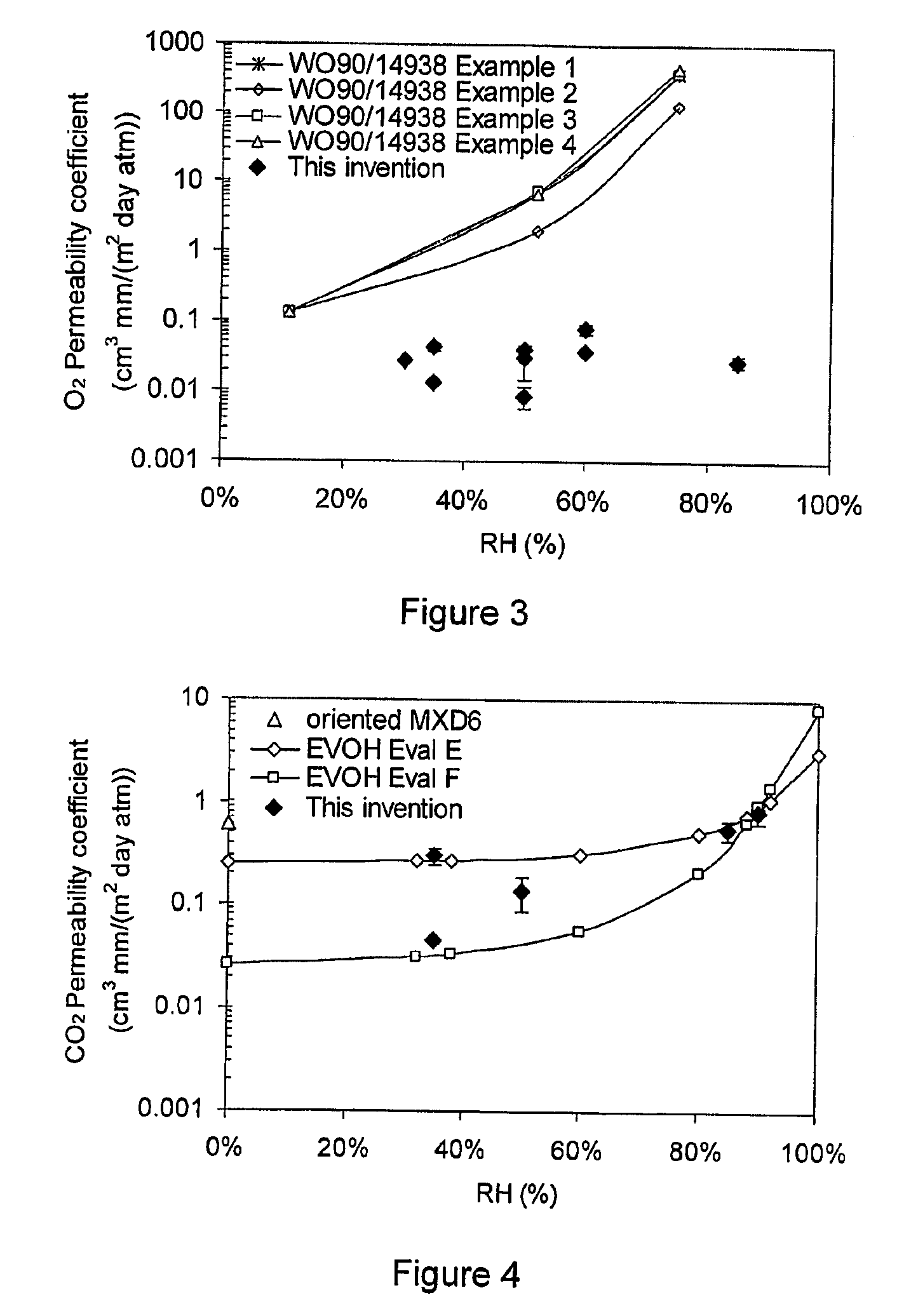

Barrier film

InactiveUS20090110942A1Stable mechanical propertiesImprove homogeneityFireproof paintsFibre treatmentMolten statePolyethylene oxide

A barrier composition which is injection mouldable and able to be made into a transparent film or incorporated (by co-extrusion and / or lamination) into multi-layer film products, the composition on dry basis: a) from 45 to 90% by weight of a starch and / or a modified starch selected from starches modified by reaction with a hydroxyl alkyl group, an acetate or a dicarboxylic acid anhydride or a grafting polymer; b) from 4 to 12% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinylalcohol which have a melting point compatible with the molten state of the starch components c) from 5 to 45% by weight of a non-crystallising mixture of sorbitol and at least one other plasticizer selected from glycerol, maltitol, xylitol, mannitol, glycerol trioleate, epoxidised linseed or soybean oil, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate; polyethylene oxide or polyethylene glycol; d) from 0.3 to 2.5 % by weight of a C12-22 fatty acid or salt; e) from 0.25% to 3% of an emulsifier system having a hydrophilic lipophilic balance value between 2 and 10. The barrier film may be co-injection moulded with polyethylene terephthalate (PET) or polylactic acid (PLA) for blow moulding into beverage bottles, with polyethylene (PE) or polypropylene (PP) or biodegradable polymers for high gas-barrier containers or closures, or may be co-extruded with polyethylene, polypropylene or polylactic acid for thin film packaging applications or for blow-moulded containers.

Owner:PLANTIC TECH

Process for forming multilayer containers

A co-injection process is provided for fabricating improved multi-layer containers, including but not limited to blood collection tubes, evacuated blood collection tubes, culture bottles, centrifuges tubes, and syringe barrels. The container includes a tube (10) having a bottom wall (12) and a side wall (14) with an open end (18). The container can be provided with a stopper having an upper portion (22) and a skirt with an outside portion (30), a well (34) and a cavity (36). The tube and stopper assembly can be used for medical purposes including containing a blood sample within an enclosed interior space (40).

Owner:BECTON DICKINSON & CO

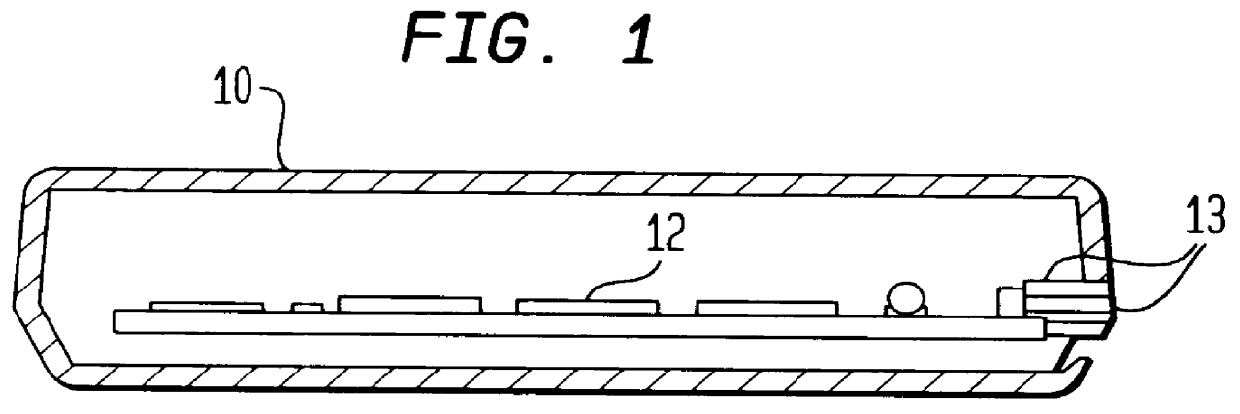

Article comprising molded circuit

InactiveUS6110576ASynthetic resin layered productsElectrical equipmentMulti materialConductive materials

An article comprising a molded circuit for providing a path for electrical current is disclosed. The molded circuit is formed of a first material layer and a second material layer. The first material layer is an electrically insulating material. The second material layer is an electrically conductive material. In an alternate embodiment, the second material layer is surrounded between two layers of the first material layer. The molded circuit can be formed using multi-material injection molding such as co-injection molding or two-shot injection molding. A printed circuit board can comprise the molded circuit.

Owner:LUCENT TECH INC +1

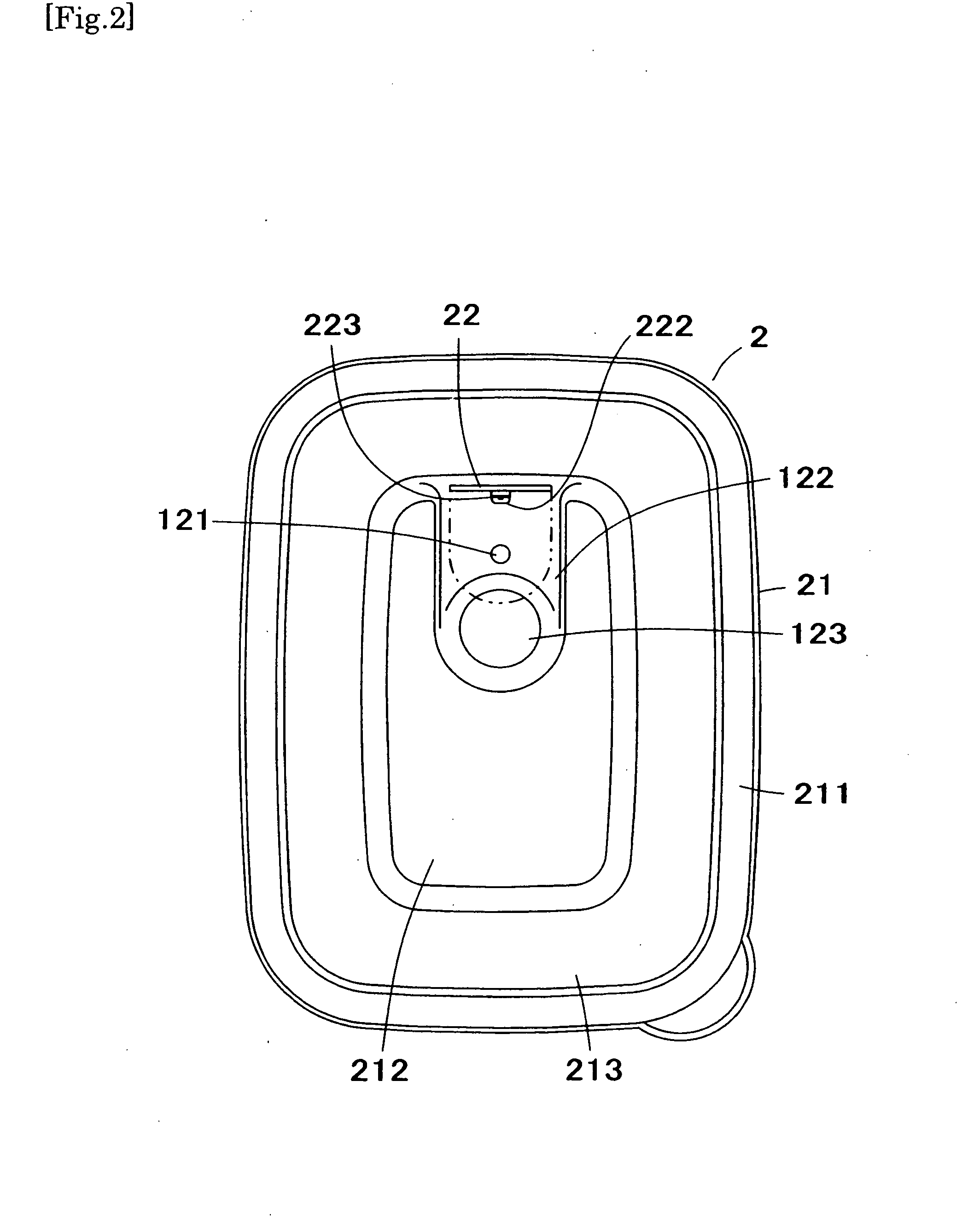

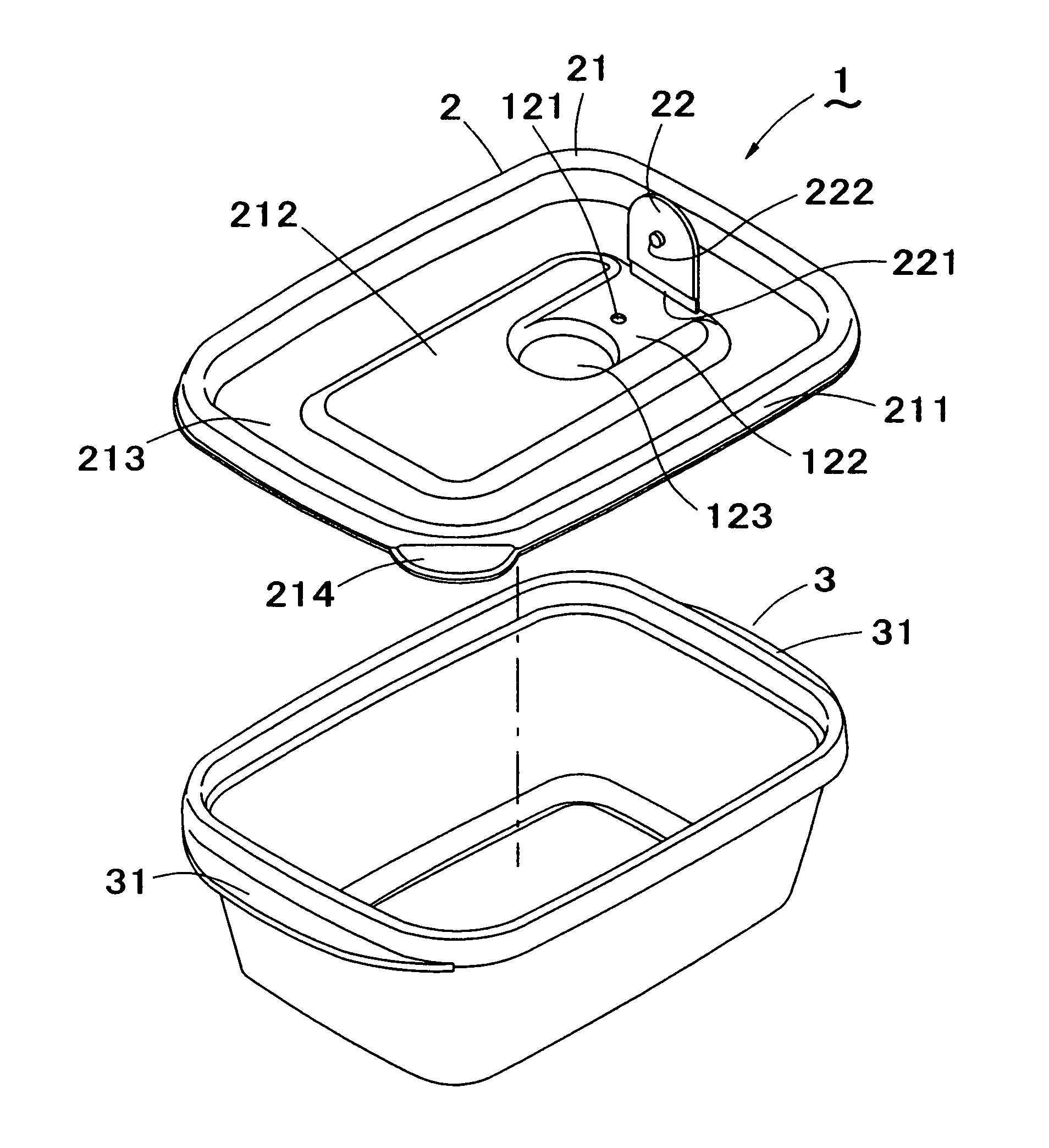

Cover, a container assembly including the cover, a molding device for molding the cover and a method for manufacturing the cover

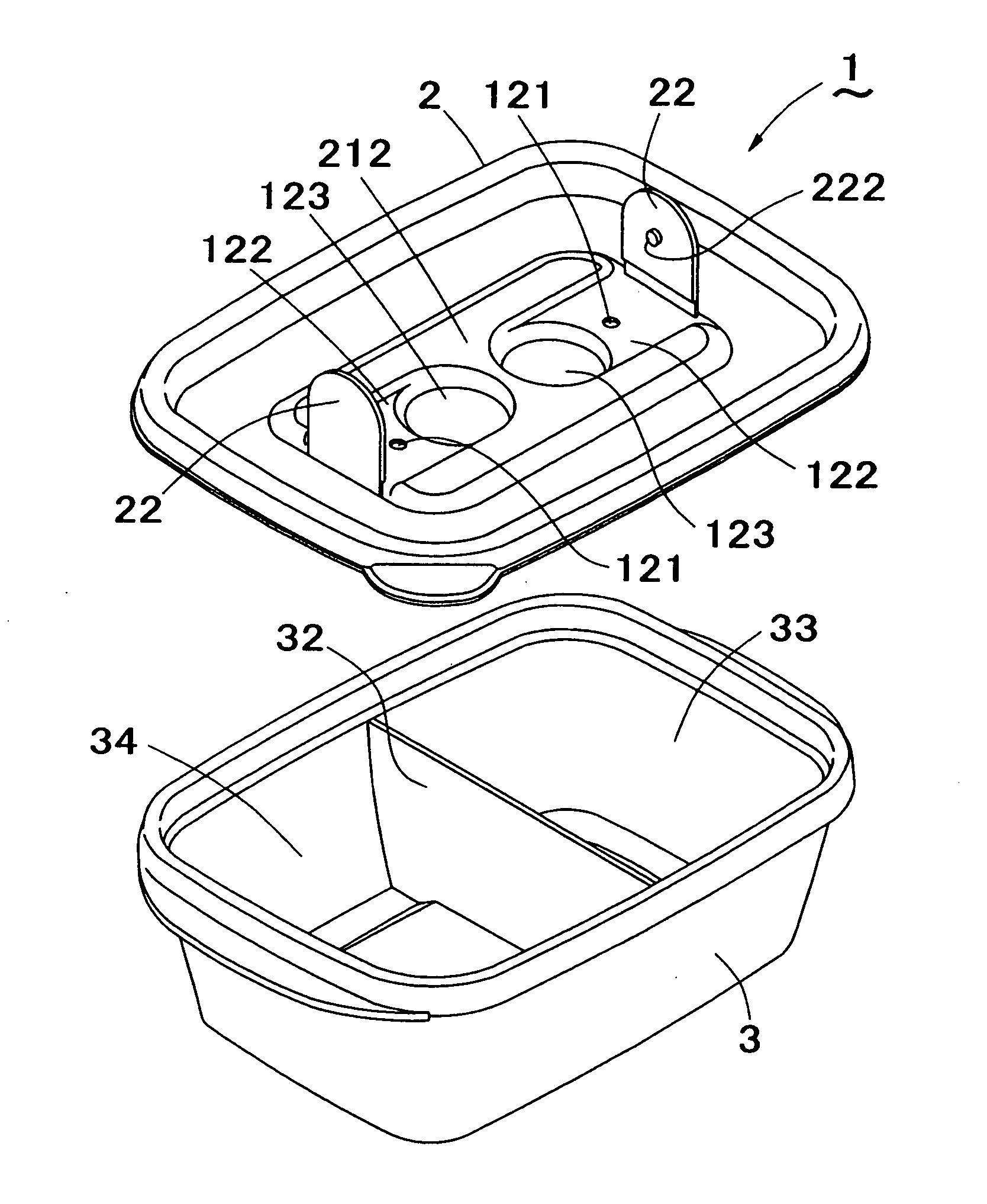

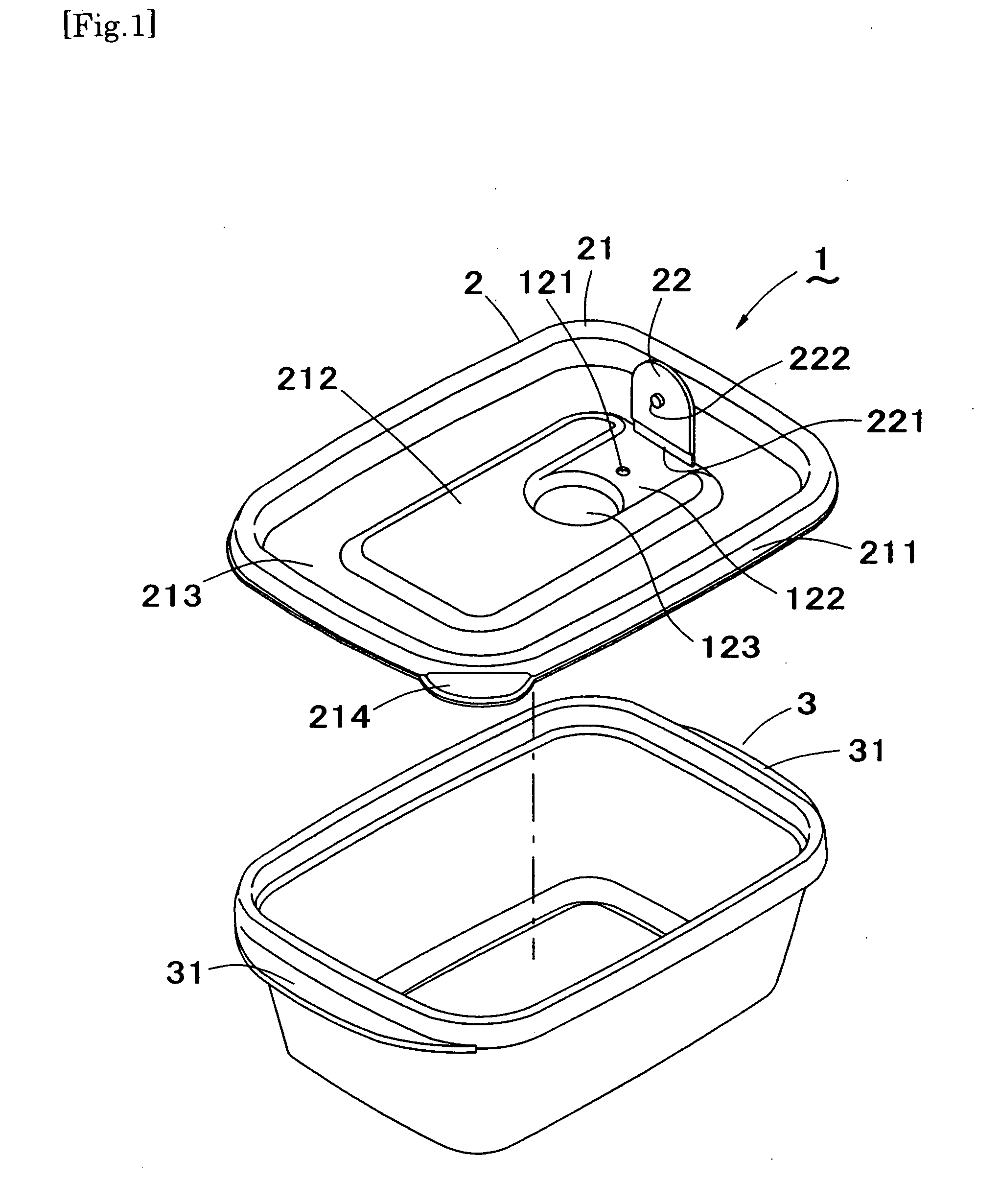

ActiveUS20090200296A1More stressProlong lifeClosure capsClosure with auxillary devicesMicrowaveCo injection

[Purpose]To provide a container assembly suitable for heating a food stuff therein with a heating device such as a microwave and a cover thereof.[Solution]A cover for covering an opening of a container for a food stuff comprising: a substantially flat cover body including at least one aperture, at least one substantially flat flap including a linear proximal end configured to connect with the cover body, the proximal end allowing the at least one flap to rotate with respect to the cover body, wherein a lower surface of the at least one flap includes a protrusion configured to close the at least one aperture when the at least one flap is at a first position in which the at least one flap is in parallel with the cover body, the cover body and the at least one flap are integrally formed by a co-injection molding.

Owner:IWASAKI IND

High-performance double-layer polyester bottle

InactiveCN101172525AGood molding effectPromote migrationFlexible coversWrappersBlow moldingFruit juice

The invention discloses a high-performance double layer polyester bottle, which selects PET resin as an outer layer, and another polyester resin with high barrier property as an inner layer, and color concentrate can not be added on the inner layer. A double material / double color injection molding machine or a double layer co-injection molding machine is adopted with a double layer perform mould, after the double layer compact is injected twice or synchronistically, the invention is made through the prewarming of a bottle perform heating machine and a bidirectional draw blow molding machine. The invention has the advantages that the high-performance double layer polyester bottle has higher barrier property and better sanitary property, can be applied to food bulking such as the beer, fruit juices, and medicines and so on under the condition of adding no anti corrosion agent or less anti corrosion agent.

Owner:徐跃

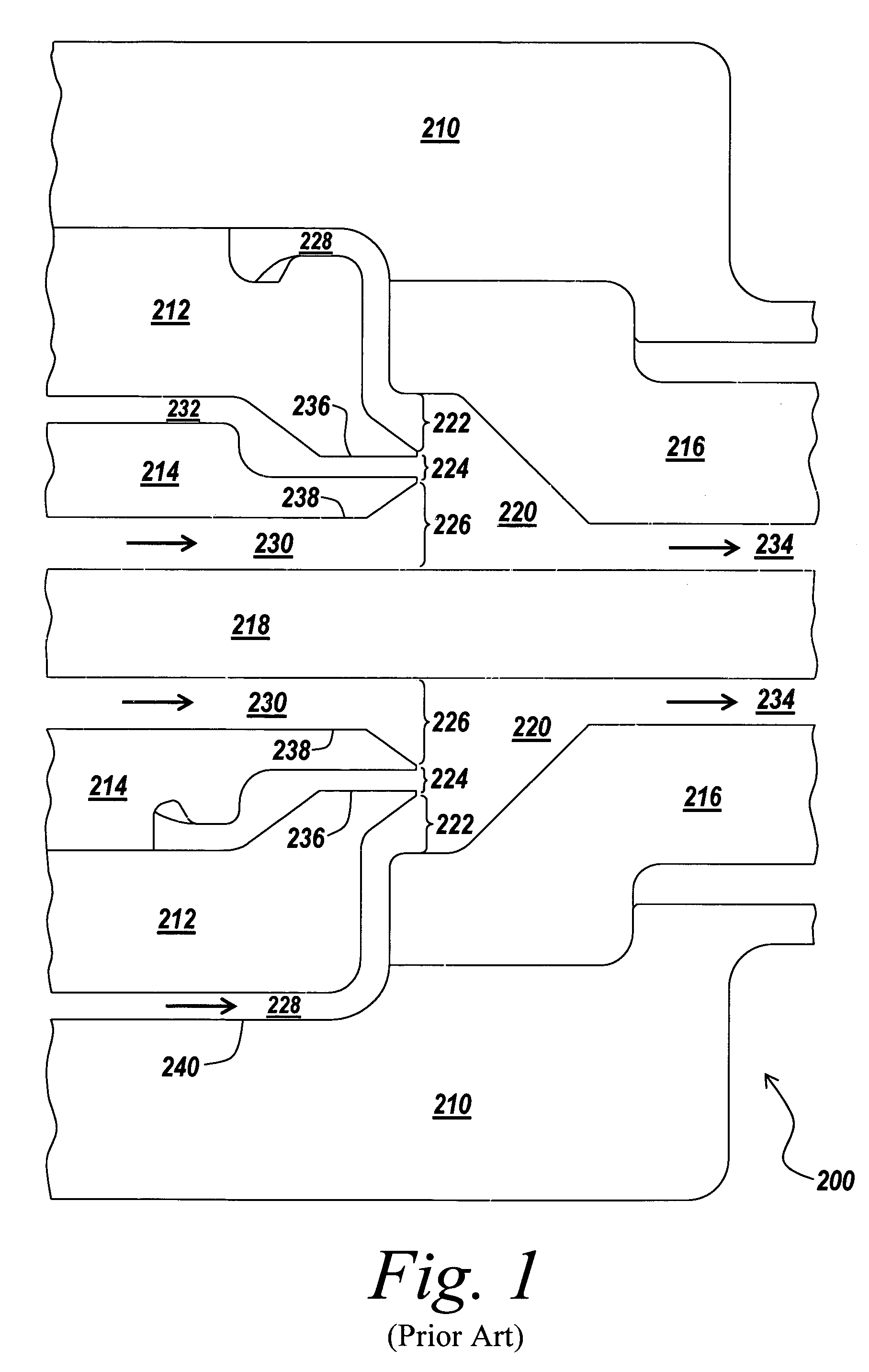

Co-injection nozzle with improved interior layer termination

ActiveUS7306446B2Easy to controlImproved barrier layer protectionButtonsRecord carriersEngineeringCo injection

Disclosed herein are a method and apparatus for combining two or more streams of a polymeric material to form a plastic object. The method and apparatus are capable of ending an interior layer of the plastic object at a desired length to avoid the need to clean selected surfaces of components used to form the plastic object. The method and apparatus increase the velocity of the polymeric material used to form the plastic object in certain components used to form the plastic object. The increase in the velocity of the polymeric material facilitates the ending of the interior layer of the plastic object.

Owner:CINCINNATI MILACRON INC

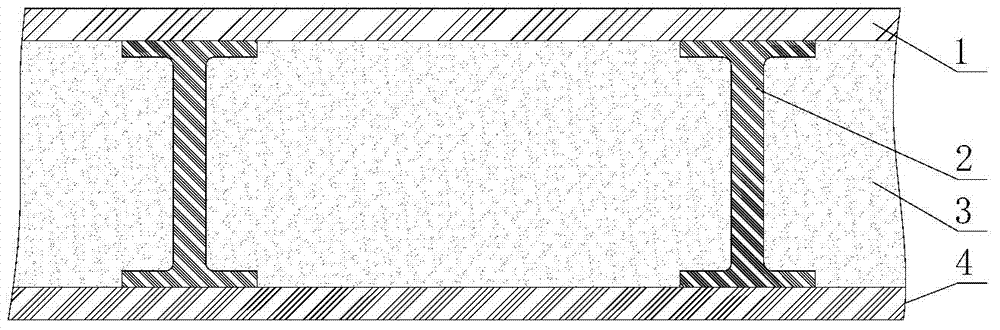

Foamed reinforced composite material structure vacuum co-injection integral forming method

The invention belongs to the field of composite materials, and relates to a foamed reinforced composite material structure vacuum co-injection integral forming method. The formed interlayer structure comprises an upper skin, a lower skin, reinforcing ribs, and a foamed interlayer. According to the invention, a single-sided mold with a frame is adopted; the lower skin is formed by vacuum injection; the part is not de-molded, and the foamed interlayer and a rib reinforcing material precast are directly paved on the lower skin; an upper skin reinforcing material precast is paved; vacuum sealing is carried out, and resin is injected, such that integral forming is realized; and curing and de-molding are carried out, and a product can be obtained. With the method provided by the invention, foamed reinforced composite material structure net-size integral forming can be realized. No edge-trimming processing is needed, scrap rate is low, and production efficiency is high. Therefore, the method is suitable for large-scale productions.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

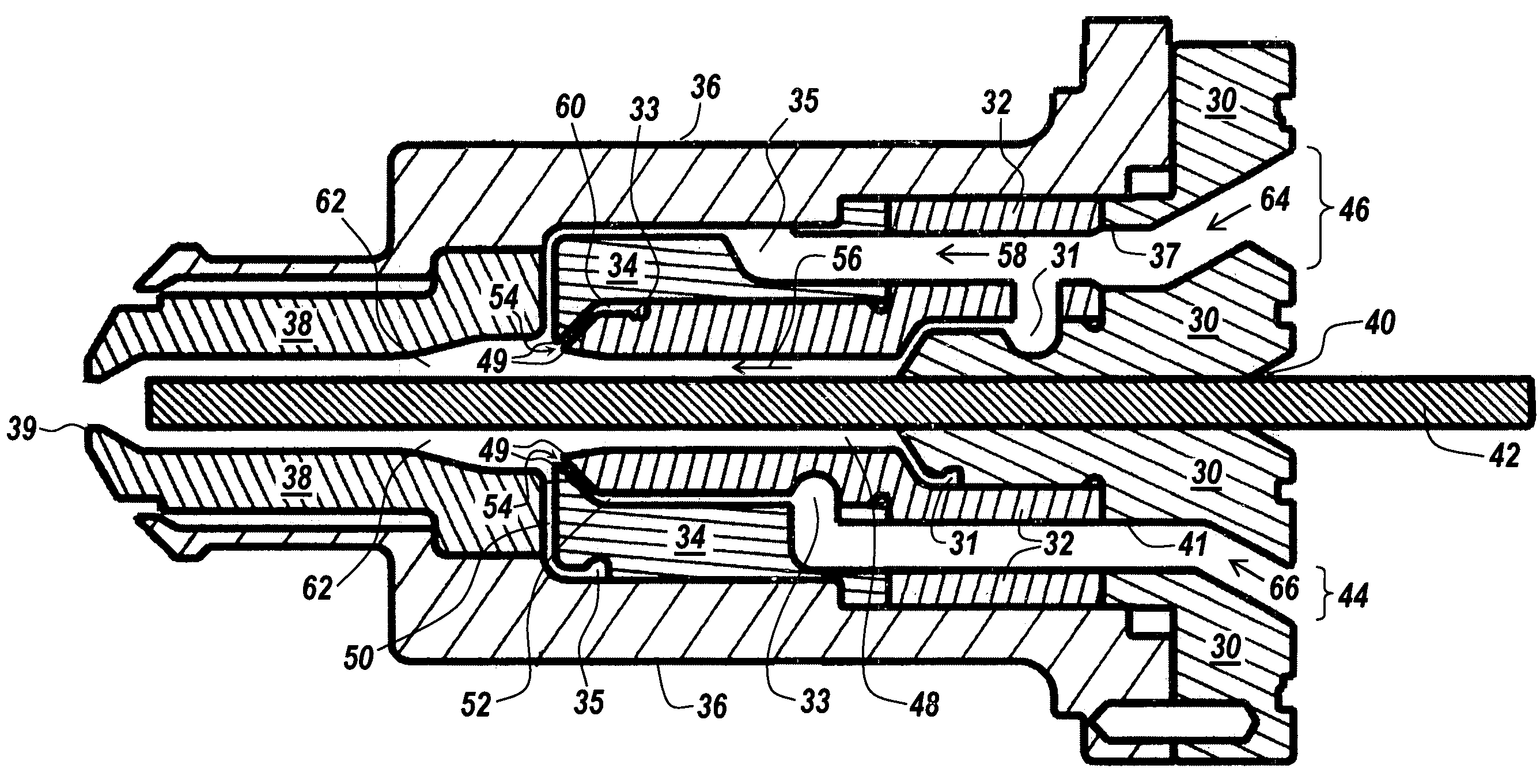

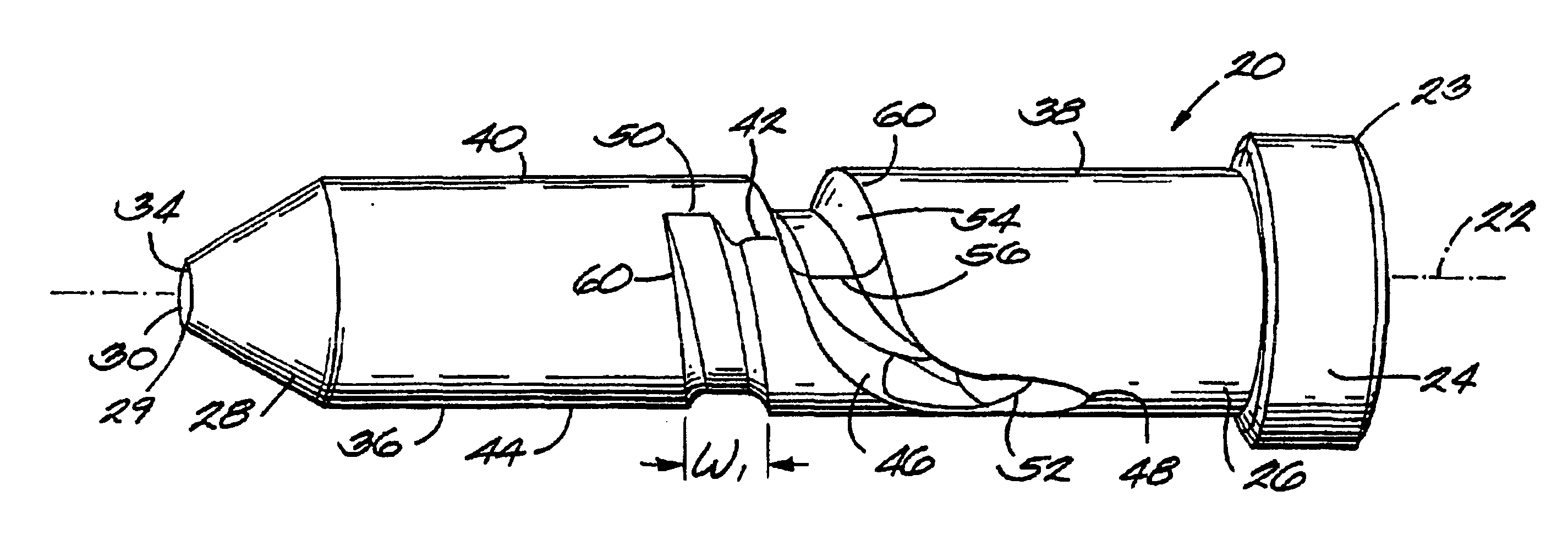

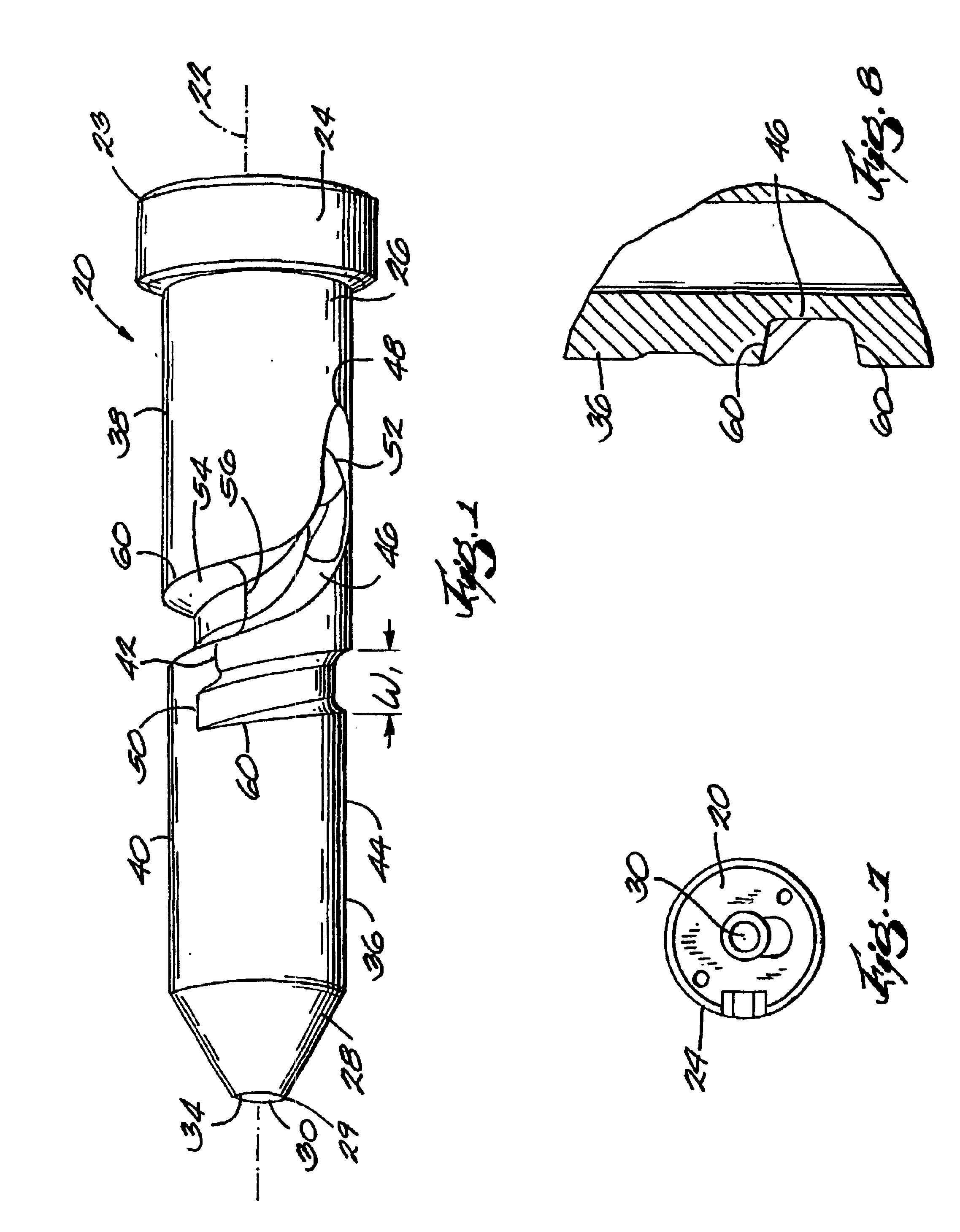

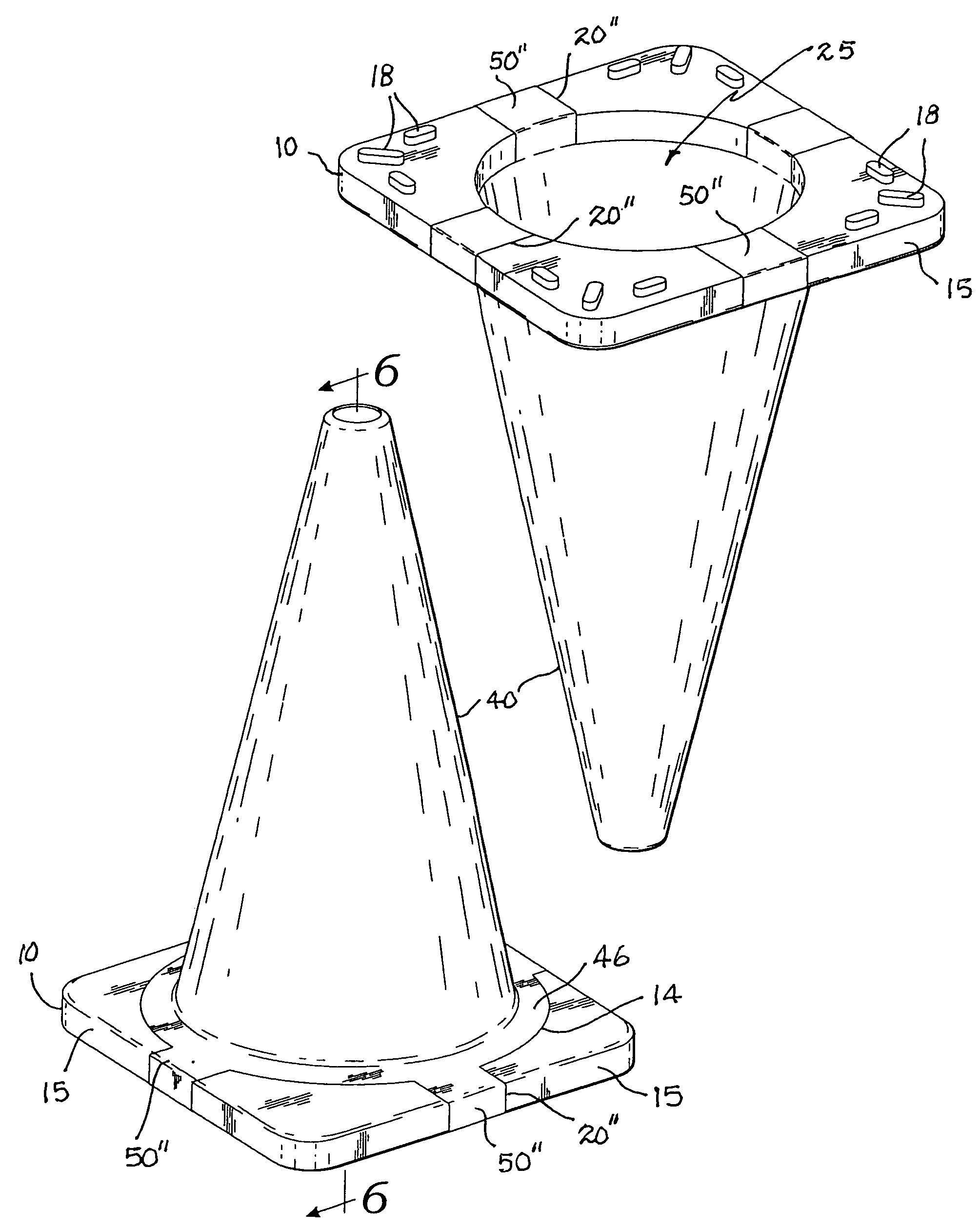

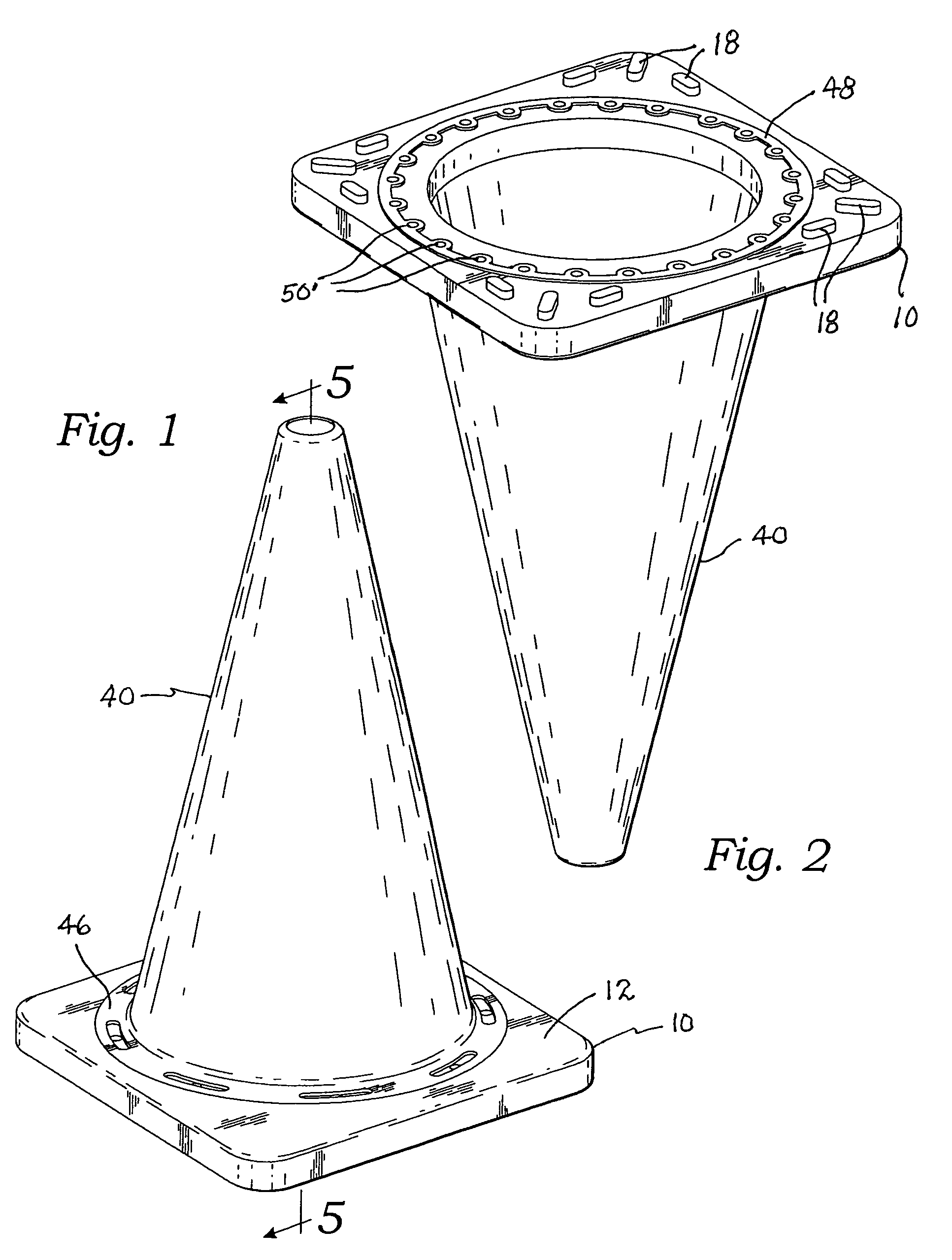

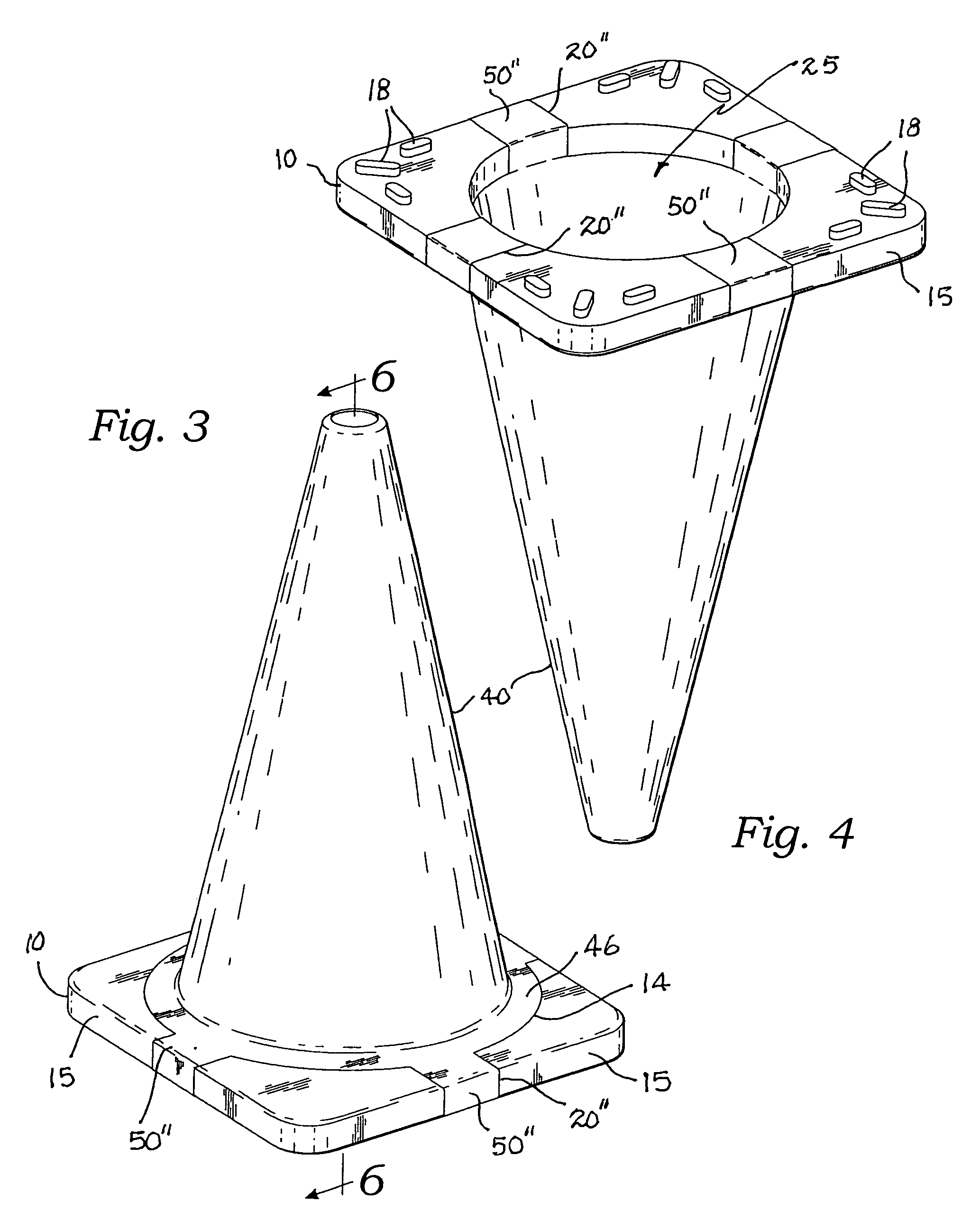

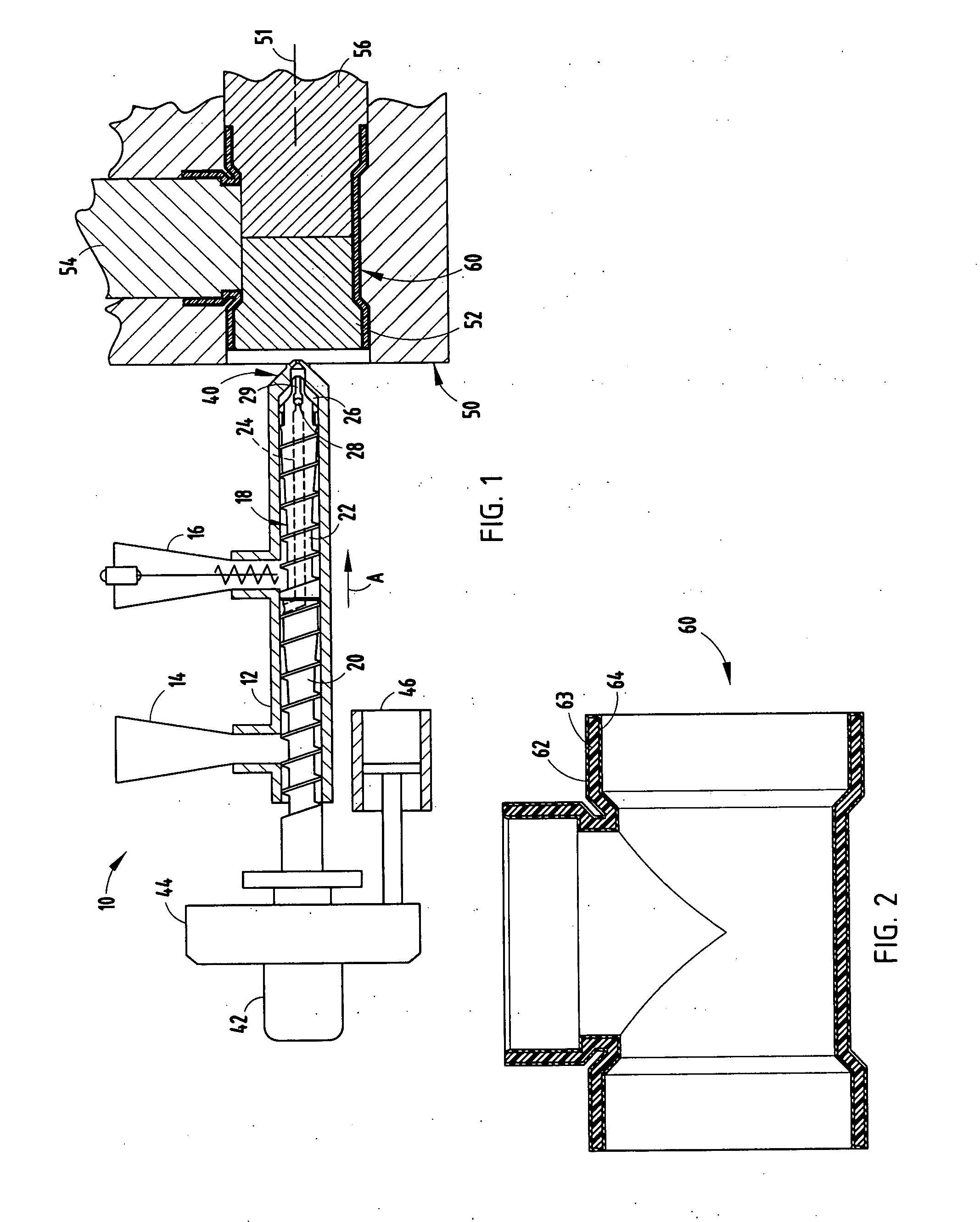

Co-injection apparatus for injection molding

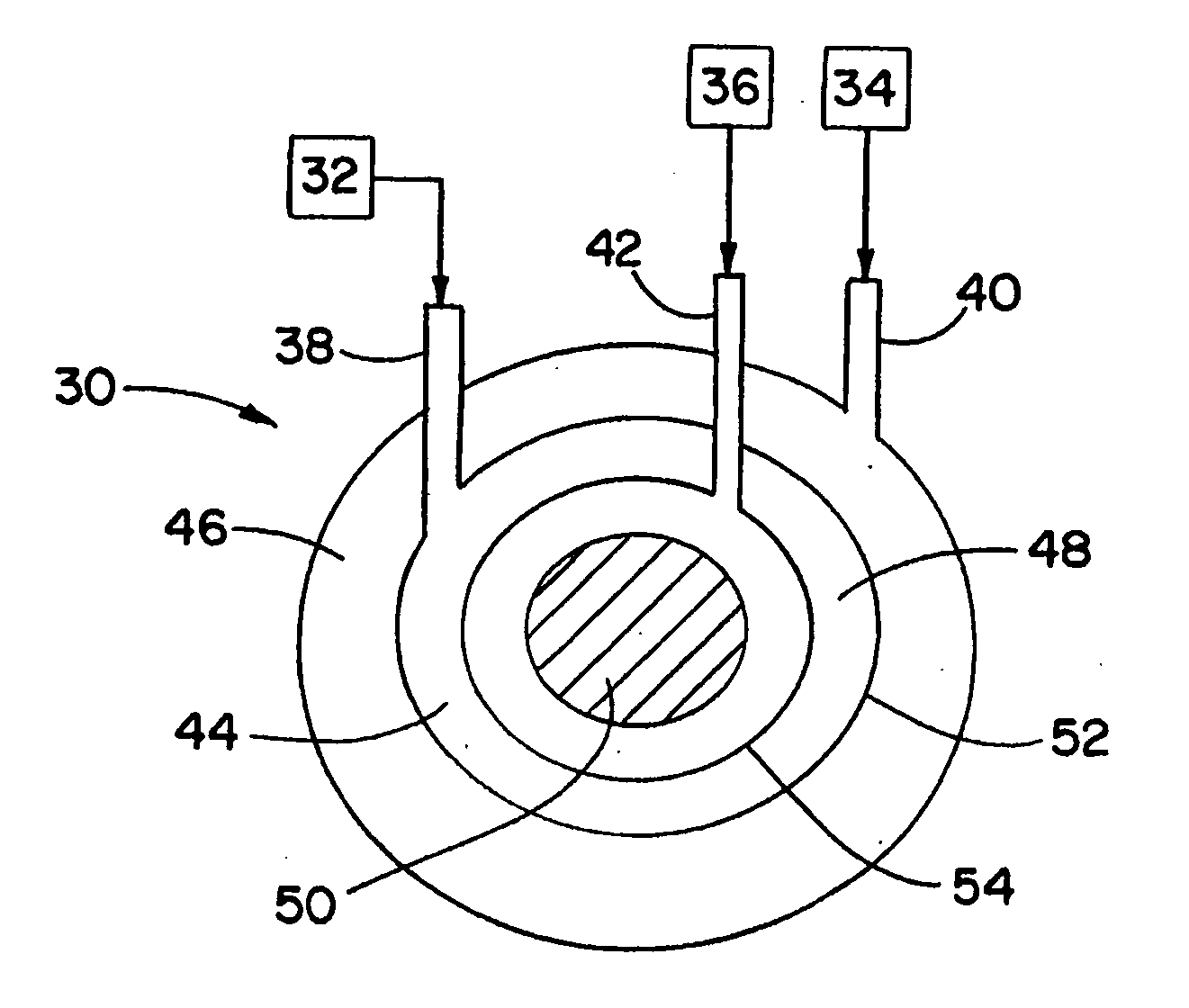

A co-injection nozzle pin (20) having downstream and upstream ends. The nozzle pin has therein a central bore (30) including an upstream end (32) adapted to communicate with a first material and a downstream end (34) exiting at the downstream end of the pin. The nozzle pin also has an outer surface (36) including a first portion (38) having a diameter D1, a second portion (40) having a diameter D2, wherein D2 is less than D1 and the first portion is rearward of the second portion. The pin further includes a channel (46) spiralling around the outer surface and being adapted to communicate with a second material. The channel (46) includes a first segment (52) defined in the first portion (38) of the outer surface and increasing in depth as it travels in a downstream direction and a second segment (54) defined in the second portion (40) of the outer surface and decreasing in depth as it travels in a downstream direction.

Owner:BEMIS MANUFACTURING CO

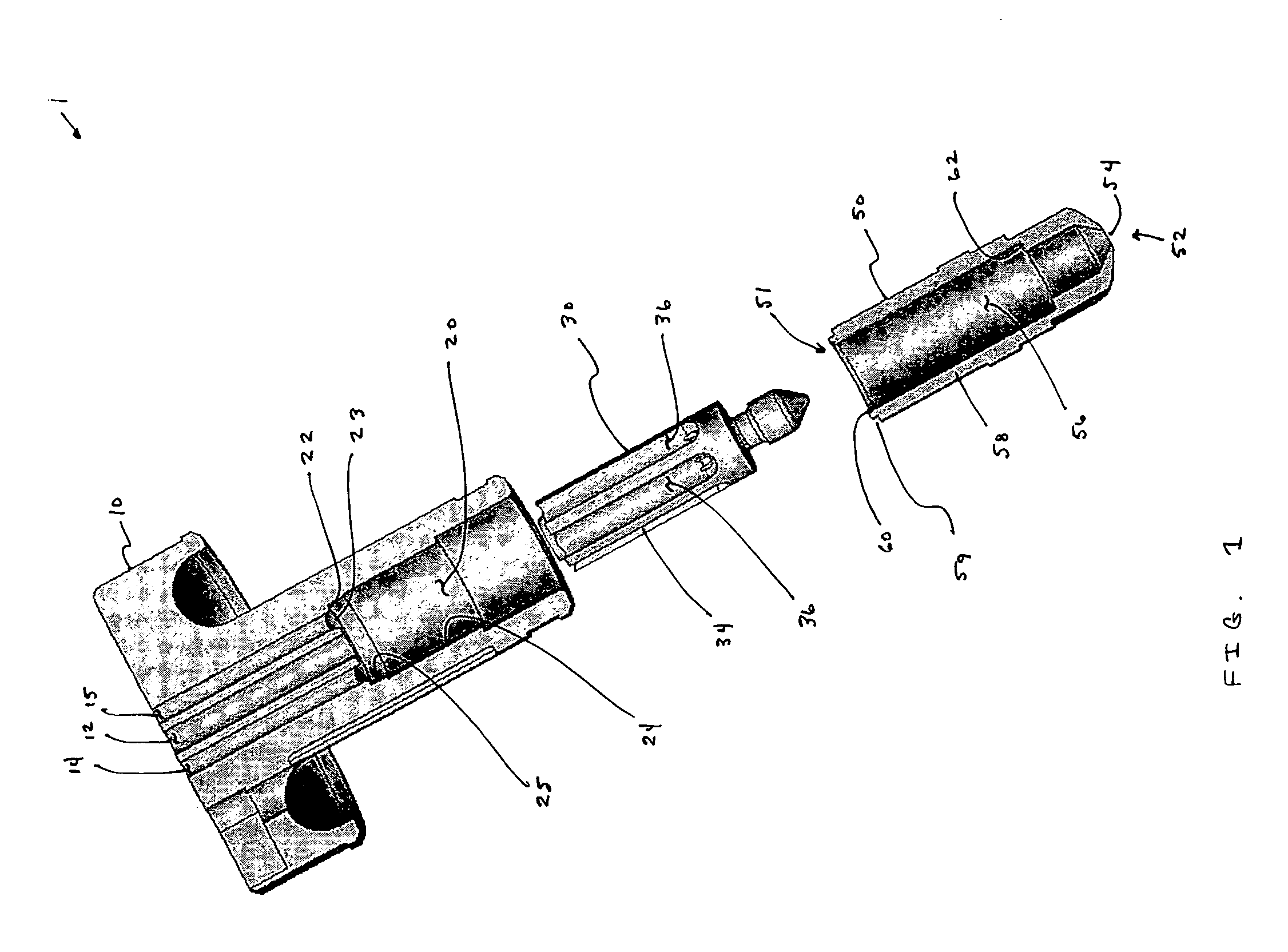

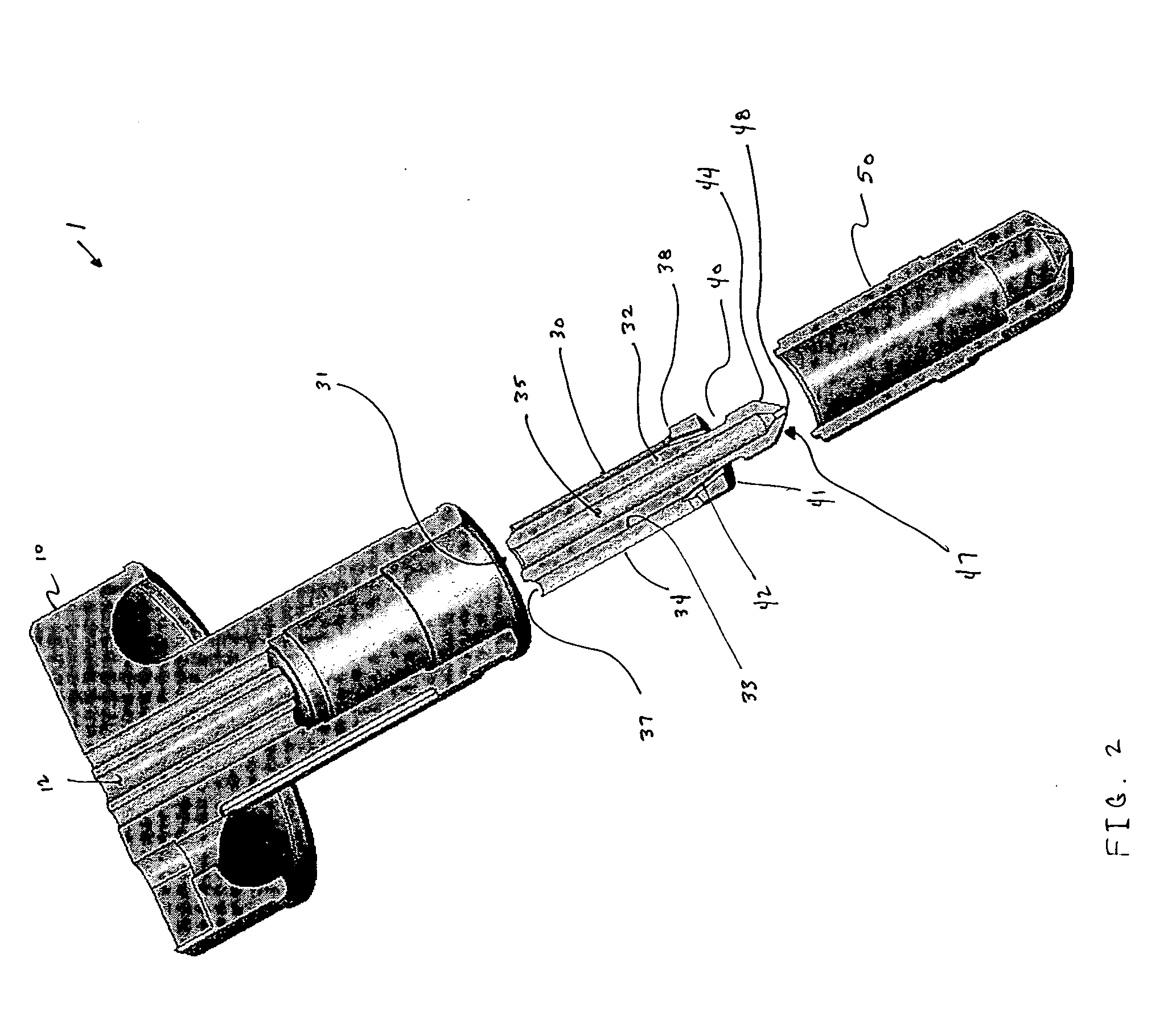

Co-injection nozzle, method of its use, and resulting golf ball

InactiveUS20050140061A1Facilitate material flowMinimizing and eliminating wasteConfectionerySweetmeatsInjection molding machineGolf Ball

A nozzle for an injection molding machine is disclosed. The nozzle includes a nozzle body, an inner nozzle, and an outer nozzle. The nozzle defines two independent flow paths therethrough. The nozzle can simultaneously discharge two materials. A method of using the nozzle and a resulting golf ball product are also disclosed.

Owner:ACUSHNET CO

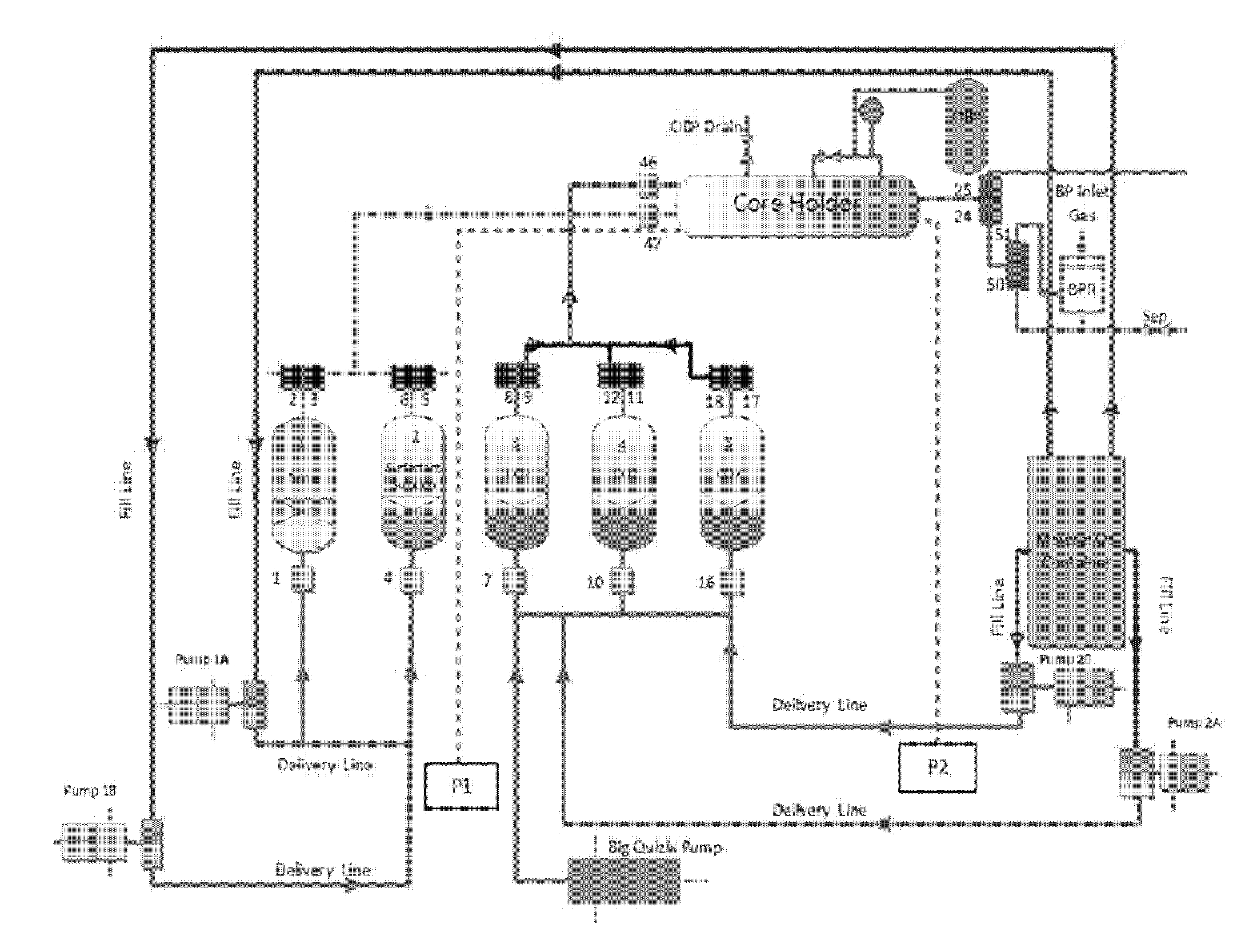

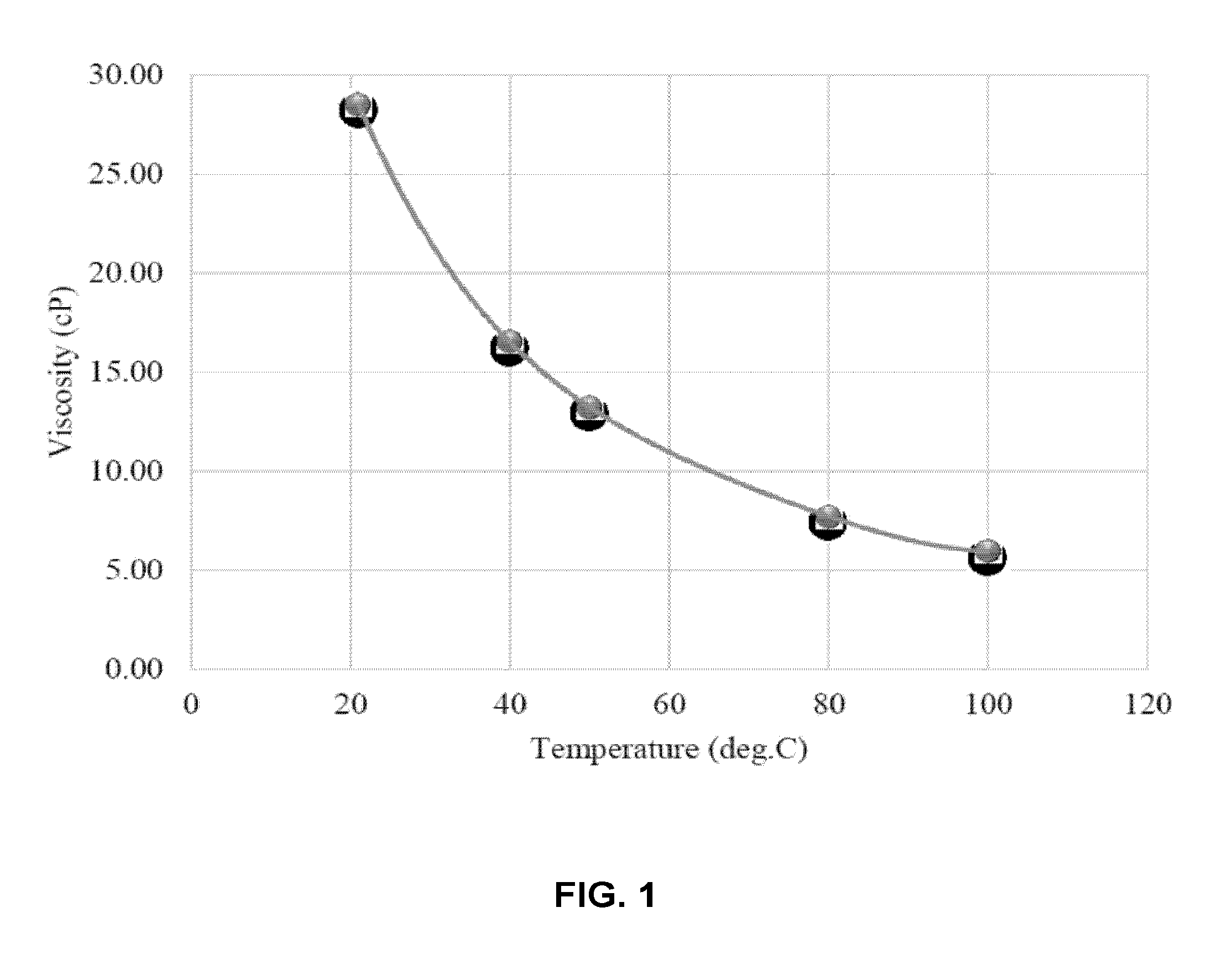

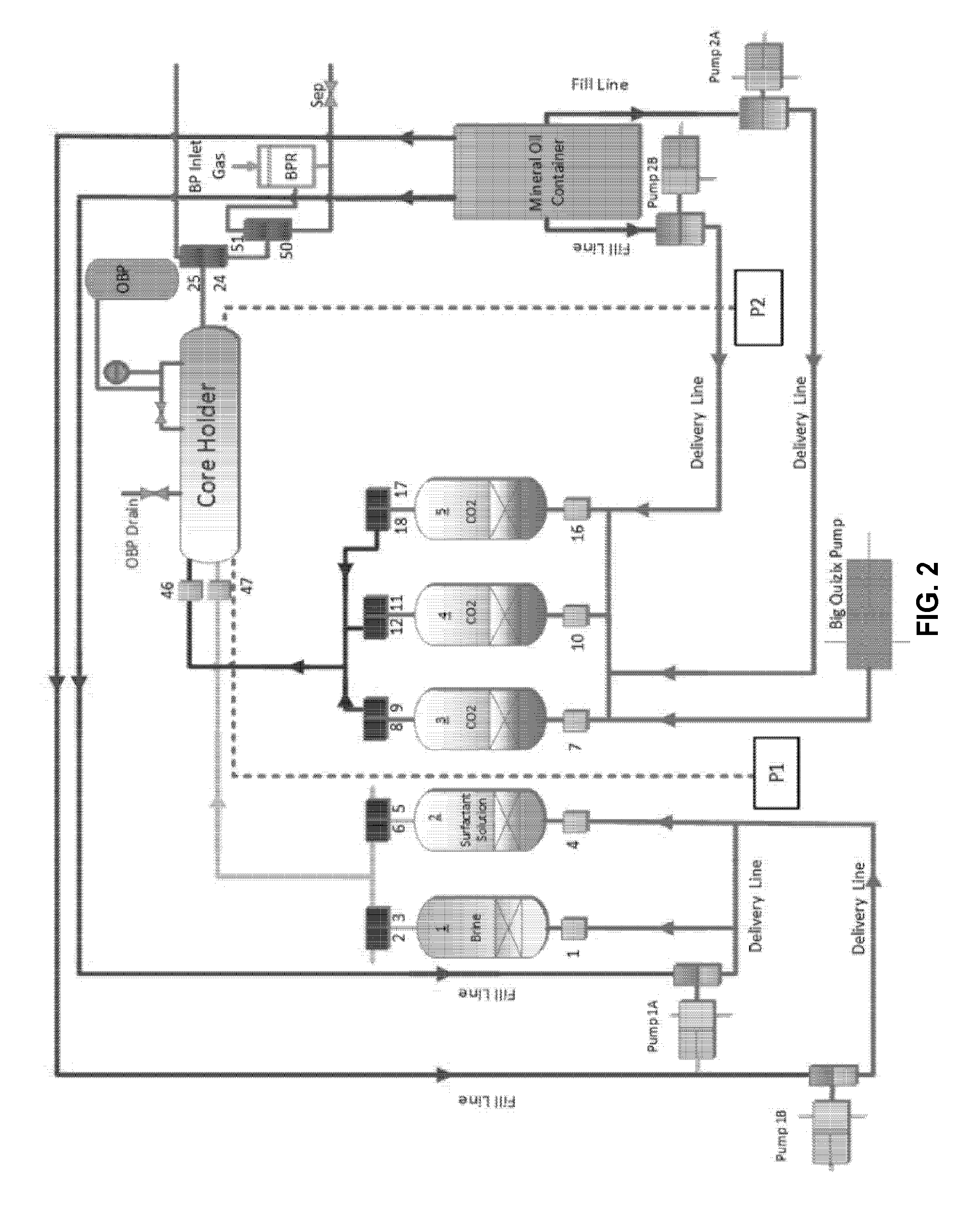

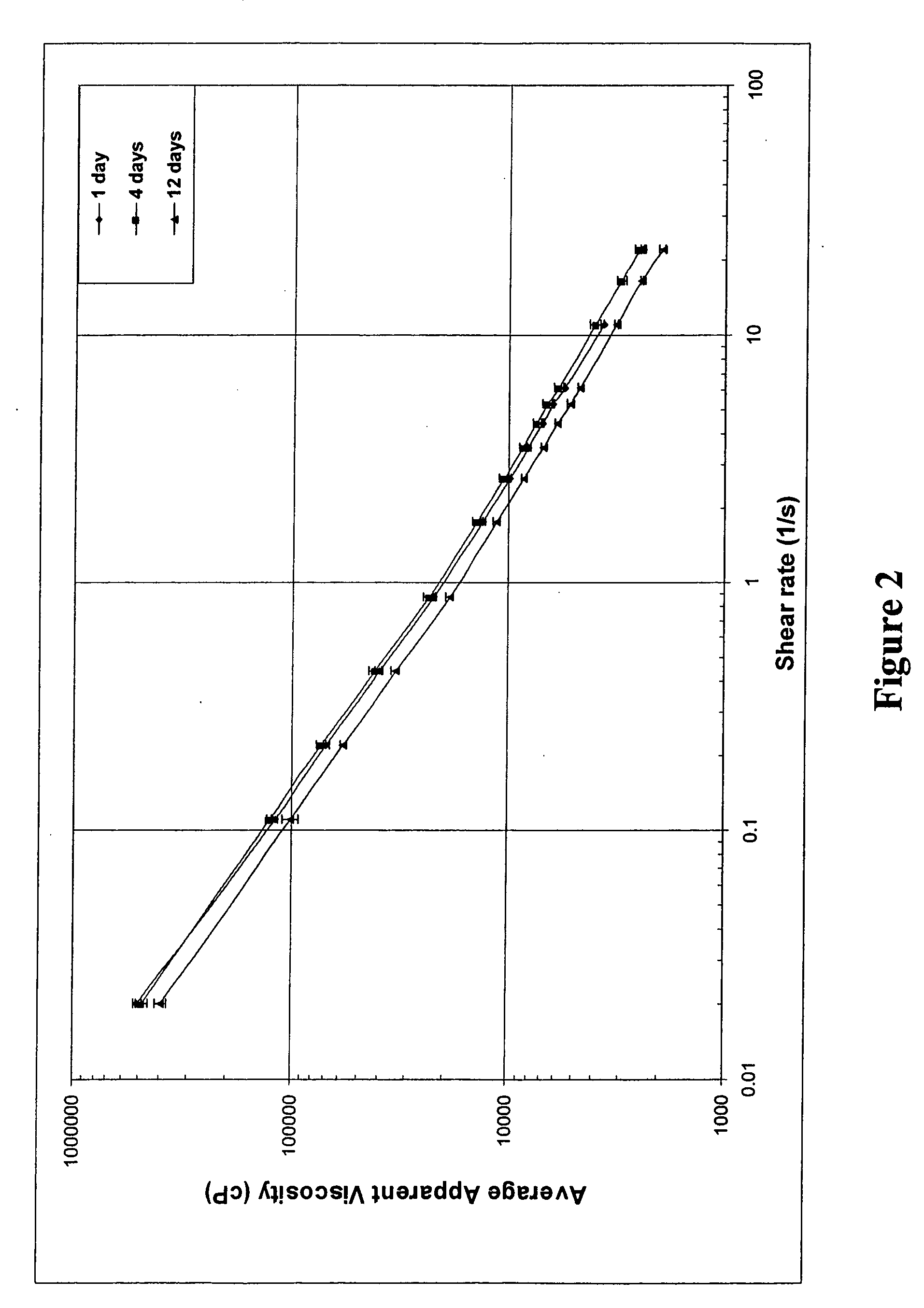

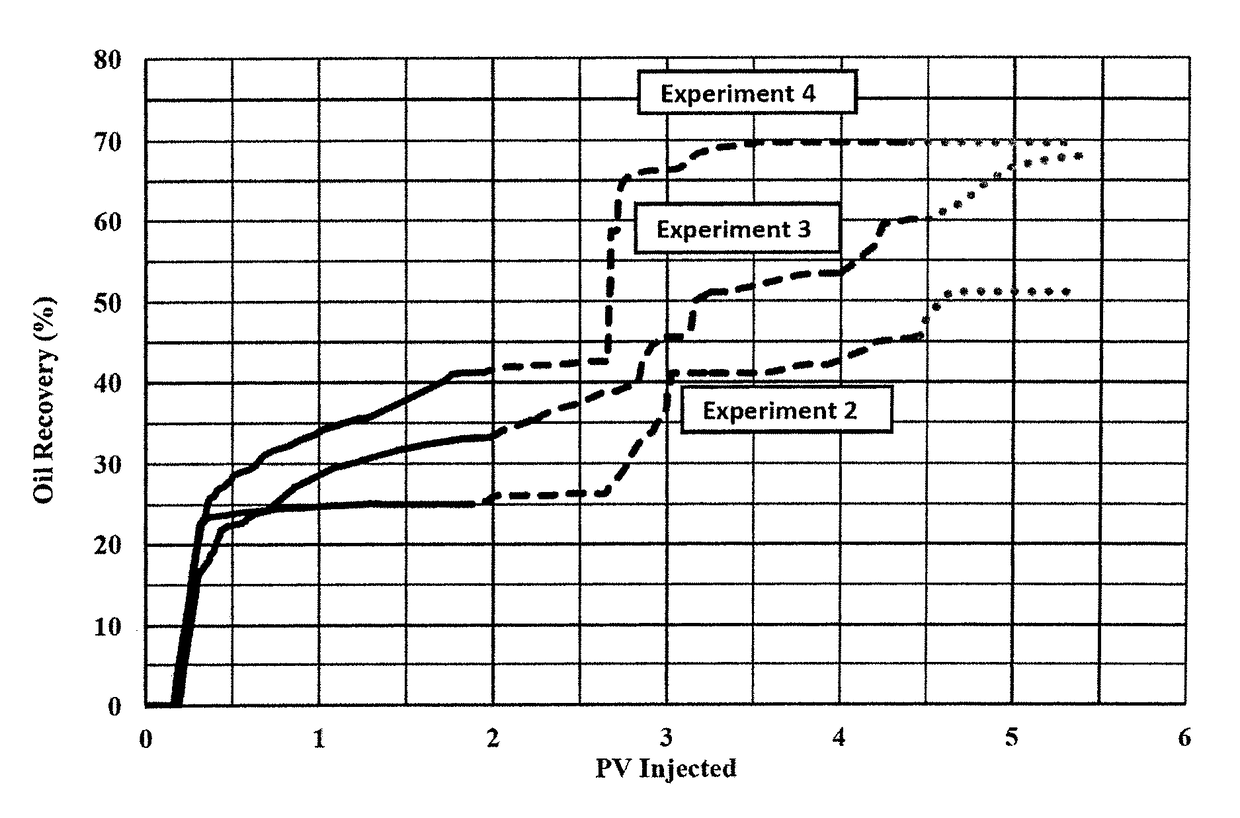

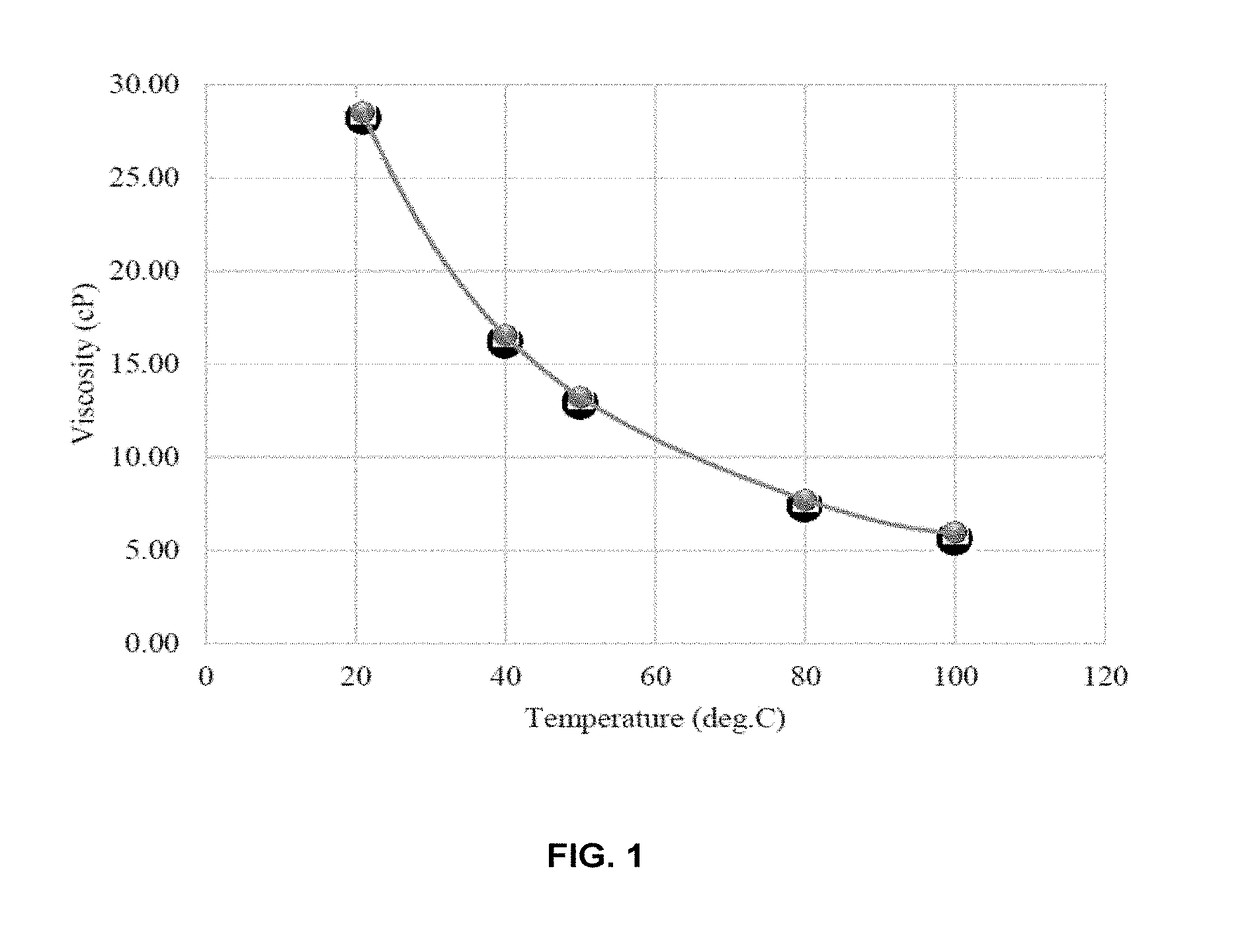

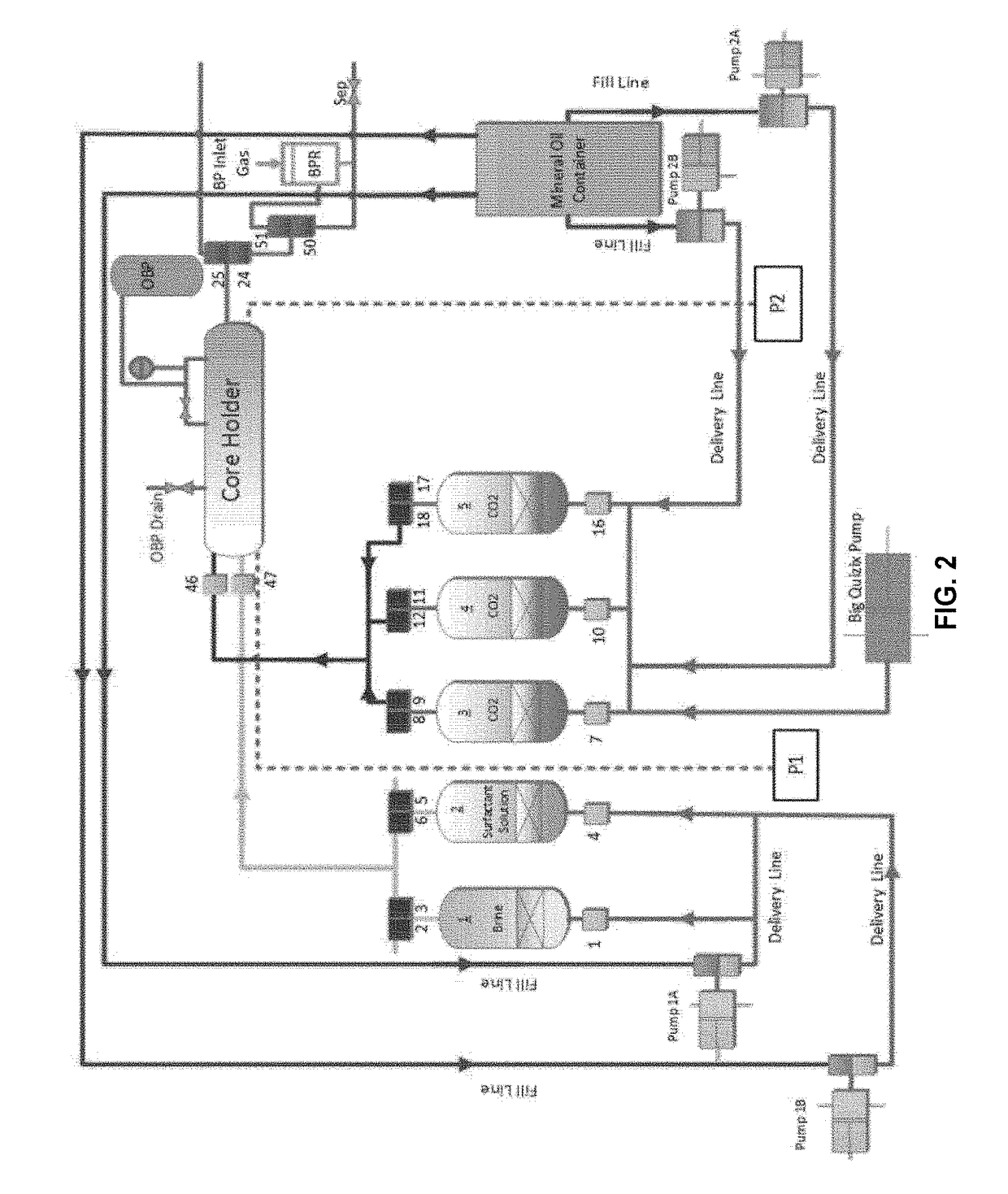

Oil recovery processes at high salinity carbonate reservoirs

InactiveUS20160289539A1Low viscosityOther gas emission reduction technologiesFluid removalSweep efficiencySalinity

A process for recovering oil from a carbonate reservoir of high salinity, wherein supercritical CO2 floodings are combined with a fluorosurfactant in the tertiary recovery. Embodiments include alternating injection and co-injection schemes of the supercritical CO2 and the fluorosurfactant. A stable fluorosurfactant-CO2 foam that is not susceptible to the harsh conditions of the reservoir (temperature, pressure and salinity) can be successfully generated, leading to a reduction in the mobility of CO2, an increase in the mobility of the reservoir oil, higher contact between the injected fluid with the oil and a better sweep efficiency of the oil.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

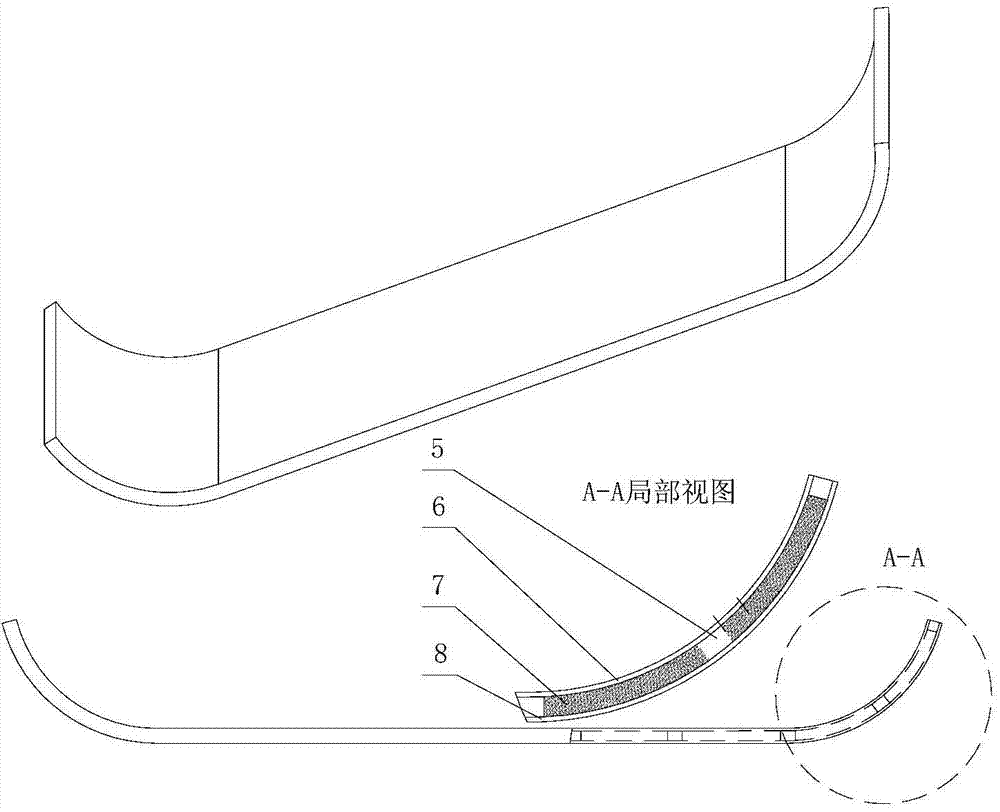

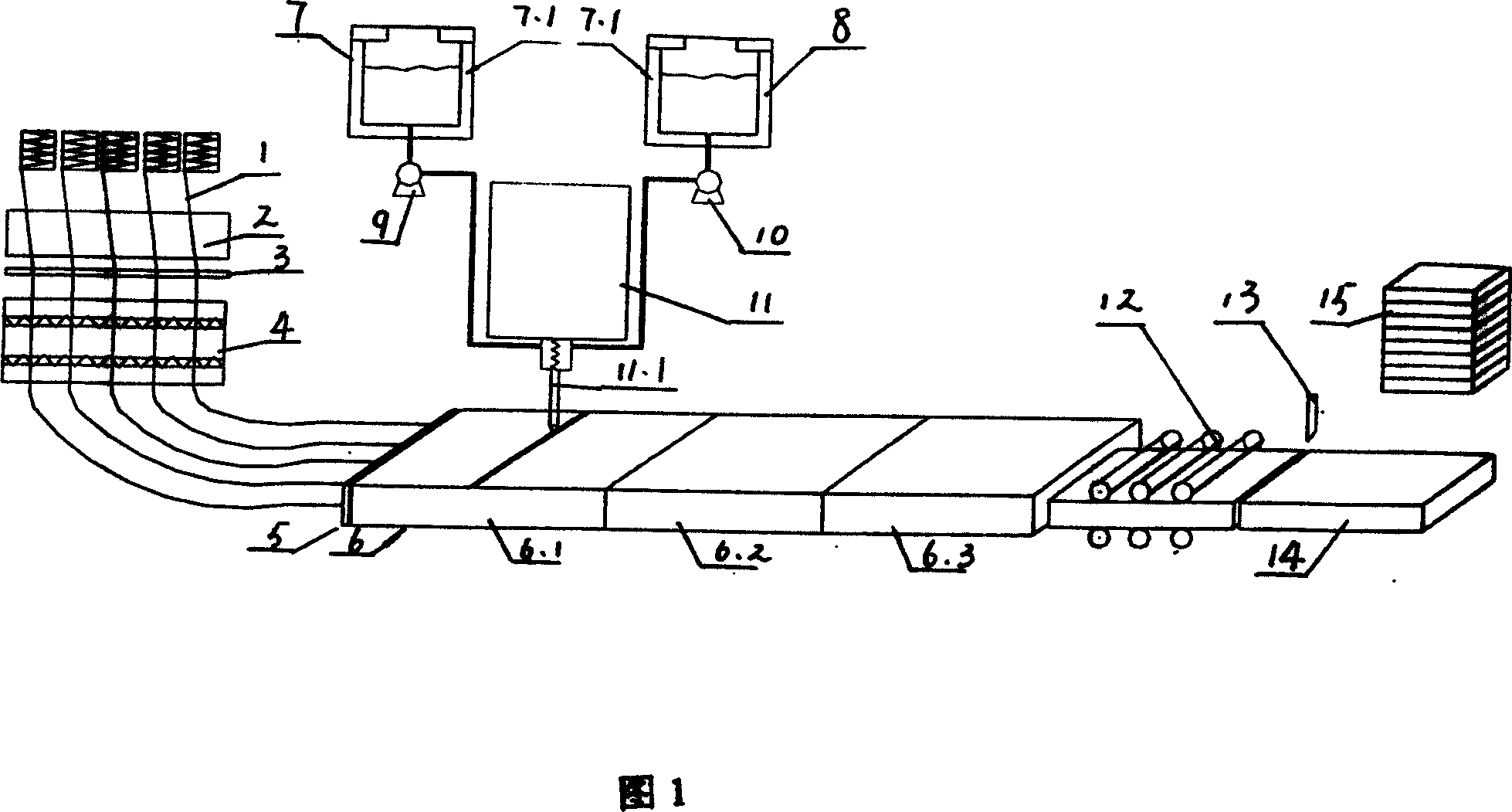

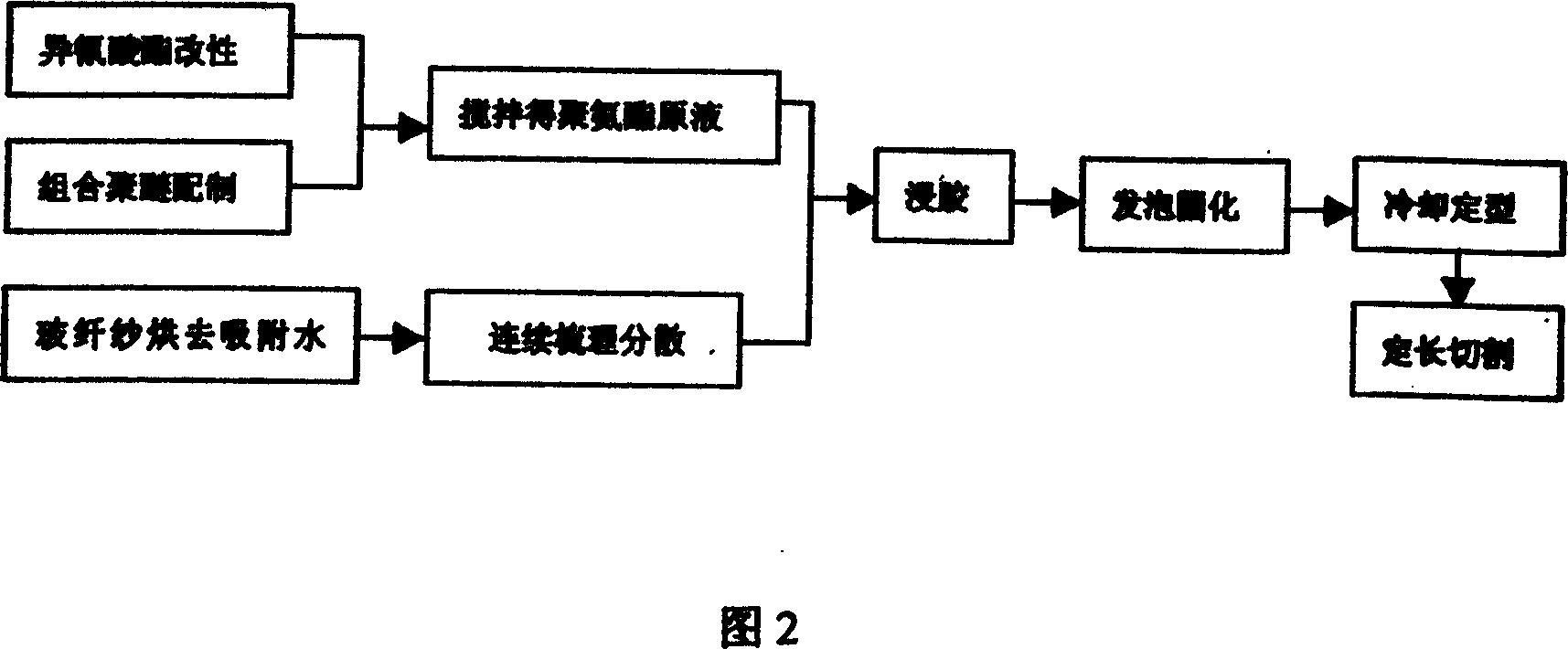

Section material product of continuous glass-fiber reinforced hard polyurethane microfoam and coextrusion forming process

A composite section material product of continuous glass-fiber gauze reinforced hard polyurethane micro-foam and its co-extrusion formation process are disclosed. The process is carried out by collocating for modified isocyanate and combined polyether, carding while dispersing for continuous glass-fiber gauze, passing it through co-injection cavity, heat foaming curing area and cooling sizing area continuously, wetting glass-fiber gauze by bi-component polyurethane stoste and cutting. It has long usage life, excellent mechanical, anti-corrosive and insulating performances. It can be used for railway sleeper rail, container wall board, architecture section materials and sport appliances.

Owner:江苏双良复合材料有限公司

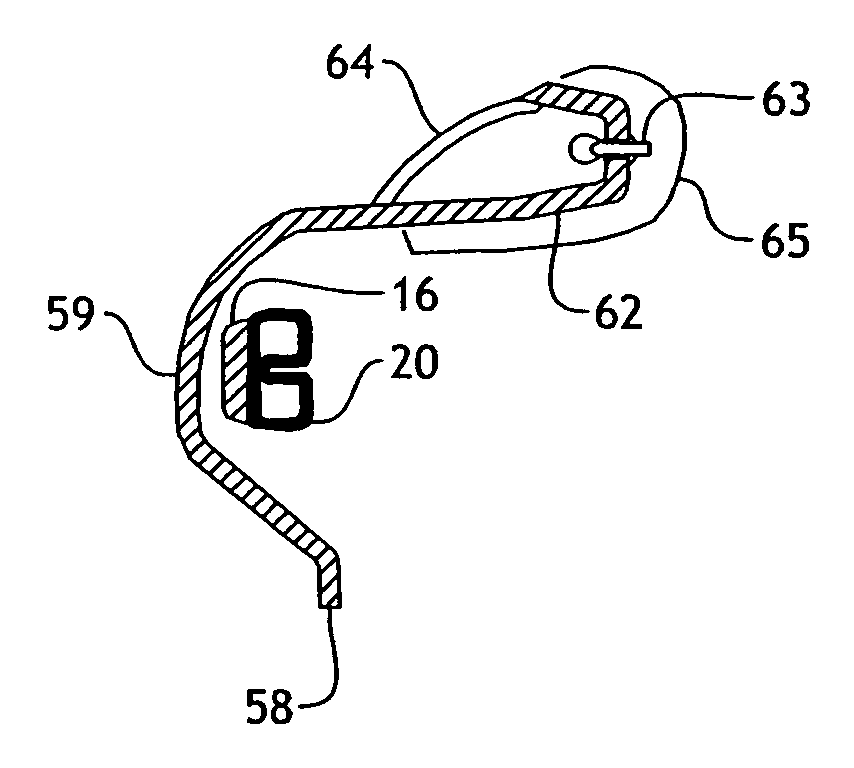

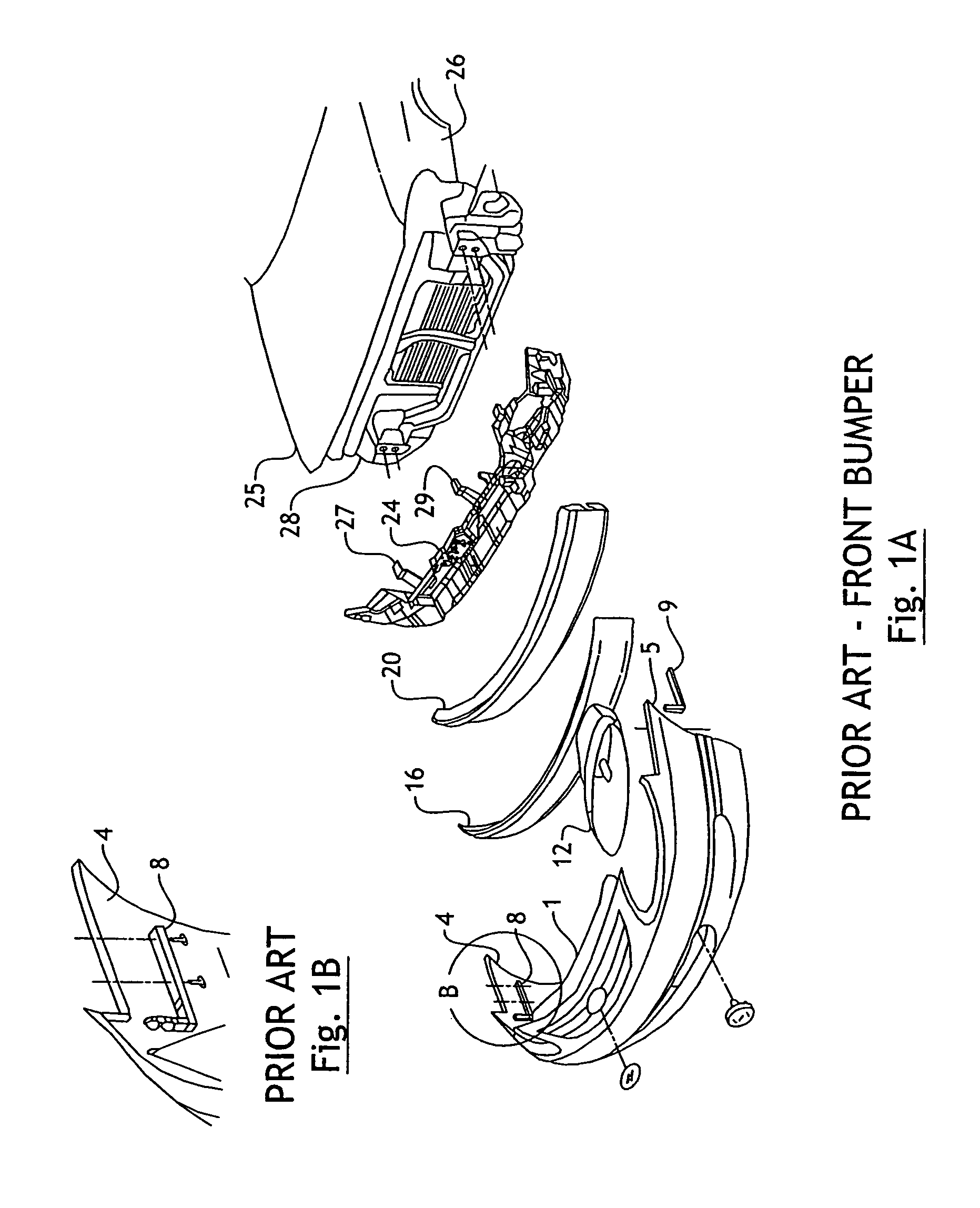

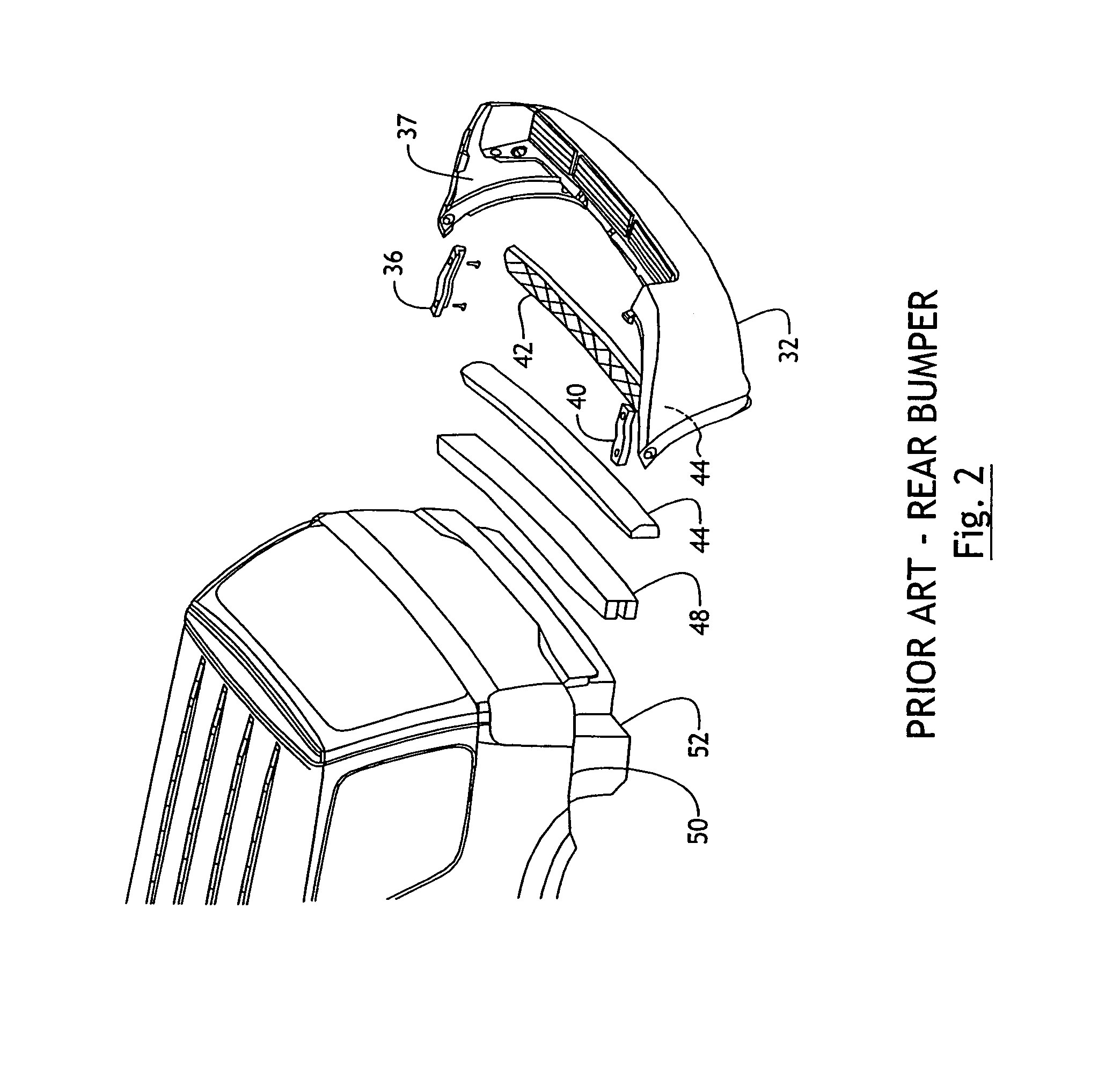

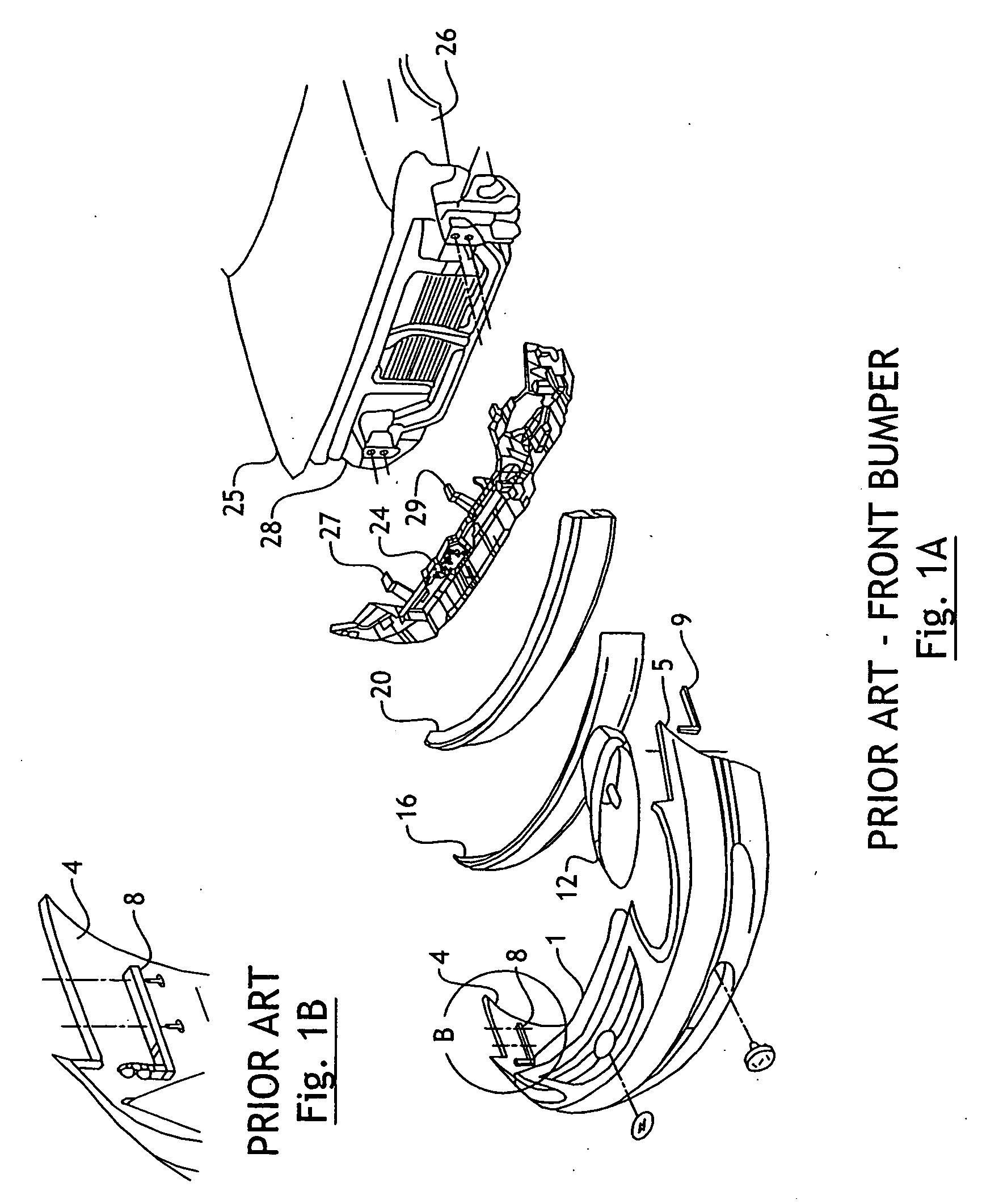

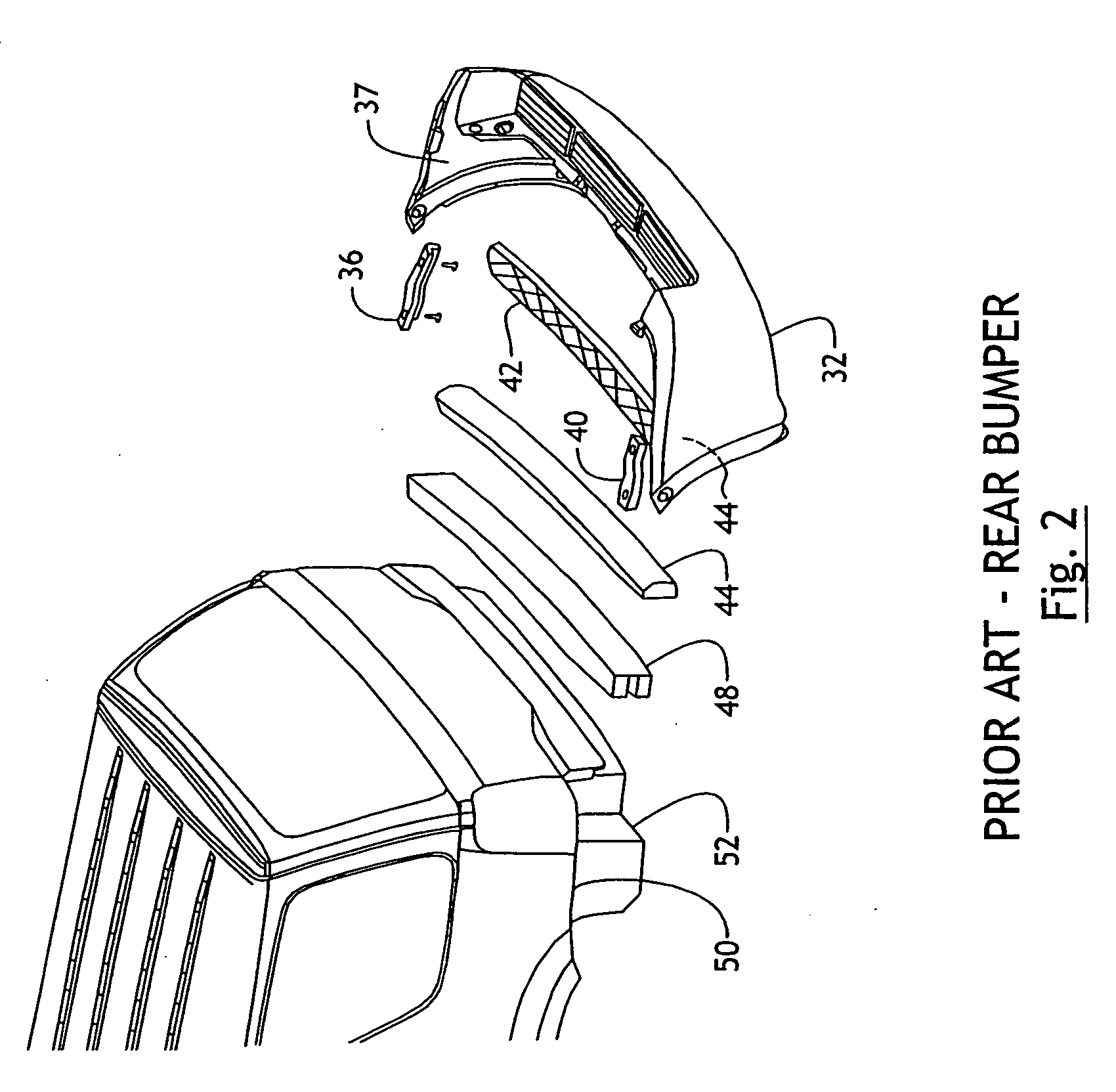

Integrated co-injection molded vehicle components and methods of making the same

InactiveUS6998174B2Low densityLow costVehicle interior lightingSynthetic resin layered productsHigh stiffnessPlastic materials

A vehicle bumper (20) integrates rigid and flexible components into a single co-injection molded structure. In a preferred embodiment, a flexible fascia (58) is provided with integrated rigid fastener brackets (62, 66, 70, 71), energy absorption structure and head lamp brackets and housings (62). A method for manufacturing such a bumper provides for the injection of two different plastic materials during the same molding process. The flexible plastic material first injected into the mold. Then, the rigid plastic material is injected at gates located where the rigid material is desired. In one embodiment, the rigid material is completely contained within the flexible material. The rigid material may be either a higher stiffness plastic or a fiber reinforced plastic.

Owner:CONIX

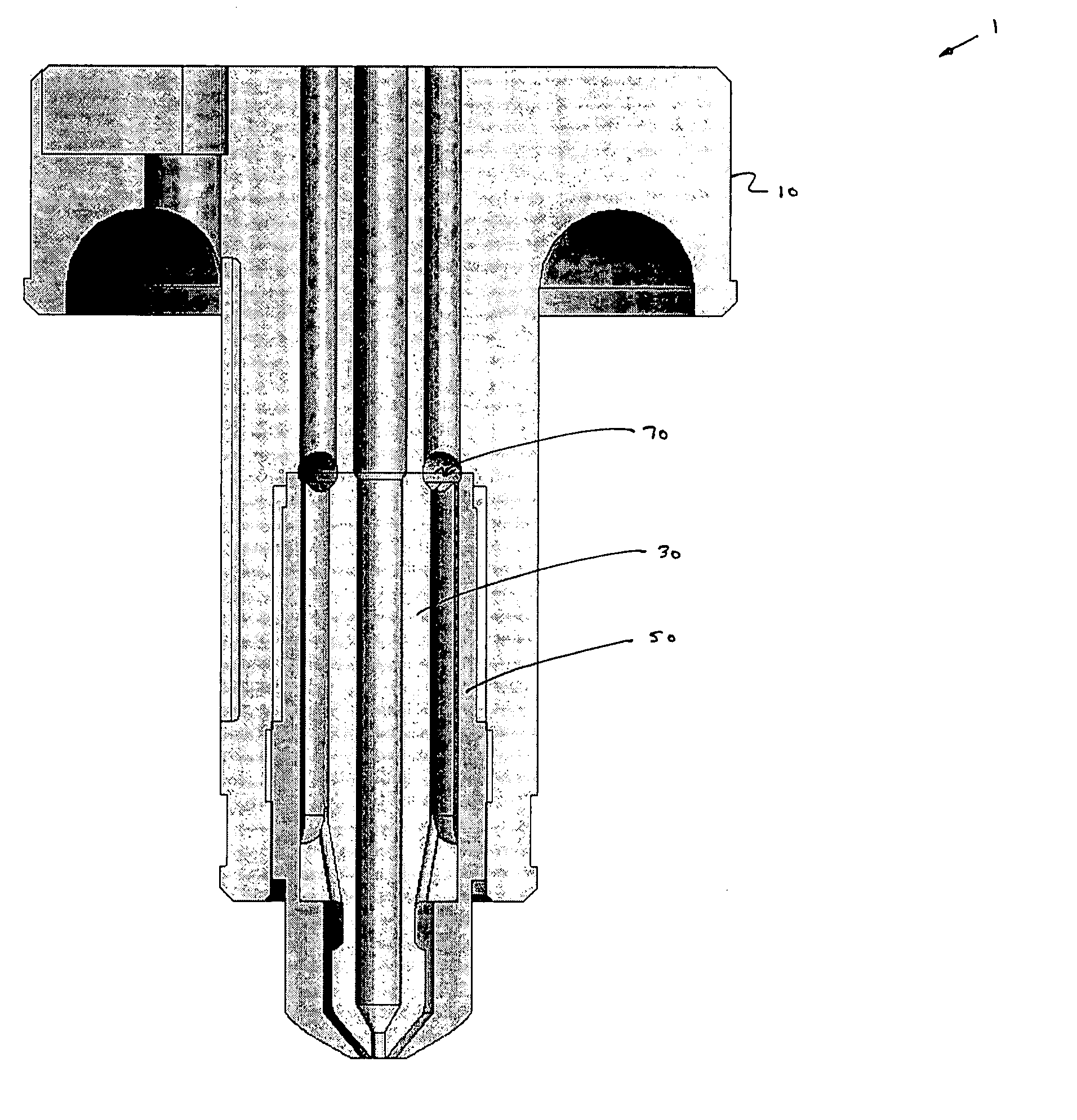

Hot runner co-injection nozzle

This invention teaches a hot runner injection molding apparatus for co-injecting at least two different materials into a mold cavity. A pin valve gated hot runner nozzle includes separate melt channels for each material and a melt chamber for accurately metering one of the materials. The melt chamber is in communication with an injection piston. The controlled movement of the valve pin and of the injection piston insures that the desired amount of a first and at least a second material is injected into the mold cavity. Depending of the composition and the processing window of the materials, the co-injection hot runner nozzle is in communication with either a single or multiple manifolds.

Owner:MOLD MASTERS 2007

Composite components with integral protective casings

InactiveUS20080237922A1Avoid the needHigh strengthMouldsThin material handlingPorositySecondary bonding

Methods and compositions for fabricating composite parts including at least one structural material and at least one protective material that are integrally bonded without the use of secondary bonding operations. One or more of the materials forming the layers of the composite parts may be a ceramic composition with or without porosity and one or more of the materials may be a polymer composition. Methods including co-injection processes also are provided for fabricating multi-layered structures in which each layer serves a desired function while still being integrated into the overall structure.

Owner:ADVANCED CERAMICS

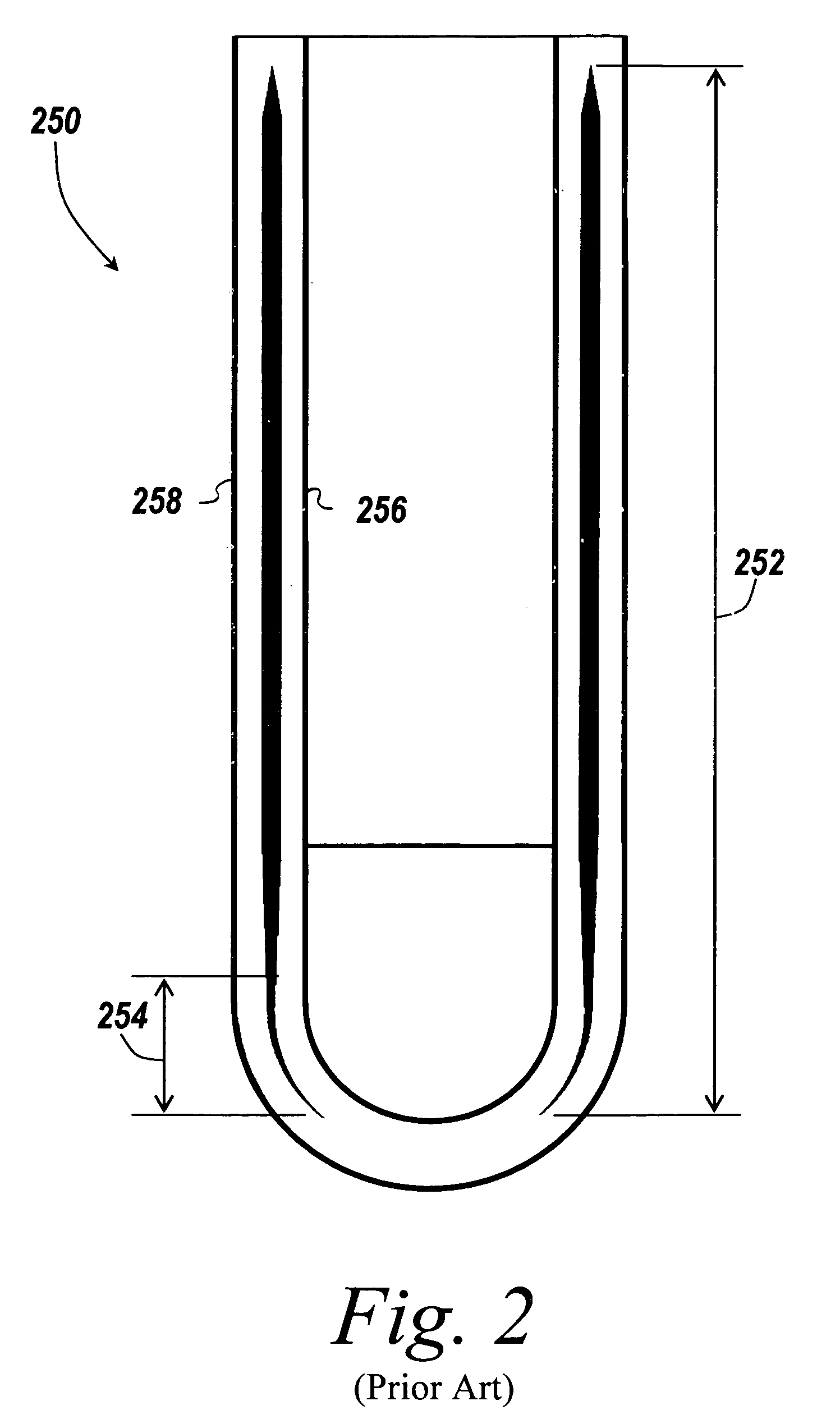

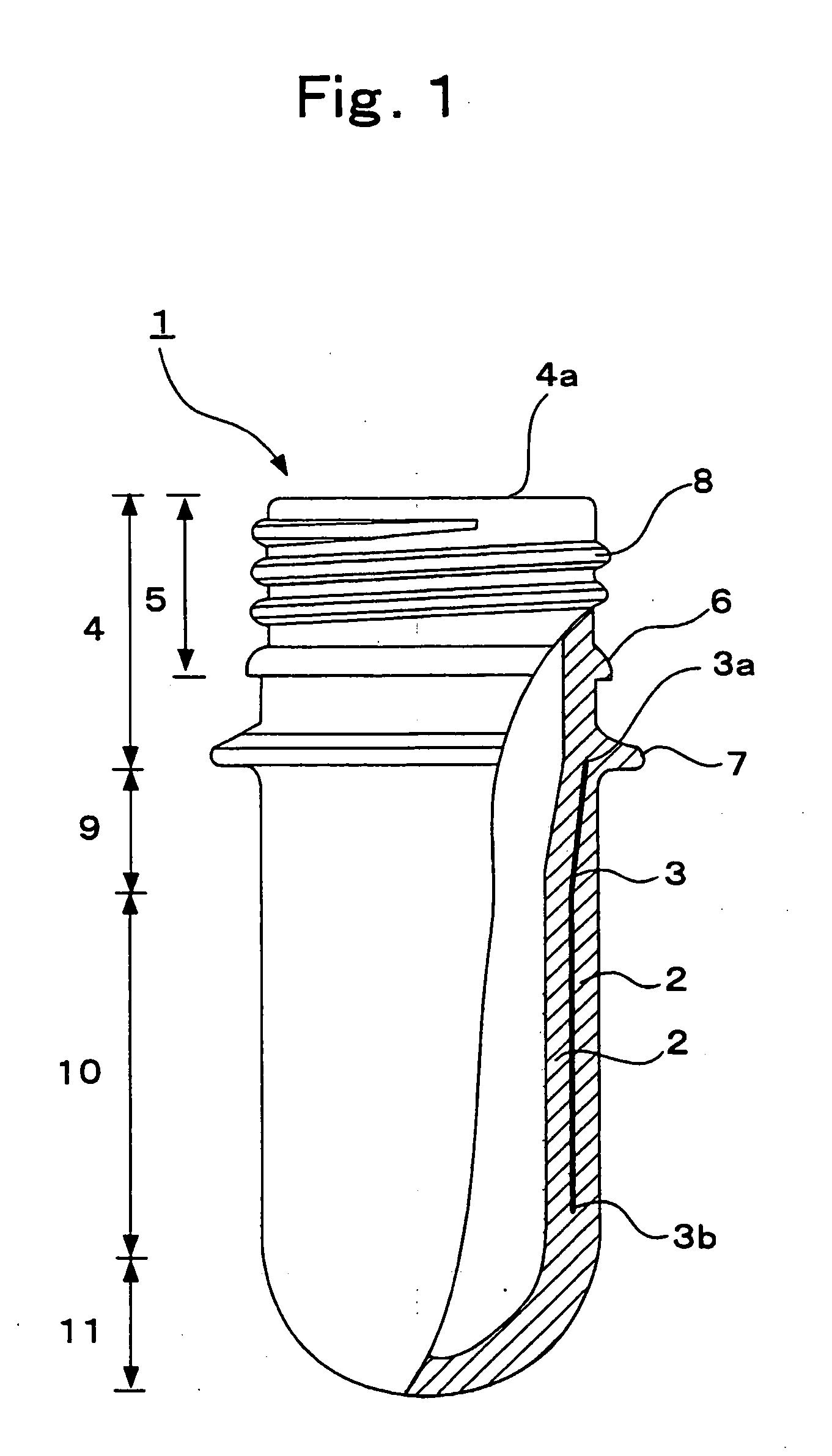

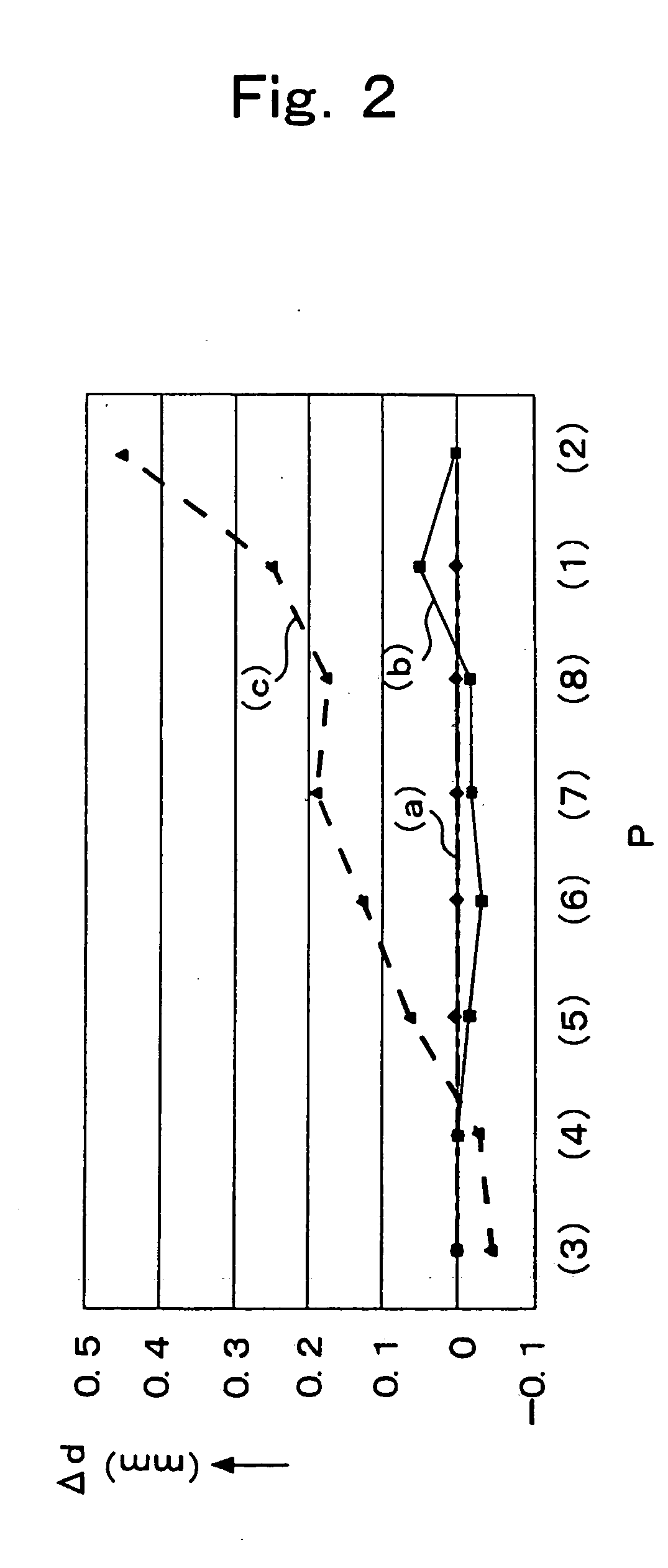

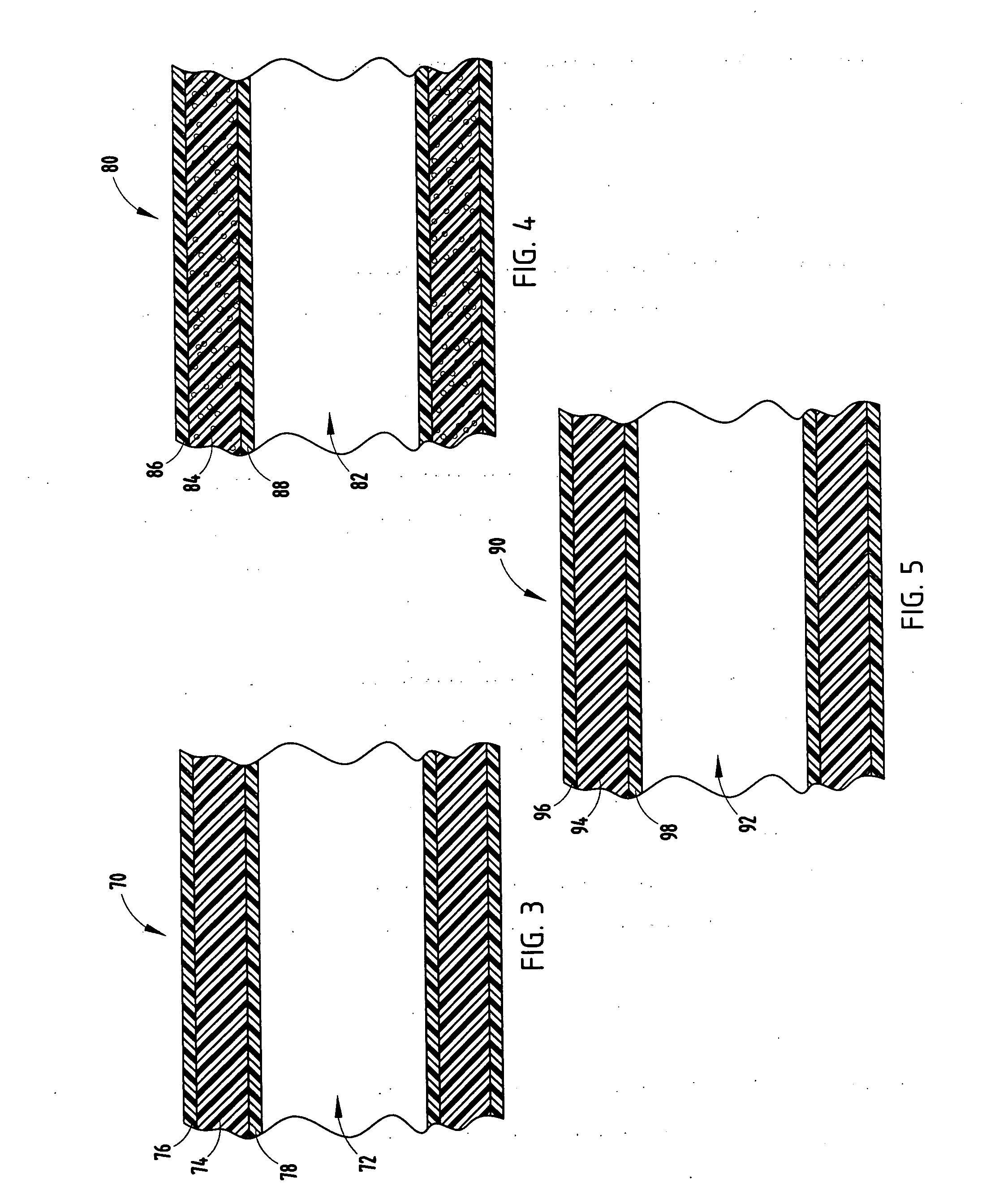

Biaxially oriented, blown-molded bottles and preform thereof

The purpose of this invention is to set the position of the gas barrier layer in such a manner as to solve the problem of decreased accuracy of neck molding dimensions created by the thermal crystallization and the problem of interlaminar separation in the bottom, both of which are associated with the provision of the gas barrier layer. Problems should be solved without being affected by the displacement of the gas barrier layer, which may take place during the co-injection operation of the PET resin layers and the gas barrier layer. A biaxially drawn, blow-molded bottle and its preform comprise at least a layer of a gas barrier material 3 laminated inside the PET resin layers 2, a functional portion 5 having a screw thread 8 raised spirally in the upper portion of neck 4 and also having a stop ring 6 disposed under the screw thread 8, and a neck ring 7 disposed at the lower end of the neck 4. In these preform and bottle, the leading edge 3a of the gas barrier layer 3 is positioned at a half height of the neck ring 7 where the most advanced front of the leading edge 3a neither reaches a half height of the stop ring 6 nor extends to the functional portion 5. It is intended here that the neck 4 would not be affected by the shrinking deformation caused by the existence of the gas barrier layer 3 in the functional portion 5 of the neck 4, which is treated for thermal crystallization.

Owner:YOSHINO KOGYOSHO CO LTD

Traffic cone apparatus and method of production

InactiveUS7513212B2Increase weightLow costTraffic signalsRoad signsMethods of productionCo injection

Owner:THREE D PLASTICS

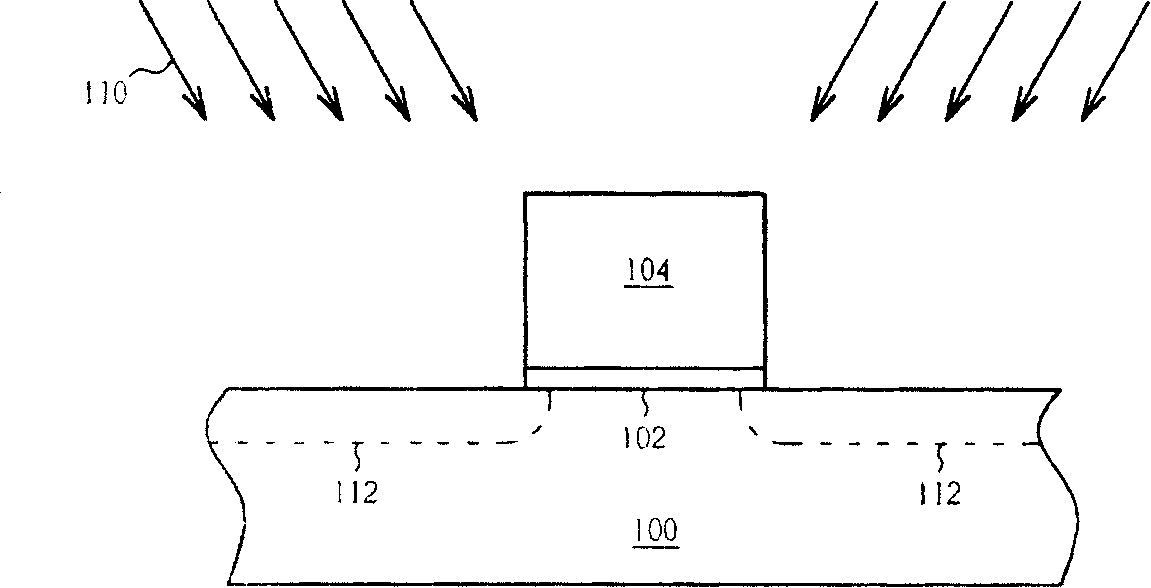

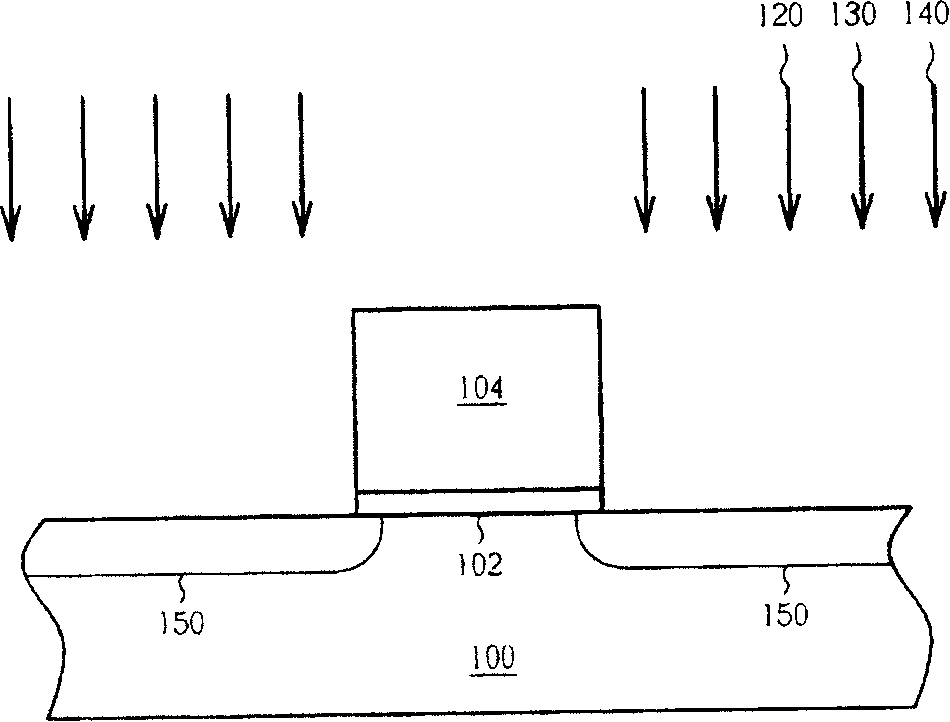

Method for manufacturing metal-oxide-semiconductor transistor

ActiveCN101179027AReduce lateral spreadReduced TED effectSemiconductor/solid-state device manufacturingEngineeringCo injection

The invention provides a method for manufacturing an MOS transistor. The method provides a substrate including a gate structure. Then a pre-non-crystallization technology is carried out and a non-crystallization region is formed in the substrate at two sides of the gate structure; the co-injection technology is carried out, and the impurity for co-injection is injected in the non-crystallization region. A first ion injection technology and a first quick-annealing technology are carried out in such a manner that a slight-doping drain electrode is formed. Finally, a separation wall is respectively formed at two sides of the gate structure in such a manner that a source cathode or a drain electrode is formed.

Owner:UNITED MICROELECTRONICS CORP

Integrated co-injection molded vehicle components and methods of making the same

InactiveUS20060051569A1Improve structural strengthIncrease stiffnessConfectionerySweetmeatsHigh stiffnessEnergy absorption

A vehicle bumper (20) integrates rigid and flexible components into a single co-injection molded structure. In a preferred embodiment, a flexible fascia (58) is provided with integrated rigid fastener brackets (62, 66, 70, 71), energy absorption structure and head lamp brackets and housings (62). A method for manufacturing such a bumper provides for the injection of two different plastic materials during the same molding process. The flexible plastic material first injected into the mold. Then, the rigid plastic material is injected at gates located where the rigid material is desired. In one embodiment, the rigid material is completely contained within the flexible material. The rigid material may be either a higher stiffness plastic or a fiber reinforced plastic.

Owner:CONIX

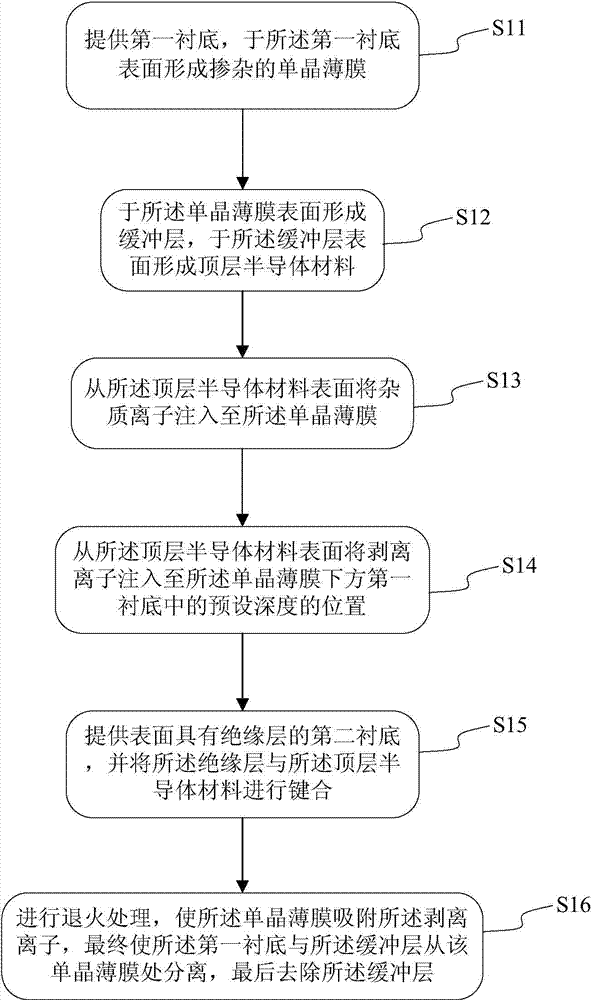

Method for preparing semiconductor-on-insulator material by utilizing ion injection technology

ActiveCN104517883AQuality improvementIncrease stressSemiconductor/solid-state device manufacturingSemiconductor materialsDual effect

The invention provides a method for preparing semiconductor-on-insulator material by utilizing an ion injection technology. The method comprises the steps that 1) a doped mono-crystal thin-film is formed on the surface of a first substrate; 2) a buffer layer and top layer semiconductor material are formed on the surface of the mono-crystal thin-film; 3) foreign ions are injected into the mono-crystal thin-film; 4) stripping ions are injected into the position of the preset depth in the first substrate below the mono-crystal thin-film; 5) bonding is performed between the top layer semiconductor material and a second substrate with an insulating layer; 6) and annealing processing is performed so that the first substrate and the buffer layer are separated from the mono-crystal thin-film, and the buffer layer is removed. Dual effect of ion co-injection and doped mono-crystal thin-film stripping is combined so that stripping dose is effectively reduced. The foreign ions are injected so that the mono-crystal thin-film is enabled to generate stress and adsorption capacity of the mono-crystal thin-film is increased. Stripping is realized after H-ion injection and annealing. Stripping occurs at the position of the ultrathin mono-crystal thin-film so that a crack is quite small, and the high-quality semiconductor-on-insulator material can be obtained.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Oil recovery processes at high salinity carbonate reservoirs

A process for recovering oil from a carbonate reservoir of high salinity, wherein supercritical CO2 floodings are combined with a fluorosurfactant in the tertiary recovery. Embodiments include alternating injection and co-injection schemes of the supercritical CO2 and the fluorosurfactant. A stable fluorosurfactant-CO2 foam that is not susceptible to the harsh conditions of the reservoir (temperature, pressure and salinity) can be successfully generated, leading to a reduction in the mobility of CO2, an increase in the mobility of the reservoir oil, higher contact between the injected fluid with the oil and a better sweep efficiency of the oil.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Cover, a container assembly including the cover, a molding device for molding the cover and a method for manufacturing the cover

ActiveUS8729438B2More stressProlong lifeClosure capsClosure with auxillary devicesEngineeringCo injection

A cover for covering an opening of a container for a food stuff includes a substantially flat cover body including at least one aperture and at least one substantially flat flap. The at least one flap includes a linear proximal end configured to connect with the cover body and allow the at least one flap to rotate with respect to the cover body. A lower surface of the at least one flap includes a protrusion configured to close the at least one aperture when the at least one flap is at a first position in which the at least one flap is in parallel with the cover body. The cover body and the at least one flap are integrally formed by a co-injection molding. The container and cover are suitable for heating a food stuff in a microwave.

Owner:IWASAKI IND

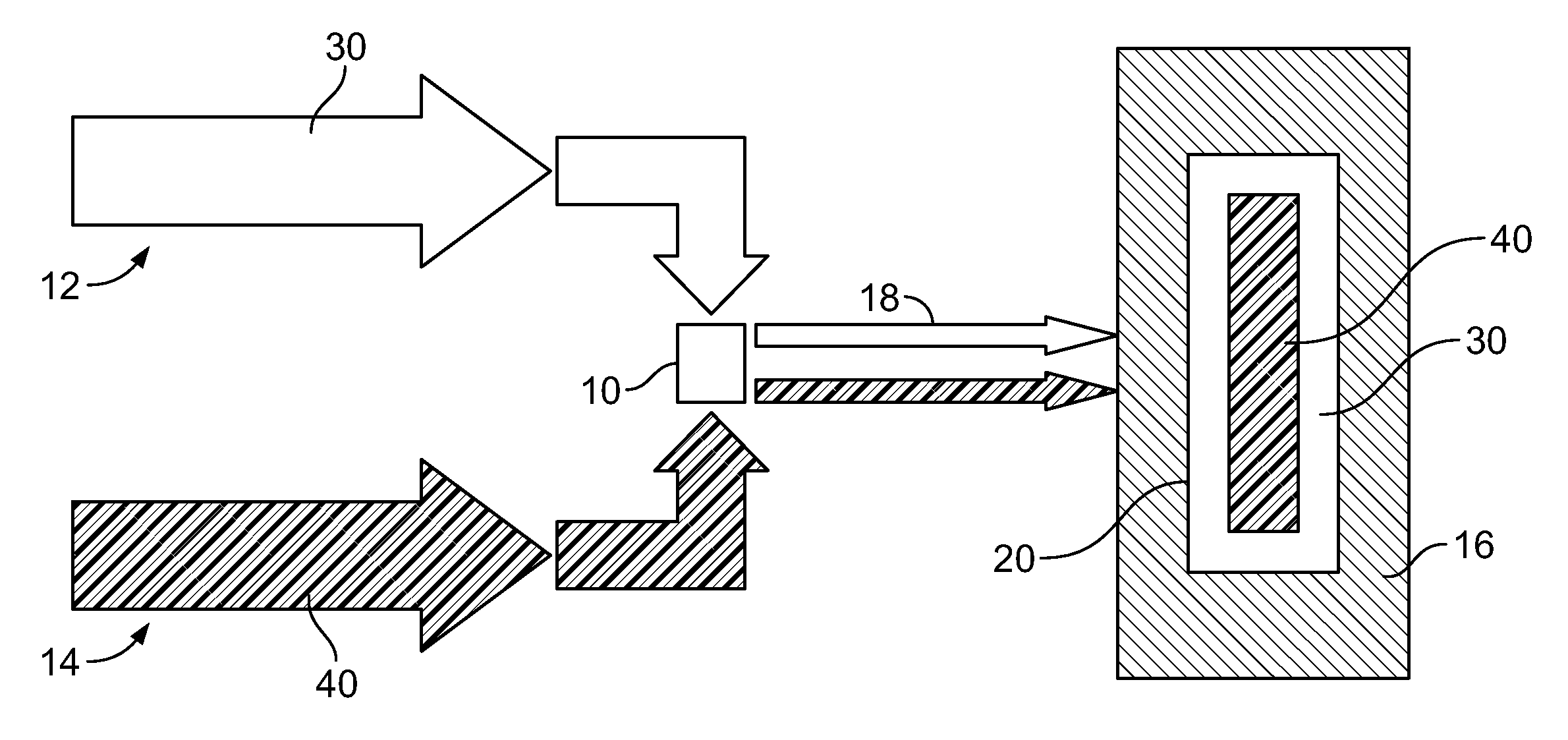

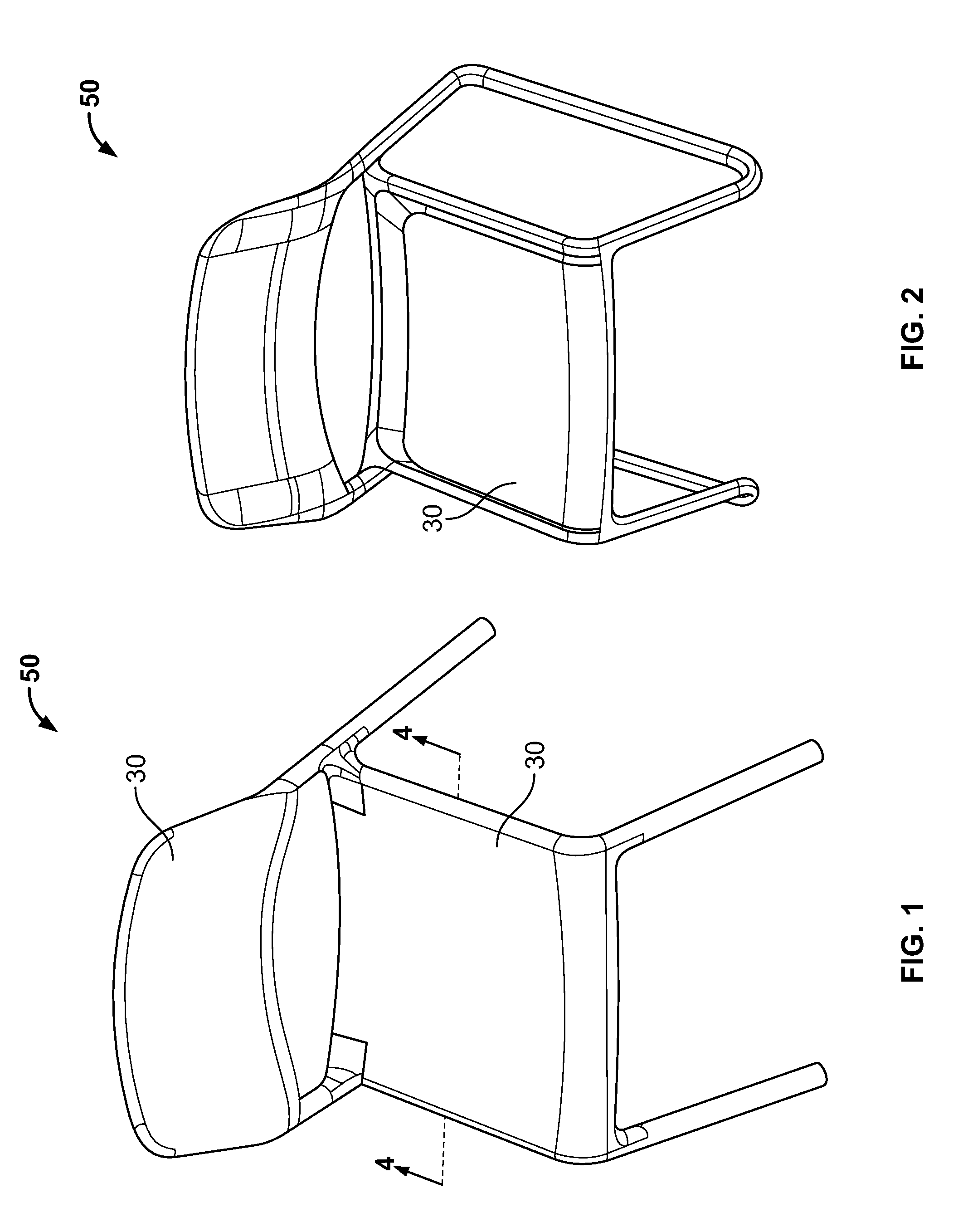

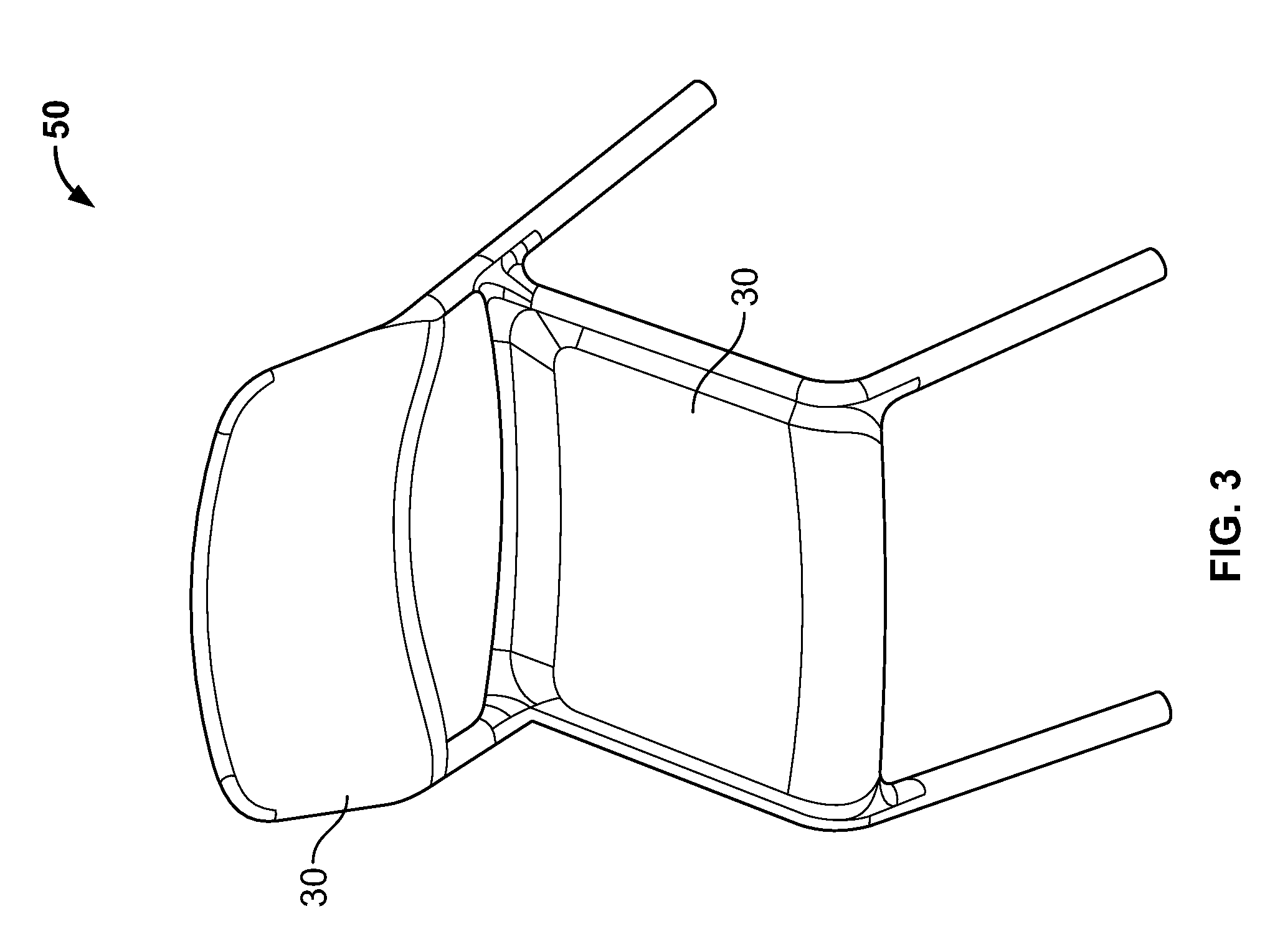

Gas-assisted co-injection molded chair

ActiveUS8663514B2Minimize impactSwelling of the chair is minimizedMouldsStoolsFoaming agentProduct gas

Owner:KNOLL INC

Co-injection molded chair

InactiveUS20100283308A1Shorten cycle timeReduce needDomestic articlesAuditorium chairsCo injectionBlowing agent

The invention is directed to an article made from co-injection molding. The article has an inner material and an outer material. The inner material has a blowing agent uniformly distributed throughout the inner material. The outer material surrounds the inner material. The use of the blowing agent in the inner material produces a repeatable and consistent structure, as the blowing agent is uniformly activated through the product.

Owner:KNOLL INC

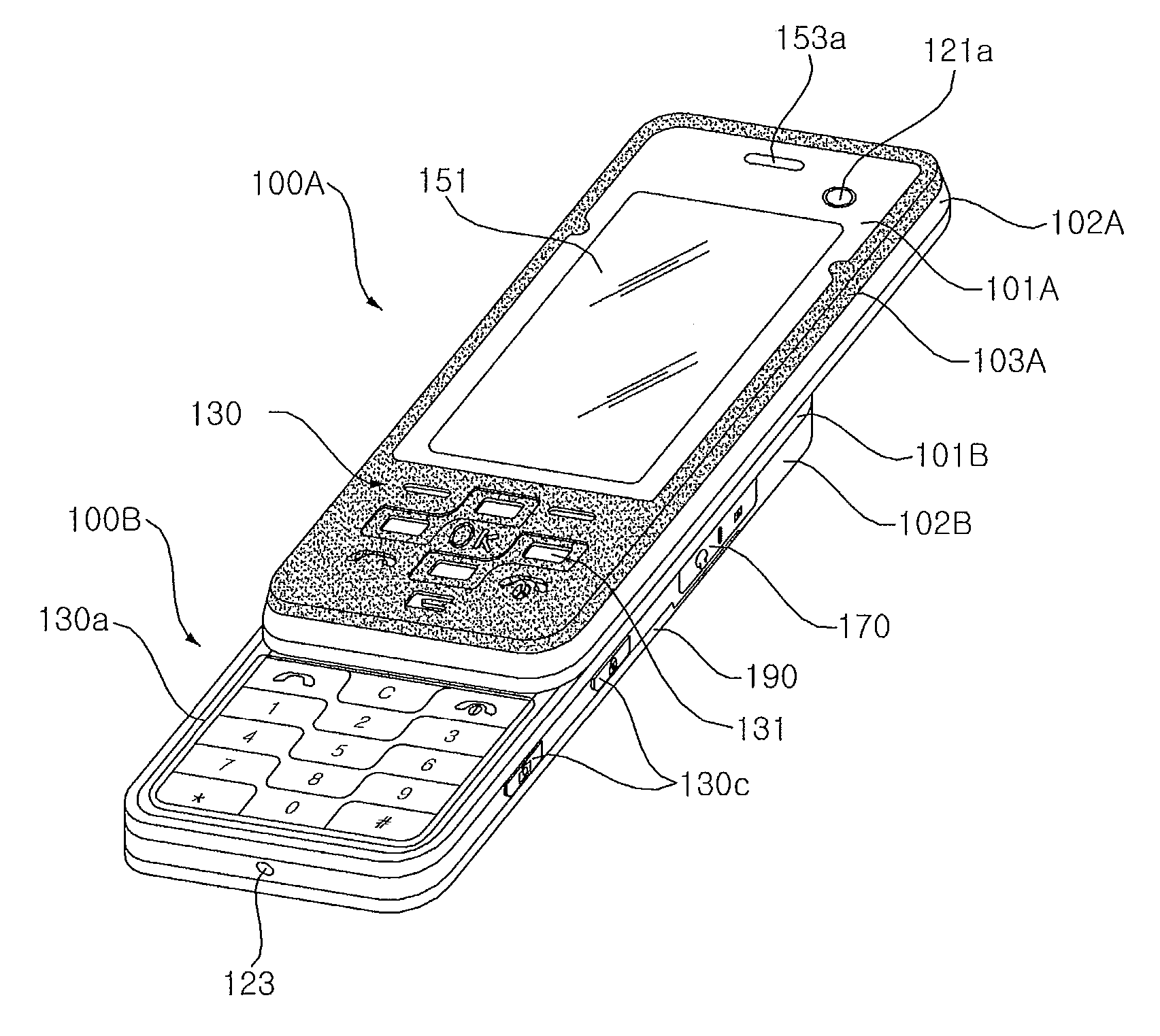

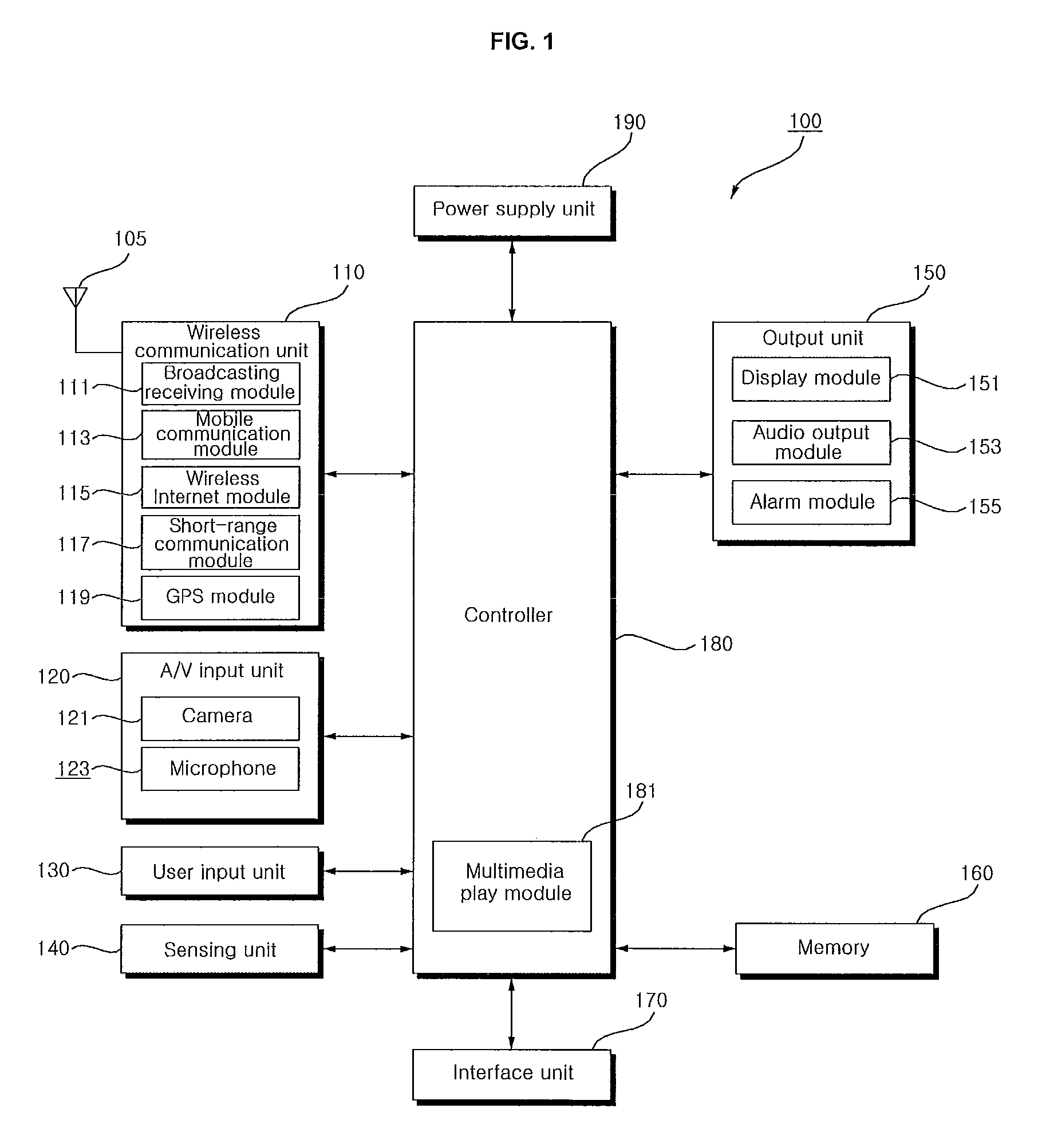

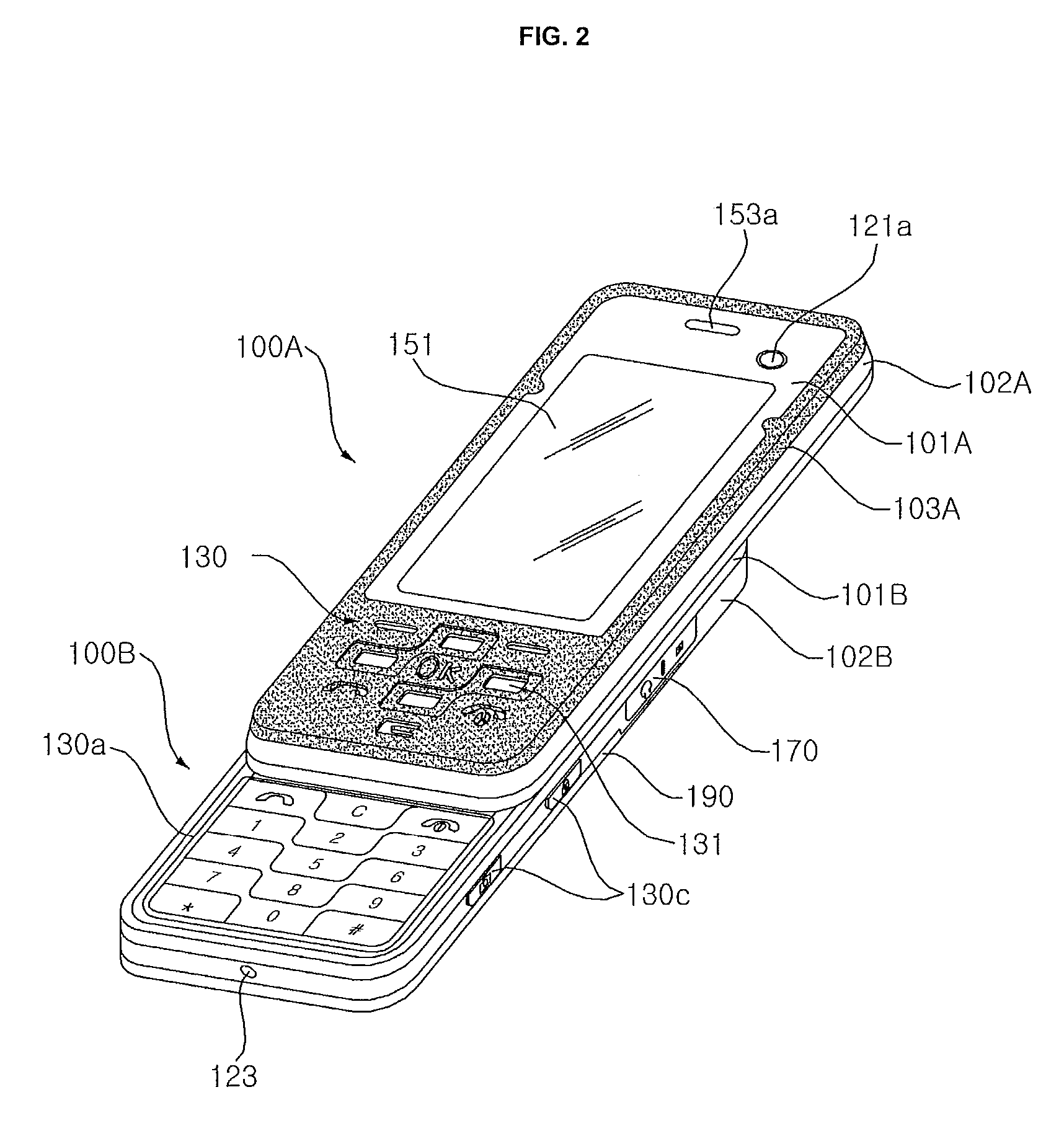

Mobile terminal

InactiveUS20090312066A1Improve waterproof performanceReduce in quantitySubstation equipmentTransmissionInjection mouldingCo injection

Owner:LG ELECTRONICS INC

Naphthalate based polyester resin compositions

InactiveUS20070232763A1Increase temperatureBottlesSynthetic resin layered productsBursting strengthPasteurization

The invention provides polyester polymers suitable for production of monolayer and multilayer preforms and containers by a process of injection molding or co-injection molding and stretch blow molding technology for monolayer and multilayer containers. Containers of the invention not only have adequate CO2 barriers, but also have adequate O2 and UV barriers, high thermal stability, and burst strength to withstand tunnel pasteurization processes at about 60° C. for 20-30 minutes at 10 bar CO2 pressure for beer applications. There will further be no limitations due to humidity in respect of processing the resin / preforms and storage of preforms beyond what is required for normal PET. The polymers of the invention do not possess tie layer nor delamination problems and satisfy recycling criteria.

Owner:FUTURA POLYESTERS LTD

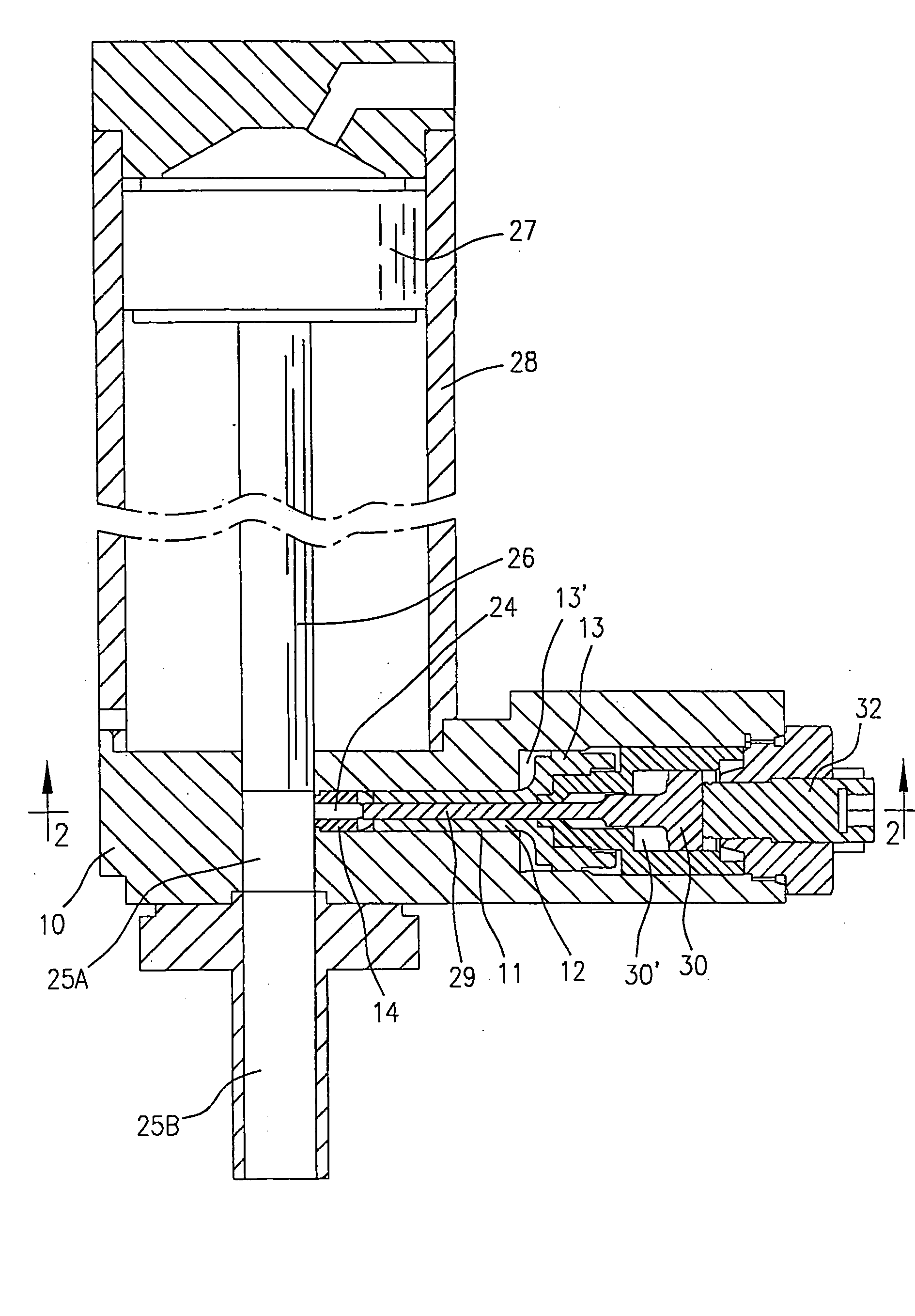

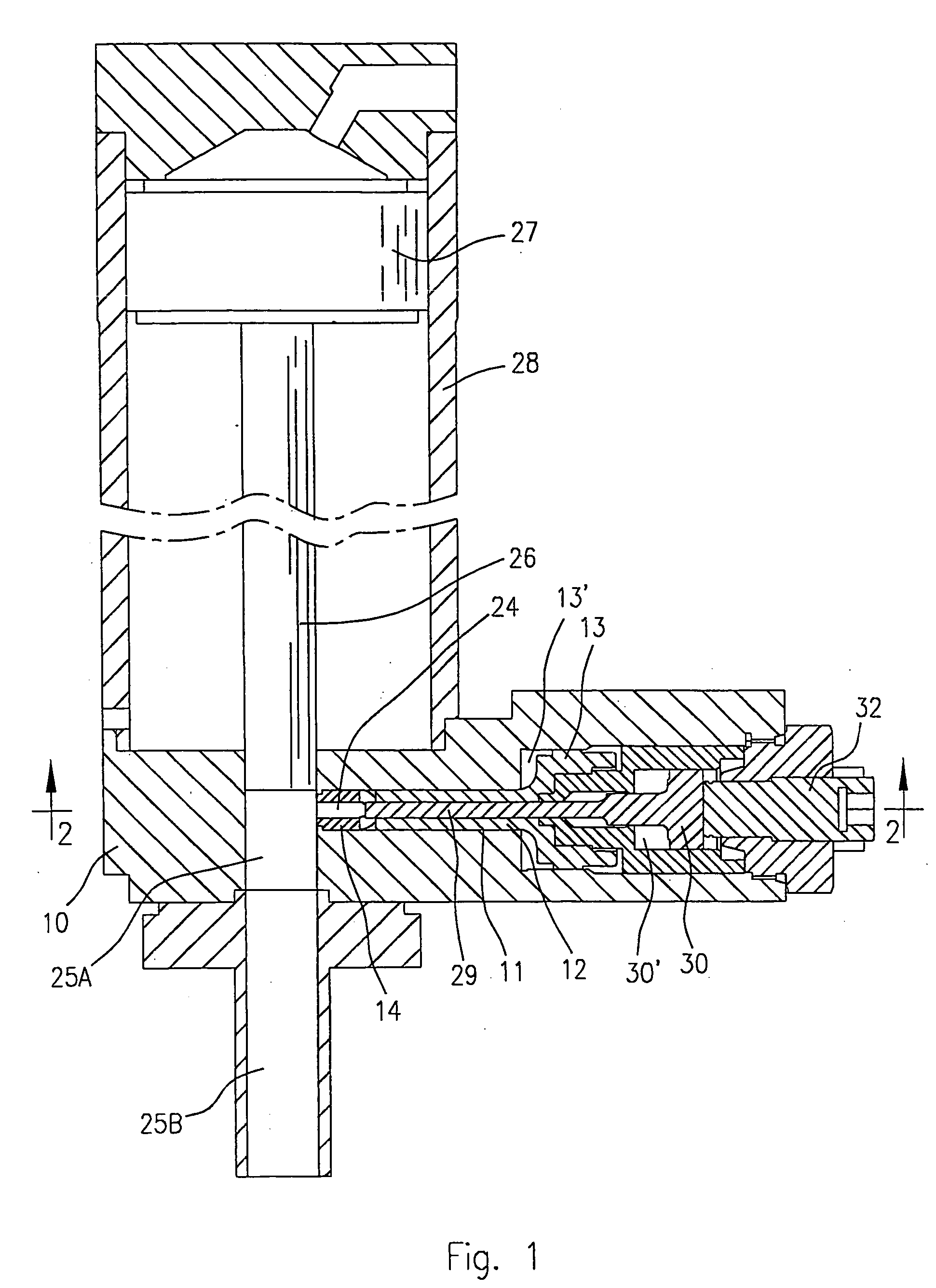

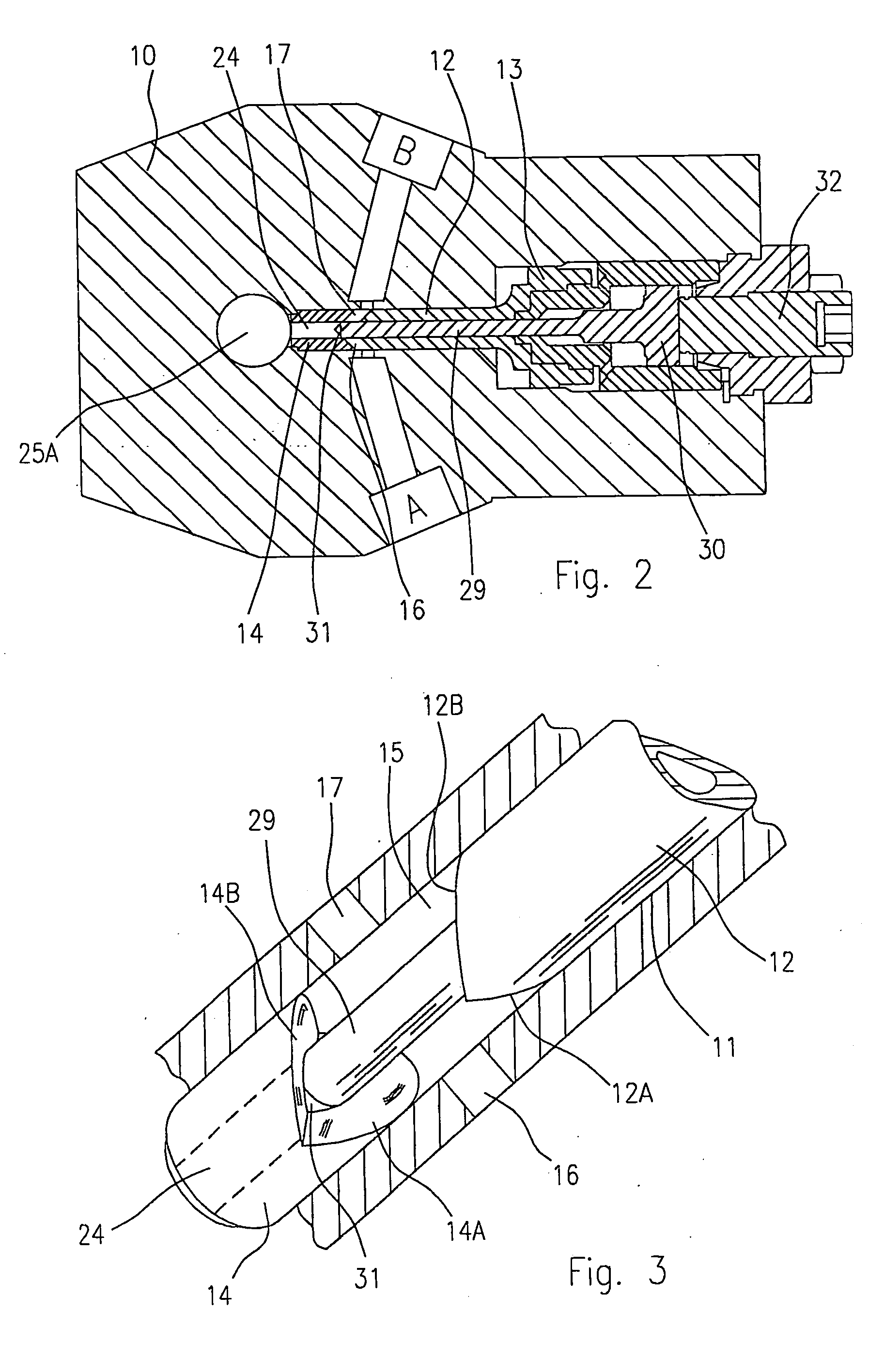

Co-injection mixing method and apparatus

InactiveUS20060104155A1Inhibition formationEasy to controlMixer accessoriesChemical compositionProcess engineering

Method and device (10) for mixing polyurethane—forming reactive chemical components; at least first and second chemical components (A, B) are introduced into a common pressure and feeding chamber, from where the chemical components are made to flow and co-injected through one or more narrow orifices (31) into a mixing chamber. During co-injection of the chemical components (A, B) a first mixing takes place into the jet strim, while a final intimate mixing is performed by impingement and collision into the mixing chamber (24) of the device; selectively actuable cleaning members (12, 29) eject the residual chemical material remaining into the common pressure and feeding chamber (15), and the mixing chamber (24) of the mixing device (10).

Owner:AFROS

Co-injected pipe fitting

InactiveUS20060249216A1Light weightImprove structural propertiesPipe connection arrangementsRigid pipesSodium bicarbonatePipe fitting

A co-injected fitting has a core made of recycled or reground PVC and ABS, which is less expensive and to which, in some embodiments, a blowing agent, such as azo and / or sodium bicarbonate, can be added to lower the weight. The fitting includes a skin on opposite sides of the core forming the internal side of the fitting and the external side of the fitting, respectively, in concentric relationship to the inner core. Such fittings may also include a strengthening core material, such as polycarbonate, to provide a stronger pipe fitting which likewise can be co-injection molded.

Owner:NIBCO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com